API Plans Syamal

-

Upload

sherif-adel -

Category

Documents

-

view

232 -

download

6

description

Transcript of API Plans Syamal

-

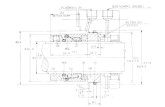

API Piping PlansReview of Piping Plan Schematics Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans-IntroductionThe seal faces and the seal assembly generate heat in the seal chamber due toliquid turbulence in the seal chamberliquid shear in the sealed fluid between the seal facesmechanical motion in the seal assemblyoccasionally bumping or touching of the seal faces

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans-IntroductionThis heat must be removed in most applications to maintain stable operationIn high temperature applications the opposite may be true. The heat in the seal chamber must be maintained to provide a stable operationTo control the temperature in the seal chamber and to provide adequate lubrication for the seal faces, a seal flush is required for the vast majority of applications

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans-IntroductionThe various seal flush arrangements have been categorized by APIThe plans are numbered and identified as API Piping Plan XX eg. ( API Plan 11 + 62)A brief overview of the various piping plans commonly encountered follows

-

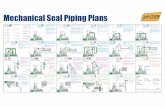

Installation & Troubleshooting Guidelines for API Seal Flush Plans-IntroductionAPI Piping Plan Summary (* = not covered)01*,02*Pump feature flush plan 11,12*,13,14By pass Flush- Flush plans intended to keep the seal area clean and remove seal generated heat 21,22*,23.Cooling Flush plan - Flush plans intend to cool the seal area31,32,33*.Slurry Flush Plan - Flush plan intended to keep the slurries away from the sealing area.41*....a combination plan for cooling and slurry52,53.....Dual Seal Flush plans61,62.Atmospheric flush plans to provide for a suitable atmosphere outside the seal area or behind the primary seal faces-Quench

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 11The seal flush line should be checked regularly with a temperature indicator. It should be the same temperature at both ends of the line.The typical mode of failure is a clogged orifice or a closed valve.

-

API Piping Plan 13 Line from seal flange through orifice to pump suction Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 13The seal flush line should be checked regularly with a temperature indicator. It should be the same temperature at both ends of the line.The typical mode of failure is a clogged orifice or a closed valve.

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 21The seal flush line should be checked regularly with a temperature indicator. When the pump is running the outlet of the seal cooler should be noticeably cooler than the inletThe cooling water lines should be checked regularly with a temperature indicator as well. The outlet cooling water line should be warmer than the inlet cooling water line.

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 21The typical modes of failure areclogged orifice or a closed valveloss of cooling water flowmissing or oversized orificeThe body of the heat exchanger should be warm while the pump is in operationThe heat exchanger case drain should be opened periodically to purge the heat exchanger of accumulated solids and debris

-

API PIPING PLAN 23Line from seal to coolerand back to seal flange Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 23The typical mode of failure are an unvented system, a closed valve in the seal flush circulation lines, or loss of cooling water flowThe body of the heat exchanger should be warm while the pump is in operationThe heat exchanger case drain should be opened periodically to purge the heat exchanger of accumulated solids and debris

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 31The seal flush line should be checked regularly with a temperature indicator. It should be the same temperature as the pump case throughout its entire length.The typical mode of failure is a clogged orifice, a closed valve, a clogged cyclone separator, or a clogged line from the cyclone separator back to suction.

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 32The seal flush line should be checked regularly with a temperature indicator. It should be the same temperature at both ends of the line.The typical mode of failure is a clogged orifice, a defective flow or pressure controller, loss of pressure in the line, or a closed valve.

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 52When a level increase is observed, also check the pressure reading.A level decrease in the reservoir is a symptom of a leaking secondary seal. Check all the seal circulation piping and connections. Make sure the drain valve is closed.

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansSource of gasor clean liquidAPI Piping Plan 53Circulation of Clean PressurizedBarrier Fluid from Seal to Reservoir and back to Seal18-24DrainValveCooling WaterConnectionsPressureIndicatorBlock andBleed ValvePressureSwitchBlockValvePressureRegulatorCheck ValveFill ConnectionLow LevelSwitchTemperatureIndicatorLong RadiusTubing BendsRequired

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 53The double seal reservoir should be checked on normal operator rounds on a regular basis. The base level should be checked for fluid loss or gain. The base pressure of the system should also be monitored. The temperature of the reservoir should be checked.A pressure loss in the reservoir may be an indication of either a primary or secondary seal leak. Small fluctuations are acceptable since the supply pressure to the pressure controller may also be variable. A pressure loss can also be due to a defective controller.

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 53 A pressure increase in the reservoir is usually due to a malfunction in the pressure controller. High pressure services will normally have a bias regulator. Tap on the regulator to see if it is stuck. If the pressure increases or becomes erratic, shut down the pump in an orderly manner for maintenance. The regulator may need to be replaced or recalibrated. If it is a bias regulator, the pressure sensing line may be clogged.

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 53 GasThe seal system should be checked on normal operator roundsThe gas panel should be checked for proper pressure and gas flow readings. Significant changes in these readings can indicate the primary and/or secondary seal is beginning to leak and should be monitored carefully

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 61The line to the flare header should be checked regularly. The pressure in the line should be zero or less than or equal to the flare header pressure. It should not be cold (for light hydrocarbons) or warm (for hot services)The typical mode of failure is a clogged orifice, an open drain valve, a stuck check valve, or a closed valve in the flare line.

-

Installation & Troubleshooting Guidelines for API Seal Flush Plans

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansPreventive Maintenance and Troubleshooting-Plan 62-Steam QuenchThe steam quench should be checked regularly. If a pressure gauge is used, it should be checked to make sure the set point has been maintained. Steam condensate should be visible on a cold object held near the drain port.The typical mode of failure is a clogged orifice, a defective pressure controller, loss of pressure in the line, or a closed valve.

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansLine Up Procedure-API Plan 62-Water QuenchOpen the line from the water source.Open the block valve for the water quench. If a regulator and gauge are used make sure the gauge shows the proper pressure. If a needle valve is used, open the needle valve until the desired amount of drippage is observed at the bushing or drain port or line on the seal flange.

-

Installation & Troubleshooting Guidelines for API Seal Flush PlansLine Up Procedure-API Plan 62-Water Quench ContinuedCheck for leaks around valves, fittings, and the orifice if used in the quench lineProceed with opening all valves for serviceStart pump per normal procedureOnce running check to make sure the water quench is still in operation. All water should be coming out of the drain port or line. There should not be any water visible on the pump shaft.