API SC13 Meeting

description

Transcript of API SC13 Meeting

TG # 6

API SC13 Meeting

Winter Standards Meeting

January 24 – 28, 2011

Fort Worth, Texas

TG # 6

AgendaTG-6: Testing of Heavy Brine

TG ChargesRoll CallPrevious Meeting Minutes – ApprovalPublication Status/ Reports / Data / Conclusions / Recommendations/ Gantt ChartOld BusinessNew Business - Next Scheduled MeetingAction ItemsAdjourn

TG # 6

TG – 6 Charge

Recommend, develop and evaluate procedures for field and laboratory testing of heavy brines.

Update, revise and expand API RP-13J, “Testing of Heavy Brines” and “ISO/WD 13503, Part 3: Testing of heavy brines”.

Form Work Groups to achieve specific charges.

TG # 6

TG-6 Members / Role Call1. Paul H. Javora – Baker Hughes – Chair2. Saleh Al-Ammari - Aramco 3. William J. Benton – Cabot4. Brent Estes – ChevronTexaco5. Judy Guy-Caffey – Tetra6. Bill Foxenberg – Schlumberger (Adelina Son)7. Catalin Ivan – ExxonMobil8. Paul Scott – ConocoPhillips9. Tom Shumate – Baroid10. Cheryl L. Stark – ret. 11. Victoria Qiu - Shell (Tom Jones – BHI)

TG # 6

Previous Meeting Minutes

Met in Washington, DC, June 2010Members Present

1. Brent Estes2. Judy Guy-Caffey3. Catalin Ivan4. Lirio Quintero for Tom Jones5. Tom Shumate6. Paul Scott7. Del Son8. Cheryl Stark9. Saleh Al-Ammari

Absent: Paul Javora, William Benton

TG # 6

Approval of Previous Minutes

Motion:

Maker:

Second:

Result:

TG # 6

Report1. Revisions to Testing of Heavy Brines WG (ISO 13503-

3 & RP-13J) Edit, revise & process DIS/FDIS comments of submitted documents – Adopt back as RP-13J

2. Buffer Work Group, Chaired by Del Son – Document completedPrepare a method for determining the buffering capacity of brine, Document completed, reviewed and submitted for ISO formatting, etc, participate in ISO acceptance of the document.Del Son – Chair, Beth Prasek – MI-SWACO, Kingsley Nzeadibe – Halliburton-Baroid, Siv Howard – Cabot, Mohammad Tej – Baker Hughes Drilling Fluids, Judy Guy-Caffey – Tetra Technologies, Paul Javora – BJ Services

3. PCT Work Group, Don Isaac, Chair, HalliburtonEvaluate and qualify “in-house” PCT test procedures. Draft document on the Round Robin testing for the PCT of Brines completed, Last Round Robin to be completed January 2011 May 2011Ferrill G. Dalton - Halliburton-Baroid, Paul Javora – BJ Services, Weyman Dunaway – Tetra Technologies, Andree Dunston – Ambar Lonestar, Mohammad Tej – Baker Hughes Drilling Fluids, Ken Slater – MI-SWACO, Charlie Svoboda – MI-SWACO, William Benton – Cabot

TG # 6

Report4. Corrosion Work Group, Judy Guy-Caffey, Chair, Tetra

Technologies, Inc., Document completedUpdate and complete the corrosion section of RP-13J, document completed, reviewed and submitted, participate in ISO acceptance of the document.Ed Malachosky (Co-secretary) – Baker Hughes Drilling Fluids, Mohammad Tej (Co-secretary) – Baker Hughes Drilling Fluids, John Augsburger – Halliburton-Baroid, Bill Bailey – Baker Oil Tools, William Benton – Cabot, Rashmi Bhavsar – Schlumberger, Yue Chen – Shell, Andree Dunston – Ambar Lonestar Fluid Services, Dodie Ezzat – Halliburton-Baroid, Bob Horton – MI-SWACO, retired, Don Isaac – Halliburton-Baroid, Paul Javora – BJ Services, Ardjan Kopliku – BP, Keith Sharp – BJ Services – Retired, Adelina J. Son – Champion Technologies

