Anti - Surge Valve

-

Upload

pablos-hernandez -

Category

Documents

-

view

87 -

download

7

description

Transcript of Anti - Surge Valve

-

Engineering Practice

Anti-surge Valves ferDynamie Cempressers

Follow this guidance toimprove the selection

and sizing of anti-surgevalves for axial and

centrifugal compressors

Amin AlmasiWorleyParsons Services Pty. Ltd.

One of the most significant limi-tations on the operation of dy-namic compressors (axial andcentrifugal compressors) isthe low-flow limit known as "surge".A sudden valve closing, such as foremergency shutdowns or for a suc-tion/discharge valve, presents sig-nificant challenges to anti-surgevalve sizing and selection. Anti-surgevalve requirements depend to a largedegree on the compressor type, thecompression system arrangement,and particularly the volume of thedischarge piping downstream of thecompressor. Important aspects ofanti-surge valve sizing and selectionfor plants in the chemical process in-dustries (CPI), as well as examples,are discussed in this article.

The basicsAt low fiows, the performance of adynamic compressor particularlycentrifugal and axial compressors is limited by the occurrence of aero-dynamic flow instabilities that couldlead to a catastrophic failure of thecompressor due to mechanical or ther-mal loads. The surge is an unstableflow situation that occurs when thefiow is too low. When a dynamic com-pressor reaches its surge limit, theflow pattern through the compressor

FIGURE 1. Thispicture shows anexample of an anti-surge valve

collapses, and a sudden backward fiowof gas occurs from the discharge to thesuction side of the compressor.

This surge phenomenon can cause areversal of the thrust loads (large dy-namic/transient forces on the rotor),which can result in damages to bear-ings (particularly thrust bearings),seals and other parts of the compres-sor. For these reasons a surge andparticularly high-energy surges should be avoided. Recent innovationsin control technology, dynamic simula-tions, rotating machinery knowledgeand control-valve design (the anti-surge valve) have made it possible tosupply anti-surge systems that arecapable of coping with rapid flow fluc-tuations and process gas variations.

A dynamic compressor, also knownas a "turbo-compressor", is generallyprovided with an anti-surge valve (Fig-ure 1) in order to keep the compres-sor in a stable operating range. Thisis achieved by assuring a suction flowthat is higher than the correspondingflow at the surge. An anti-surge valveis placed in the anti-surge circuit (arecycle circuit).

The main purpose of this valve is toavoid a surge and surge-related dam-ages, particularly irreparable dam-ages (Figure 2). The anti-surge systemand the controller, which comprise

both hardware and software, shouldbe based on a design algorithm thatoperates very quickly when openingthe anti-surge (recycle) valve to avoidthe surge. However, this anti-surgesystem should be designed and pro-grammed so as to not make the circuit(or the compression unit) unstable.

Centrifugal and axial compressorsexperience a surge whenever theyare suddenly tripped. Controlling thehead and total energy of the surgeevent, particularly a surge at the trip,is the main objective of dynamic simu-lations and anti-surge valve sizingand selection. Meaningful gains canbe made by a better understanding ofthe interactions between the compres-sor, the anti-surge valve(s) and thefacility piping and layout (includingcoolers, scrubbers, check valves, ventvalves and more). Key parameters foranti-surge valve selection and sizinginclude the following: fast response,optimum size, high integrity, accuracyand noise abatement.

The anti-surge valveThe size of an anti-surge valve influ-ences the amount of fluid that can bemoved from the discharge side of thecompressor to the suction side. Largervalves allow more fiow. The speedwith which an anti-surge valve opens

CHEMICAL ENGINEERING WWW.CHE.COM NOVEMBER 2012 4 3

-

Engineering Practice

is also important in rapidly reducingthe discharge pressure (the head andstored energy at the compressor dis-charge). One important trade-off inrelation to anti-surge valves is thatlarger valves exhibit slower openingrates. There are certainly cases whena faster, smaller valve is better than alarger, slower valve, but in all cases,the anti-surge valve should be largeenough to handle the flow supplied bythe compressor at a sufficiently lowdifferential pressure (head).

Another important factor is control-lability. Larger valves are more dif-ficult to control. The faster the valvecan be opened, the more flow can passthrough it and the more effective it isin surge prevention. There are limitsto the valve opening speed, dictatedby the need to control intermediatepositions of the valve. There are somepractical limits to the power of the ac-tuator. The situation may be improvedby using a valve that is boosted toopen, combining a high opening speedfor the surge avoidance with the capa-bility to avoid oscillations.

During a surge event, the flow in-creases rapidly at first and then de-creases more slowly as the pressuredifference across the compressor and consequently the anti-surgevalve, too decreases. With a rela-tively large anti-surge valve, the en-ergy level at which the surge occursis much lower compared to a smalleranti-surge valve. An anti-surge valvewith a relatively large capacity (com-pared to the compressor's volumetricflowrate), but with the same openingtime (compared to relatively smallanti-surge valves), will allow theshutdown surge to be avoided (or theshutdown surge will occur at a lowerhead condition). On the other hand, arelatively small anti-surge valve couldcause a more energetic and more po-tentially damaging shutdown.

The ability to quantify these ef-fects and select a proper valve sizeby dynamic modeling can be veryuseful. Because of this, accuratesimulations are encouraged in orderto select an anti-surge valve with anoptimum size.The effect of valve flow coefficient.In a case study for a centrifugal com-pressor in a CPI plant, two anti-surge

valves with the same opening time(around one second) were evaluatedand compared. The small anti-surgevalve resulted in a drop in flowratewithout much change in the pressurehead. The shutdown surge occurred ata moderately high discharge pressure.The large anti-surge valve with avalve flow coefficient (Cy) about twotimes that of the small valve re-sulted in a major reduction in thehead. The shutdown surge occurredat a discharge pressure just above thesuction pressure. The surge event inthis case was not even noticeable. Theflow reversed through the compressorat a low head point. This case studyshows the surge-preventing effects ofan anti-surge valve with a higher Ccompared to a smaller valve with alower Cy.

Additional requirements for anti-surge valves include the following:1. The reduction of stroke time (in

response to control signal stepchanges)

2. A stable response3. Minimized overshooting during

the valve adjustment stepsThe requirements for an anti-surgevalve should always be optimized. Toofast a response can result in excessiveovershoot and poor accuracy. How-ever, too slow a response could resultin sluggish opening of the anti-surgevalve and possible inadequate pro-tection of a compressor from a surge.Most information required for the siz-ing of anti-surge valves is availableon the compressor map (the compres-sor curves). Well-known compressormanufacturers and anti-surge systemsuppliers have their own standardsfor the safety margins on anti-surgevalve capacity. This figure is usuallybased on the compression system dy-namics, the valve response and thesystem characteristics.

The anti-surge valve should be ca-pable of passing 100% of the surgeflowrate at around 50% of the valveopening. In other words, the anti-surge valve's Cy is selected to be ap-proximately two times that of the re-quired Cy, based on the compressorsurge flow on the highest compressorspeed curve (on the compressor map).Valve noise. When the anti-surgevalve is opened by the anti-surge sys-

tem, the valve dissipates a large por-tion of operating power of the compres-sor. A portion of the power dissipatedby the valve is converted into acousticenergy, which becomes valve noise.Apart from the noise, considerationsshould also be given to the fluid veloc-ity in the valve outlet. This should bekept within some limits to avoid pipevibrations. Typically, CPI plants usean anti-surge-valve noise limit range(before the external attenuation) from85 to 100 dB(A). The anticipated noiselevel (before the external attenuation)should not exceed 105 dB(A) with fluidvelocities below Mach 0.3.

Anti-surge valves should be de-signed to increase the total systemefficiency over a wide range of the op-eration. The inline and symmetricalflow path eliminates indirect flowsand unnecessary changes in the flowdirections through the valve. Axial-flow anti-surge valves are most oftenspecified. This design is rugged andoffers high performance. It is highlyreliable and requires little mainte-nance. The "breaker vanes" are oftenused in the downstream section of thevalve body (downstream of the valve'sflow-control internals), which cut andstreamline any flow turbulence. Thiscan result in significant reductions inthe noise and the turbulence, elimi-nating excessive vibrations in thevalve and the associated piping, sup-ports and structures.

The anti-surge valve should be ca-pable of changing its position in ashort period of time. For reasons ofreliability, a spring-loaded actuator isdesirable. The typical control instru-mentation and accessories providedon an anti-surge valve can include avalve positioner, a volume booster anda solenoid. In other words, usually asolenoid valve with a well-designedbooster device (that accelerates thepositioner operation) is used.

The correct size and configuration ofthe required actuators, instrumenta-tion and accessories could guaranteean anti-surge-valve response time ofless than 2 s (to fully open). An over-shoot on intermediate changes shouldbe kept to an absolute minimum.Control range. The anti-surge valveshould have a wide control range. Thewhole valve system should operate

4 4 CHEMICAL ENGINEERING WWW.CHE.COM NOVEMBER 2012

-

very quickly in case of an emergency(particularly an emergency-trip surgeevent). A very high operating range-ability is usually required. Typically, arangeability of 150:1 is specified. Therangeability parameter is defined asthe ratio hetween the rated C for acompletely open valve and the mini-mum C that the valve can control.A high rangeability value means suc-cessful control even with a high differ-ential pressure and a low flow.

To increase the rangeability, specialtrims are used where the area distri-bution is made according to the valvecharacteristic curve. For example, insome valve designs, until 40% of thestroke, the C^ is typically limited to15-25% of its maximum value to ob-tain superior controllability. Too often,a special trim with multiple jumps isspecified for an anti-surge valve.Service reliability. Good service re-liability even under very severe condi-tions (for example, compression ratioslower than 0.3, a discharge pressureranging up to 600 bars or more, andother difficult situations) is required.In order to obtain these requirements,the following considerations shouldbe respected: Anti-surge valves in various trim

styles are usually fitted with pres-sure halanced pistons. The requiredthrust should be virtually indepen-dent of the differential pressureacross the valve

Bushings should be anti-seize andself-lubricated. The internal slid-ing area requires high-quality andspecial design and materials (usu-ally chromium-plated internals arespecified)

Proper packings should be used.Typically, a charged polytetrafiuo-

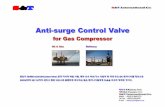

FIGURE 2.Axial com-pressors arevery vulnera-ble to damagefrom surges.This photo de-picts the typeof blade dam-age that canbe expectedas a result ofa surge eventin an axialcompressor

roethylene (PTFE) with a specialdesign is specified. For low molecu-lar-weight gases (such as hydrogen)high-quality graphite packing iscommonly specified

The trim materials should be cho-sen for good corrosion-proofing anderosion-proofing. For usual services,a proper stainless-steel alloy is typi-cally specified. For a special appli-cation, a special, sintered tungstencarbide could be a good selection.The trim design should allow for ex-cellent sealing

For high-pressure anti-surge valves,additional requirements should beconsidered. For example, the weldedseat is replaced by a high-qualitycage seat for superior sealing, bettercentering and easier maintenanceand operation

Leakage. Leaks across an anti-surgevalve can influence the efficiency of acompressor system. Even under themost severe working conditions, high-quality anti-surge valves should main-tain a tight shut-off (within practicallimits) over the full pressure range.With this feature, the compressor ef-ficiency is maintained at the highestlevels during the normal operatingmode. In a case study for a medium-size high-pressure centrifugal com-pressor (8-in. ASME Class 900 recyclecontrol valve), with an ASME ClassIV leakage rate and a differentialpressure of around 70 hars, the valveleaked approximately 150 Nm^/h of acompressed gas.

The leakage feature should he inde-pendent of the actuation method. Newdesigns do not need a higher torque aswas required in older designs. In mod-em designs, the ASME Class IV seal-ing class is usually achieved hy the

position and not by the torque. Rapidchanges in the differential pressureacross the anti-surge valve shouldhave no effect on the stability of thevalve position. A fast response is usu-ally achieved with properly sized ac-tuators in contrast to those fitted onconventional control valves. Theseadvanced actuators are usually veryefficient and compact. They cannotbe bulky or massive. Modern designscontain a minimum number of movingparts and a short valve stroke. Theseadvanced designs permit fast actionsand reliable operation.

Various studies, different simula-tions and extensive operational ex-periences pertain to a typical "oneanti-surge valve, one compressorcasing" arrangement. More com-plex systems of cascaded valves (orvalves around multiple compressors)require a more detailed analysis andsophisticated provisions.Valve and size selection. An anti-surge valve should be sized to meettwo diverse objectives: steady-stateoperation and transient cases.

During steady-state recycling, therequired capacity of the anti-surgevalve can be directly derived fromthe compressor map (the compressorcurve). Typically, smaller valves ex-hihit smoother control. During tran-sient conditions, however, the requiredvalve capacity increases. To avoid asurge during an emergency shutdown(or similar transient events, such asa sudden suction or discharge valveclosing, or others), a bigger valve willgive better performance. To fulfill bothahove-mentioned requirements, ananti-surge valve with an equal per-centage characteristic (defined helow)is recommended. Two types of anti-surge valves are generally used: globevalves and ball valves (noise-attenu-ating ball valves).

The equal percentage characteris-tic spreads the first half (50%) of thevalve's fully open capacity over thefirst two thirds (66%) of the valve'stravel for a globe valve, and about onethird (33%) of the valve's fully opencapacity over the first two thirds ofthe valve's travel for a ball valve. Ananti-surge valve should be describedby its maximum capacity (C^), and byits capacity as a function of the valve

CHEMICAL ENGINEERING WWW.CHE.COM NOVEMBER 2012 4 5

-

Engineering Practice

travel, and the opening behavior. Theglobe valve's C approximately var-ies with the square of the percentagetravel. The ball valve's capacity variesroughly with the cube of the percent-age travel. A ball valve will have morecapacity to depressurize the dischargevolume compared to a glohe valve ofthe same size.

In a case study for a 6-in. (150 mm)anti-surge valve, the C of a ball valvewas more than 2.5 times of the Cfor a same-sized (6-in.) globe valve.At two thirds of valve travel, the ballvalve flowrate was more than 50%higher than that for the same-sizedglobe valve. This additional now ca-pacity would sometimes, theoretically,make the ball valve a better choice inan anti-surge application. This is par-ticularly true where there is only asingle anti-surge valve per stage (forexample, there is no hot-gas bypass)and the discharge volumes are large(especially when the anti-surge loopis taken from downstream of the dis-charge cooler). However, this is just atheoretical and textbook idea.

From a practical standpoint, theglobe valve behavior is more predict-able. The globe valve is more comfort-able to control and manage. It is rela-tively less nonlinear. The ball valveusually offers a highly nonlinear be-havior (Cy varies with the cube of thepercentage of travel).

The anti-surge valve should bematched to the compressor system.Both globe and ball valves are used inmodern anti-surge systems (depend-ing on the application). Practically, aglobe valve is more common in anti-surge systems.

In some compressor installations,it is necessary to have both a nor-mal anti-surge valve (the recycle linetaken from downstream of the after-cooler or the anti-surge line that in-cludes a cooler) and a hot-gas bypassvalve, which can be opened to rapidlytransfer the compressed gas hack tothe suction side of the compressorwithout cooling (usually for a shortperiod of time). A hot-gas-bypass al-lows the pressure head across a com-pressor to be rapidly reduced duringa trip. Various options for anti-surgevalve size, opening rate, recycle looparrangement and operation sequence

should be evaluated. Parametric stud-ies of the anti-surge valve size andopening time can yield optimum sizesfor an anti-surge valve (and a hot-gas-bypass valve, if required).Overheating. A large portion of themechanical energy produced by a com-pressor is converted into heat in thedischarged gas. In an uncooled recy-cle-loop system, this heat is recycledinto the compressor suction end, andthen more heat energy is added to therecycling gas. In a typical natural-gascentrifugal compressor at a 100% re-cycle without recycle cooling, the tem-perature of the gas increases about1C per second. Eventually, this couldlead to overheating at the compressordischarge side.

In theory, the recycling can lead toheating whenever the compressed gascannot be cooled to the initial operat-ing temperature at the compressorsuction side. This is the case both for ahot-gas bypass and a partially cooledbjrpass (if the cooled bypass is notdesigned properly, for example, whensufficient cooling capacity is not pro-vided). The overheating could be de-fined as the gas temperature withinthe compressor exceeding 150-190C,depending on the process. The sameproblem may also occur if there is along period of time between the startof rotation (the compressor startup)and overcoming the pressure down-stream of the discharge check valve,when some kind of hot-gas bypass isused for the startup.

Control and testingAn anti-surge-system configurationusually allows an operator to openthe anti-surge valve further than thevalve position that is defined by theanti-surge controller (based on the al-gorithm) in manual-mode operation.However, the operator cannot closethe anti-surge valve any further thanthe surge controller permits. The con-troller can override the manual mode,if necessary, to open the anti-surgevalve. The "fail safe" philosophy thatis commonly employed is that theanti-surge valve should be an "air-to-close" valve (fails open). The controlis used to force the anti-surge valvefully open whenever the compressoris shutdown. This helps to prevent a

surge on a compressor shutdown, andalso holds the anti-surge valve in afully open position for a startup.

Extreme care has to be taken whentesting an anti-surge system duringoperation. The compressor shouldnot accidentally be pushed into asurge. The controller should takeover if something causes the oper-ating point to head toward a surge.Such features should be available,enabled and working correctly. A sud-den movement of the anti-surge valvecould have an adverse impact on theremaining gas system (the upstreamand the downstream of the com-pressor). All of these control actionsshould be evaluated properly.

It could be useful to assess how theanti-surge valve behaves in responseto a small 1-2% change in the com-mand signal. Bad signs are hunting,stiction (the static friction that needsto be overcome when the anti-surgevalve-position should he changed), hys-teresis and delayed lifting, all of whichcould make the control more difficult.

The anti-surge step test should beperformed with the controller in themanual mode and with the valve offits seat, preferably somewhere be-tween 15-85% open. The compressorwill be on partial-recycle through-out the test (the remaining processshould be able to cope). The firstvalve step could probably be in theopen direction so as to move the com-pressor further from the surge. If theresponse is unknown, a small valvemovement (even typically 1-2%)should be selected.

One important consideration whenoperating in the recycle mode is thatthe gas could thin out due to loss ofthe heavier components. The surgeline of the lower molecular-weightgas may be rather different from thenormal gas. Some amounts of new gasshould always be fed through the com-pressor. Another useful test is to in-troduce a disturbance to the compres-sor, such as cutting back the suctionthrottle valve slightly or changing thedriver speed (if it is a variable-speedcompressor train). It should be veri-fied that the anti-surge valve changesposition without any delay and alsowithout a significant undershoot ofthe setpoint.

4 6 CHEMICAL ENGINEERING WWW.CHE.COM NOVEMBER 2012

-

ExamplesExample 1. The first example is pre-sented for a two-process-stage centrifu-gal compressor. The two process stagesare low pressure (LP) and high pres-sure (HP). The compressor is a vari-able-speed synchronous electric-motor-driven unit (using gears) to compressnatural gas from around 10 barg to ap-proximately 100 barg. Each compres-sor stage has an anti-surge valve.

The calculated C for the LP andHP compressor casings (at the surgeflow of the high-speed curve) are 215and 81, respectively. The selectedanti-surge valve's C values for theLP and HP stages are 385 and 169,respectively. In other words, the Cfactors (the anti-surge valve C / thecalculated C^ at the high-speed surgeflow) are approximately 1.79 and 2.09for the LP and HP loops, respectively.

The selected anti-surge valves areglobe valves. The opening time is2 s and the closing time is 5 s. Thevalves were purchased with a NACE(National Association of CorrosionEngineers)-compliant carbon-steelbody, a stainless-steel (grade 17-4-PH)trim and special PTFE packing. Grade17-4-PH stainless steel is a precipita-tion hardened (a chromium-copperprecipitation hardened) stainlesssteel, employed for applications re-quiring high-strength and a high levelof corrosion resistance.Example 2. The second example ispresented for a petroleum-refinerytype hydrogen-service centrifugalcompressor. It is a steam-turbine-driven, hydrogen-recycle centrifugalcompressor for a hydrocracker unit tocompress the hydrogen from around140 to 190 barg. The calculated C forthe surge point at the high-speed curve(on the compressor map) is 179. Therecommended range for the anti-surgeC is 1.7-2.1 times the calculated Cfor the maximum-speed surge flow.Applying the 1.7 factor (the minimumfactor) results in an anti-surge valveC above 305.

The selected anti-surge valve is an8-in. globe valve, 1500# class, RTJ (ringtype joint) facing, with a Q of 308,an opening time of 2 s and a closingtime of 6 s. The anti-surge valve wasselected with a carbon-steel body (aNACE grade), a stainless-steel (grade

17-4-PH) trim and a special graphitepacking. Since the compressor traininertia is low (it is a steam-turbine,direct-driven compressor train), theanti-surge loop is taken from the im-mediate downstream of the compres-sor (upstream of the cooler).

Based on experience, for a compres-sor configuration like this, a relativelylow C (around or lower than 1.7) issometimes specified by vendors. Somevendors used C factors (the anti-surgevalve C divided by the calculated C atthe high-speed surge flow) even as lowas 1.55 or 1.6 to keep the anti-surgevalve size small. This is not recom-mended, however, since a sufficientlylarge anti-surge valve is necessary tohandle emergency rapid shutdown sit-uations and unscheduled trips at un-common (off-design) operating cases.

In other words, 1.7 is the minimumacceptable factor. This hydrogen com-pressor train is expected to compressnitrogen during the initial startup

of the unit. The calculated C for thenitrogen operation (the surge flowat the high-speed curve) is around260. In other words, a surge could beexpected in case of an unscheduledrapid trip during the operation withthe nitrogen, if a small anti-surgevalve is selected.

Edited by Dorothy LozowskiAuthor

Amin Almasi is a leadrotating equipment engi-neer at WorleyParsons Ser-vices Pty Ltd. in Brisbane,Australia ([email protected]). He pre-viously worked in TechnicasReunidas (Madrid) and FluorI various offices). He holds achartered professional engi-neer's license from EngineersAustralia (MIEAust CPEng-

Mechanical), and a chartered engineer certificatefrom IMechE (CEng MIMechE), RPEQ (Regis-tered Professional Engineer in Queensland). Healso holds M.S. and B.S. degrees in mechanicalengineering. He specializes in rotating machinesincluding centrifugal, screw and reciprocatingcompressors, gas and steam turhines, pumps,condition monitoring and reliability. He has au-thored more than 45 papers and articles dealingwith rotating machines.

Circle 4 on p. 60 or go to adlinks.che.com/40273-04CHEMICAL ENGINEERING WWW.CHE.COM NOVEMBER 2012 4 7

-

Copyright of Chemical Engineering is the property of Access Intelligence LLC d/b/a PBIMedia, LLC and its content may not be copied or emailed to multiple sites or posted to alistserv without the copyright holder's express written permission. However, users may print,download, or email articles for individual use.