Anton Bergant, Uroš Karadžić, John Vitovský, Igor ... · Anton Bergant - Uroı Karadžiæ -...

Transcript of Anton Bergant, Uroš Karadžić, John Vitovský, Igor ... · Anton Bergant - Uroı Karadžiæ -...

PUBLISHED VERSION

Anton Bergant, Uroš Karadžić, John Vitovský, Igor Vušanović, Angus R. Simpson A discrete gas-cavity model that considers the frictional effects of unsteady pipe flow Strojniski Vestnik-Journal of Mechanical Engineering, 2005; 51(11):692-710 © Strojniski Vestnik-Journal of Mechanical Engineering

http://www.sv-jme.eu/scripts/download.php?file=/data/upload/2005/11/SV-JME_51(2005)11_692-710_Bergant%20.pdf

www.sv-jme.eu

http://hdl.handle.net/2440/16752

PERMISSIONS

Permission received from editor – see email 21 April 2015

21 April, 2015

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

692 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

Diskretni plinski kavitacijski model z upo�tevanjem vplivanestalnega kapljevinskega trenja v cevi

A Discrete Gas-Cavity Model that Considers the Frictional Effects ofUnsteady Pipe Flow

Anton Bergant - Uro� Karad�iæ - John Vítkovský - Igor Vu�anoviæ - Angus R. Simpson

Prehodni kavitacijski tok pare v cevi vzbudi padec tlaka na parni tlak kapljevine. Podan je kratekoris metode karakteristik, temu slede osnove nestalnega kapljevinskega trenja in prehodnega kavitacijskegatoka v cevi. Glavni cilj tega prispevka je predstavitev novega plinskega kavitacijskega modela (DPKM) zupo�tevanjem vplivov nestalnega trenja. Rezultati izraèuna so primerjani z rezultati meritev v laboratoriju.Upo�tevanje nestalnega trenja v DPKM da bolj natanène raèunske rezultate.© 2005 Strojni�ki vestnik. Vse pravice pridr�ane.(Kljuène besede: sistemi cevni, udari vodni, tok kavitacijski, modeli kavitacijski diskretni plinski, trenjenestalno)

Transient, vaporous, cavitating pipe flow occurs when the pressure drops to the liquid�s vapourpressure. A brief description of the method of the characteristics and fundamentals of unsteady pipe-flowfriction and transient, cavitating pipe flow are given. The main objective of this paper is to present a novel,discrete gas-cavity model (DGCM) with a consideration of unsteady frictional effects. The numerical resultsare compared with the results from laboratory measurements. The inclusion of unsteady friction into theDGCM significantly improves the numerical results.© 2005 Journal of Mechanical Engineering. All rights reserved.(Keywords: piping systems, water hammer, cavitating flow, discrete gas cavity models, unsteady friction)

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710UDK - UDC 532.528:532.542Izvirni znanstveni èlanek - Original scientific paper (1.01)

0 INTRODUCTION

Hydraulic piping systems should work safelyover a broad range of operating regimes. Water ham-mer induces pressure fluctuations in piping systems,rotational speed variations (overspeed, reverse ro-tation) in hydraulic machinery or water-level oscilla-tions in surge tanks. Transients in pipelines cancause a drop in pressure large enough to break theliquid�s homogeneity and continuity (liquid columnseparation). Undesirable water-hammer effects candisturb the overall operation of hydraulic systems(hydroelectric power plant, pumping system) anddamage system components; for example, pipe rup-ture can occur. Water-hammer loads can be keptwithin the prescribed limits by the adequate controlof the operational regimes, the installation of surge-control devices or the redesign of the original pipe-line layout ([1] and [2]). The calibration and monitor-

0 UVOD

Hidravlièni cevni sistemi morajo varnodelovati v �irokem pasu obratovalnih re�imov. Vodniudar vzbudi nihanje tlaka v cevnih sistemih,spremembo vrtilne frekvence (narastek, nasprotnovrtenje) v hidravliènih strojih in nihanje gladine vodev izravnalnikih. Prehodni pojavi v ceveh lahkopovzroèijo zadosten padec tlaka, ki vodi do prekinitvehomogenosti in kontinuitete kapljevine (pretrganjekapljevinskega stebra). Ne�eleni vplivi vodnegaudara lahko ustavijo obratovanje hidravliènihsistemov (hidroelektrarna, èrpalni sistem) inpo�kodujejo elemente sistema; na primer zru�itevcevovoda. Obremenitve vodnega udara v dopustnihmejah lahko dose�emo z ustreznim krmiljenjemobratovalnih re�imov, vgradnjo elementov za bla�itevvodnega udara ali prerazporeditvijo elementovcevnega sistema ([1] in [2]). Umerjanje in nadzor

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

693Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

ing of hydraulic systems requires a detailed knowl-edge of water-hammer waveforms [3].

The first part of the paper deals with mathemati-cal tools for modeling unsteady pipe-flow friction andtransient vaporous cavitation (liquid column separa-tion). The method of characteristics transformation ofthe unsteady pipe-flow equations gives the water-ham-mer solution procedure. A convolution-based un-steady friction model using state-of-the-art numericaltools [4] is explicitly incorporated into the staggeredgrid of the method of characteristics. Incorporating dis-crete cavities into the water-hammer model leads to thediscrete-cavity model ([2] and [5]). A novel discretegas-cavity model (DGCM) with consideration of theunsteady pipe-flow friction effects is presented in thepaper. The experimental apparatus for measurementsof the water-hammer pressure waves is briefly described.The paper concludes with a number of case studiesshowing how the inclusion of unsteady friction intothe DGCM significantly affects the pressure traces in asimple reservoir-pipeline-valve system.

1 THEORETICAL MODEL

Water hammer is the transmission of pres-sure waves in liquid-filled pipelines. Unsteady pipeflow is described by the continuity equation and theequation of motion [2]:

(1)

(2).

Note that all the symbols are defined in Section6. The flow in the pipe is assumed to be one-dimensional(cross-sectional averaged velocity and pressure distri-butions), the pressure is greater than the liquid vapourpressure, the pipe wall and the liquid behave linearlyelastically, unsteady friction losses are approximated assteady friction losses, the amount of free gas in the liq-uid is negligible and the fluid-structure coupling is weak.For most engineering applications, the transport termsV(¶H/¶x), V(¶V/¶x) and Vsinq, are very small comparedto the other terms and can be neglected ([1] and [2]). Asimplified form of Eqs. (1) and (2) using the dischargeQ=VA instead of the flow velocity V is:

(3)

(4).

hidravliènih sistemov narekujeta potrebo po globljempoznavanju fizike tlaènih valov [3].

Prvi del prispevka obravnava matematiènaorodja za modeliranje nestalnega kapljevinskegatrenja in prehodnega parnega kavitacijskega toka(pretrganje kapljevinskega stebra). Premena enaèbnestalnega toka v cevi z uporabo metode karakteristikda osnove algoritma za vodni udar. V deltoidno mre�ometode karakteristik je vgrajen konvolucijski modelnestalnega trenja z uporabo zmogljivih raèunskihorodij [4]. Vgradnja diskretnih kavitacij v modelvodnega udara da diskretni kavitacijski model ([2] in[5]). V prispevku je podan nov diskretni plinskikavitacijski model (DPKM) z upo�tevanjem vplivanestalnega kapljevinskega trenja v cevi. Podan jekratek oris preizkusne postaje za meritev vodnegaudara. V zakljuènem delu prispevka so podani �tevilniprimeri, iz katerih izhaja, da upo�tevanje nestalnegakapljevinskega trenja v DPKM pomembno vpliva nanapoved tlaènih valov v preprostem cevnem sistemuz ventilom.