5. Future-Projects Work Group, Judy Guy-Caffey, Chair, Tetra Technologies, Inc.Establish/Suggest future projects for TG-6 to go beyond 2009. Future-Projects were identified, reviewed, submitted, selected and established. Document completed.John Augsburger – Halliburton-Baroid, Ferrill Dalton – Halliburton-Baroid, Paul Javora - BJ Services, Del Son, William Benton – Cabot, Siv Howard – Cabot, Bob Horton – MI-SWACO (Retired )

TG # 6

Report6. Return Permeability Work Group, Dodie Ezzat, Chair,

Halliburton1. Compile and evaluate test procedures

2. Summarize testing parameters

3. Determine essential/desired parameters

4. Establish a suitable method or methods that satisfy oilfield requirements

NOTE 1: Round-Robin testing not in scope

NOTE 2: Confer with the ISO Project (13503 Series) already convened

Members: Keith Morton - Chevron, Carl Stouffer, Mel Schmit, Paul Javora – Baker Hughes, Saleh Al-Ammari – Saudi Arabia, William Benton, Cabot

TG # 6

Report7. Displacement Work Group, Ed Malachosky, Chair

1. Compile and evaluate test procedures

2. Summarize testing parameters

3. Determine essential/desired parameters

4. Conduct Round Robin Testing

5. Establish a suitable method or methods that satisfy oilfield

requirements Members: Marshall Chiasson – Tetra, Keith Morton - Chevron, Ed Robinson –

Halliburton, Dodie Ezzat – Halliburton, Paul Javora – Baker Hughes, Katrina Schultz – Baker Hughes, William Benton, Cabot

TG # 6

Report8. Hydrate Work Group, Keith Morton, Chevron, Chair (Del Son)

1. Compile a list of hydrate programs

2. Summarize capabilities of each program

3. Generate test fluid compositions and parameters to compare programs

4. Conduct hydrate calculations with each program for the test fluids/conditions

5. Correlate the test results

6. Identify those programs that satisfy oilfield requirements

NOTE 1: Round-Robin testing not in scope

Members: Jennifer Shafer – Tetra, Dodie Ezzat – Halliburton, Paul Javora – Baker Hughes, William Benton, Cabot

TG # 6

Report9. Scale Work Group, Judy Guy-Caffey, Tetra, Chair

1. Identify & compile oilfield scaling issues

2. Compile & evaluate test procedures

3. Identify & summarize essential/desired parameters

4. Summarize findings into a ‘knowledge document’ for completion engineers

Members: Victoria Qiu – Shell, DonaldLindblad – Paladin Solutions, Curtis Sitz, Vice-Chair – CorsiTech, Kern Smith - Baker Hughes, Brittany Gitch, Secretary - Baker Hughes, Marc Lehmann - Baker Hughes, Vu Thieu – Baker Hughes, - Schlumberger, Paul Javora – Baker Hughes

TG # 6

Report10. Emulsion Technology Work Group, Paul Javora, Chair

ISO 13503 Series Work Group

Establish a laboratory method or methods to evaluate the tendency to form emulsions or sludge when drilling, completing, fracturing or treating fluids contact formation fluids.Phase I – Establish Base-Line Profile (In-house & Standard Procedures)

Phase II – Develop a Round Robin SchemeCurrent need: 55 gallons of crude oil - untreated

Members: Keith Morton - Chevron, Brent Estes – Chevron, David Ekas – Marathon, Dodie Ezzat – Halliburton, Ferrill Dalton – Halliburton, Gary McGuffey, Paul Javora – Baker Hughes, Katrina Schultz – Baker Hughes, William Benton – Cabot, Patricia Potts – Baker Hughes, Phillip Kaufman – CESI Chemical, John Vian - Schlumberger

TG # 6

Report11. API CRA Testing Program, Paul Javora, Baker Hughes, Chair

Implement and monitor the API CRA Testing Program.

Funding Year 3 completed and the final results were reviewed and sent to the Participants.

Funding Year 4 was initiated in 2010, tests were discussed and planned, and the first four tests were implemented. Results expected in February.

The first in a series of meetings to critically review Year 1 and 2 results was held December 2010.

