APM Catalogue

-

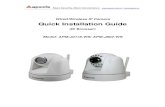

Upload

spoonful-burnside -

Category

Documents

-

view

149 -

download

1

Transcript of APM Catalogue

Contents

About APM

Applications

Products

Ordering INFO.

01

02

04

15

Experience

Established in 1991, APM helps customers to solve diffi cult manufacturing problems, increase

productivity, improve quality, and reduce costs. Our profound experience in this market and the

support of our customers has enabled us to become one of the leading liquid fi ltration equipment

manufacturers in Taiwan.

Services

Customer satisfaction is the core value that permeates everything we do. It is our goal to provide

our customers with unparalleled service. Our enthusiasm and professional services have built well-

connected relationships with our customers.

Products

APM takes pride in providing a complete line of fi lters for a wide range of industrial applications. In

2001, APM obtained many kinds of patents in bag fi lter housings. We are also striving to consistently

meet the quality standards in the liquid fi ltration fi eld.

Vision

As APM is growing, we are strategically positioned worldwide to serve the growing needs of our

customers. Continuous improvements in quality and service are vital to the survival of our company

in today’s competitive environment. We are committed to being a total solution provider and leading

product supplier to the industries worldwide.

About APM

1

AP

M

Applications

APM products include uses in water purifi cation and other in-plant liquids, food processing,

beverages, chemicals, petrochemicals, pharmaceuticals, cosmetics, photographic solutions, fuels,

lubricants and plating solutions.

An easy solution to your fi ltration needs

Chemical

Electronics

Environment Industry

Petrochemicals

Water Purifi cation

Pharmaceutical

2

AP

M

Chemical

Polishing of aqueous process fl uids, alkalis, acids

and solvents, emulsions, adhesive.

Food & Beverage

Wine, spirits and beer, oil, liquid sugar, juice, syrup,

soft drink.

Petrochemicals

Lube oils, fuel additives, amine solutions, glycol

fl uids, oil drilling and injection fl uids.

Resins, Inks and Coatings

Resins, plastics, printing ink, paper coatings,

electrodeposition, paints, automotive top coats.

Pharmaceutical

Active carbon purifi cation, gelatins, vitamin

extracts, herbal mixtures.

Electronics

Chip processing, photo-chemical polishing, Pre-RO

filtration, DI water pre-filtration.

Paint and Lacquer

Agglomerates, paint coagulates, storage conta-

minants.

Water Purifi cation

Drinking water, industry water, swimming pool,

fi shing pool, domestic water fi ltration.

3

AP

M

‧APM BAG FILTER

HOUSINGS Single Bag Filter Housings -Standard Series -Low Pressure Series -Top-In Series

Mutibag Filter Housings

‧APM CARTRIDGE FILTER

HOUSINGS

-SC Series -TK Series -TKH Series -DL Series

‧Food Processing Filter

Housings

‧APM Ceramic Candle Filter

Housings

‧APM Filter Bags

‧APM Filter Cartridges

‧Accessories for Filter

Housings

Products

4

AP

M

APM BAG FILTER HOUSINGS

APM Liquid Filter Housings come in many sizes and styles. Housing covers are

easily removed without special tools. We not only provide our customers with

well-designed, durable products but also with competitive pricing.

Features & Benefi ts‧304 or 316 stainless steel construction for best chemical

compatibility and corrosion resistance.

‧Low pressure drops, high fi ltration effi ciency.

‧Electro-polished external housing for superior fi nish.

‧Easy access for housings cleaning or bags change-out, no tool

needed!

‧Lid o-ring sealing between cover and housing, preventing liquid

leakage.

‧Patent-design bag positioning ring provide positive sealing

when used with APM fi lter bags, preventing bypass of unfi ltered

liquid.

‧Heavy-duty bag support baskets.

‧Multiple pressure ratings available.

5

AP

MStandard SeriesLow Pressure Series

Multibag Filter Housing

Top-In Series

APM CRATRIDGE FILTER HOUSINGS

APM controls the manufacturing process of all of our components from tooling design to automatic

welding. Our excellent fi ltration technology is designed to provide maximum performance and optimum

solutions.

Features & Benefi ts‧304 or 316 stainless steel construction for best chemical compatibility and corrosion resistance.

‧Low pressure drops, high fi ltration effi ciency.

‧Electro-polished external housing for superior fi nish.

‧Easy access for housings cleaning or cartridges change-out, no tool needed!

‧Lid o-ring sealing between cover and housing, preventing liquid leakage.

‧Cartridge hold down plate and v-posts assure alignment and positive seal for cartridges.

‧Seat cups accept 222 double open end or single open end cartridges.

‧Multiple pressure ratings available.

6

AP

M

TKH Series TK Series

APM FOOD PROCESSING FILTER HOUSINGS

To meet all customer needs, APM refi nes Filter Housings via high-tech electro polishing. APM Food

Processing Filter Housings are used in the fi elds of Chemical, Electronic, Biotechnology, Food & Beverage,

Wine, Cosmetics, Pharmaceutical industries, and Laboratory technology.

Features & Benefi ts‧304 or 316 stainless steel construction for lasting durability, best thermal and chemical

compatibility.

‧Electro-polished exteriors and interiors for fast and easy housing cleaning.

‧Quick opening V-band clamp closure for easy elements change-out, without disconnecting pipe

lines.

‧Equipped with 2” Tri-Clamp as standard inlet/outlet connections.

‧Cartridge housings accept standard 222 DOE or SOE cartridges.

‧Standard models and custom designs available.

‧Filtration rate:

Filter Bag:1~200 micron

Cartridge: 0.2 ~ 20 micron

‧Filter element:

Filter Bag: size P1A, P2A

Cartridge: length 10”, 20”, 30”, 40”

Bag Filter HousingCartridge Filter Housing

7

AP

M

CERAMIC CANDLE FILTER HOUSINGS

Special sitting cups are designed and collocated with Doulton ceramic fi lter candle. It is the best choice for

water fi ltration.

Features & Benefi ts‧Heavy-duty fi lter housings designed for industrial or domestic water fi ltration.

‧Available in 304 or 316 stainless steel for lasting durability, best thermal compatibility.

‧Easy access for housing cleaning and fi lter candles change-out, no tool needed.

‧Variety of different options including V-band clamp or swing bolts with eyenuts, loose covers or

hand wheel davit.

‧Equipped with single lid o-ring for positive sealing between housing and cover.

‧Accept Doulton ceramic fi lter candles or cartridges.

‧Available in 9 sizes for 1 to 100 fi lter candles/cartridges.

‧Standard models and custom designs available.

Multi-Cartridge Housing Single Cartridge Housing

8

AP

M

Energetic Water System

APU889C1-WF14

Water molecules gathered together in a stream by fi ve or even dozen molecules in normal conditions. This is known as a Molecule Cluster. The water processed by the Energetic Water System is called TT water. The cluster of TT water is smaller than normal, and is more activated. The smaller the water cluster is, the higher the oxygen content is. It is also tastier and can enhance metabolism. The research of Dr. S. Yamashita of Nagoya University in Japan uses “Magnetic Power Theory” to combine a dozen elements with rare magnetite under high temperatures and special Bio Ceramics, enabling the hydrogen ions (H+) and hydroxide ions (OH-) in source water to transform into the stable water molecule as H2O. The transformation increases the surface tension and the penetrability of water. The water becomes clear and tasty, duplicating the wonderful water mentioned in the Cha Jing (Tea Bible), written by Lu Yu hundreds of years ago.

Construction & Function‧First Filter: High Density Sophisticated Fiber Cartridge Function: For fi lter contaminants in water, such as sediments, fi ne dust, hair, sand and pollen, etc.‧Second Filter: High-Iodine Active Carbon Cartridge Function: For eliminate chlorine, organisms, chemicals, trihalomethanes, heavy metal particles, etc. ‧Third Filter: Doulton Ceramic Filter Candle‧Function: Can remove a wide range of water borne contaminants, bacteria, cysts and turbidity to a high

level of effi ciency.‧Fourth Filter: Far Infrared Resonance H2O Small Molecule Activating Device‧Made by elements incurred when refi ning many different ores. Able to release physical infrared wavelength

to operate rapid resonance between molecules. Can slice water molecules into smaller groups, increase oxygen containing and enhance activity. Processed water is able to improve metabolism, immunity, and reach the effect of beautifi cation and health care.

‧Fifth Filter: Circular TT Undulated-Magnetic Energy Generator‧Using static energy-magnetic line to divide water molecule groups into smaller water cluster, making

water more easily absorbed, and improving metabolism. It helps remove toxins in human body and increases the content of water oxygen.

‧Sixth Filter: UF Bacteria-Sieving Hallow membranes‧UF membrane is able to fi lter molecule quantities of about 50,000~100,000. The pressure required is smaller

than Reverse Osmosis, but the fl ow rate is much higher. UF membrane is immune to microorganisms and contaminants, and has longer service life than RO membrane.

‧Function: For fi ltration of viruses, microorganisms, dirt and escherichia.

One Stage Filtration System:There is an activated carbon fi ber inside it that can remove the chlorine from water. This Filtration System also has NSF certifi cation.Carbon fi lter-model: AWATERCTO

Two-Stage Filtration System:The fi rst stage is CTO activated carbon fi ber, which can remove the chlorine from water. The second stage is an absolute 0.22um fi lter that can remove impurities.Carbon fi lter-model: AWATERCTO0.22um-model: SC-10-0.22

APU889W2-WF14

APU889W3-WF14

Countertop Filters :

9

AP

M

Three-Stage Filtration System:The fi rst stage is a PP meltblown with NSF Certifi cation, and the second stage is CTO activated carbon fi ber with NSF certifi cation. The third stage is a Doulton ceramic cartridge fi lter which can remove bacteria from water. The absolute is 0.9um, and the non-absolute is 0.2 micron.PP meltblow-model: AWATER5P10Carbon fi lter-model: AWATERCTODoulton-model: W9220402

FILTER BAGS‧High density fi lter bags with high particle removal effi ciency and

longer service life.

‧Hard-plastic collar makes installation and disposal easier.

‧Provide best positive sealing when used in APM fi lter housings.

‧Fit most major competitive fi lter housings.

‧Custom size and shape are available upon request.

‧Micron rating available: 0.5 to 800 micron.

FILTER CARTRIDGES ‧Various cartridges type: melt-blown, wound, pleated, active-carbon.

‧Graded density construction, low pressure drop and high fl ow rates.

‧High dirt holding capacity, reduces fi lter change-outs.

‧Long service life for consistent fi ltration effi ciency.

‧Melt-Blown cartridges are made of 100% polypropylene fi bers.

‧Lengths from 5” to 50”, fi tting most cartridge housings in the fi eld.

‧Micron rating available: 0.2 to 100 micron.

‧Baskets: perforated, mesh lined.

‧Floats.

‧Lid o-rings.

‧Bag hold down assembly.

‧Springs seal assembly, clamps.

‧Pressure gages, pressure switches

ACCESSORIES

Special RequirementsAPM team members are engaged to working with our customers to create effective fi ltration solutions. To

customize our products, we provide many options for our customers.

‧Duplex and mutiplex fi ltration systems

‧Steam jacket ‧Hydraulic davit cover

‧Different housing surface treatment: coating, polishing, painting, etc.

10

AP

M

SDF Series Sediment Filter Cartridges100% pure polypropylene fi bers.

SDF SERIES 2.5" DIAMETER CARTRIDGES

2.5" diameter SDF cartridges coreless design is an

economical solution to pre-fi ltration for many applications.

Used widely as pre-fi ltration for RO systems and post-

fi ltration for GAC fi lters. Also used in applications such as

Ice Machines, Film Processing, Beverage, Coffee, Analytical,

Wineries, and many other applications.

SDF SERIES 4.5" DIAMETER CARTRIDGES

Our 4.5" diameter SDF fi lters have true step fi ltration

integrated in its design. Utilizing our technology to create

4 separate layers of micron fi ltration, our outside-in fl ow

allows the outer layer to trap the larger micron particles

with a much lower pressure drop.

Step-by-step, trapping the larger particles layer-by-layer,

allows our SDF fi lters a much higher dirt holding capacity

than standard spun polypropylene and string wound

cartridges.

MATERIALS OF CONSTRUCTION• FILTER MEDIA POLYPROPYLENE

• TEMPERATURE RANGE 40°F TO 145°F (4.4°C TO 62.8°C)

Performance Chart

11

AP

M

Poly Ray Pleated Cartridges manufactured with melt-blow polypropylene

fi ber media, our Poly-Ray pleated fi lter cartridge combine exceptional

dirt holding capacities with higher accuracy than depth fi lters. The

double layer of melt-blown media provide absolute particle retention

with longer service life than most other cartridges with similar design.

Well suited for pre-fi ltration of membranes. Poly Ray Pleated Cartridge

have high fl ow rates with reduced loss, contain no binders, adhesives or

surfactants for a wide compatibility of solvents.

Poly-Ray PP Pleated Cartridge

Initial Pressure Drop:

Poly-Nylon fi lter cartridges feature a naturally hydrophilic polyamide Nylon membrane with a narrow

pore size distribution and high porosity at the specifi ed pore size rating. Poly-Nylon fi lter are suitable

for the sub-micro fi ltration of a wide range of process liquid, in application where the characteristics

of a naturally hydrophilic membrane are required. Various grades of cartridges are used for pure water

supply and fi ne chemicals.

Poly-Nylon Thin Pleated Cartridge

Initial Pressure Drop:

Poly-Philic pleated fi lter cartridge is a PES (polyethersulfone) membrane in a polypropylene casing.

The fi lter media polyethersulfone is the mirrored asymmetric structure that ensure lower pressure

drop at high fl ow rate, and extended service life. PES membrane has excellent chemical resistance and

hydrophilization is widely use in BOE etchant, clean, DI water circulated fi ltration of semiconductor

industry & photoelectric industry and the terminal fi ne fi ltration of general food & beverage factory.

Poly-Philic Thin Pleated Cartridge

Initial Pressure Drop:

AR Series:

12

AP

M

Activated Carbon CartridgesAPM-CBC series‧Premium Containment: Carbon block fi lters consist of a high quality virgin

premium performance activated carbon. Activated carbon media available

from bamboo, coconut shell & coal. Specifi c formulation to reduce heavy metal

available.

‧Advantage: Lower pressure drop, no release of carbon fi nes, great physical

strength, highly porous, high adsorption, steady fl ow, highly uniform, and solid

structure integrity.

‧Reliable Performance: Reduce free chlorine, bad taste, odor THM, organics,

hazardous chemicals, and pesticides.

‧Stable Quality: The whole series products are made in Taiwan with automatic

processing to deliver the excellent and reliable quality.

‧Life cycle: Depending on inlet water quality and fl ow rate, six months or 3500

gallon water treated. Carbon block Operation Spec (Custom design and specs

are available.)

‧Cost Effective: Raw material control with cost effective material burden and

operation cost.

‧Ramp Capacity: Automatic process with huge orders capacity.

APM-SCBC series‧Premium Containment: Advanced nano-silver technology impregnating fi ber

wrapping carbon block fi lters consist of premium performance Activated

carbon media available from bamboo, coconut shell & coal.

‧Specifi c formulation to reduce heavy metal available.

‧Functions and performance maintained by LJ-CBC series, with enhancement of

bacteria resistance.

APM-BBt series‧Dispensable design with containment of coconut shell activated carbon or

alternative with bamboo, and Silver non-woven warping carbon block.

‧Transparent housing and bamboo look housing are both available.

‧Function is highly effective for reducing tastes and odors, chlorine and certain

organic. A nominal 5 micron post-fi lter is incorporated to reduce carbon fi nes

and other suspended particle to achieve maximum absorption. Silver non-

woven carbon block with extra function for bacteria resistance.

‧All components conform to FDA standard.

13

AP

M

APM-t-SCBC series‧Nano-silver impregnated non-woven cloth with activated carbon block

structure for removing chlorine and bacteria in water.

‧High tech nano-silver impregnated non-woven cloth, no contamination or

silver ion leakage.

‧Activated carbon made from natural coconut shell.

‧This product was all made from Taiwan with reliable quality and conform to

USD FDA standard.

APM-GACNLJ-GAC-C: coconut shell activated carbon cartridge

LJ-GAC-B: bamboo activated carbon cartridge

LJ-GAC-S: nano-silver impregnated activated carbon

cartridge

‧Full range of media containment - coconut shell activated

carbon, KDF55, nano-silver impregnated carbon, bamboo

activated carbon, mineral stone, or infrared ray media.

‧Transparent Housing with fl exible tube length from 5” to

20”.

‧User DIY friendly design for life cycle judgment.

‧All components conform to FDA standard.

‧Functions: Highly effective for reducing tastes and odors,

chlorine and certain organic. A nominal 5 micron post-

fi lter is incorporated to reduce carbon fi nes and other

suspended particle to achieve maximum absorption.

Bacteria-resistant nano-silver impregnated activated

carbon with secure enhancement function can extend

the service life of membrane and RO device. Maintenance

free.

14

AP

M

Ordering INFO.APM BAG FILTER HOUSINGS

Model Material Inlet/Outlet Flow Range Bag Size Surface Area Max. WorkingPressure

0 – 90 gpm

0 – 200 gpm

0 – 25 gpm

0 – 45 gpm

0 – 90 gpm

0 – 200 gpm

0 – 90 gpm

0 – 200 gpm

0 – 25 gpm

0 – 45 gpm

0 – 400 gpm

0 – 600 gpm

0 – 800 gpm

0 – 1000 gpm

0 – 1200 gpm

0 –1400 gpm

0 – 1600 gpm

0 – 1800 gpm

0 – 2000 gpm

0 – 2400 gpm

0 – 2800 gpm

0 – 3200 gpm

0 – 3600 gpm

0 – 4000 gpm

0 –4 400 gpm

0 – 4800 gpm

2"

2"

1"

1"

2"

2"

2"

2"

1"

1"

3” -4”

3” -4”

3” -6”

3” -6”

3” -6”

3” -8”

4” -8”

6” -8”

6” -10”

8” -10”

8” -10”

8” -12”

8” -12”

8” -12”

10” -12”

10” -12”

APM11

APM12

APM13

APM14

APM11-L

APM12-L

APM11S

APM12S

APM13S

APM14S

APM400

APM600

APM800

APM1000

APM1200

APM1400

APM1600

APM1800

APM2000

APM2400

APM2800

APM3200

APM3600

APM4000

APM4400

APM4800

P1A

P2A

P3A

P4A

P1A

P2A

P1A

P2A

P3A

P4A

2.0 ft2

4.4 ft2

0.5 ft2

1.0 ft2

2.0 ft2

4.4 ft2

2.0 ft2

4.4 ft2

0.5 ft2

1.0 ft2

8.8 ft2

13.2 ft2

17.6 ft2

22.0 ft2

26.40 ft2

30.8 ft2

35.2 ft2

39.6 ft2

44.0 ft2

52.8 ft2

61.6 ft2

70.4 ft2

79.2 ft2

88.0 ft2

96.8 ft2

105.6 ft2

SUS304

SUS316

SUS316L

SUS304

SUS316

SUS316L

SUS304

SUS316

SUS316L

SUS304

SUS316

SUS316L

P2A

150 PSI

( 10kg /cm2 )

100 PSI

( 7kg /cm2 )

150 PSI

( 10kg /cm2 )

150 PSI

( 10kg /cm2 )

Single Bag Filter Housings-Standard Series

Single Bag Filter Housings-Low Pressure Series

Single Bag Filter Housings-Top-In Series

Multibag Filter Housings

15

AP

M

APM CARTRIDGE FILTER HOUSINGS

Model Material Inlet/Outlet Flow Range Cartridge Length & No Max. WorkingPressure

10" × 1

20" × 1

30" × 1

40" × 1

10” × 5

20” × 5

30” × 5

40” × 5

10” × 7

20” × 7

30” × 7

40” × 7

10” × 5

20” × 5

30” × 5

40” × 5

10” × 7

20” × 7

30” × 7

40” × 7

30” × (8~12)

40"× (8~12)

30” × (13~20)

40"× (13~20)

30” × (21~28)

40"× (21~28)

30” × (29~36)

40"× (29~36)

30” × (37~46)

40"× (37~46)

30” × (47~56)

40"× (47~56)

30” × (57~81)

40"× (57~81)

30” × (82~95)

40"× (82~95)

30” × (96~135)

40"× (96~135)

30” × (136~155)

40"× (136~155)

30” × (156~173)

40"× (156~173)

100 PSI

( 7kg /cm2 )

SC Series

0-5 gpm

0-10 gpm

0-15 gpm

0-20 gpm

0 – 25 gpm

0 – 50 gpm

0 – 75 gpm

0 – 100 gpm

0 – 35 gpm

0 – 70 gpm

0 – 105 gpm

0 – 140 gpm

0 – 25 gpm

0 – 50 gpm

0 – 75 gpm

0 – 100 gpm

0 – 35 gpm

0 – 50 gpm

0 – 105 gpm

0 – 140 gpm

120~180 gpm

150~240 gpm

195~300 gpm

260~400 gpm

315~420 gpm

420~560 gpm

435~540 gpm

580~720 gpm

555~690 gpm

740~920 gpm

705~840 gpm

940~1120 gpm

855~1215 gpm

1140~1620 gpm

1230~1425 gpm

1640~1900 gpm

1440~2025 gpm

1920~2700 gpm

2040~2325 gpm

2720~3100 gpm

2340~2595 gpm

3120~3460 gpm

APM-SC1

APM-SC2

APM-SC3

APM-SC4

APM-TK5

APM-TK10

APM-TK15

APM-TK20

APM-TK7

APM-TK14

APM-TK21

APM-TK28

APM-TK5H

APM-TK10H

APM-TK15H

APM-TK20H

APM-TK7H

APM-TK14H

APM-TK21H

APM-TK28H

APM 8DL 30~ 12DL 30

APM 8DL 40~ 12DL 40

APM 13DL 30~ 20DL 30

APM 13DL 40~ 20DL 40

APM 21DL 30~ 28DL 30

APM 21DL 40~ 28DL 40

APM 29DL 30~ 36DL 30

APM 29DL 40~ 36DL 40

APM 37DL 30~ 46DL 30

APM 37DL 40~ 46DL 40

APM 47DL 30~ 56DL 30

APM 47DL 40~ 56DL 40

APM 57DL 30~ 81DL 30

APM 57DL 40~ 81DL 40

APM 82DL 30~ 95DL 30

APM 82DL 40~ 95DL 40

APM 96DL 30~ 135DL 30

APM 96DL 40~ 135DL 40

APM 136DL 30~ 155DL 30

APM 136DL 40~ 155DL 40

APM 156DL 30~ 173DL 30

APM 156DL 40~ 173DL 40

SUS304

SUS316

SUS316L

TKH Series

DL Series

SUS304

SUS316

SUS316L

SUS304

SUS316

SUS316L

150 PSI

( 10kg /cm2 )

150 PSI

( 10kg /cm2 )

1”

2”

1-1/ 2”

2”

2"~ 4"F

3"~ 4"F

4" ~ 6"F

6"~ 8"F

8"~ 10"F

10"~ 12"F

TK Series

SUS304 SUS316

1-1/ 2”

150 PSI

( 10kg /cm2 )

16

AP

M

Food Processing Filter Housings

Model Material Inlet/Outlet Flow Range Max. WorkingPressure

0 - 90 gpm

0 - 200 gpm2”Tri-Clamp

P 1A (F)

P 2A (F)

Bag Size

APM 11L -FP

APM 12L -FP

Model Material Inlet/Outlet Flow Range Max. WorkingPressure

Cartridge Length & No

APM-FP103

APM-FP203

APM-FP303

APM-FP403

APM-FP104

APM-FP204

APM-FP304

APM-FP404

APM-FP105

APM-FP205

APM-FP305

APM-FP405

APM-FP106

APM-FP206

APM-FP306

APM-FP406

100 PSI

( 7 kg /cm2 )

SUS304SUS316

SUS316L

0-64 gpm

0-127 gpm

0-190 gpm

0-254 gpm

0-85 gpm

0-169 gpm

0-254 gpm

0-338 gpm

0-106 gpm

0-211 gpm

0-317 gpm

0-423 gpm

0-127 gpm

0-254 gpm

0-380 gpm

0-507 gpm

10" x 3

20" x 3

30" x 3

40" x 3

10" x 4

20" x 4

30" x 4

40" x 4

10" x 5

20" x 5

30" x 5

40" x 5

10" x 6

20" x 6

30" x 6

40" x 6

SUS304

SUS316

SUS316L

2”Tri-Clamp 100 PSI

( 7 kg / cm2 )

APM Ceramic Candle Filter Housings

Model Material Standard Inlet/Outlet Max. Flow Rate Max. WorkingPressure

Cartridge Length & No

APM 1DL 1

APM 3DL 1

APM 5DL 1

APM 10DL 1

APM 20DL 1

APM 40DL 1

APM 60DL 1

APM 80DL 1

APM 100DL 1

3/4"

3/4"

3/4"

1"

1"

1 1/2"

1 1/2"

2"

2"

1.33 gpm

3.96 gpm

6.60 gpm

13.30 gpm

26.60 gpm

53.20 gpm

79.80 gpm

106.40 gpm

133.00 gpm

10"×1

10"×3

10"×5

10"×10

10"×20

10"×40

10"×60

10"×80

10"×100

SUS304

SUS316

SUS316L

150 PSI(10 kg/cm2)

150 PSI

(10 kg/cm2)

100 PSI

(7 kg/cm2)

17

AP

M

APM Filter Bags

Model P1A P2A P4AP3A

Size (D x L)

Surface Area

Max. Flow Rate

Compatible APM

Housing Model

Material

Micron Rating

7" x 16.5”

(17.8cm x 41.9cm)

2.0 ft2

90 GPM

APM11

APM11-L

APM11S

7"x 32"

( 17.8cm x 81.3cm )

4.4 ft2

200 GPM

APM12

APM12-L

APM12S

4"x 9"

( 10.2cm x 22.9cm)

0.5 ft2

25 GPM

APM13

APM13S

4"x 15"

( 10.2cm x 38.1cm )

1.0 ft2

45 GPM

APM14

APM14S

Polyester, Polypropylene, Nylon

0.5, 1, 5, 10, 25, 50, 75, 100, 150, 200, 250, 300, 400, 500, 600, 800

APM Filter CartridgesMelt-Blown Cartridges

Wound Cartridges

Model Material Micron Rating Outer DiameterLength

Polypropylene 0.5, 1, 2, 5, 10, 20, 30, 50, 75,

100 µm

5" ~ 50"MC Series

Polypropylene 1, 5, 10, 20, 50 µm 9 7/8", 20", 30", 40"

40, 50, 64, 69, 115 mm

63.5, 114 mmSDF Series

Model Material Core Material Outer DiameterMicron Rating

Polypropylene

PET

Cotton

Polypropylene

SUS304

SUS316

0.5, 1, 5, 10, 20, 30,

50, 75, 100 µm

60, 63.5, 65, 115

mm

WC Series

Length

5" ~ 50"

Carbon Block Cartridges

Model Material Micron Rating Outer DiameterLength

Active Carbon 10 µm 9 7/8", 20"CB Series 63.5, 114 mm

Pleated Cartridges: ( AR series )

Model Material Micron Rating End cap. Length Outer

Diameter

Poly Ray EPDM, Buna N,

Silicone, Viton,

Viton encapsulated

PFA

0.2, 0.45, 1, 5, 10,

20um

F=Double open end (DOE)0=222 Flat (SOE)5=222Fin (SOE)6=226 Flat (SOE)7=226 Fin (SOE)

10”, 20”, 30”,

40”

69mm

Poly Nylon EPDM, NBR, Silicon,

Viton, Viton

encapsulate with

Tefl on

0.10, 0.20, 0.45,

0.65, 1.00um

F=Double open end (DOE)0=222 Flat (SOE)5=222Fin (SOE)6=226 Flat (SOE)7=226 Fin (SOE)

10”, 20”, 30”,

40”

69mm

Poly Philic EPDM, Buna N,

Silicone, Viton,

Viton encapsulate

with Tefl on

0.04, 0.10, 0.20,

0.45, 0.65, 1.2um

F=Double open end (DOE)0=222 Flat (SOE)5=222Fin (SOE)6=226 Flat (SOE)7=226 Fin (SOE)

10”, 20”, 30”,

40”

69mm

18

AP

M

Accessories for Filter Housings

Lid O-Ring

Basket

Float

Others

Material:

Material:

Lining options:

Material:

‧NBR, EPDM , Viton, Tefl on, Silicone, Tefl on Encapsulated Viton,

Tefl on Encapsulated Silicon

‧SUS 304,SUS316, SUS 316L

‧20、40、60、80、100、150、200、250、300 mesh

‧SUS 304, SUS316 ,SUS 316L

Bag hold down assembly, spring seal assembly, cartridge posts, v-band clamps,

pressure gages, pressure switches.

Part Number Diameter & Length Micron Rating (Nominal) Flow Rate (gpm)

ASDF250501 2.5" X 4 7/8" 1 2 gpm @0.3psi

ASDF250505 2.5" X 4 7/8" 5 2 gpm @0.3psi

ASDF251001 2.5” X 9 7/8” 1 5 gpm @0.6psi

ASDF251005 2.5” X 9 7/8” 5 5 gpm @0.4psi

ASDF251010 2.5” X 9 7/8” 10 5 gpm @0.2psi

ASDF251020 2.5” X 9 7/8” 20 5 gpm @0.2psi

ASDF251050 2.5” X 9 7/8” 50 5 gpm @0.2psi

ASDF252001 2.5” X 20” 1 10 gpm @0.6psi

ASDF252005 2.5” X 20” 5 10 gpm @0.4psi

ASDF252010 2.5” X 20” 10 10 gpm @0.3psi

ASDF252020 2.5” X 20” 20 10 gpm @0.3psi

ASDF252050 2.5” X 20” 50 10 gpm @0.3psi

ASDF253001 2.5" X 30" 1 15 gpm @0.4psi

ASDF253005 2.5” X 30” 5 15 gpm @0.3psi

ASDF254001 2.5” X 40” 1 20 gpm @0.3psi

ASDF254005 2.5” X 40” 5 20 gpm @0.3psi

ASDF254025 2.5” X 40” 25 20 gpm @0.2psi

ASDF254075 2.5” X 40” 75 20 gpm @0.2psi

ASDF Series Sediment Filter Cartridges

Part Number Diameter & Length Micron Rating (Nominal) Flow Rate (gpm)

ASDF451001 4.5” X 9 7/8” 25~1 10 gpm @1psi

ASDF451005 4.5” X 9 7/8” 50~5 10 gpm @1psi

ASDF451010 4.5” X 9 7/8” 75~10 10 gpm @1psi

ASDF451020 4.5” X 9 7/8” 100~20 10 gpm @1psi

ASDF451050 4.5” X 9 7/8” 150~50 10 gpm @1psi

ASDF452001 4.5” X 20” 25~1 20 gpm @1psi

ASDF452005 4.5” X 20” 50~5 20 gpm @1psi

ASDF452010 4.5” X 20” 75~10 20 gpm @1psi

ASDF452020 4.5” X 20” 100~20 20 gpm @1psi

ASDF452050 4.5” X 20” 150~50 20 gpm @1psi

19

AP

M

Activated Carbon Cartridges

LJ-CBC Series

Model No. Dimension WeightDechlorination

Effi ciencyMicron Rating Initial Pressure Drop

CTO-10-10 2.5”X10” 330±20g ≧3500gal@1G/min ≦10um 0.75kg/cm2 @1G/min

CTO-10-20 2.5”X20” 650±20g ≧4000gal@2G/min ≦10um 0.045kg/cm2 @2G/min

LJ-SCBC Series

Model No. Dimension WeightDechlorination

Effi ciencyMicron Rating Initial Pressure Drop

SCTO-10-10 2.5”X10” 400±20g ≧3500gal@1G/min ≦10um 0.75kg/cm2 @1G/min

SCTO-10-20 2.5”X20” 720±20g ≧4000gal@2G/min ≦10um 0.045kg/cm2 @2G/min

LJ-BBt Series

Specifi cation: Activated Carbon Granular: 12x40 mesh

LJ-GAC Series

Media Specifi cation: 12x40 mesh nano-silver impregnated coconut shell activated carbon.

Filtratrion size: 10 micron

Silver density weight: 0.011%

Silver leakage: non detected

PH of fi ltering water: PH7-9

Ash ≦5%

lodine value≧1100

Initial pressure drop 0.75kg/cm2 @1G/min

20

AP

M

APM Sand Filters are designed for countries or areas

where maintaining water quality is an urgent problem.

Made of stainless steel 304 or 316, all APM Sand Filters are

electropolished for best surface fi nish and easy housing

cleaning. Design pressure is up to 150 PSI for most industries

and household applications. There are two choices for

backwashing: manual operation or automatic operation.

Manual operation fi lters equipped with a multi-port valve

with handle. Users use the handle to switch between

three modes as necessary: backwash, rinse or fi ltration. An

automatic control device is installed on the automatic fi lter,

the operation is monitored on elapsed time set by user. With

the regular backwash process, automatic fi lters assure the

user to have high quality water.

APM Sand Filters allow for various fi lter media, such as coarse

gravel, fi ne sand, silica sand, manganese greensand, granular

active carbon, ion exchange resin, ceramic ball, energetic

stone. APM Sand Filters are ideal for treatment of drinking

water, process water, cooling water, and cultivating water.

Housing only, exclusive elements.

APM SAND FILTERS

ManualOperation

AutomaticOperation

Model

Connections

Capacity(liter)

Dimensions (mm)

Water Inlet/Outlet

Filter Media Inlet

Filter Media Outlet

Diameter Height

SF18 2-1/2” NPT 1” NPT 1” NPT 18.60 237 600

SF25 2-1/2” NPT 1” NPT 1” NPT 24.95 237 750

SF30 2-1/2” NPT 1” NPT 1” NPT 30.30 237 880

SF40 2-1/2” NPT 1” NPT 1” NPT 41.50 237 1150

SF50 2-1/2” NPT 1” NPT 1” NPT 50.60 237 1370

SF60 2-1/2” NPT 1” NPT 1” NPT 60.05 300 1085

SF70 2-1/2” NPT 1” NPT 1” NPT 70.65 300 1235

SF80 2-1/2” NPT 1” NPT 1” NPT 84.78 300 1435

SF100 2-1/2” NPT 1” NPT 1” NPT 105.97 300 1735

21

AP

M

1F., No. 39, Fu An 10 Street, Shi-Tun Dist., Taichung, Taiwan 407

Tel: 8864-2359-7300 Fax: 8864-2359-7305

E-mail: [email protected]

Website: http://www.airpower.com.tw