1 TEORETIÈNI MODEL

Vodni udar popisuje potovanje tlaènih valovv ceveh s kapljevino. Nestalni tok v cevi popi�emo skontinuitetno in gibalno enaèbo [2]:

Naj omenimo, da so vse oznaèbe definirane vpoglavju 6. Postavimo tok v eni razse�nosti (poprerezu povpreèena hitrost in tlak), tlak veèji odparnega tlaka kapljevine, linearen elastièni odzivstene cevi in kapljevine, nestalno trenje kapljevinenadome�èamo s stalnim, zanemarljivo kolièino prostihplinskih kavitacij v kapljevini in �ibko interakcijo medkapljevino in ogrado. Konvektivni èleni V(¶H/¶x),V(¶V/¶x) in Vsinq so majhni v primerjavi s preostalimièleni in jih v in�enirski uporabi lahko zanemarimo([1] in [2]). Z vpeljavo pretoka Q = VA namestopovpreène pretoène hitrosti V se poenostavljenisistem enaèb (1) in (2) glasi:

2

sin 0H H a V

V Vt x g x

q¶ ¶ ¶

+ - + =¶ ¶ ¶

02

V VH V Vg V f

x t x D

¶ ¶ ¶+ + + =

¶ ¶ ¶

2

0H a Q

t gA x

¶ ¶+ =

¶ ¶

2

10

2

Q QH Qf

x gA t gDA

¶ ¶+ + =

¶ ¶

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

694 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

The method of characteristics (MOC) trans-formation of the simplified equations (3) and (4) pro-duces the water-hammer compatibility equations,which are valid along the characteristics lines. Thecompatibility equations in finite-difference form arenumerically stable unless the friction is large andthe computational grid is coarse and, when writtenfor a computational section i (Fig. 1), are [2]- along the C+ characteristic line (Dx/Dt = a)

(5),

- along the C- characteristic line (Dx/Dt = -a)

(6).

The discharge at the upstream side of thecomputational section i ((Q

u)

i) and the discharge at

the downstream side of the section ((Qd)

i) are identi-

cal for the water-hammer case (unsteady liquid flow).At a boundary (reservoir, valve), a device-specificequation replaces one of the water-hammer compat-ibility equations. The staggered grid in applying themethod of characteristics [2] is used in this paper.

1.1 Unsteady Pipe Flow Friction

Traditionally, the steady or quasi-steady fric-tion terms are incorporated into the water-hammer

Premena poenostavljenih enaèb (3) in (4) zmetodo karakteristik (MK) da zdru�ljivostne enaèbevodnega udara, ki veljajo vzdol� karakteristiènihkrivulj. Zdru�ljivostne enaèbe v koraèni obliki sonumerièno stabilne razen v primeru velikih izgubzaradi trenja in redke raèunske mre�e. Obravnavaneenaèbe, zapisane za raèunsko toèko i (sl. 1), se glase[2]:- vzdol� C+ karakteristike (Dx/Dt = a)

- vzdol� C- karakteristike (Dx/Dt = -a)

V primeru vodnega udara sta pretok nanavzgornjem koncu raèunske toèke i ((Q

u)

i) in

pretok na navzdolnjem koncu toèke ((Qd)

i) enaka

(nestalni kapljevinski tok). Na robu (rezervoar,ventil) enaèba robnega pogoja nadomesti eno odzdru�ljivostnih enaèb vodnega udara. V temprispevku bomo uporabili deltoidno mre�o metodekarakteristik [2].

1.1 Nestalno kapljevinsko trenje v cevi

V algoritmih za vodni udar obièajnouporabimo stalni ali navidezno stalni èlen trenja. Ta

( ) ( )( ) ( ) ( ), 1, 2, 1, , 1,0

2i t i t t u d u di t i t t i t i t t

a f xH H Q Q Q Q

gA gDA- -D - -D - -D

D- + - + =

( ) ( )( ) ( ) ( ), 1, 2, 1, , 1,0

2i t i t t d u d ui t i t t i t i t t

a f xH H Q Q Q Q

gA gDA+ -D + -D + -D

D- - - - =

Sl. 1. Deltoidna mre�a metode karakteristik za sistem hram - cevovod - ventilFig. 1. The method of characteristics staggered grid for a reservoir-pipe-valve system

Dx

0 L

C

x

i-1 i i+1

t-Dt

t

Dt

C

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

695Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

algorithms. This assumption is satisfactory for slowtransients where the wall shear stress has a quasi-steadybehaviour. Previous investigations using the quasi-steady friction approximation for rapid transients ([6]to [8]) showed significant discrepancies in the attenu-ation, the shape and the timing of the pressure traceswhen computational results were compared withmeasurements. The friction factor, explicitly used inEqs. (5) and (6), can be expressed as the sum of thequasi-steady part f

q and the unsteady part f

u [9]:

(7).

The quasi-steady friction factor, fq, depends on

the Reynolds number and the relative pipe roughness. Anumber of unsteady-friction models have been proposedin the literature including one-dimensional (1D) and two-dimensional (2D) models. The 1D models approximatethe actual 2D cross-sectional velocity profile and thecorresponding viscous losses in different ways. The 2Dmodels compute the actual cross-sectional velocity pro-file continuously during the water-hammer event. Thefriction term can be classified into six groups [7]:1) The friction term is dependent on instantaneous

mean flow velocity, V,2) The friction term is dependent on instantaneous

mean flow velocity, V, and the instantaneous lo-cal acceleration, ¶V/¶t,

3) The friction term is dependent on the instantane-ous mean flow velocity, V, the instantaneous localacceleration, ¶V/¶t, and the instantaneous con-vective acceleration, a¶V/¶x (Brunone�s model),

4) The friction term is dependent on the instanta-neous mean flow velocity, V, and the diffusion,¶2V/¶x2,

5) The friction term is dependent on the instantane-ous mean flow velocity, V, and the weights for pastvelocity changes, W(t) (convolution-based model),

6) The friction term is based on the cross-sectional dis-tribution of instantaneous flow velocity (2D models).

This paper deals with the convolution-basedunsteady-friction model ([4], [10] to [12]).

1.2 Transient Cavitating Pipe Flow

Cavitating pipe flow usually occurs as a re-sult of low pressures during a transient event. Tran-sient cavitation significantly changes the water-ham-mer waveform. Water-hammer equations developedfor a one-phase liquid are not valid for the two-phasetransient fluid flow. There are two basic types of

postavka velja za poèasne prehode, pri katerih sostri�ne sile navidezno stalne. Uporaba navideznostalnega modela trenja za hitre prehode da, kakor sopokazale primerjave med rezultati izraèuna in meritev([6] do [8]), znatna odstopanja v du�enju, obliki inèasu poteka tlaènih valov. Koeficient trenja, zapisanneposredno v enaèbah (5) in (6), lahko izrazimo kotvsoto navidezno stalnega dela f

q in nestalnega dela

fu [9]:

Navidezno stalni koeficient trenja fq je

odvisen od Reynoldsovega �tevila in relativnehrapavosti cevi. V literaturi so predlagani �tevilnimodeli nestalnega trenja, ki jih delimo na enorazse�ne(1D) in dvorazse�ne (2D) modele. V 1D modelihpribli�amo dejanski 2D preèni profil hitrosti inustrezajoèe izgube trenja. Z 2D modeli raèunamodejanski preèni profil hitrosti med prehodnimpojavom. Modele trenja lahko razporedimo v �estskupin [7]:1) èlen trenja je odvisen od trenutne povpreène

hitrosti V,2) èlen trenja je odvisen od trenutne povpreène

hitrosti V in trenutnega krajevnega pospe�ka¶V/¶t,

3) èlen trenja je odvisen od trenutne povpreènehitrosti V, trenutnega krajevnega pospe�ka ¶V/¶t in trenutnega konvektivnega pospe�ka a¶V/¶x (Brunonejev model),

4) èlen trenja je odvisen od trenutne povpreènehitrosti V in difuzije ¶2V/¶x2,

5) èlen trenja je odvisen od trenutne povpreènehitrosti V in ute�i za hitrostne spremembe vpreteklosti W(t) (konvolucijski model),

6) èlen trenja je odvisen od trenutne porazdelitvehitrosti po prerezu (2D modeli).

V prispevku bomo obravnavali konvolucijskimodel nestalnega trenja ([4], [10] do [12]).

1.2 Prehodni kavitacijski tok

Kavitacijski tok v cevi se pojavi pri nizkihtlakih med prehodnimi pojavi . Prehodnakavitacija znatno vpliva na obliko tlaènega vala.Enaèbe vodnega udara postavljene za enofazniprehodni tok, ne veljajo za dvofazni prehodnitok. Prehodna kavitacija v ceveh se pojavi v dveh

q uf f f= +

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

696 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

transient cavitating flow in pipelines ([2] and [3]):1) One-component two-phase transient flow (va-

porous cavitation, column separation),2) Two-component two-phase transient flow (gas-

eous cavitation, free gas in liquid flow).This paper deals with vaporous cavitating

pipe flow. Cavitation can occur as localized cavita-tion with a large void fraction, such as when a cavityforms at a boundary or at a high point along thepipeline, or as distributed cavitation with a small voidfraction, such as when cavity bubbles are distrib-uted homogeneously in a liquid.

Vaporous cavitation occurs in pipelines whenthe liquid pressure drops to the vapour pressure of theliquid. The amount of free and/or released gas in theliquid is assumed to be small. This is usually the case inmost industrial piping systems. The water-hammer wavepropagates at a constant speed as long as the pressureis above the vapour pressure. Pressure waves do notpropagate through an established mixture of liquid andvapour bubbles. The inability of pressure waves topropagate through a distributed vaporous cavitationzone is a major feature distinguishing the flow withvaporous cavitation from the flow with gaseous cavi-tation. A number of numerical models have been devel-oped to describe vaporous cavitation, including thediscrete vapour-cavity model (DVCM), the discretegas-cavity model (DGCM) by utilizing a low gas voidfraction (a

g £ 10-7) and the interface vaporous cavita-

tion model ([2] and [5]). The discrete gas-cavity modelis simple and performs accurately over a broad rangeof input parameters [13]. An improved DGCM that con-siders unsteady pipe friction is presented in this paper.

2 A DISCRETE GAS-CAVITY MODEL THATCONSIDERS UNSTEADY FRICTION

The discrete gas-cavity model (DGCM) al-lows gas cavities to form at computational sectionsin the method of characteristics numerical grid. Aliquid phase with a constant wave speed a is as-sumed to occupy the computational reach. The dis-crete gas-cavity model is described by the water-hammer compatibility equations (5) and (6), the con-tinuity equation for the gas volume, and the ideal-gas equation [14]. Numerical forms of the continuityequation for the gas volume and the ideal gas equa-tion within the staggered grid of the method of char-acteristics are:- the continuity equation for the gas volume

oblikah ([2] in [3]):1) enokomponentni dvofazni tok (parna kavitacija,

pretrganje stebra),2) dvokomponentni dvofazni tok (plinska

kavitacija, prost plin v kapljevinskem toku).V prispevku obravnavamo parno kavitacijo

v ceveh. Kavitacija se lahko pojavi kot krajevnakavitacija z velikim kavitacijskim razmernikom -kavitacija na robu ali visokem kolenu vzdol� cevi, alikot nepretrgani kavitacijski tok z majhnimkavitacijskim razmernikom - enakomerno porazdeljenimehurèki v kapljevini.

Parna kavitacija v ceveh se pojavi, ko se tlakkapljevine zni�a na parni tlak kapljevine. Postavimozanemarljivo majhno kolièino prostega in/aliizloèenega plina v kapljevini. Ta postavka velja vveèini industrijskih cevnih sistemov. Tlaèni val vcevi potuje s stalno hitrostjo pri tlaku, veèjem odparnega tlaka kapljevine. Tlaèni valovi ne obstajajov podroèju nepretrganega parnega kavitacijskegatoka. Nezmo�nost potovanja tlaènega vala vpodroèju nepretrganega parnega toka jekarakteristièna loènica med parno in plinskokavitacijo. Razviti so bili �tevilni modeli za popisparne kavitacije, to so diskretni parni kavitacijskimodel (DPAKM), diskretni plinski kavitacijski model(DPKM) z upo�tevanjem majhnega plinskegarazmernika (a

g £ 10-7) in kombinirani parni

kavitacijski model ([2] in [5]). Diskretni plinskikavitacijski model je preprost in daje natanènerezultate v �irokem pasu obratovanja sistema [13].V prispevku podajamo nov DPKM z upo�tevanjemnestalnega kapljevinskega trenja v cevi.

2 DISKRETNI PLINSKI KAVITACIJSKI MODEL ZUPO�TEVANJEM NESTALNEGA TRENJA

Diskretni plinski kavitacijski model (DPKM)dopu�èa plinske kavitacije v raèunskih toèkahnumeriène mre�e metode karakteristik. V cevnihodsekih med numeriènimi toèkami obstaja kapljevina,kjer potujejo udarni valovi s stalno hitrostjo a.Diskretno plinsko kavitacijo popi�emo zzdru�ljivostnima enaèbama vodnega udara (5) in (6),kontinuitetno enaèbo za prostornino plinskekavitacije in plinsko enaèbo [14]. V raèunski toèkideltoidne mre�e metode karakteristik se kontinuitetnaenaèba za prostornino plinske kavitacije in plinskaenaèba glasita:- kontinuitetna enaèba za prostornino plinske

kavitacije

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

697Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

(8),

- the ideal-gas equation

(9).

The DGCM model has been successfully usedfor the simulation of both gaseous and vaporous (a

g0

£ 10-7) cavitation. In the latter case, when the discretecavity volume calculated by Eq. (8) is negative, thenthe cavity volume is recalculated by Equation (9).

2.1 Convolution-Based Unsteady Friction Model

Zielke [10] analytically developed the convo-lution-based model (CBM) of unsteady friction fortransient laminar flow. The unsteady part of the fric-tion factor in Eq. (7) is defined by the convolution ofa weighting function with past temporal accelerations:

(10).

Zielke evaluated Eq. (10) using the full convo-lution scheme, which is computationally intensive be-cause it requires convolution with a complete historyof past velocities. The most recent approach to evalu-ate the CBM, which is efficient and accurate, makesan approximation of the weighting function W(t) by afinite sum of N exponential terms [4]:

(11).

The unsteady part of the friction factor isnow defined as:

(12),

where the component yk(t) is expressed as follows:

(13).

And where the constant K (= 4n/D2) convertsthe time t into the dimensionless time t = 4nt/D2. Attime t + 2Dt the component y

k is:

(14).

Solving the integral and writing it in terms ofthe dimensionless time step Dt (= KDt) finally givesan efficient recursive expression for the componenty

k and hence for f

u:

- plinska enaèba

DPKM se uspe�no uporablja za simuliranjeplinske in parne (a

g0 £ 10-7) kavitacije. V slednjem

primeru se izraèun prostornine diskretne kavitacijepo enaèbi (9) ponovi, ko je izraèunana prostorninapo enaèbi (8) negativna.

2.1 Konvolucijski nestalni model trenja

Zielke [10] je s pomoèjo analitiènih orodij razvilkonvolucijski model (KM) nestalnega trenja zaprehodni laminarni tok. Nestalni del koeficienta trenjav enaèbi (7) popi�emo kot konvolucijo ute�ne funkcijes krajevnimi pospe�ki v opazovanem èasovnem pasu:

Zielke je re�il enaèbo (10) z upo�tevanjempolne konvolucije, ki pa je raèunsko obse�na, sajobsega hitrosti v celotnem opazovanem èasovnempasu. Prispevek avtorjev k raèunsko uèinkoviti indovolj natanèni re�itvi KM je v aproksimaciji ute�nefunkcije W(t) kot konène vsote z N eksponentnimièleni [4]:

Nestalni del koeficienta trenja je tedajdefiniran kot:

kjer so èleni yk(t) izra�eni:

Pri tem konstanta K (= 4n/D2) spremeni èas tv brezrazse�ni èas t = 4nt/D2. V èasu t + 2Dt èlen y

k

izrazimo z enaèbo:

Re�itev gornjega integrala v obliki zapisa zbrezrazse�nim èasovnim korakom Dt (= KDt) dauèinkovit vrnilni izraz za èlen y

k in s tem tudi za f

u:

( ) ( ) ( ) ( )( ) ( ) ( ) ( )( )( ), , , 2 , 2, , 21 2g g d u d ui t i t i t t i t ti t i t t

Q Q Q Q ty y- D - D- D

" = " + - + - - D

( )( )

( )0 0

0,,

vg g ii t

i t i v

H z HA x

H z Ha

- -" = D

- -

( )* *0*

0

32 t

u

A Qf W t t dt

DQ Q t

n ¶= -

¶ò

( )1

k

Nn

app kk

W m e tt -

=

= å

( )1

32 N

u kk

Af y t

DQ Q

n

=

= å

( )( )*

**

0

k

tn K t t

k k

Qy t m e dt

t

- -¶=

¶ò

( )( )*

22 *

*0

2 k

t tn K t t t

k k

Qy t t m e dt

t

+ D- + D -¶

+ D =¶ò

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

698 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

(15).

The component yk(t) was calculated during a

previous time step and is known at time t + 2Dt. Thereis now no convolution with the complete history ofvelocities required. The coefficients of the exponen-tial sum m

k and n

k were developed both for Zielke�s

weighting function for transient laminar flow [10] andfor Vardy-Brown�s weighting functions for transientturbulent flow ([11] and [12]) and can be found in [4].

The CBM of unsteady friction cannot pro-duce the small low-frequency shift observed in ex-perimental results ([15] and [16]). The low-frequencyshift is related to the lowest-frequency componentsof the transient event, which are normally at the fun-damental frequency. This suggests that the truewave speed is slightly lower than expected and theliquid has an extra inertia due to the velocity distri-bution, which is related to the momentum correctionfactor b [16]. The momentum correction factor (MCF)is defined as:

(16).

Realistic values of b do not vary greatly duringa transient event ([17] and [18]). It is assumed that b isconstant and based on the steady conditions preced-ing the transient event, i.e., b = b

0. This is common to

other analyses, such as the Vardy and Brown unsteady-friction weighting function. The MCF can be deter-mined from either the log or power laws for the velocitydistribution [19]. Using the Reynolds transport theo-rem, it can be shown that if the constant MCF is con-sidered, then the equation of motion (4) becomes:

(17).

The finite-difference form of water-hammercompatibility equations obtained by the MOC trans-formation of Equations (3) and (17) is- along the C+ characteristic line ( )0/ /x t a bD D =

(18),

- along the C- characteristic line ( )0/ /x t a bD D = -

(19).

The inclusion of b0 in the water-hammer equa-

tions causes the slope of the characteristics to de-crease, representing a slowing of the transient.

Èlen yk(t) je izraèunan v predhodnem

èasovnem koraku in je znan v èasu t + 2Dt. Tako nitreba izvajati konvolucije v celotnem opazovanempasu. Izpeljali smo koeficiente eksponente vrste m

k

in nk za Zielkejevo ute�no funkcijo za prehodni

laminarni tok [10] in za Vardy-Brownove ute�nefunkcije za prehodni turbulentni tok ([11] in [12]),dobimo jih v [4].

CBM model nestalnega trenja ne napoverahlega faznega odmika tlaka, ki ga razberemo izrezultatov meritev ([15] in [16]). Fazni odmik jeposledica nizkofrekvenènih komponent karakteristikprehodnega pojava, ki so obièajno reda velikostiosnovne frekvence. Iz tega izhaja, da je dejanskahitrost �irjenja valov rahlo ni�ja od napovedane.Kapljevina ima dodatno vztrajnost zaradi nestalneporazdelitve hitrosti po prerezu, ki jo popi�emo zvztrajnostnim popravnim koeficientom b [16].Vztrajnostni popravni koeficient (VPF) definiramo:

Dejansko se b malo spreminja med prehodnimpojavom ([17] in [18]). Postavimo, da je koeficient bnespremenjen in sloni na zaèetnih pretoènih pogojih,tj. b = b

0. Obravnavni postopek je uporabljen tudi v

podobnih primerih, kakor je izpeljava Vardy-Brownoveute�ne funkcije. VPF lahko doloèimo iz logaritmiènegaali potenènega zakona porazdelitve hitrosti [19].Uporabimo Reynoldsov transportni teorem,postavimo nespremenljivo vrednost VPF in dobimogibalno enaèbo, ki se razlikuje od enaèbe (4):

Premena enaèb (3) in (17) z metodokarakteristik da zdru�ljivostne enaèbe vodnegaudara, ki se v koraèni obliki glase:- vzdol� C+ karakteristike ( )0/ /x t a bD D =

- vzdol� C- karakteristike ( )0/ /x t a bD D = -

Vpeljava b0 v enaèbe vodnega udara da manj

strme karakteristike, ki upoèasnijo potek prehodnegapojava.

( ) ( ) ( ) ( ){ }2 2k kn K t n K tk k ky t t e e y t m Q t t Q t- D - D+ D = + + D -é ùë û

22

1

A

v dAAV

b = ò

( ) ( )( ) ( ) ( )0, 1, 2, 1, , 1,

02i t i t t u d u di t i t t i t i t t

a f xH H Q Q Q Q

gA gDA

b- -D - -D - -D

D- + - + =

02

02

Q QH Qf

x gA t gDA

b¶ ¶+ + =

¶ ¶

( ) ( )( ) ( ) ( )0, 1, 2, 1, , 1,

02i t i t t d u d ui t i t t i t i t t

a f xH H Q Q Q Q

gA gDA

b+ -D + -D + -D

D- - - - =

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

699Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

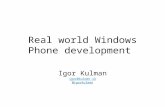

3 EXPERIMENTAL APPARATUS

Laboratory apparatus for investigatingwater-hammer and column-separation events inpipelines was constructed in the Robin HydraulicsLaboratory at the University of Adelaide, Australia[20]. The apparatus comprises a straight 37.23 m(U

x = ±0.01 m) long sloping copper pipe of 22.1 mm

(Ux = ±0.1 mm) internal diameter and of 1.63 mm

(Ux = ±0.05 mm) wall thickness connecting two

pressurized tanks (Fig. 2). The uncertainty in ameasurement, U

x, is expressed as a root-sum-

square combination of the bias and precision error[21]. The pipe slope is constant at 5.45% (U

x =

±0.01 %).A specified pressure in each of the tanks is

controlled by a computerized pressure-control system.The net water volume in both tanks and the capacity ofthe air compressor limits the maximum steady-statevelocity to 1.5 m/s and the maximum operating pressure(pressure head) in each tank to 400 kPa (40 m). A transientevent in the apparatus is initiated by a rapid closure ofthe ball valve. Fast closure of the valve is carried outeither by a torsional spring actuator (the valve closuretime t

c may be set from 5 to 10 milliseconds) or manually

by hand. Each experiment using the apparatus consistsof two phases. First, an initial steady-state velocitycondition (U

x = ±1% for the volumetric method) is

established. Second, a transient event is initiated by arapid closure of the valve. The wave-propagationvelocity (U

x = ±0.1% ) is obtained from the measured

time for the initial pressure wave (the first pressure wavepassing the transducers) to travel between the closedvalve and the quarter point nearest to the valve.

3 PREIZKUSNA POSTAJA

Preizkusna postaja za raziskave vodnegaudara in kavitacijskega toka v ceveh je postavljenav Robinovem hidravliènem laboratoriju univerze vAdelaidi, Avstralija [20]. Merilna postaja jesestavljena iz ravnega bakrenega cevovoda znagnjeno strmino dol�ine 37,23 m (U

x = ± 0,01 m),

notranjega premera 22,1 mm (Ux = ± 0,1 mm) in

debeline stene cevi 1,63 mm (Ux = ± 0,05 mm).

Cevovod je prikljuèen na tlaèni hram z leve in tlaènihram z desne strani (sl. 2). Merilna negotovost U

x je

definirana kot kvadratni koren vsote kvadratovrelativne in absolutne napake [21]. Strmina cevovodaje nagnjena s 5,45 % (U

x = ± 0,01 %).

�eleni tlak v obeh tlaènih hramih krmilimoz raèunalnikom. Neto prostornina vode v obehtlaènih hramih in zmogljivost kompresorjaomejujeta najveèjo stalno hitrost na 1,5 m/s innajveèji delovni tlak (tlaèno vi�ino) v obeh hramihna 400 kPa (40 m). Prehodni pojav na postaji jevzbujen s hitrim zapiranjem kroglastega zasuna.Hitro zaprtje ventila se lahko izvede z zapiralnimmehanizmom na torzijsko vzmet (èas zapiranjaventila t

c je nastavljiv od 5 do 10 milisekund) ali

pa roèno. Vsak preizkus je izveden v dveh fazah.V prvi fazi dose�emo stalno pretoèno hitrost (U

x

= ± 1 % za prostorninsko metodo). V drugi fazihitro zapiranje ventila vzbudi prehodni pojav.Hitrost �irjenja udarnih valov (U

x = ± 0,1 % ) je

doloèena iz èasa potovanja primarnega udarnegavala (prvi val, ki ga zazna tlaèno zaznavalo) medzaprtim ventilom in bli�njo èetrtino dol�inecevovoda.

Sl. 2. Preizkusna postajaFig. 2. Experimental apparatus layout

2.03 m

0.0 m

PipelineCevovod

D = 22.1 mmL = 37.23 m

VentilValve

Tlaèno zaznavaloPressure transducer

Tlaèni rezervoar T1Pressurized reservoir T1

Tlaèni rezervoar T2Pressurized reservoir T2

Hv1

Hv2

Hmp

Tlaèni hram T1

Tlaèni hram T2

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

700 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

Three flush-mounted piezoelectric-typepressure transducers (Kistler 610 B, U

x = ± 0.7 %) are

positioned at the endpoints and at the midpoint. Thewater temperature (U

x = ±0.5oC) in reservoir T1 is

continuously monitored and the valve positionduring closure is measured using optical sensors(U

x = ±0.0001 s). Data acquisition and processing

were performed with a Concurrent 6655 real-timeUNIX data-acquisition computer.

4 COMPARISON OF COMPUTATIONAL ANDEXPERIMENTAL RESULTS

A numerical and experimental analysis of thetransient events in the laboratory apparatus (Fig. 2) ispresented for two different initial flow-velocity casesV

0 = {0.30; 1.40} m/s at a constant static head in the

pressurized reservoir T2 HT2

= 22 m [5]. The numericalresults from the DGCM and the CBM of unsteady fric-tion with the momentum correction factor(DGCM+CBM+MCF) are compared with the results ofmeasurements. Computational and experimental runswere performed for a rapid closure of the valve posi-tioned at the downstream end of the upward slopingpipe at the pressurized tank T1 (Fig. 2). The valve clo-sure time for the two runs was identical, t

c = 0.009 s,

which is significantly shorter than the water-hammerwave-reflection time of 2L/a = 2´37.23/1319 = 0.056 s(a = 1319 m/s is the measured water-hammer wavespeed). The rapid valve closure begins at time t = 0.0 s.Different numbers of reaches were selected for each com-putational run N = {16, 32, 64, 128, 256} to examine thenumerical robustness of the model [22]. The value of theweighting factor y = 1.0 was used in Eq. (8), and a smallgas void fraction of a

g0 = 10-7 was selected in Eq. (9) ([13]

and [14]). The momentum correction factor depends onthe initial flow velocity [19] and its value used in Eqs.(18) and (19) is b

0 = 1.0332 for V

0 = 0.30 m/s and b

0 =

1.0224 for V0 = 1.40 m/s. In addition, the DGCM and the

quasi-steady friction model (DGCM+QSF) results areincluded in the analysis to compare the effect of frictionmodelling on the computational results. The computa-tional and experimental results are compared at the valve(H

v1) and at the midpoint (H

mp) (Fig. 2).

A comparison of the numerical and experimentalresults for an initial flow velocity V

0 = 0.30 m/s and differ-

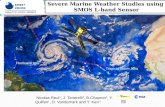

ent numbers of computational reaches N = {32, 128} ispresented in Figs. 3 and 4 respectively. Traditionally, alower number of reaches is used in water-hammer analy-sis. A higher number of reaches should give more accu-rate results (convergence and stability criteria).

Na navzgornjem in navzdolnjem koncucevovoda ter na polovici dol�ine cevovoda so nanotranji premer cevi vgrajena piezoelektrièna tlaènazaznavala (Kistler 610 B, U

x = ± 0,7 %). Temperatura

vode (Ux = ± 0,5 oC) je stalno merjena v hramu T1.

Lega ventila med zapiranjem je merjena z optiènimizaznavali (U

x = ± 0,0001 s). Meritev je registrirana in

analizirana z merilnim raèunalnikom Concurrent 6655v okolju UNIX.

4 PRIMERJAVA REZULTATOV IZRAÈUNA INMERITEV

Rezultati izraèunov in meritev prehodnihpojavov v preizkusni postaji (sl. 2) so podani za dvaprimera z zaèetnima pretoènima hitrostima V

0 = {0,30;

1,40} m/s pri stalni statièni vi�ini v tlaènem hramu T2H

T2 = 22 m [5]. Raèunski rezultati, dobljeni z DPKM z

upo�tevanjem nestalnega trenja po KM invztrajnostnega popravnega koeficienta (DPKM +KM + VPF), so primerjani z rezultati meritev. Izraèuniin meritve so bili izdelani za primer hitrega zapiranjaventila na navzdolnjem koncu cevovoda s pozitivnostrmino pri tlaènem hramu T1 (sl. 2). Èas zapiranjaventila za oba primera je bil enak, t

c = 0,009 s, kar je

precej kraj�e od odbojnega èasa udarnega vala 2L/a= 2×37,23/1319 = 0,056 s (a = 1319 m/s je izmerjenahitrost udarnega vala). Ventil zaène hitro zapirati vèasu t = 0,0 s. V izraèunu je izbran nabor �tevila cevnihodsekov N = {16, 32, 64, 128, 256}, da se preverigrobost raèunskega modela [22]. V enaèbi (8) je bilizbran ute�ni koeficient y = 1,0, v enaèbi (9) pa je bilaizbrana dovolj majhna vrednost plinskegakavitacijskega razmernika a

g0 = 10-7 ([13] in [14]).

Vztrajnostni koeficient v enaèbah (18) in (19) jeodvisen od zaèetne pretoène hitrosti [19]; za V

0 =

0,30 m/s zna�a b0 = 1,0332, za V

0 = 1,40 m/s pa b

0 =

1,0224. Izdelali smo tudi izraèune z DPKM zupo�tevanjem navidezno stalnega modela trenja(DPKM+NST), da bi izlu�èili vpliv modelov trenjana rezultate izraèuna. Izraèunani in izmerjeni rezultatiso primerjani pri ventilu (H

v1) in na polovici dol�ine

cevovoda (Hmp

) (sl. 2).Primerjava rezultatov izraèuna in meritev za

primer z zaèetno pretoèno hitrostjo V0 = 0,30 m/s in

dveh �tevil raèunskih cevnih odsekov N = {32, 128}je podana na slikah 3 in 4. Manj�e �tevilo cevnihodsekov je obièajno izbrano v in�enirskih analizahvodnega udara. Veèje �tevilo cevnih odsekov bimoralo dati bolj natanène rezultate izraèuna(konvergenèni in stabilnostni kriterij).

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

701Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

A rapid valve closure for HT2

= 22 m and aninitial flow velocity V

0 = 0.30 m/s generates a water-

hammer event with liquid column separation. The maxi-mum measured head at the valve H

v1; max = 95.6 m oc-

curs as a short-duration pressure pulse after the firstcavity collapses. The duration of the maximum head isvery short (0.00628 s). The maximum computed headspredicted by DGCM+QSF and DGCM+CBM+MCF areH

v1; max = 99.6 m and H

v1; max = 95.1m, respectively. The

computational results obtained by the DGCM+QSFagree well with the experimental results for the first andthe second pressure-head pulse. The discrepanciesbetween the results are greater for later times. The re-sults obtained using the DGCM+CBM+MCF give pres-sure histories that are in good agreement with the ex-perimental results for longer time periods.

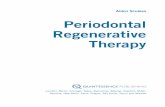

A comparison of the numerical and experimen-tal results for an initial flow velocity V

0 = 1.40 m/s and

different numbers of computational reachesN = {32, 128} is presented in Figs. 5 and 6, respectively.

The maximum head at the valve for this caseis the water-hammer head generated at a time of2L/a after the valve closure. The value of the maxi-mum measured head is H

v1; max = 210.9 m. The maxi-

mum head predicted by the DGCM+QSF and

Hitro zapiranje ventila v primeru za HT2

=22 m in zaèetno hitrost V

0 = 0,30 m/s vzbudi vodni

udar s pretrganjem kapljevinskega stebra.Najveèjo izmerjeno vi�ino pri ventilu H

v1; max = 95,6 m

razberemo po zru�itvi prve kavitacije v oblikiozkega tlaènega utripa. Obremenitev z najveèjovi�ino je kratkotrajna (0,00628 s). Najveèjaizraèunana vi�ina z DPKM+NST je H

v1; max = 99,6 m

in z DPKM+KM+VPF Hv1; max

= 95,1m. Rezultatiizraèuna, dobljeni z DPKM+NST, se dobroujemajo z izmerjenimi rezultati za prvi in drugitlaèni utrip. Odstopanja med rezultati se veèajo sèasom prehoda. Rezultati, dobljeni zDPKM+KM+VPF, se dobro ujemajo z izmerjenimirezultati v �irokem pasu opazovanja prehodnegapojava.

Primerjava rezultatov izraèuna in meritev zaprimer z zaèetno pretoèno hitrostjo V

0 = 1,40 m/s in

dveh �tevil raèunskih cevnih odsekov N = {32, 128}je podana na slikah 5 in 6.

V obravnavanem primeru je najveèja vi�inapri ventilu enaka vi�ini vodnega udara v èasu 2L/apo zaprtju ventila. Izmerjena najveèja vi�ina jeH

v1; max = 210,9 m. Najveèji vi�ini, doloèeni z

DPKM+NST in DPKM+KM+VPF, se dobro ujemata

Sl. 3. Primerjava vi�in pri ventilu (Hv1

) in na polovici dol�ine cevovoda (Hmp

):Fig. 3. Comparison of heads at the valve (H

v1) and at the midpoint (H

mp):

V0 = 0.30 m/s, H

T2 = 22 m, N = 32

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

Meritev DGCM+QSF

H

v1 (

m)

t (s)

Measurement DGCM+CBM+MCF

H

v1 (

m)

t (s)

Meritev DGCM+QSF

H

mp (

m)

t (s)

Measurement DGCM+CBM+MCF

d)c)

b)a)

H

mp (

m)

t (s)

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

702 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

Meritev DGCM+QSF

H

v1 (

m)

t (s)

Measurement DGCM+CBM+MCF

H

v1 (

m)

t (s)

Meritev DGCM+QSF

H

mp (

m)

t (s)

Measurement DGCM+CBM+MCF

d)c)

b)a)

H

mp (

m)

t (s)

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

Sl. 4. Primerjava vi�in pri ventilu (Hv1

) in na polovici dol�ine cevovoda (Hmp

):Fig. 4. Comparison of heads at the valve (H

v1) and at the midpoint (H

mp):

V0 = 0.30 m/s, H

T2 = 22 m, N = 128

Sl. 5. Primerjava vi�in pri ventilu (Hv1

) in na polovici dol�ine cevovoda (Hmp

):Fig. 5. Comparison of heads at the valve (H

v1) and at the midpoint (H

mp):

V0 = 1.40 m/s, H

T2 = 22 m, N = 32

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

Meritev DGCM+QSF

H

v1 (

m)

t (s)

Measurement DGCM+CBM+MCF

H

v1 (

m)

t (s)

Meritev DGCM+QSF

H

mp (

m)

t (s)

Measurement DGCM+CBM+MCF

d)c)

b)a)

H

mp (

m)

t (s)

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

703Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

DGCM+CBM+MCF closely matches the measuredhead. The duration of the first cavity at the valve ispredicted better by the DGCM+CBM+MCF than bythe DGCM+QSF (measurement: 0.318 s; DGCM+QSF:0.331 s; DGCM+CBM+MCF: 0.325 s). Computationalresults obtained with the DGCM+QSF agree well withexperimental results until the first cavity at the valvecollapses. The results from the DGCM+CBM+MCFshow significant improvement in terms of both theattenuation and phase shift of the pressure-headtraces when compared to the DGCM+QSF results.When the number of computational reaches is in-creased, the computational and measured results agreebetter. Inclusion of the unsteady-friction model intothe DGCM (DGCM+CBM+MCF) significantly im-proves the results compared to those using the quasi-steady friction model (DGCM+QSF).

4.1 Convergence and Stability

The numerical solution of theDGCM+CBM+MCF incorporated into the MOC com-putational grid should satisfy the convergence and sta-bility criteria. Convergence relates to the behaviour of

z izmerjeno vi�ino. Èas obstoja prve kavitacije priventilu, doloèen z DPKM+KM+VPF, se boljeujema od èasa, doloèenega z DPKM+NST(meritev: 0,318 s; DPKM+NST: 0,331 s;DPKM+KM+VPF: 0,325 s). Rezultati izraèuna,dobljeni z DPKM+NST, se dobro ujemajo z rezultatimeritve do zru�itve prve kavitacije pri ventilu. Izrezultatov, dobljenih z DPKM+KM+VPF,razberemo znatno izbolj�anje napovedi du�enja infaznega odmika tlaènih utripov v primerjavi zrezultati, dobljenimi z DPKM+NST. Rezultatiizraèuna z veèjim �tevilom cevnih odsekov se boljeujemajo z rezultati meritev. Sklepamo, daupo�tevanje modela nestalnega trenja v DPKM(DPKM+KM+VPF) da bolj natanène rezultate vprimerjavi z rezultati, dobljenimi z upo�tevanjemmodela navidezno stalnega trenja (DPKM+NST).

4.1 Konvergenca in stabilnost

Numerièni model DPKM+KM+VPF, vgrajenv MK raèunsko mre�o, mora zadostitikonvergenènim in stabilnostnim kriterijem.Konvergenca definira stalno re�itev, ko se Dx in

Sl. 6. Primerjava vi�in pri ventilu (Hv1

) in na polovici dol�ine cevovoda (Hmp

):Fig. 6. Comparison of heads at the valve (H

v1) and at the midpoint (H

mp):

V0 = 1.40 m/s, H

T2 = 22 m, N = 128

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

-20.020.060.0

100.0140.0180.0220.0260.0

Meritev DGCM+QSF

H

v1 (

m)

t (s)

Measurement DGCM+CBM+MCF

H

v1 (

m)

t (s)

Meritev DGCM+QSF

H

mp (

m)

t (s)

Measurement DGCM+CBM+MCF

d)c)

b)a)

H

mp (

m)

t (s)

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

MeritevMeasurement

DPKM+NSTDGCM+QSF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+NSTDGCM+QSF

DPKM+KM+VPFDGCM+CBM+MCF

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

704 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

-20.0

0.0

20.0

40.0

60.0

80.0

100.0

-20.0

0.0

20.0

40.0

60.0

80.0

100.0

-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80-20.0

0.0

20.0

40.0

60.0

80.0

100.0

0.00 0.20 0.40 0.60 0.80

DGCM+QSF

N=16 N=32 N=64

H

v1 (

m)

DGCM+QSF

N=64 N=128 N=256

DGCM+QSF

N=16 N=32 N=64

H

mp (

m)

DGCM+QSF

N=64 N=128 N=256

DGCM+CBM+MCF

N=16 N=32 N=64

H

v1 (

m)

N=64 N=128 N=256

DGCM+CBM+MCF

DGCM+CBM+MCF

N=16 N=32 N=64

H

mp (

m)

t (s) t (s)

DGCM+CBM+MCF

N=64 N=128 N=256

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

the solution as Dx and Dt tends to zero, while stability isconcerned with the round-off error growth [1]. The influ-ence of the different numbers of computational reachesN = {16, 32, 64, 128, 256} is investigated for theDGCM+CBM+MCF [22]. In addition, a numerical analy-sis of the DGCM+QSF model is included as well. Fig. 7

Dt pribli�ujeta nièli, stabilnost re�itve pa je odvisnaod napake zaokro�itve [1]. V tem prispevku stakonvergenca in stabilnost DPKM+KM+VP inDPKM+NST preverjena z metodo nabora cevnihodsekov [22] v pasu N = {16, 32, 64, 128, 256}. Nasliki 7 so podani rezultati izraèuna za primer z

Sl. 7. Raèunska analiza: V0 = 0,30 m/s, H

T2 = 22 m

Fig. 7. Numerical analysis: V0 = 0.30 m/s, H

T2 = 22 m

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

705Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

0.0

40.0

80.0

120.0

160.0

200.0

240.0

280.0

0.0

40.0

80.0

120.0

160.0

200.0

240.0

280.0

0.0

40.0

80.0

120.0

160.0

200.0

240.0

280.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

0.0

40.0

80.0

120.0

160.0

200.0

240.0

280.0

0.00 0.20 0.40 0.60 0.80 1.00 1.20

DGCM+QSF

N=16 N=32 N=64

H

v1 (

m)

DGCM+QSF

N=64 N=128 N=256

DGCM+QSF

N=16 N=32 N=64

H

mp (

m)

DGCM+QSF

N=64 N=128 N=256

DGCM+CBM+MCF

N=16 N=32 N=64

H

v1 (

m)

N=64 N=128 N=256

DGCM+CBM+MCF

DGCM+CBM+MCF

N=16 N=32 N=64

H

mp (

m)

t (s) t (s)

DGCM+CBM+MCF

N=64 N=128 N=256

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+NSTDGCM+QSF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

DPKM+KM+VPFDGCM+CBM+MCF

shows the numerical results for the case with an initialflow velocity V

0 = 0.30 m/s with moderate cavitation.

The results for both models are consistent as the numberof reaches is increased. This is not the case for the nu-merical runs with initial velocity V

0 = 1.40 m/s in Fig. 8.

Severe cavitation along the pipeline forms distributed,

zaèetno pretoèno hitrostjo V0 = 0,30 m/s z blago

kavitacijo. Rezultati, dobljeni z obema modelomaso konzistentni s poveèanjem �tevila odsekov. Topa ne velja za rezultate izraèuna v primeru z zaèetnohitrostjo V

0 = 1,40 m/s na sliki 8. Intenzivna

kavitacija vzdol� cevi v obliki podroèij

Sl. 8. Raèunska analiza: V0 = 1,40 m/s, H

T2 = 22 m

Fig. 8. Numerical analysis: V0 = 1.40 m/s, H

T2 = 22 m

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

706 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

vaporous cavitation zones and intermediate cavities thathave been recorded by measurements and only approxi-mately accounted for in the DGCMs (Figs. 5 and 6). Thecollapse of a large cavity at the valve and intermediatecavities along the pipe create steep pressure wave frontsthat travel along the pipe. Comparisons between themeasured and computed results clearly showed (Figs. 5and 6) that the DGCM+CBM+MCF better representsthe real flow situation as the number of computationalreaches is increased. Generally, the magnitude and tim-ing of the main pressure pulses predicted by the DGCMmodel using either the quasi-steady or the convolution-based model converge as the number of reaches is in-creased (although each method converges to a slightlydifferent solution). The DGCM model does not generatelarge, unrealistic pressure spikes in comparison to thediscrete vapour-cavity model (DVCM) ([7] and [13]). How-ever, there still remain some high-frequency peaks in theexperimental measurements that are not reproduced byeither numerical model. Previous experimental studiesclearly showed that transient cavities along the pipelineare not distributed homogeneously ([23] and [24]); there-fore, some high-frequency peaks are not repeatable anddo not affect the main pressure pulses significantly. Asimilar behaviour is revealed in the DGCM computationalresults in that some high-frequency peaks vary with thedifferent numbers of reaches. This behaviour occurs inregions with distributed vaporous cavitation and inter-mediate cavities where small-scale cavitation takes placein slightly different ways for different numbers of compu-tational reaches. However, typically this behaviour is smallcompared to the bulk transient response.

5 CONCLUSION

Results from the discrete gas-cavity model withthe quasi-steady friction approximation (DGCM+QSF)and with the convolution-based unsteady-friction model(DGCM+CBM+MCF) are compared with the results ofmeasurements for a fast-downstream end-valve closurein a simple reservoir-pipeline-valve laboratory apparatus.A comparative analysis includes experimental tests fortwo different flow conditions with moderate and severecavitation. The convolution-based unsteady-frictionmodel better captures the behaviour of unsteady fluidfriction than the quasi-steady friction approximation. Theresults clearly show that the inclusion of unsteadyfriction into the DGCM significantly improves thenumerical results. The influence of the different numbersof reaches is also investigated. The examination of thecomputational results reveals the numerically robust

nepretrganega parnega kavitacijskega toka indiskretnih kavitacij, ki jih razberemo iz meritev, jev DPKM modelih (sl. 5 in 6) popisana pribli�no.Zru�itev velike kavitacije pri ventilu in diskretnihkavitacij vzdol� cevovoda vzbudi strma tlaènavalovna èela, ki potujejo vzdol� cevi. Primerjavarezultatov izraèuna in meritev (sl. 5 in 6) jasnopoka�e, da DPKM+KM+VPF bolje popi�e fizikalnipojav pri veèjem �tevilu cevnih odsekov. Vsplo�nem amplituda in èasovni potek glavnihtlaènih utripov, doloèenih z upo�tevanjemnavidezno stalnega in nestalnega trenja,konvergirata s poveèanjem �tevila cevnih odsekov(vsak model konvergira k nekoliko razliènemurezultatu). DPKMne vzbudi visokih fizikalnonerealnih tlaènih utripov v primerjavi z diskretnimparnim kavitacijskim modelom (DPAKM) ([7] in[13]). Raèunska modela pa ne napovesta nekaterihvisokofrekvenènih utripov, razbranih v meritvah.Dosedanje preizkusne raziskave so pokazale, daprehodne kavitacije vzdol� cevi niso homogene([23] in [24]), zato nekateri visokofrekvenèni pulziniso ponovljivi in tudi ne vplivajo na glavne tlaèneutripe. Podoben pojav lahko izlu�èimo v rezultatihizraèuna z DPKM, pri katerih so nekaterivisokofrekvenèni tlaèni utripi vplivani s �tevilomcevnih odsekov. Ta pojav zaznamo v podroèjih zblago kavitacijo vzdol� cevovoda (nepretrganiparni kavitacijski tok, diskretne kavitacije) kotposledico popisa kavitacije z razliènim �tevilomcevnih odsekov. Ta vpliv pa je zanemarljiv vprimerjavi z odzivom na veliki skali.

5 SKLEP

Podana je primerjava med rezultati izraèunain meritev za primer hitrega zapiranja navzdolnjegaventila v preprostem cevnem sistemu. Primerjanasta diskretni plinski kavitacijski model zupo�tevanjem navidezno stalnega kapljevinskegatrenja (DPKM+NST) in nestalnega trenja z uporabokonvolucijega modela (DPKM+KM+VPF).Primerjalna analiza obsega primer z blago in primerz intenzivno kavitacijo. Konvolucijski modelnestalnega trenja bolj natanèno popi�e nestalnokapljevinsko trenje v primerjavi z navidezno stalnimpribli�kom. Upo�tevanje nestalnega trenja vDPKM da zato bolj natanène raèunske rezultate.Raziskali smo tudi vpliv izbire �tevila cevnihodsekov. Raèunska analiza poka�e, da jeDPKM+KM+VPF grob s poveèanjem �tevila cevnih

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

707Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

behaviour of the DGCM+CBM+MCF as the number ofreaches increases. Due to the excellent matches withexperimental data and the robust numerical algorithmthis model is recommended for engineering practice.

Acknowlegments

This paper was written during Mr Karad�iæ�svisit to Litostroj E.I. d.o.o. from January 5 to Febru-ary 28, 2005. The authors wish to thanks Litostrojand CMEPIUS (Centre of the Republic of Sloveniafor Mobility and European Programmes for Educa-tion and Training) who supported this visit. Thesupport of the research by ARRS (Slovenian Re-search Agency) is gratefully acknowledged as well.

odsekov. Obravnavani model zaradi dobregaujemanja rezultatov izraèuna z meritvami inraèunske grobosti priporoèamo za in�enirskouporabo.

Zahvala

Ta prispevek je bil napisan med obiskomgospoda Karad�iæa v Litostroju E.I. d.o.o. od 5.januarja do 28. februarja 2005. Avtorji se toplozahvaljujejo Litostroju in CMEPIUSu (Center zamobilnost in evropske programe izobra�evanja inusposabljanja) za podporo tega obiska. Za podpororaziskav se toplo zahvaljujejo tudi ARRSu (Agencijaza raziskovalno dejavnost Republike Slovenije).

preèni prerezhitrost �irjenja udarnih (tlaènih) valovpremer ceviDarcy-Weisbachov koeficient trenjazemeljski pospe�ekpiezometrièna vi�ina (vi�ina)parna tlaèna vi�inadol�ina cevikoeficienti eksponentne vrste�tevilo cevnih odsekovpretoknavzdolnji pretoknavzgornji pretokReynoldsovo �tevilo = VD/nèasèas zapiranja ventilamerilna negotovostpovpreèna pretoèna hitrostpretoèna hitrostute�na funkcijakordinata vzdol� cevièlen ute�ne funkcijegeodetska vi�inaplinski kavitacijski razmernikvztrajnostni korekcijski koeficientèasovni korakdol�ina cevnega odsekabrezrazse�ni èasovni korakstrmina cevovodakinematièna viskoznostbrezrazse�ni èasute�ni koeficientdiskretna prostornina kavitacije

6 OZNAÈBE6 SYMBOLS

A pipe areaa water-hammer (pressure) wave speedD pipe diameterf Darcy-Weisbach friction factorg gravitational accelerationH piezometric head (head)H

vgauge vapour pressure head

L pipe lengthm

k, n

kexponential sum coefficients

N number of computational reachesQ dischargeQ

dnode downstream end discharge

Qu

node upstream end dischargeR

eReynolds number = VD/n

t, t* timet

cvalve closure time

Ux

uncertainty in a measurementV average flow velocityv flow velocityW weighting functionx distance along the pipey

kcomponent of the weighting function

z pipeline elevationa

ggas void fraction

b momentum correction factorD t time stepDx reach lengthDt dimensionless time stepq pipe slopen kinematic viscosityt dimensionless timey weighting factor

" discrete cavity volume

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

708 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

Indeksi:pribli�enplinraèunska toèkapolovica dol�ine cevovodanavidezno stalni delhramèasnestalni delventilstalen (zaèeten) ali referenèen

Okraj�ave:diskretni plinski kavitacijski modeldiskretni plinski kavitacijski model z

navidezno stalnim trenjemdiskretni plinski kavitacijski model s

konvolucijskim modelom invztrajnostnim popravnim faktorjem

diskretni parni kavitacijski modelmetoda karakteristik

Subscripts:app approximateg gasi node numbermp midpointq quasi-steady partT tank (reservoir)t timeu unsteady partv valve0 steady state (initial) or reference

Abbreviations:DPKM/DGCM discrete gas-cavity modelDPKM+NST/ discrete gas-cavity model withDGCM+QSF quasi-steady frictionDPKM+KM+ discrete gas-cavity model with +VPF/DGCM+ convolution-based model and momentum +CBM+MCF correction factorDPAKM/DVCM discrete vapour-cavity modelMK/MOC method of characteristics

7 LITERATURA7 REFERENCES

[1] Chaudhry, M.H. (1987) Applied hydraulic transients. Van Nostrand Reinhold Company, New York, ZDA.[2] Wylie, E.B., Streeter, V.L. (1993) Fluid transients in systems. Prentice Hall, Englewood Cliffs, ZDA.[3] Bergant, A., Tijsseling, A. (2001) Parameters affecting water hammer wave attenuation, shape and timing.

Proceedings of the 10th International Meeting of the IAHR Work Group on the Behaviour of HydraulicMachinery under Steady Oscillatory Conditions, Trondheim, Norve�ka, Prispevek C2, 12 strani.

[4] Vítkovský, J., Stephens, M., Bergant, A., Lambert, M., Simpson, A.R. (2004) Efficient and accurate calcu-lation of Zielke and Vardy-Brown unsteady friction in pipe transients. Proceedings of the 9th Interna-tional Conference on Pressure Surges, BHR Group, Chester, Velika Britanija, 15 strani.

[5] Bergant A., Simpson, A.R. (1999) Pipeline column separation flow regimes. Journal of Hydraulic Engi-neering, ASCE,125(8), 835 - 848.

[6] Golia, U.M. (1990) Sulla valutazione delle forze resistenti nel colpo d�ariete. Report No.639, Departmentof Hydraulic and Environmental Engineering, University of Naples, Naples, Italija (v italjan�èini).

[7] Bergant A., Simpson, A.R. (1994) Estimating unsteady friction in transient cavitating pipe flow. Proceed-ings of the 2nd International Conference on Water Pipeline Systems, BHR Group, Edinburgh, VelikaBritanija, 333 - 342.

[8] Bergant, A., Simpson, A.R., Vítkovský, J. (2001) Developments in unsteady pipe flow friction modeling.Journal of Hydraulic Research, IAHR, 39(3), 249 - 257.

[9] Vardy, A.E. (1980) Unsteady flow: fact and friction. Proceedings of the 3rd International Conference onPressure Surges, BHRA, Cantenbury, Velika Britanija, 15 - 26.

[10] Zielke, W. (1968) Frequency-dependent friction in transient pipe flow. Journal of Basic Engineering,ASME, 90(1), 109 - 115.

[11] Vardy, A.E., Brown, J.M.B. (2003) Transient turbulent friction in smooth pipe flows. Journal of Sound andVibration, 259(5), 1011 - 1036.

[12] Vardy, A.E., Brown, J.M.B. (2004) Transient turbulent friction in fully rough pipe flows. Journal of Soundand Vibration, 270, 233 - 257.

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

709Diskretni plinski kavitacijski model - A Discrete Gas-Cavity Model

[13] Simpson, A.R., Bergant, A. (1994) Numerical comparison of pipe-column-separation models. Journal ofHydraulic Engineering, ASCE, 120(3), 361 - 377.

[14] Wylie, E. B. (1984) Simulation of vaporous and gaseous cavitation. Journal of Fluids Engineering,ASME, 106(3), 307 - 311.

[15] Brown, F.T., Margolis, D.L., Shah, R.P. (1969) Small-amplitude frequency behavior of fluid lines withturbulent flow. Journal of Basic Engineering, ASME, 91(4), 678 - 693.

[16] Bergant, A., Tijsseling, A., Vítkovský, J., Covas, D., Simpson, A.R., Lambert, M. (2003) Further investiga-tions of parameters affecting water hammer wave attenuation, shape and timing. Part 1: Mathematicaltools. Proceedings of the 11th International Meeting of the IAHR Work Group on the Behaviour ofHydraulic Machinery under Steady Oscillatory Conditions, Stuttgart, Nemèija, 12 strani.

[17] Buthaud, H. (1977) On the momentum correction factor in pulsatile blood flow. Journal of AppliedMechanics, ASME, 44(2), 343 - 344.

[18] Brunone, B., Golia, M.U., Greco, M. (1991) Some remarks on the momentum equation for fast transients.International Meeting on Hydraulic Transients with Column Separation, 9th Round Table, IAHR,Valencia, �panija, 140 - 148.

[19] Chen, C.L. (1992) Momentum and energy coefficients based on power-law velocity profile. Journal ofHydraulic Engineering, ASCE, 118(11), 1571 - 1584.

[20] Bergant, A., Simpson, A.R. (1995) Water hammer and column separation measurements in an experimentalapparatus. Research Report No. R128, Department of Civil and Environmental Engineering, Universityof Adelaide, Adelaide, Avstralija.

[21] Coleman, H.W., Steele, W.G. (1989) Experimentation and uncertainty analysis for engineers. John Wileyand Sons, New York, ZDA.

[22] Maudsley, D. (1984) Errors in simulation of pressure transients in a hydraulic system. Proceedings of theInstitute of Measurement and Control, 6(1), 7 - 12.

[23] Fan, D., Tijsseling, A. (1992) Fluid-structure interaction with cavitation in transient pipe flows. Journal ofFluids Engineering, ASME, 114(2), 268 - 274.

[24] Simpson, A.R., Bergant, A. (1996) Interesting lessons from column separation experiments. Proceedingsof the 7th International Conference on Pressure Surges, BHR Group, Harrogate, Velika Britanija, 83 - 97.

Naslovi avtorjev: doc.dr. Anton BergantLitostroj E.I. d.o.o.Litostrojska 501000 [email protected]

mag. Uro� Karad�iæUniverzitet Crne GoreMa�inski fakultetCetinjski put b.b.81000 PodgoricaSrbija i Crna [email protected]

dr. John P. VítkovskýOddelek za naravne vire inrudarstvoIndooroopilly, QLD [email protected]

Authors� Addresses: Doc.Dr. Anton BergantLitostroj E.I. d.o.o.Litostrojska 501000 Ljubljana, [email protected]

Mag. Uro� Karad�iæUniversity of MontenegroFaculty of Mechanical EngineeringCetinjski put n.n.81000 PodgoricaSerbia and [email protected]

Dr. John P. VítkovskýDepartment of NaturalResources & MinesIndooroopilly, QLD [email protected]

Strojni�ki vestnik - Journal of Mechanical Engineering 51(2005)11, 692-710

710 Bergant A. - Karad�iæ U. - Vítkovský J. - Vu�anoviæ I. - Simpson A.R.

Dr. Igor Vu�anoviæUniversity of MontenegroFaculty of Mechanical EngineeringCetinjski put n.n.81000 PodgoricaSerbia and [email protected]

Prof. Angus R. SimpsonSchool of Civil & EnvironmentalEngineeringUniversity of AdelaideAdelaide, SA [email protected]

dr. Igor Vu�anoviæUniverzitet Crne GoreMa�inski fakultetCetinjski put b.b.81000 PodgoricaSrbija i Crna [email protected]

prof. Angus R. Simpson�ola gradbenega in okoljskegain�enirstvaUniverza v AdelaidiAdelaide, SA [email protected]

Prejeto: 18.2.2005

Sprejeto: 29.6.2005

Odprto za diskusijo: 1 letoReceived: Accepted: Open for discussion: 1 year