TG # 6

17 Participating Companies for Year 4

Baker HughesBJ Services CompanyCabot Specialty Fluids

ChevronTexaco Energy Technology CompanyConocoPhillips

ExxonMobilHalliburton Energy Services

Hamilton Metals, Inc.Marathon Oil Company

M-I SWACOSaudi AramcoSchlumberger

Shell International E&P Inc.Siderca SAIC – Tenaris

Sumitomo MetalSynergy Fluids

Tetra Technology Inc.

TG # 6

Old Business

1. A

2. B

3. C

TG # 6

New Business

1. Testing Heavy Brines, API 13 J – ISO DIS 13503-3 Bernard Fraboulet, TOTAL Technology Specialists

2. B

3. C

TG # 6

API Exploration & Production Standards Winter Meeting Fort Worth , January 26th, 2011

Testing Heavy BrinesAPI 13 J – ISO DIS 13503-3

Hydrometers & Density measurements

Bernard Fraboulet, TOTAL Technology Specialists

TG # 6

Density & specific gravity measurements Hydrometers

Density hydrometerConcept : mass per unit of volume (ρ) SI Graduations in g/ml - kg/m3 USC Graduations in ppg Reference temperatures SI 20°C USC : 70°C ( 21.1°C)

Relative density (specific gravity) hydrometerConcept : ratio of ρ sample by ρ water at the same temperatureGraduation dimensionless Reference temperature 15.56°C /60°FRatio of sample density to water density at 60°F :

999,012 kg/m3 ≡ 0, 999 012 g/ml (8,337 ppg)

TG # 6

Hydrometer and normative references

ISO 387: 1977 Principles of construction and adjustment

ISO 649:1981 Density hydrometer for general purposes

part 1 : SpecificationsPart 2 : Test methods and use

for both part : no adoption by USA

ISO 650 :1977 Relative density 60/60°F hydrometers for general purposes

Not adoption by France and Germany and then by CEN

TG # 6

Reference & Reporting temperatureISO 387 Reference temperature

• Clause 4.1 - density hydrometer : − 20 °C (68°F) − In special circumstances : substitution to 15°C (59°F) or 27°C

(80.6°F)− 27°C i.e 80°F recommended − other reference temperatures ? USA : 70 °F ?

• Clause 4.2 : relative density hydrometer − 60°F ( 15,56°C) for liquid and water

Density reporting temperature For any measurement done at a temperature which is not the reference one, a

correction is required. General reporting : when density hydrometer is used why to report at a

different temperature than the reference ’s one ? Does it need to get a direct conversion between SI ref. temperature to

USC’s (20°C – 68°F) or between USC ref. temperature to SI’s (70°F – 21°C) ?

• Reporting temperature proposal : SI report : 20°C USC report : 70°F Left to users

TG # 6

Clause 6.2.1 Hydrometer description

More accurate description • As per ISO’s : class M100 hydrometer• 6.2.1.1 Density hydrometer• 6.2.2.1 Relative density hydrometer

Calibration :• at least quarterly

TG # 6

Temperature Correction factor

Density hydrometer • Only a correction linked to hydrometer volumetric

change is required : − Standard glass thermal volume expansion 20 x 10-6 − Table linked to readings and temperature − Minor difference lower than uncertainty if the same

table is used for 20°C or 70°F as reference temperature

− Two tables ( SI and USC) possible

TG # 6

Temperature Correction factor

Relative density hydrometer• Reference temperature 60°F • Correction whatever the reporting temperature • Correction linked to

− Glass volumetric change − Water temperature density variation

Correction factor : − Complex equation − tables of coefficient − variations as per author/references

TG # 6

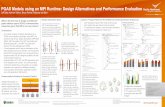

Proposed changesClause 6.4.1 Temperature correction for hydrometer

6.4.1.1 Density hydrometerCorrection factor (unit kg/m3 or 10-3 g/ml)

6.4.1.2 Relative density hydrometer sub clause 6.4.1 no changes Add SI equations

TG # 6

Next Scheduled Meeting

San Francisco, June 2011

TG # 6

Action Items

1. a

2. b

3. c

TG # 6

Adjourn

Motion:

Maker:

Second:

Result:

Time of adjournment: