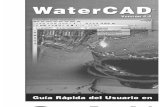

Appendix A WaterCAD Models for Wingham and Blyth

Transcript of Appendix A WaterCAD Models for Wingham and Blyth

Appendix A

WaterCAD Models for Wingham and Blyth

P-395

P-1250

P-1

425

P-670

P-360

P-1

025

P-195

P-1

000

P-1

0

P-9 1

5

P-2

15P

-895

P-8

85

P-110

P-5

85

P-2

30

P-175

P-1375

P-7

20

P-1

275

P-7

85

P-1

060

P-2

45

P-5

65

P-980

P-2

20

P-225

P-9

00

P-6

65

P-9

10

P-675

P-1

005

P-6

05

P-2

40

P-7

75

P-1295

P-905

P-1045

P-1

355

P-1350

P-35

P-3

80

P-3

90

P-470

P-955

P-485

P-165

P-5

80

P-50

P-3

70

P-830

P-405

P-139

0P

-1385

P-1325

P-590

P-9

95

P-1

015

P-6

30

P-1

020

P-865

P-1050

P-8

40

P-400

P-350

P-505

P-120

P-595

P-125

P-71

0

P-860

P-185

P-1

90

P-825

P-25

P-680

P-6

25

P-535

P-1290

P-8

75

P-1

05

P-3

15

P-730

P-1

215

P-8

45

P-355

P-550

P-8

50

P-8

10

P-8

35

P-375

P-920

P-880

P-3

20

P-3

35

P-115

P-815

P-6

35

P-70

P-555

P-525

P-1010

P-480

P-1310

P-1455P-1450

P-155

P-510

P-4

60

P-520

P-965

P-1

80

P-1

445

P-80

P-150

P-4

50

P-205

P-795

P-12

45 P-3

10

P-435

P-285

P-820

P-575

P-640 P-95

P-1

60

P-8

05

P-545

P-6

15

P-90

P-1415

P-1410

P-1

040

P-1

400

P-20

P-385

P-9

35

P-1

40

P-1

380

P-6

85

P-1

370

P-1315

P-8

70

P-330

P-65

P-660

P-4

30

P-2

65

P-1

365

P-770

P-9

40

P-1360

P-1

70

P-1

065

P-530

P-9

45

P-4

45

P-8

00

P-5

15

P-6

20

P-420

P-5

40

P-134

5

P-455

P-1

340

P-465

P-755

P-985

P-1

335

P-1280

P-9

30

P-85

P-4

75

P-6

90

P-1320

P-1270

P-1265

P-2

95

P-1260

P-2

10

P-735

P-6

10

P-1300

P-650

P-6

45

P-135

P-4

10

P-4

90

P-1

420

P-275

P-1

240

P-960

P-8

90

P-6

55

P-1225

P-425

P-6

0

P-725

P-4

40

P-5P-600

P-1035

P-3

05

P-7

15

P-970

P-14

5P

-950

P-7

80

P-260

P-1

255

P-45

P-340

P-560

P-1

00

P-7

05

P-300

P-500

P-280

P-1

195

P-1

230

P-9

90

P-1395

P-1

170

P-1

155

P-250

P-9

25

P-1235

P-760

P-1

135

P-1220

P-570

P-345

P-74

0

P-975

P-1

055

P-235

P-1465

P-1115

P-415

P-1

210

P-1

205

P-1200

P-290

P-1190

P-1

185

P-1180

P-1175P-1095

P-1

165

P-1

160

P-75

P-1150

P-1

330

P-1145

P-1

140

P-7

65

P-1085

P-1080

P-1130

P-1

125

P-4

95

P-200

P-1120

P-255

P-1110

P-1105

P-1435P-1430

P-1

1 00

P-1030

P-1

090

P-1

285

P-1460

P-1405

P-85

5

P-5

5

P-7

45

P-2

70

P-1075

P-7

50

P-700

P-695

P-1070 P

-325

P-130

P-1305

P-790

P-1

440

P-30

P-40

P-1

5

P-365J-300

J-295J-775

J-770

J-290 J-285

J-705

J-765

J-985

J-760

J-690

J-50

J-280J-275

J-950

J-270

J-745

J-265

J-1015

J-260J-255

J-735

J-250

J-730

J-245

J-725

J-1000

J-240

J-715

J-710

J-45

J-700

J-695

J-235

J-230

J-650

J-615

J-225

J-640

J-220

J-980

J-40

J-680

J-35

J-215

J-675

J-210

J-670

J-205

J-665

J-200

J-195

J-660

J-655

J-30

J-190

J-610

J-645

J-185

J-160

J-1100

J-895

J-180

J-1080

J-635

J-175

J-630

J-1020

J-170

J-625

J-165

J-620

J-25

J-155

J-20

J-15

J-970

J-905

J-150

J-605

J-145

J-600

J-595

J-590

J-585

J-140

J-580

J-575

J-1060

J-1085

J-570

J-1055

J-565

J-560

J-1045

J-1070

J-555

J-550

J-545

J-865

J-965

J-960

J-1090

J-540 J-920

J-955

J-535

J-530

J-135

J-495

J-525

J-945

J-940

J-1025

J-130

J-935

J-930

J-520

J-10

J-515J-925

J-1075

J-510

J-900

J-505

J-465

J-500

J-855

J-125

J-850

J-490

J-890

J-485

J-120

J-1030

J-915

J-115

J-450

J-480

J-475J-470

J-1065

J-910

J-1040

J-110

J-870

J-460

J-1035

J-740

J-455

J-860

J-105

J-445

J-440

J-1050

J-840

J-885

J-880

J-100

J-435

J-875

J-430

J-1095

J-425

J-420

J-990

J-415

J-825

J-95

J-390

J-410J-405

J-815

J-810

J-845

J-1010

J-90

J-5

J-1005

J-400

J-835

J-395

J-350

J-755

J-830

J-85

J-790

J-385

J-80

J-685

J-380

J-785

J-375

J-75

J-370

J-70

J-365

J-820

J-360J-355

J-65

J-720

J-345

J-805

J-60

J-800

J-340

J-55

J-335

J-330

J-750

J-975

J-795

J-325

J-320

J-315

J-310

J-305

J-780

J-995

T-2

R-Well 3

R-Well 4

Color Coding Legend

Pipe: Diameter (mm)

<= 100

<= 150

<= 200

<= 250

<= 300

<= 350

<= 400

Other

Scenario: Maximum Day + Fire, Well 3 + 2 Well 4 HLPs

27 Siemon Company Drive Suite 200 W Watertown, CT 06795 USA +1-203-755-16664/1/2020Bentley Systems, Inc. Haestad Methods Solution Center17181-2018 base model.wtg

Page 1 of 18

Job # : 17181Date : August 13, 2018Revised :

1.0 Background

2.0 Analysis & Model Data

2.1 Data

Reference Item17181 Existing avg. day demand 14.2 L/s

= 1226 m3/dExisting max. day demand 26.4 L/s

= 2277 m3/dMaximum day factor 1.86

17181 Wingham town pop. (2016) 4932 personsWingham no. of households 2209 householdsPersons per household unit 2.23 PPU

Township of North HuronWaterCAD Modelling for Master PlanCalculations and Notes for Wingham

September 6, 2019

The Township of North Huron is completing a water and wastewater Master Plan process. The water supply component will include a review of servicing existing development and future development areas, as well as evaluate new storage options related to standpipe replacement. The purpose of these notes is to summarize data used to create a WaterCAD model, and the results of that modelling for the community of Wingham.

MOECC Peak hour factor - ex. pop. 3.00Peak hour factor - fut. pop. 3.00

DWWP Well PumpsPump rating (Well No. 3) 76 L/s

@ 91 m TDHPump rating (Well No. 4 HLPs) 33 L/s

@ 70 m TDH95140 Well No. 3 discharge pressure 70.0 m95140 Well No. 4 HLPs elev. 309.6 mASL

Town info HLP off (tower level) 30.0 m= 366.0 mASL

HLP on (tower level) 26.0 m= 362.0 mASL

DWWP/ Standpipe

78011 Total volume 1680 m3

Usable volume 232 m3

Diameter 8.5 m95140 HWL 366.00 mASL

Bottom operating range 362.00 mASLGrade at base 336.00 mASL

17181 Assume future storage is at 5 m elevation increaseHWL 371.00 mASLBottom operating range 367.00 mASLGrade at base 336.00 mASL

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 2 of 18

MOE Guide Pipe C-factorsPipe Dia. (mm) C

150 100200-250 110300-600 120

>600 130

MOE Guide Normal operating pressure range target 350 to 480 kPaMOE Guide Normal operating pressure minimum 275 kPaMOE Guide Fire flow system pressure minimum 140 kPaMOE Guide Maximum allowable system pressure 700 kPa

2.2 Water Demands by Junction

(a) Existing Conditions

The top 10 water users, based on 2015 and 2016 data, are as follows:

Average Day Demand 2015-

2016(L/s)

Maximum Day Demand based on

Factor(L/s)

Model Junction to

Apply Demand

0.30 0.56 J-9750.41 0.76 J-502.81 5.22 J-5450.13 0.24 J-2800.12 0.22 J-10050.08 0.14 J-9300.09 0.17 J-9350.12 0.22 J-965

Wescast 200 WaterFE MadillCar WashValu-Mart

Tim Hortons

Community ComplexHospital

Wescast Amberley

Property

0.12 0.22 J-9650.40 0.74 J-2100.13 0.25 J-7254.59 8.52

* for four months of year only

Total number of junctions - existing model 220

Remaining average day demand 9.60Remaining maximum day demand 17.83Total junctions minus 10 for top users 210Average day demand per typical junction 0.046 L/sMaximum day demand per typical junction 0.085 L/s

See attached map for area junctions.

Design fire flow demands will vary from about 50 L/s for residential areas to 150 L/s or greater in ICI areas. Considering the relatively small demand associated with consumption as compared to fire flow, and the fact that there are few customers with significant water demand, it is concluded that there is no need to further analyze the distribution of average and maximum day demand beyond what is provided above.

Splash Pad*Wescast 100 Water

Total

After accounting for the top 10 water users and the 10 model junctions that represent them, calculate demand per typical junction:

Wescast Amberley

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 3 of 18

(b) Future Conditions

A2A 454 unitsHutton Heights 100 units

Morris-Turnberry CSA 682.50 m3/d

Calculate applicable average and maximum day demands for each:

A2A average day demand 2.92 L/sA2A maximum day demand 5.42 L/s

Hutton Heights average day demand 0.64 L/sHutton Heights maximum day demand 1.19 L/s

Morris-Turnberry CSA average day demand 7.90 L/sMorris-Turnberry CSA maximum day demand 14.67 L/s

Development Area

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Model Junction to

Apply Demand

A2A 1.46 2.71 J-730

Over 95% of the Morris-Turnberry CSA allocation applies to the Wescast Amberley Road site. Apply all the CSA allocation to that junction. Split the A2A demand over two junctions.

Demands for existing development are left unchanged, and the incremental future demand for development areas is applied to the nearest model junctions within or adjacent to the development lands.

With reference to 17181 Technical Memo 1 (TM1-revised), applicable developments/commitments include:

A2A 1.46 2.71 J-730A2A 1.46 2.71 J-795

Hutton Heights 0.64 1.19 J-935M-T CSA 7.90 14.67 J-965

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 4 of 18

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)J-5 315.7 0.046 0.085 0.137 0.046 0.085 0.137J-10 311.5 0.046 0.085 0.137 0.046 0.085 0.137J-15 312.0 0.046 0.085 0.137 0.046 0.085 0.137J-20 338.8 0.046 0.085 0.137 0.046 0.085 0.137J-25 327.0 0.046 0.085 0.137 0.046 0.085 0.137J-30 312.8 0.046 0.085 0.137 0.046 0.085 0.137J-35 311.5 0.046 0.085 0.137 0.046 0.085 0.137J-40 338.8 0.046 0.085 0.137 0.046 0.085 0.137J-45 333.5 0.046 0.085 0.137 0.046 0.085 0.137J-50 332.6 0.410 0.761 1.230 0.410 0.761 1.230J-55 307.6 0.046 0.085 0.137 0.046 0.085 0.137J-60 317.0 0.046 0.085 0.137 0.046 0.085 0.137J-65 316.5 0.046 0.085 0.137 0.046 0.085 0.137J-70 326.0 0.046 0.085 0.137 0.046 0.085 0.137J-75 321.0 0.046 0.085 0.137 0.046 0.085 0.137J-80 316.1 0.046 0.085 0.137 0.046 0.085 0.137J-85 318.1 0.046 0.085 0.137 0.046 0.085 0.137J-90 308.4 0.046 0.085 0.137 0.046 0.085 0.137J-95 313.1 0.046 0.085 0.137 0.046 0.085 0.137

J-100 315.4 0.046 0.085 0.137 0.046 0.085 0.137J-105 317.9 0.046 0.085 0.137 0.046 0.085 0.137J-110 310.8 0.046 0.085 0.137 0.046 0.085 0.137J-115 312.3 0.046 0.085 0.137 0.046 0.085 0.137J-120 319.5 0.046 0.085 0.137 0.046 0.085 0.137J-125 311.9 0.046 0.085 0.137 0.046 0.085 0.137J-130 312.8 0.046 0.085 0.137 0.046 0.085 0.137J-135 329.0 0.046 0.085 0.137 0.046 0.085 0.137J-140 307.5 0.046 0.085 0.137 0.046 0.085 0.137J-145 328.8 0.046 0.085 0.137 0.046 0.085 0.137J-150 318.3 0.046 0.085 0.137 0.046 0.085 0.137J-155 317.8 0.046 0.085 0.137 0.046 0.085 0.137J-160 314.0 0.046 0.085 0.137 0.046 0.085 0.137J-165 316.9 0.046 0.085 0.137 0.046 0.085 0.137J-170 310.8 0.046 0.085 0.137 0.046 0.085 0.137J-175 315.9 0.046 0.085 0.137 0.046 0.085 0.137J-180 313.2 0.046 0.085 0.137 0.046 0.085 0.137J-185 320.0 0.046 0.085 0.137 0.046 0.085 0.137J-190 321.3 0.046 0.085 0.137 0.046 0.085 0.137J-195 317.7 0.046 0.085 0.137 0.046 0.085 0.137J-200 317.5 0.046 0.085 0.137 0.046 0.085 0.137J-205 316.5 0.046 0.085 0.137 0.046 0.085 0.137J-210 312.0 0.400 0.743 1.200 0.400 0.743 1.200J-215 314.0 0.046 0.085 0.137 0.046 0.085 0.137J-220 316.8 0.046 0.085 0.137 0.046 0.085 0.137J-225 315.7 0.046 0.085 0.137 0.046 0.085 0.137J-230 315.0 0.046 0.085 0.137 0.046 0.085 0.137J-235 309.1 0.046 0.085 0.137 0.046 0.085 0.137J-240 327.6 0.046 0.085 0.137 0.046 0.085 0.137J-245 316.4 0.046 0.085 0.137 0.046 0.085 0.137J-250 313.6 0.046 0.085 0.137 0.046 0.085 0.137J-255 317.5 0.046 0.085 0.137 0.046 0.085 0.137

Existing Future

Model Junction

Elevation(mASL)

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 5 of 18

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Existing Future

Model Junction

Elevation(mASL)

J-260 317.5 0.046 0.085 0.137 0.046 0.085 0.137J-265 313.7 0.046 0.085 0.137 0.046 0.085 0.137J-270 317.1 0.046 0.085 0.137 0.046 0.085 0.137J-275 338.3 0.046 0.085 0.137 0.046 0.085 0.137J-280 337.9 0.130 0.241 0.390 0.130 0.241 0.390J-285 321.3 0.046 0.085 0.137 0.046 0.085 0.137J-290 321.2 0.046 0.085 0.137 0.046 0.085 0.137J-295 313.6 0.046 0.085 0.137 0.046 0.085 0.137J-300 317.1 0.046 0.085 0.137 0.046 0.085 0.137J-305 325.3 0.046 0.085 0.137 0.046 0.085 0.137J-310 310.9 0.046 0.085 0.137 0.046 0.085 0.137J-315 316.0 0.046 0.085 0.137 0.046 0.085 0.137J-320 315.6 0.046 0.085 0.137 0.046 0.085 0.137J-325 322.8 0.046 0.085 0.137 0.046 0.085 0.137J-330 313.2 0.046 0.085 0.137 0.046 0.085 0.137J-335 337.4 0.046 0.085 0.137 0.046 0.085 0.137J-340 325.4 0.046 0.085 0.137 0.046 0.085 0.137J-345 329.4 0.046 0.085 0.137 0.046 0.085 0.137J-350 318.0 0.046 0.085 0.137 0.046 0.085 0.137J-355 312.4 0.046 0.085 0.137 0.046 0.085 0.137J-360 312.3 0.046 0.085 0.137 0.046 0.085 0.137J-365 315.5 0.046 0.085 0.137 0.046 0.085 0.137J-370 316.0 0.046 0.085 0.137 0.046 0.085 0.137J-375 319.3 0.046 0.085 0.137 0.046 0.085 0.137J-380 315.0 0.046 0.085 0.137 0.046 0.085 0.137J-385 315.8 0.046 0.085 0.137 0.046 0.085 0.137J-390 316.0 0.046 0.085 0.137 0.046 0.085 0.137J-395 311.1 0.046 0.085 0.137 0.046 0.085 0.137J-400 331.5 0.046 0.085 0.137 0.046 0.085 0.137J-405 316.5 0.046 0.085 0.137 0.046 0.085 0.137J-410 316.9 0.046 0.085 0.137 0.046 0.085 0.137J-415 322.4 0.046 0.085 0.137 0.046 0.085 0.137J-420 307.5 0.046 0.085 0.137 0.046 0.085 0.137J-425 317.4 0.046 0.085 0.137 0.046 0.085 0.137J-430 314.5 0.046 0.085 0.137 0.046 0.085 0.137J-435 316.9 0.046 0.085 0.137 0.046 0.085 0.137J-440 313.6 0.046 0.085 0.137 0.046 0.085 0.137J-445 312.7 0.046 0.085 0.137 0.046 0.085 0.137J-450 318.3 0.046 0.085 0.137 0.046 0.085 0.137J-455 321.6 0.046 0.085 0.137 0.046 0.085 0.137J-460 325.0 0.046 0.085 0.137 0.046 0.085 0.137J-465 314.5 0.046 0.085 0.137 0.046 0.085 0.137J-470 317.0 0.046 0.085 0.137 0.046 0.085 0.137J-475 317.1 0.046 0.085 0.137 0.046 0.085 0.137J-480 311.5 0.046 0.085 0.137 0.046 0.085 0.137J-485 316.9 0.046 0.085 0.137 0.046 0.085 0.137J-490 316.6 0.046 0.085 0.137 0.046 0.085 0.137J-495 313.3 0.046 0.085 0.137 0.046 0.085 0.137J-500 308.0 0.046 0.085 0.137 0.046 0.085 0.137J-505 310.7 0.046 0.085 0.137 0.046 0.085 0.137J-510 317.4 0.046 0.085 0.137 0.046 0.085 0.137

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 6 of 18

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Existing Future

Model Junction

Elevation(mASL)

J-515 322.6 0.046 0.085 0.137 0.046 0.085 0.137J-520 311.2 0.046 0.085 0.137 0.046 0.085 0.137J-525 316.1 0.046 0.085 0.137 0.046 0.085 0.137J-530 311.5 0.046 0.085 0.137 0.046 0.085 0.137J-535 311.1 0.046 0.085 0.137 0.046 0.085 0.137J-540 307.6 0.046 0.085 0.137 0.046 0.085 0.137J-545 317.5 2.808 5.215 8.424 2.808 5.215 8.424J-550 321.1 0.046 0.085 0.137 0.046 0.085 0.137J-555 335.0 0.046 0.085 0.137 0.046 0.085 0.137J-560 327.2 0.046 0.085 0.137 0.046 0.085 0.137J-565 311.4 0.046 0.085 0.137 0.046 0.085 0.137J-570 314.5 0.046 0.085 0.137 0.046 0.085 0.137J-575 318.6 0.046 0.085 0.137 0.046 0.085 0.137J-580 317.2 0.046 0.085 0.137 0.046 0.085 0.137J-585 317.4 0.046 0.085 0.137 0.046 0.085 0.137J-590 310.5 0.046 0.085 0.137 0.046 0.085 0.137J-595 310.2 0.046 0.085 0.137 0.046 0.085 0.137J-600 319.7 0.046 0.085 0.137 0.046 0.085 0.137J-605 322.7 0.046 0.085 0.137 0.046 0.085 0.137J-610 323.7 0.046 0.085 0.137 0.046 0.085 0.137J-615 320.9 0.046 0.085 0.137 0.046 0.085 0.137J-620 332.3 0.046 0.085 0.137 0.046 0.085 0.137J-625 310.8 0.046 0.085 0.137 0.046 0.085 0.137J-630 316.0 0.046 0.085 0.137 0.046 0.085 0.137J-635 316.0 0.046 0.085 0.137 0.046 0.085 0.137J-640 317.5 0.046 0.085 0.137 0.046 0.085 0.137J-645 319.6 0.046 0.085 0.137 0.046 0.085 0.137J-650 312.6 0.046 0.085 0.137 0.046 0.085 0.137J-655 318.1 0.046 0.085 0.137 0.046 0.085 0.137J-660 326.2 0.046 0.085 0.137 0.046 0.085 0.137J-665 314.0 0.046 0.085 0.137 0.046 0.085 0.137J-670 321.8 0.046 0.085 0.137 0.046 0.085 0.137J-675 317.4 0.046 0.085 0.137 0.046 0.085 0.137J-680 323.4 0.046 0.085 0.137 0.046 0.085 0.137J-685 312.7 0.046 0.085 0.137 0.046 0.085 0.137J-690 319.8 0.046 0.085 0.137 0.046 0.085 0.137J-695 321.4 0.046 0.085 0.137 0.046 0.085 0.137J-700 318.9 0.046 0.085 0.137 0.046 0.085 0.137J-705 309.4 0.046 0.085 0.137 0.046 0.085 0.137J-710 322.0 0.046 0.085 0.137 0.046 0.085 0.137J-715 321.5 0.046 0.085 0.137 0.046 0.085 0.137J-720 313.0 0.046 0.085 0.137 0.046 0.085 0.137J-725 317.1 0.133 0.247 0.399 0.133 0.247 0.399J-730 328.0 0.046 0.085 0.137 1.504 2.793 4.512J-735 316.4 0.046 0.085 0.137 0.046 0.085 0.137J-740 317.7 0.046 0.085 0.137 0.046 0.085 0.137J-745 318.5 0.046 0.085 0.137 0.046 0.085 0.137J-750 318.0 0.046 0.085 0.137 0.046 0.085 0.137J-755 317.5 0.046 0.085 0.137 0.046 0.085 0.137J-760 335.9 0.046 0.085 0.137 0.046 0.085 0.137J-765 321.0 0.046 0.085 0.137 0.046 0.085 0.137

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 7 of 18

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Existing Future

Model Junction

Elevation(mASL)

J-770 311.7 0.046 0.085 0.137 0.046 0.085 0.137J-775 317.5 0.046 0.085 0.137 0.046 0.085 0.137J-780 314.0 0.046 0.085 0.137 0.046 0.085 0.137J-785 338.1 0.046 0.085 0.137 0.046 0.085 0.137J-790 317.7 0.046 0.085 0.137 0.046 0.085 0.137J-795 323.8 0.046 0.085 0.137 1.504 2.793 4.512J-800 331.8 0.046 0.085 0.137 0.046 0.085 0.137J-805 314.1 0.046 0.085 0.137 0.046 0.085 0.137J-810 317.3 0.046 0.085 0.137 0.046 0.085 0.137J-815 313.9 0.046 0.085 0.137 0.046 0.085 0.137J-820 314.8 0.046 0.085 0.137 0.046 0.085 0.137J-825 321.7 0.046 0.085 0.137 0.046 0.085 0.137J-830 333.1 0.046 0.085 0.137 0.046 0.085 0.137J-835 314.8 0.046 0.085 0.137 0.046 0.085 0.137J-840 322.1 0.046 0.085 0.137 0.046 0.085 0.137J-845 311.7 0.046 0.085 0.137 0.046 0.085 0.137J-850 309.0 0.046 0.085 0.137 0.046 0.085 0.137J-855 333.7 0.046 0.085 0.137 0.046 0.085 0.137J-860 322.7 0.046 0.085 0.137 0.046 0.085 0.137J-865 325.0 0.046 0.085 0.137 0.046 0.085 0.137J-870 312.5 0.046 0.085 0.137 0.046 0.085 0.137J-875 320.1 0.046 0.085 0.137 0.046 0.085 0.137J-880 320.1 0.046 0.085 0.137 0.046 0.085 0.137J-885 324.6 0.046 0.085 0.137 0.046 0.085 0.137J-890 332.7 0.046 0.085 0.137 0.046 0.085 0.137J-895 323.4 0.046 0.085 0.137 0.046 0.085 0.137J-900 328.0 0.046 0.085 0.137 0.046 0.085 0.137J-905 317.9 0.046 0.085 0.137 0.046 0.085 0.137J-910 327.5 0.046 0.085 0.137 0.046 0.085 0.137J-915 327.2 0.046 0.085 0.137 0.046 0.085 0.137J-920 324.1 0.046 0.085 0.137 0.046 0.085 0.137J-925 310.0 0.046 0.085 0.137 0.046 0.085 0.137J-930 307.8 0.076 0.141 0.228 0.076 0.141 0.228J-935 305.0 0.093 0.173 0.279 0.735 1.366 2.206J-940 313.7 0.046 0.085 0.137 0.046 0.085 0.137J-945 320.1 0.046 0.085 0.137 0.046 0.085 0.137J-950 317.0 0.046 0.085 0.137 0.046 0.085 0.137J-955 314.8 0.046 0.085 0.137 0.046 0.085 0.137J-960 328.5 0.046 0.085 0.137 0.046 0.085 0.137J-965 328.1 0.118 0.219 0.354 8.017 14.890 24.052J-970 308.8 0.046 0.085 0.137 0.046 0.085 0.137J-975 305.0 0.299 0.555 0.897 0.299 0.555 0.897J-980 311.1 0.046 0.085 0.137 0.046 0.085 0.137J-985 314.7 0.046 0.085 0.137 0.046 0.085 0.137J-990 328.5 0.046 0.085 0.137 0.046 0.085 0.137J-995 317.9 0.046 0.085 0.137 0.046 0.085 0.137J-1000 317.2 0.046 0.085 0.137 0.046 0.085 0.137J-1005 308.1 0.120 0.223 0.360 0.120 0.223 0.360J-1010 308.0 0.046 0.085 0.137 0.046 0.085 0.137J-1015 305.7 0.046 0.085 0.137 0.046 0.085 0.137J-1020 317.9 0.046 0.085 0.137 0.046 0.085 0.137

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 8 of 18

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Existing Future

Model Junction

Elevation(mASL)

J-1025 317.5 0.046 0.085 0.137 0.046 0.085 0.137J-1030 310.0 0.046 0.085 0.137 0.046 0.085 0.137J-1035 333.3 0.046 0.085 0.137 0.046 0.085 0.137J-1040 333.1 0.046 0.085 0.137 0.046 0.085 0.137J-1045 321.5 0.046 0.085 0.137 0.046 0.085 0.137J-1050 328.0 0.046 0.085 0.137 0.046 0.085 0.137J-1055 328.0 0.046 0.085 0.137 0.046 0.085 0.137J-1060 322.9 0.046 0.085 0.137 0.046 0.085 0.137J-1065 323.8 0.046 0.085 0.137 0.046 0.085 0.137J-1070 314.8 0.046 0.085 0.137 0.046 0.085 0.137J-1075 325.0 0.046 0.085 0.137 0.046 0.085 0.137J-1080 337.9 0.046 0.085 0.137 0.046 0.085 0.137J-1085 316.5 0.046 0.085 0.137 0.046 0.085 0.137J-1090 330.0 0.046 0.085 0.137 0.046 0.085 0.137J-1095 328.3 0.046 0.085 0.137 0.046 0.085 0.137J-1100 316.0 0.046 0.085 0.137 0.046 0.085 0.137

Minimum 305.0 0.046 0.085 0.137 0.046 0.085 0.137Maximum 338.8 2.808 5.215 8.424 8.017 14.890 24.052Total 14.2 26.4 42.6 25.6 47.6 76.9

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 9 of 183.0 Model Results - 2018 Demands

3.1 Existing Conditions

Standpipe 366.0 mASL, Pumps Off

Standpipe 365.0 mASL,

W3 On

Standpipe 362.0 mASL, W3 & 2xW4

J-5 491 483 110 115 119J-10 532 525 245 264 299J-15 527 518 51 53 52J-20 267 266 500 500 500J-25 380 372 102 108 112J-30 519 512 125 130 134J-35 532 525 145 151 159J-40 266 266 500 500 500J-45 318 317 407 402 376J-50 326 323 186 195 203J-55 570 563 134 139 143J-60 478 471 94 98 99J-65 483 476 105 109 111J-70 391 390 122 121 115J-75 439 431 115 122 128J-80 488 480 209 226 255J-85 468 461 178 191 211J-90 563 555 61 62 61J-95 516 507 39 39 39

J-100 493 484 126 140 154J-105 469 461 91 96 100J-110 540 533 254 273 307J-115 524 516 191 212 248J-120 454 446 125 133 139J-125 528 521 208 223 247J-130 519 511 141 149 159J-135 362 361 112 110 104J-140 572 565 174 182 192J-145 364 357 136 145 152J-150 466 458 127 134 142J-155 470 461 106 116 125J-160 508 501 172 182 196J-165 479 470 99 111 119J-170 539 532 129 134 139J-175 489 482 212 229 258J-180 516 509 96 97 96J-185 449 442 165 175 190J-190 437 429 115 121 126J-195 472 465 134 141 149J-200 474 466 126 133 142J-205 483 474 118 130 142J-210 527 520 111 115 118J-215 508 502 89 90 89

For average and peak analysis, use no pumps operating and standpipe water level at top level of 366.0 mASL. For fire flow analysis, use three scenarios: standpipe top level of 366.0 mASL with no pumps, standpipe level of 365.0 mASL with Well 3 Pump on, and standpipe level of 362.0 mASL with Well 3 Pump and 2 Well 4 site HLPs on.

Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 10 of 18

Standpipe 366.0 mASL, Pumps Off

Standpipe 365.0 mASL,

W3 On

Standpipe 362.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-220 481 473 177 190 210J-225 491 482 109 118 127J-230 498 491 231 251 287J-235 556 549 238 254 281J-240 376 374 112 111 104J-245 484 476 229 252 295J-250 512 506 271 294 336J-255 473 464 162 189 223J-260 473 464 161 188 222J-265 511 502 212 238 291J-270 477 468 110 126 137J-275 271 271 500 500 486J-280 275 275 500 500 469J-285 436 427 88 95 100J-290 437 428 89 96 101J-295 511 502 106 115 122J-300 478 469 169 196 233J-305 398 393 167 175 182J-310 538 529 194 221 263J-315 488 479 166 190 223J-320 492 483 164 187 219J-325 422 416 66 67 65J-330 515 508 133 139 145J-335 280 278 370 383 391J-340 397 392 264 285 317J-345 358 357 144 143 135J-350 469 460 154 181 212J-355 523 515 193 215 253J-360 525 516 197 220 260J-365 493 484 75 79 80J-370 488 481 243 267 311J-375 456 450 82 84 83J-380 498 490 133 141 149J-385 490 483 245 267 308J-390 488 479 100 109 116J-395 537 529 188 199 217J-400 337 334 285 305 336J-405 483 475 124 132 142J-410 479 471 113 119 126J-415 426 418 124 131 137J-420 572 565 207 218 236J-425 475 467 136 143 151J-430 503 494 124 137 150J-435 479 470 128 145 162J-440 512 505 249 267 295J-445 521 514 259 278 311J-450 466 458 165 181 208J-455 433 425 107 112 115J-460 401 394 108 113 114J-465 503 494 137 153 171

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 11 of 18

Standpipe 366.0 mASL, Pumps Off

Standpipe 365.0 mASL,

W3 On

Standpipe 362.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-470 478 469 119 134 147J-475 477 468 116 130 143J-480 532 526 196 206 220J-485 479 470 107 122 132J-490 482 473 98 110 117J-495 515 508 267 291 333J-500 567 560 218 231 251J-505 540 531 198 224 268J-510 475 467 118 125 131J-515 424 417 151 160 170J-520 535 529 95 96 95J-525 487 480 230 251 289J-530 532 524 211 238 290J-535 536 528 209 236 286J-540 571 564 147 152 158J-545 473 464 153 177 206J-550 438 431 94 98 99J-555 302 296 90 93 89J-560 379 370 106 113 118J-565 533 525 213 240 293J-570 503 496 224 238 259J-575 463 456 88 90 88J-580 477 467 104 115 124J-585 474 466 122 129 136J-590 542 534 186 206 239J-595 545 536 183 203 235J-600 452 445 252 274 313J-605 423 415 86 89 90J-610 413 406 45 45 43J-615 441 433 125 132 139J-620 330 329 391 386 363J-625 539 531 149 159 173J-630 488 480 132 139 147J-635 488 479 151 171 197J-640 473 464 94 106 112J-645 453 445 99 103 106J-650 522 516 253 272 304J-655 468 462 218 232 252J-660 389 381 102 108 112J-665 507 499 137 145 153J-670 432 425 70 71 69J-675 474 465 109 122 133J-680 416 408 110 116 120J-685 521 512 90 93 95J-690 451 445 253 275 313J-695 436 429 127 132 137J-700 460 452 125 132 139J-705 553 547 187 196 209J-710 430 423 62 63 60J-715 435 428 63 63 61

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 12 of 18

Standpipe 366.0 mASL, Pumps Off

Standpipe 365.0 mASL,

W3 On

Standpipe 362.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-720 517 509 104 108 111J-725 477 468 81 88 91J-730 372 371 78 77 73J-735 485 476 121 128 133J-740 471 463 153 165 181J-745 464 456 137 146 156J-750 469 460 123 130 136J-755 474 466 214 238 282J-760 294 293 126 123 112J-765 439 431 80 83 83J-770 530 523 114 118 121J-775 473 464 125 146 163J-780 508 501 227 245 277J-785 273 270 47 46 41J-790 471 462 122 142 158J-795 412 403 73 75 75J-800 335 334 127 124 115J-805 507 499 170 187 214J-810 476 468 175 193 226J-815 509 501 131 138 146J-820 500 492 135 143 151J-825 432 424 118 125 131J-830 321 318 115 115 108J-835 500 491 113 119 123J-840 429 421 91 95 96J-845 530 523 132 137 142J-850 557 550 246 263 292J-855 315 309 108 112 111J-860 423 415 84 87 87J-865 400 392 106 112 116J-870 523 515 222 239 267J-875 448 439 77 82 84J-880 448 440 118 124 129J-885 404 396 110 117 122J-890 326 320 143 151 155J-895 416 411 248 269 303J-900 371 363 103 110 114J-905 470 462 154 164 178J-910 376 369 120 127 130J-915 379 373 139 146 152J-920 409 403 173 182 191J-925 547 539 116 120 123J-930 569 562 115 118 120J-935 596 589 106 108 110J-940 511 503 125 130 135J-945 448 439 74 77 78J-950 479 469 71 77 78J-955 499 491 164 183 212J-960 366 359 52 53 50J-965 370 363 53 54 51

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 13 of 18

Standpipe 366.0 mASL, Pumps Off

Standpipe 365.0 mASL,

W3 On

Standpipe 362.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-970 559 552 79 81 81J-975 596 589 75 76 76J-980 536 530 82 83 81J-985 501 495 73 74 72J-990 366 360 139 145 148J-995 469 460 156 183 215

J-1000 477 468 168 195 232J-1005 566 559 92 94 94J-1010 567 559 86 88 88J-1015 589 582 84 85 85J-1020 469 460 155 182 214J-1025 473 464 143 170 196J-1030 547 540 67 68 67J-1035 320 317 115 115 108J-1040 322 319 109 109 102J-1045 435 428 57 57 55J-1050 371 364 53 53 51J-1055 371 364 53 53 51J-1060 421 414 64 65 63J-1065 412 404 110 116 120J-1070 500 491 142 157 177J-1075 400 392 106 112 116J-1080 275 274 163 159 142J-1085 483 475 130 140 153J-1090 352 352 285 281 264J-1095 369 368 174 171 160J-1100 488 482 70 71 69

Min 266 266Max 596 589

Notes:denotes operating pressure less than 275 kPadenotes operating pressure above 275 kPa but less than 350 kPadenotes operating pressure greater than 480 kPadenotes fire flow of less than 50 L/s at 140 kPa minimum system pressure

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 14 of 183.0 Model Results - Future Conditions

3.2 Future Conditions

Standpipe 371.0 mASL, Pumps Off

Standpipe 370.0 mASL,

W3 On

Standpipe 367.0 mASL, W3 & 2xW4

J-5 538 517 114 120 125J-10 579 559 250 270 306J-15 574 553 54 56 56J-20 315 314 500 500 500J-25 427 406 107 114 120J-30 566 546 130 135 141J-35 579 560 150 157 166J-40 315 314 500 500 500J-45 367 365 458 455 433J-50 374 364 204 213 225J-55 617 597 138 143 148J-60 526 506 99 103 105J-65 530 511 110 114 118J-70 440 434 132 131 125J-75 486 466 121 129 136J-80 535 515 216 233 263J-85 515 495 184 198 220J-90 610 590 64 65 65J-95 563 542 41 42 42

J-100 540 519 132 145 162J-105 516 496 96 102 107J-110 587 567 259 278 313J-115 571 550 197 217 255J-120 501 481 131 139 147J-125 575 555 214 229 254J-130 566 546 146 154 166J-135 410 406 122 121 114J-140 619 599 178 186 198J-145 411 394 146 156 166J-150 513 493 133 141 150J-155 518 496 111 122 132J-160 555 535 177 188 204J-165 526 504 104 117 126J-170 586 567 134 140 146J-175 536 516 218 235 266J-180 562 536 122 125 127J-185 496 477 172 183 199J-190 484 463 120 127 134J-195 519 499 140 148 157J-200 521 501 131 139 150J-205 530 509 123 136 149J-210 574 554 116 120 124J-215 554 529 108 111 112

For average and peak analysis, use no pumps operating and future standpipe water level at top level of 371.0 mASL. For fire flow analysis, use three scenarios: standpipe top level of 371.0 mASL with no pumps, standpipe level of 370.0 mASL with Well 3 Pump on, and standpipe level of 367.0 mASL with Well 3 Pump and 2 Well 4 site HLPs on. Actual conditions for future standpipe will include adjacent BPS to utilize full standpipe volume. Future model includes known watermain upgrades in vicinity of Carling Terrace & Diagonal Road.

Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 15 of 18

Standpipe 371.0 mASL, Pumps Off

Standpipe 370.0 mASL,

W3 On

Standpipe 367.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-220 528 508 183 197 218J-225 538 516 114 124 134J-230 545 525 237 257 294J-235 603 583 243 259 287J-240 424 419 121 120 114J-245 531 511 235 259 302J-250 559 540 273 296 338J-255 520 499 168 196 231J-260 520 499 168 195 230J-265 558 537 218 245 297J-270 524 503 115 132 144J-275 320 319 500 500 500J-280 324 322 500 500 500J-285 483 462 93 101 108J-290 484 463 94 102 109J-295 558 537 111 120 129J-300 525 503 175 202 240J-305 446 432 177 185 195J-310 585 564 200 226 269J-315 535 514 172 196 230J-320 539 518 170 193 226J-325 468 439 85 87 86J-330 562 543 138 145 152J-335 329 324 420 436 452J-340 444 431 276 297 331J-345 407 401 157 157 151J-350 516 494 161 187 219J-355 570 549 199 221 260J-360 572 551 203 225 267J-365 540 518 78 83 86J-370 535 516 249 273 318J-375 503 481 119 123 126J-380 545 524 138 146 155J-385 537 518 250 273 315J-390 535 514 105 114 122J-395 584 564 193 205 224J-400 385 376 306 327 362J-405 530 510 129 138 149J-410 526 506 118 125 133J-415 473 453 131 138 146J-420 619 599 211 223 242J-425 522 502 142 149 159J-430 550 528 130 142 157J-435 527 505 134 151 170J-440 559 539 245 263 293J-445 568 548 255 275 308J-450 513 492 171 188 216J-455 480 460 113 118 123J-460 448 431 115 121 125J-465 550 528 143 159 178

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 16 of 18

Standpipe 371.0 mASL, Pumps Off

Standpipe 370.0 mASL,

W3 On

Standpipe 367.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-470 525 503 124 140 155J-475 524 503 122 136 151J-480 579 560 200 211 227J-485 526 505 113 128 139J-490 529 508 103 115 124J-495 562 542 272 296 339J-500 614 594 222 236 257J-505 587 566 203 230 274J-510 522 501 123 130 138J-515 471 453 159 168 181J-520 581 551 124 128 130J-525 534 515 236 257 296J-530 579 558 217 243 296J-535 583 562 215 241 292J-540 618 598 151 157 164J-545 520 499 159 183 214J-550 486 466 99 104 107J-555 349 327 97 101 100J-560 426 405 112 120 127J-565 580 559 219 245 299J-570 550 530 231 245 268J-575 509 481 125 129 131J-580 524 502 109 121 131J-585 521 500 127 134 143J-590 589 568 191 211 245J-595 592 571 189 209 242J-600 499 480 259 281 321J-605 470 450 91 95 97J-610 459 430 51 52 51J-615 488 468 131 139 147J-620 379 377 437 434 414J-625 587 566 154 165 180J-630 535 514 136 144 154J-635 535 514 157 177 204J-640 520 499 99 111 119J-645 500 480 105 109 114J-650 569 550 258 277 310J-655 515 495 221 236 258J-660 436 415 108 115 120J-665 554 533 141 149 159J-670 478 449 90 92 91J-675 521 499 115 128 140J-680 463 443 115 122 128J-685 568 547 94 97 100J-690 498 480 260 282 322J-695 483 465 133 140 146J-700 507 486 130 138 146J-705 600 581 192 201 215J-710 475 441 95 97 97J-715 480 446 97 99 99

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 17 of 18

Standpipe 371.0 mASL, Pumps Off

Standpipe 370.0 mASL,

W3 On

Standpipe 367.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-720 564 544 108 113 117J-725 525 503 86 93 97J-730 420 415 84 83 79J-735 532 511 126 133 140J-740 518 498 159 172 189J-745 511 491 143 152 165J-750 516 495 128 135 143J-755 521 500 220 244 290J-760 343 340 144 142 133J-765 486 466 85 88 89J-770 577 557 118 123 127J-775 520 499 131 152 170J-780 555 535 232 251 284J-785 321 310 54 54 49J-790 519 497 127 148 165J-795 458 437 76 79 80J-800 384 381 140 139 131J-805 554 533 176 193 221J-810 523 502 181 200 234J-815 556 535 136 143 152J-820 547 526 140 148 158J-825 479 458 123 131 139J-830 369 361 128 129 124J-835 547 526 118 123 129J-840 476 457 97 101 104J-845 577 558 137 143 149J-850 604 584 250 267 297J-855 362 340 115 121 123J-860 470 451 89 92 94J-865 447 426 111 118 124J-870 570 550 228 245 274J-875 495 474 81 87 91J-880 495 475 124 130 138J-885 451 430 115 123 130J-890 373 359 156 165 173J-895 464 447 256 278 314J-900 418 397 109 117 123J-905 517 497 160 171 187J-910 423 406 128 136 142J-915 427 410 148 156 165J-920 456 436 180 190 203J-925 594 574 120 124 129J-930 616 596 118 121 125J-935 643 623 108 111 113J-940 558 538 130 136 143J-945 495 474 79 82 84J-950 526 504 75 81 84J-955 547 525 169 190 220J-960 411 376 77 79 78J-965 415 380 79 81 80

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Page 18 of 18

Standpipe 371.0 mASL, Pumps Off

Standpipe 370.0 mASL,

W3 On

Standpipe 367.0 mASL, W3 & 2xW4 Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa(L/s)

J-970 606 586 83 84 85J-975 643 623 78 79 79J-980 581 552 122 126 128J-985 546 516 120 124 125J-990 413 392 146 154 160J-995 516 495 162 190 222

J-1000 524 502 174 201 239J-1005 613 593 95 98 99J-1010 614 594 89 91 92J-1015 636 616 87 89 90J-1020 516 495 162 189 222J-1025 520 499 149 176 203J-1030 594 574 70 72 72J-1035 368 360 128 129 124J-1040 370 362 121 122 117J-1045 480 446 79 81 80J-1050 416 381 78 80 79J-1055 416 381 77 79 78J-1060 466 438 83 85 84J-1065 459 438 115 122 129J-1070 547 525 148 163 184J-1075 447 426 111 118 124J-1080 324 322 191 188 174J-1085 530 509 136 146 160J-1090 401 399 316 313 298J-1095 418 416 192 189 180J-1100 533 502 113 116 117

Min 315 310Max 643 623

Notes:denotes operating pressure less than 275 kPadenotes operating pressure above 275 kPa but less than 350 kPadenotes operating pressure greater than 480 kPadenotes fire flow of less than 50 L/s at 140 kPa minimum system pressure

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-18Aug13 Wingham Modelling Design Brief.xls

Scenario: Maximum Day Demand + Fire, Fire Pump On

PB-320

PB-35

PB-30

PB-305PB-275

P-P5a

PB-230

PB-225

P-405

P-FPb

PB-215

PB-210

PB-205

PB-190

PB-185

PB-180

PB-175

P-HLP1b

PB-170

P-HLP

2a

PB-165

P-P5b

PB-160

PB-150

P-HLP1a

PB-145

PB-10

PB-140

PB-5

PB-135

P-HLP

2b

P-FP

a

PB-120

PB-115

PB-110

PB-380

PB-350

PB-365

PB-85

PB-355

R-Well1&2

27 Siemon Company Drive Suite 200 W Watertown, CT 06795 USA +1-203-755-16664/1/2020Bentley Systems, Inc. Haestad Methods Solution Center17181-Blyth 2018 Base.wtg

Page 1 of 8

Job # : 17181Date : March 4, 2019Revised :

1.0 Background

2.0 Analysis & Model Data

2.1 Data

Reference Item17181 Existing avg. day demand 5.1 L/s

= 444 m3/dExisting max. day demand 9.4 L/s

= 810 m3/dMaximum day factor 1.82

17181 Blyth town pop. (2016) 989 personsBlyth no. of households 442 householdsPersons per household unit 2.24 PPU

Township of North HuronWaterCAD Modelling for Master Plan

Calculations and Notes for Blyth

The Township of North Huron is completing a water and wastewater Master Plan process. The water supply component will include a review of servicing existing development and future development areas, as well as evaluate new storage options related to standpipe replacement. The purpose of these notes is to summarize data used to create a WaterCAD model, and the results of that modelling for the community of Wingham

Persons per household unit 2.24 PPU

MOECC Peak hour factor - ex. pop. 1.50 x Maximum dayPeak hour factor - fut. pop. 1.50 x Maximum day

DWWP Well PumpsPump rating (HLP 1) 11 L/s

@ 53 m TDH

Pump rating (HLP 2) 10 L/s@ 53 m TDH

Pump rating (Fire Pump) 63 L/s@ 70 m TDH

Pump rating (Well 5) 20 L/s@ 92 m TDH

2018 HLP 1 & 2 typical discharge 85 psiAnnual pressure = 586 kPaReport

Well 5 typical discharge 59 psipressure = 407 kPa

It is known from operator comment that the fire pump does not operate normally, given mechanical concern with pumphouse mechanical works.

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Page 2 of 8

MECP Guide Pipe C-factorsPipe Dia. (mm) C

150 100200-250 110300-600 120

>600 130

MECP Guide Normal operating pressure range target 350 to 480 kPaMECP Guide Normal operating pressure minimum 275 kPaMECP Guide Fire flow system pressure minimum 140 kPaMECP Guide Maximum allowable system pressure 700 kPa

2.2 Water Demands by Junction

(a) Existing Conditions

Total number of junctions - existing model 68

Average day demand 5.14Maximum day demand 9.38Average day demand per typical junction 0.076 L/sMaximum day demand per typical junction 0.138 L/s

See attached map for area junctions.

Calculate demand per junction by dividing demand evenly over all model junctions:

Use reported typical discharge pressures, from 2018 Annual Report, to set HLP 1 & 2, and Well 5 pump, discharge elevations.

(b) Future Conditions

GJAJ Holdings 105 units

Calculate applicable average and maximum day demands for each:

GJAJ average day demand 1.22 L/sGJAJ maximum day demand 2.23 L/s

Apply the GJAJ demand at junction JB-90.

See attached map for area junctions.

Demands for existing development are left unchanged, and the incremental future demand for development areas is applied to the nearest model junctions within or adjacent to the development lands.

With reference to 17181 Technical Memo 1 (TM1), applicable developments/commitments include:

Design fire flow demands will vary from about 40 L/s for residential areas to 150 L/s or greater in ICI areas. Considering the relatively small demand associated with consumption as compared to fire flow, and the fact that there are few customers with significant water demand, it is concluded that there is no need to further analyze the distribution of average and maximum day demand beyond what is provided above.

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Page 3 of 8

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)JB-5 322.0 0.076 0.138 0.207 0.076 0.138 0.207JB-10 322.0 0.076 0.138 0.207 0.076 0.138 0.207JB-15 326.0 0.076 0.138 0.207 0.076 0.138 0.207JB-20 327.0 0.076 0.138 0.207 0.076 0.138 0.207JB-25 332.0 0.076 0.138 0.207 0.076 0.138 0.207JB-30 332.0 0.076 0.138 0.207 0.076 0.138 0.207JB-35 335.0 0.076 0.138 0.207 0.076 0.138 0.207JB-40 332.0 0.076 0.138 0.207 0.076 0.138 0.207JB-45 329.0 0.076 0.138 0.207 0.076 0.138 0.207JB-50 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-55 333.0 0.076 0.138 0.207 0.076 0.138 0.207JB-60 333.0 0.076 0.138 0.207 0.076 0.138 0.207JB-65 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-70 325.0 0.076 0.138 0.207 0.076 0.138 0.207JB-75 328.0 0.076 0.138 0.207 0.076 0.138 0.207JB-80 322.0 0.076 0.138 0.207 0.076 0.138 0.207JB-85 327.0 0.076 0.138 0.207 0.076 0.138 0.207JB-90 334.0 0.076 0.138 0.207 1.296 2.365 3.547JB-95 324.0 0.076 0.138 0.207 0.076 0.138 0.207

JB-100 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-105 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-110 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-115 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-120 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-125 328.0 0.076 0.138 0.207 0.076 0.138 0.207JB-130 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-135 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-140 326.0 0.076 0.138 0.207 0.076 0.138 0.207JB-145 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-150 329.0 0.076 0.138 0.207 0.076 0.138 0.207JB-155 335.0 0.076 0.138 0.207 0.076 0.138 0.207JB-160 329.0 0.076 0.138 0.207 0.076 0.138 0.207JB-165 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-170 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-175 336.0 0.076 0.138 0.207 0.076 0.138 0.207JB-180 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-185 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-190 328.0 0.076 0.138 0.207 0.076 0.138 0.207JB-195 332.0 0.076 0.138 0.207 0.076 0.138 0.207JB-200 322.0 0.076 0.138 0.207 0.076 0.138 0.207JB-205 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-210 328.0 0.076 0.138 0.207 0.076 0.138 0.207JB-215 322.0 0.076 0.138 0.207 0.076 0.138 0.207JB-220 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-225 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-230 333.0 0.076 0.138 0.207 0.076 0.138 0.207JB-235 333.0 0.076 0.138 0.207 0.076 0.138 0.207JB-240 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-245 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-250 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-255 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-260 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-265 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-270 331.0 0.076 0.138 0.207 0.076 0.138 0.207

Existing Future

Model Junction

Elevation(mASL)

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Page 4 of 8

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Average Day Demand

(L/s)

Maximum Day Demand

(L/s)

Peak Demand

(L/s)

Existing Future

Model Junction

Elevation(mASL)

JB-275 329.0 0.076 0.138 0.207 0.076 0.138 0.207JB-280 318.0 0.076 0.138 0.207 0.076 0.138 0.207JB-285 325.0 0.076 0.138 0.207 0.076 0.138 0.207JB-290 328.0 0.076 0.138 0.207 0.076 0.138 0.207JB-295 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-300 328.0 0.076 0.138 0.207 0.076 0.138 0.207JB-305 324.0 0.076 0.138 0.207 0.076 0.138 0.207JB-310 322.0 0.076 0.138 0.207 0.076 0.138 0.207JB-315 328.0 0.076 0.138 0.207 0.076 0.138 0.207JB-320 331.0 0.076 0.138 0.207 0.076 0.138 0.207JB-325 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-330 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-335 330.0 0.076 0.138 0.207 0.076 0.138 0.207JB-340 333.0 0.076 0.138 0.207 0.076 0.138 0.207

Minimum 318.0 0.076 0.138 0.207 0.076 0.138 0.207Maximum 336.0 0.076 0.138 0.207 1.296 2.365 3.547Total 5.1 9.4 14.1 6.4 11.6 17.4

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Page 5 of 83.0 Model Results - 2018 Demands

3.1 Existing Conditions

Fire Pump On

HLP1, HLP2, Well 5 On

JB-5 500 478 87 46JB-10 500 477 87 46JB-15 461 437 71 47JB-20 451 426 68 45JB-25 401 376 67 46JB-30 401 376 52 38JB-35 372 346 61 40JB-40 401 375 45 31JB-45 431 405 64 42JB-50 411 385 60 39JB-55 392 366 42 30JB-60 390 356 2 1JB-65 409 374 1 1JB-70 469 437 2 1JB-75 441 415 61 42JB-80 500 478 87 46JB-85 451 427 79 47JB-90 382 360 57 34JB-95 480 458 71 42

JB-100 411 386 65 48 407JB-105 411 386 61 45JB-110 421 395 55 38JB-115 418 375 1 1JB-120 421 396 59 40JB-125 441 415 67 44JB-130 410 322 1 1JB-135 411 386 31 23JB-140 460 436 76 46JB-145 408 312 1 0JB-150 431 409 69 39JB-155 372 345 6 4JB-160 419 331 1 1JB-165 411 386 62 47JB-170 421 396 70 45JB-175 363 340 47 29JB-180 411 385 49 32JB-185 411 385 44 29JB-190 441 415 67 43JB-195 401 376 68 45JB-200 500 477 85 47JB-205 411 386 33 24JB-210 441 415 71 45JB-215 500 477 87 47

For average analysis use HLP2 operating, and for peak analysis use HLP1 and HLP2 on. For fire flow analysis, use two scenarios: Fire Pump only on (note - this may not actually be possible due to current mechanical issues in pumphouse); and HLP1, HLP2, and Well 5 pump on.

Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa

Operator Note - Typ. Pressure

(kPa)

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Page 6 of 8

Fire Pump On

HLP1, HLP2, Well 5 OnJunction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa

Operator Note - Typ. Pressure

(kPa)JB-220 421 396 60 41JB-225 421 396 59 40JB-230 392 366 64 41JB-235 392 366 64 42JB-240 411 385 65 42JB-245 411 386 57 39JB-250 421 395 68 44JB-255 411 386 63 47JB-260 421 394 5 3JB-265 421 396 66 44JB-270 412 389 49 32JB-275 431 405 54 38JB-280 539 517 89 47 586JB-285 470 445 46 33JB-290 441 416 73 45JB-295 421 396 49 34JB-300 441 416 66 45JB-305 480 458 87 46JB-310 500 477 86 47JB-315 441 415 53 37JB-320 411 387 74 47JB-325 413 341 1 0JB-330 400 263 0 0JB-335 421 395 51 36JB-340 392 368 4 3

Min 363 263Max 539 517

Notes:denotes operating pressure less than 275 kPadenotes operating pressure above 275 kPa but less than 350 kPadenotes operating pressure greater than 480 kPadenotes fire flow of less than 40 L/s at 140 kPa minimum system pressure

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Page 7 of 83.0 Model Results - Future Conditions

3.2 Future Conditions

Fire Pump On

HLP1, HLP2, Well 5 On

JB-5 478 443 85 45JB-10 478 443 85 45JB-15 439 403 70 46JB-20 429 392 67 45JB-25 380 342 71 46JB-30 380 342 55 38JB-35 350 313 63 41JB-40 380 342 45 31JB-45 409 372 68 44JB-50 389 352 64 43JB-55 370 332 43 30JB-60 370 332 42 29JB-65 389 352 55 37JB-70 449 414 81 45JB-75 419 382 61 41JB-80 478 444 85 45JB-85 429 393 78 46JB-90 360 324 55 32JB-95 458 424 70 41

JB-100 389 352 70 47JB-105 389 352 72 47JB-110 399 362 56 39JB-115 399 362 51 35JB-120 399 362 58 39JB-125 419 381 71 45JB-130 399 362 62 42JB-135 389 352 57 41JB-140 438 402 76 46JB-145 399 362 44 30JB-150 409 374 67 37JB-155 350 313 53 35JB-160 409 372 54 37JB-165 389 352 70 47JB-170 399 362 71 45JB-175 341 305 45 27JB-180 389 352 52 35JB-185 389 352 47 32JB-190 419 381 69 44JB-195 380 342 69 45JB-200 478 443 84 45JB-205 389 352 59 41JB-210 419 382 72 45JB-215 478 444 86 45

For average analysis use HLP2 operating, and for peak analysis use HLP1 and HLP2 on. For fire flow analysis, use two scenarios: Fire Pump only on (note - this may not actually be possible due to current mechanical issues in pumphouse); and HLP1, HLP2, and Well 5 pump on. Change all pipe less than 150 mm diameter to 150 mm diameter.

Junction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Page 8 of 8

Fire Pump On

HLP1, HLP2, Well 5 OnJunction

P at QAVG

(kPa)

P at QPEAK

(kPa)

Available Fire Flow at 140 kPa

JB-220 399 362 60 40JB-225 399 362 58 39JB-230 370 332 66 42JB-235 370 332 66 43JB-240 389 352 67 43JB-245 389 352 58 39JB-250 399 362 69 44JB-255 389 352 68 47JB-260 399 362 52 37JB-265 399 362 67 44JB-270 390 353 48 31JB-275 409 372 54 37JB-280 517 483 87 45JB-285 448 411 64 44JB-290 419 382 73 46JB-295 399 362 49 33JB-300 419 382 67 44JB-305 458 424 85 45JB-310 478 443 85 45JB-315 419 382 52 36JB-320 389 353 73 47JB-325 399 362 38 27JB-330 399 361 38 26JB-335 399 362 51 35JB-340 370 336 48 30

Min 341 305Max 517 483

Notes:denotes operating pressure less than 275 kPadenotes operating pressure above 275 kPa but less than 350 kPadenotes operating pressure greater than 480 kPadenotes fire flow of less than 40 L/s at 140 kPa minimum system pressure

Z:\17181-North_Huron-Water_Wastewater_Master_Plan\Projects\WaterCAD\17181-19Mar4 Blyth Modelling Design Brief.xls

Appendix B

Watermain Assets for Wingham and Blyth

Appendix C

Reports on Physical Condition Assessments of Electrical and HVAC

Electrical Equipment Condition Assessment Report Blyth and Wingham Water/Wastewater Facilities The Township of North Huron

Prepared for:

The Township of North Huron P.O. Box 90, 274 Josephine Street, Wingham, ON N0G 2W0 Prepared by:

Runge & Associates Inc. P.O. Box 387, 864 Hurontario St., Collingwood, ON L9Y 3Z7 May 2019 Runge File No. 17104W

The Township of North Huron Page 2

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

Table of Contents 1.0 Abbreviations .............................................................................................................................. 4

2.0 Introduction ................................................................................................................................. 4 2.1 Site Location .................................................................................................................... 4

3.0 Blyth Wastewater Treatment Plant .............................................................................................. 5 3.1 Control Building ................................................................................................................ 5 3.2 Filter Building ................................................................................................................... 6 3.3 Chlorine Contact Chamber and Clarifiers .......................................................................... 7

4.0 Blyth Water Reservoir ................................................................................................................. 8 4.1 Pumphouse ...................................................................................................................... 8 4.2 Well #1 Shed .................................................................................................................... 9 4.3 Well #2 Shed .................................................................................................................... 9 4.4 Level Control House ......................................................................................................... 9

5.0 Wingham Pollution Control Plant ................................................................................................ 9 5.1 Office/Lab ....................................................................................................................... 10 5.2 Workshop/Storage .......................................................................................................... 10 5.3 Basement ....................................................................................................................... 11 5.4 Building Exterior ............................................................................................................. 11

6.0 Wingham Well #3 Pumphouse ................................................................................................... 11 6.1 Pumphouse .................................................................................................................... 11

7.0 Wingham Well #1 and Well #4 .................................................................................................... 12 7.1 Well #4 Well House ........................................................................................................ 12 7.2 Pumphouse .................................................................................................................... 12 7.3 Well #1 Pumphouse ........................................................................................................ 13

8.0 Wingham Workshop .................................................................................................................. 13 8.1 Workshop ....................................................................................................................... 13

9.0 Wingham Standpipe .................................................................................................................. 14 9.1 Control Building .............................................................................................................. 14

10.0 Wingham Sewage Pumping Station ........................................................................................... 14 10.1 Generator Room ............................................................................................................. 14 10.2 Dry Well.......................................................................................................................... 15 10.3 Wet Well ......................................................................................................................... 15

11.0 Summary and Recommendations .............................................................................................. 15

12.0 Cost Estimate ............................................................................................................................ 16 3.0 Blyth Wastewater Treatment Plant ...................................................................................... 16 3.1 Control Building ................................................................................................................. 16 3.2 Filter Building .................................................................................................................... 17

The Township of North Huron Page 3

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

3.3 Chlorine Contact Chamber ................................................................................................ 17

4.0 Blyth Water Reservoir .................................................................................................................... 18 4.1 Pumphouse ....................................................................................................................... 18 4.2 Well #1 Shed ..................................................................................................................... 19 4.3 Well #2 Shed ..................................................................................................................... 19 4.4 Level Control House .......................................................................................................... 19

5.0 Wingham Pollution Control Plant ................................................................................................... 19 5.1 Office/Lab ......................................................................................................................... 19 5.2 Workshop/Storage ............................................................................................................. 19 5.3 Basement .......................................................................................................................... 19

6.0 Wingham Well #3 Pumphouse ........................................................................................................ 20 6.1 Pumphouse ....................................................................................................................... 20

7.0 Wingham Well #1 and Well #4 ........................................................................................................ 20 7.1 Well #4 Well House ........................................................................................................... 20 7.2 Pumphouse ....................................................................................................................... 20 7.3 Well #1 Pumphouse .......................................................................................................... 21

8.0 Wingham Workshop ....................................................................................................................... 21 8.1 Workshop .......................................................................................................................... 21

9.0 Wingham Standpipe ....................................................................................................................... 22 9.1 Control Building ................................................................................................................. 22

10.0 Wingham Sewage Pumping Station .............................................................................................. 22 10.1 Generator Room .............................................................................................................. 22 10.2 Dry Well .......................................................................................................................... 22 10.3 Wet Well .......................................................................................................................... 22

The Township of North Huron Page 4

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

1.0 Abbreviations

OESC Ontario Electrical Safety Code

ESA Electrical Safety Authority

OBC Ontario Building Code

MCC Motor Control Center

VFD Variable Frequency Drive

HIM Human Interface Module

CSA Canadian Standards Association

2.0 Introduction

2.1 Site Location

The following report will provide a review of the existing electrical equipment within the Township of North Huron water and wastewater facilities. An assessment and recommendations will be provided based on visual inspections of the existing electrical equipment within the facilities.

Assessments were performed at the following facilities:

· Blyth Wastewater Treatment Plant, North Street, Blyth, Ontario · Blyth Water Reservoir, County Road 4, Blyth, Ontario · Wingham Pollution Control Plant, Lloyd Street, Wingham, Ontario · Wingham Well #3 Pumphouse, Water Street, Wingham, Ontario · Wingham Well #1 and Well #4 Pumphouse, Albert Street, Wingham, Ontario · Wingham Workshop, Park Drive, Wingham, Ontario · Wingham Standpipe, John Street East, Wingham, Ontario · Wingham Sewage Pumping Station, Josephine Street, Wingham, Ontario

The following equipment was not reviewed and is not included as part of the electrical equipment condition assessment report:

1. Information Technology (I.T.) infrastructure. 2. Emergency power generator capacity and distribution. 3. Power distribution cables in conduit.

The Township of North Huron Page 5

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

3.0 Blyth Wastewater Treatment Plant

The Blyth Wastewater Treatment Plant was built in 1980 and consists of a Control Building, Filter Building and an Inlet Works/Chlorine Contact Building. The electrical systems, although dated, appear to be functioning adequately. No issues were raised by operators during the site visit.

3.1 Control Building

a. The existing drawings indicate the utility pad-mounted transformer is a 300kVA, 8.3kV-347/600V, 3-phase, 4-wire. The primary line runs overhead along North Street where it then goes underground to the utility transformer. The secondary underground conductors run underground to the MCC and service entrance equipment located in the Generator Room. The utility metering equipment and utility meter are also located in the Generator Room.

b. The main service equipment is dated April 1981 and is located in the Generator Room. The equipment is Westinghouse Five Star Motor Control Center; 600V, 600A, 3-phase, 4-wire, 60Hz, Shop Order No. 08B4338. Westinghouse equipment is supported by Eaton. Eaton indicated spare parts for the Five Star MCC are available.

c. Workplace Electrical Safety Standard Z462-15, Part 5.2.2 indicates that “a single line diagram for the electrical system, where provided, shall be maintained in a legible condition and shall be kept current.” Part 4.2.2.6.2 (Planning) and Annex B.5 (Maintaining Electrical Drawings) of Z462-15 also references the requirement of up-to-date single line diagrams. It is recommended that a single line diagram be created and posted at the MCC.

d. The existing generator is a Harper generator. The nameplate data indicates 125kW, 156.25kVA, 600V, 3-phase, dated 02/81. Maintenance history of the generator is unknown. If necessary, it is recommended that a full tune-up be performed on the generator, including a load bank test, oil analysis and cooling system check. The oil analysis will provide detailed information on the status of the generator.

e. Cummins was consulted regarding the generator control panel. Cummins indicated the generator control panel is all relay based with individual relays, meters, PTs and CTs. This type of panel is fairly robust and parts can be provided, as necessary.

f. Lighting Panel A and associated transformer are installed within the Generator Room. The panel directory appears accurate. Immediate attention to equipment is not required. Consider replacing the panelboard as issues arise. Ensure 1m clearance is maintained in front of the electrical equipment and equipment is clear of material.

The Township of North Huron Page 6

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

g. At the time of inspection, the generator ventilation system appeared to be undergoing repairs. Exposed wiring was visible.

h. The Generator Room’s interior lighting consists of four-foot fixtures and appears to be adequate for the intended use of the space. Bulbs are missing from the fixture above the doorway.

i. The garage area’s interior lighting consists of four-foot fixtures and appears to be adequate for the intended use of the space.

j. The Blower Room’s interior lighting consists of four-foot fixtures and appears to be adequate for the intended use of the space. The fixture between blowers 2 and 3 is not working. Replace bulbs, as required.

k. The Blower Room’s local disconnects are displaying signs of corrosion. Replace, as needed.

l. Provide a cover over hole on Blower 2 local disconnect.

m. Provide a cover over hole on Blower Room’s compressor local disconnect.

n. Exposed wiring exists from the removal of the Blower Room’s unit heaters. Rectify wiring per OESC and provide cover for junction boxes.

o. Provide a cover over hole on the junction box near the ultrasonic transmitter in the Blower Room.

p. The chemical feed pump’s local disconnects appear dated and require replacement. May not be currently in use.

q. Consider installing emergency lighting in the office area.

r. The office and former chemical room’s interior lighting consists of four-foot fixtures and appears to be adequate for the intended use of the space. The light above the sink in the office area is not working. The bulbs in the washroom area require replacement.

s. The hot water tank’s local disconnect is showing signs of corrosion. It is recommended local disconnect be replaced.

t. Exposed wiring exists in the former chemical room. Rectify wiring per OESC and provide covers for the junction boxes.

3.2 Filter Building

a. The MCC is dated April 1981 and is located in the Filter Building. The equipment is Westinghouse Five Star Motor Control Center; 600V, 600A, 3-phase, 4-wire, 60Hz, Shop Order No. 08B4340. Westinghouse equipment is supported by Eaton. Eaton indicated spare parts for the Five Star MCC are available.

The Township of North Huron Page 7

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

b. Some lighting in the Filter Building has a Class 1 Division 2 explosion proof rating. Other electrical equipment, conduit and wiring installed is unclassified. Prior to any electrical upgrades, the classification rating of the Filter Building should be confirmed. Note that depending on the building’s hazardous classification, changes to existing unclassified electrical equipment may be required.

c. Consider installing emergency lighting in the Filter Building.

d. The light below the MCC is missing a glass cover.

e. The lights behind the tank do not appear to be working.

f. The local disconnect on the tank has come loose from its mounting bracket.

g. The pressure controller’s cover is not secure. It is showing signs of corrosion. Replace this device.

h. There are eight conduits coming up from the floor slab end at the junction box. The junction box is showing signs of corrosion. Replace the junction box and repair the source of the water leak onto the junction box.

3.3 Chlorine Contact Chamber and Clarifiers

a. Some lighting in the lower level of the Chlorine Contact Chamber has a Class 1 Division 2 explosion proof rating. Other electrical equipment, conduit and wiring installed are unclassified. Prior to any electrical upgrades, the classification rating of the Filter Building should be confirmed. Note that depending on the building’s hazardous classification, changes to existing unclassified electrical equipment may be required.

b. The wiring of the drainage pump equipment does not include EYS seal fittings. Prior to any electrical upgrades, the classification rating of the drainage pump area should be confirmed. Note that depending on the building’s hazardous classification, changes to existing unclassified electrical equipment may be required.

c. The junction box cover in the lower level of the Chlorine Contact Chamber is not secure and wiring is exposed.

d. The local disconnect mounted above grade at the drainage pump is showing signs of corrosion and requires replacement.

e. The local controls mounted above grade at the drainage pump are showing signs of corrosion and require replacement.

f. Secure instrumentation junction box cover to the junction box at the Chlorine Contact Chamber.

g. The conduit to the ultrasonic sensor junction box along the wall of the Chlorine Contact Chamber to be properly secured.

The Township of North Huron Page 8

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

h. There is exposed wiring on top of the Contact Chamber. Route wiring within conduit, per OESC.

i. Comminutor junction box cover on top of the Chlorine Contact Chamber to be secured to the junction box. Local disconnect is showing signs of corrosion and requires replacement.

j. Various control panels, local disconnects and junction boxes at Clarifiers are showing signs of corrosion or are damaged and appear to require replacement. Various conduit locations to be secured to clarifier railings per OESC. Prior to any electrical upgrades, the classification rating of the Clarifier area should be confirmed. Note that depending on the area’s hazardous classification, changes to existing unclassified electrical equipment may be required.

k. Various receptacles installed in light pole require replacement and weatherproof covers.

l. The outdoor lighting on the office building appears to have been upgraded. Consider replacement of exterior lighting on other buildings to LED.

4.0 Blyth Water Reservoir

The Blyth Water Reservoir facility consists of a pumphouse, 2 well sheds and level control house. The age of these buildings is unknown. Upgrades to the facility occurred in 2003.

4.1 Pumphouse

a. The existing electrical distribution equipment consists of a main incoming service entrance disconnect, a splitter and various disconnects. The age of the electrical equipment varies. Workplace Electrical Safety Standard Z462-15, Part 5.2.2 indicates that “a single line diagram for the electrical system, where provided, shall be maintained in a legible condition and shall be kept current.” Part 4.2.2.6.2 (Planning) and Annex B.5 (Maintaining Electrical Drawings) of Z462-15 also reference the requirement of up-to-date single line diagrams. It is recommended that a single line diagram be created and posted at the Pumphouse.

b. The lighting panel directory requires updating.

c. Ensure 1m clearance is maintained in front of electrical equipment and equipment is clear of material.

d. A local disconnect is located in the Generator Room. It is assumed this disconnect is for the standby generator. Identify the disconnect and provide lamicoid nameplate on disconnect.

The Township of North Huron Page 9

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

e. The existing generator is a Marathon Electric. The nameplate data indicates 50kW, 62.5kVA, 600V, 3-phase, dated 02/81. Maintenance history of the generator is unknown. If necessary, it is recommended that a full tune-up be performed on the generator, including a load bank test, oil analysis and cooling system check. The oil analysis will provide detailed information on the status of the generator.

f. The lighting within the Pumphouse varies between incandescent bulbs hanging from the ceiling to fluorescent light fixtures. The lighting appears to be adequate. Consider replacing lighting to LED.

g. Several instances within the Pumphouse where wiring is exposed and appears unsafe. It is recommended installing wiring within conduit or removing as necessary, per OESC.

h. Secure the conduit on building’s exterior to building.

i. The conduit on the Pumphouse building’s exterior has broken and come apart from LB fitting. Repair conduit.

4.2 Well #1 Shed

a. There is exposed wiring. Route wiring in conduit.

b. The shed lighting consists of an incandescent bulb. Consider replacing lighting with LED.

4.3 Well #2 Shed

a. The well pump control panel is showing signs of corrosion. Consider replacing the pump control panel.

b. There is exposed wiring at well pump control panel. It is recommended unused wiring be removed.

c. The shed lighting consists of an incandescent bulb. Consider replacing lighting with LED.

4.4 Level Control House

a. The conduit at hatch to the reservoir is broken and in need of repair.

5.0 Wingham Pollution Control Plant

The Wingham Pollution Control Plant was built in 1991. Electrical equipment appears to be original to the construction of the plant.

The Township of North Huron Page 10

Electrical Equipment Condition Assessment Report – Blyth and Wingham Water/Wastewater Facilities

May 2019

Runge & Associates Inc. File No. 17104W

5.1 Office/Lab

a. The existing drawings do not indicate the size of the pole-mounted utility transformers. It appears the utility transformers equate to a 8.3kV-600/347V, 150kVA service. The primary line runs overhead to the pole-mounted transformers at the fence line of the plant where it then goes underground to the utility transformer. The secondary underground conductors run underground to the MCC and service entrance equipment located in the Office/Lab room. The utility metering equipment is located in the MCC and the utility meter is located on the outside wall of the building.

b. The main service equipment is Klockner-Moeller; 600V, 3-phase, 60Hz, No. 16/91-4938, Customer Order No. 1056038. Klockner-Moeller equipment is supported by Eaton. Eaton indicated spare parts are available. The MCC is showing signs of corrosion. Holes in MCC doors should be properly covered.