ANSI_AGMA_2015-1-A01

-

Upload

nilson-venancio -

Category

Documents

-

view

517 -

download

27

Transcript of ANSI_AGMA_2015-1-A01

ANSI/AGMA2015-1-A01

ANSI/AGMA 2015-1-A01(Replaces

ANSI/AGMA 2000--A88)

AMERICAN NATIONAL STANDARD

Accuracy Classification System -Tangential Measurements for CylindricalGears

ii

AccuracyClassification System - Tangential Measurements for CylindricalGearsANSI/AGMA 2015--1--A01[Revision of ANSI/AGMA 2000--A88]

Approval of an American National Standard requires verification by ANSI that the require-ments for due process, consensus, and other criteria for approval have been met by thestandards developer.

Consensus is established when, in the judgment of the ANSI Board of Standards Review,substantial agreement has been reached by directly and materially affected interests.Substantial agreement meansmuchmore than a simplemajority, but not necessarily una-nimity. Consensus requires that all views and objections be considered, and that aconcerted effort be made toward their resolution.

The use of American National Standards is completely voluntary; their existence does notin any respect preclude anyone, whether he has approved the standards or not, frommanufacturing, marketing, purchasing, or using products, processes, or procedures notconforming to the standards.

The American National Standards Institute does not develop standards and will in nocircumstances give an interpretation of any American National Standard. Moreover, noperson shall have the right or authority to issue an interpretation of an American NationalStandard in the name of the AmericanNational Standards Institute. Requests for interpre-tation of this standard should be addressed to the American Gear ManufacturersAssociation.

CAUTION NOTICE: AGMA technical publications are subject to constant improvement,revision, or withdrawal as dictated by experience. Any person who refers to any AGMAtechnical publication should be sure that the publication is the latest available from the As-sociation on the subject matter.

[Tables or other self--supporting sections may be quoted or extracted. Credit lines shouldread: Extracted from ANSI/AGMA 2015--1--A01, Accuracy Classification System --Tangential Measurements for Cylindrical Gears, with the permission of the publisher, theAmerican Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria,Virginia 22314.]

Approved August 1, 2002

ABSTRACT

This standard, for spur and helical gearing, correlates gear accuracy grades with gear tooth tolerances. It pro-vides information on minimum requirements for accuracy groups as well as gear measuring practices. Annexmaterial provides guidance on filtering and information on comparison of gear inspection methods.

Published by

American Gear Manufacturers Association1500 King Street, Suite 201, Alexandria, Virginia 22314

Copyright 2002 by American Gear Manufacturers AssociationAll rights reserved.

No part of this publication may be reproduced in any form, in an electronicretrieval system or otherwise, without prior written permission of the publisher.

Printed in the United States of America

ISBN: 1--55589--797--5

AmericanNationalStandard

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

iii

ContentsPage

Foreword iv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 Scope 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Normative references 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Symbols, terminology and definitions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Manufacturing and purchasing considerations 8. . . . . . . . . . . . . . . . . . . . . . . . . . .5 Application of the AGMA classification system 14. . . . . . . . . . . . . . . . . . . . . . . . .6 Measuring methods and practices 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Tolerance values 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Master gears 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Annexes

A Tolerance tables 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B Tolerance system development and comparison 21. . . . . . . . . . . . . . . . . . . . . . . .C Example of statistical process control (SPC) application 31. . . . . . . . . . . . . . . . .D Involute and helix data filtering 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E Sector pitch deviation 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bibliography 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figures

1 Helix deviations 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Profile deviations 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Functional profile 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Pitch deviations 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Illustration of AGMA classification number 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

1 Alphabetical table of terms with symbols, by terms 2. . . . . . . . . . . . . . . . . . . . . . .2 Alphabetical table of symbols with terms, by symbols 3. . . . . . . . . . . . . . . . . . . .3 Reference for methods and tolerances 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Gear types and measurement methods 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Minimum number of measurements 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

iv

Foreword

[The foreword, footnotes and annexes, if any, in this document are provided forinformational purposes only and are not to be construed as a part of ANSI/AGMAStandard2015--1--A01, Accuracy Classification System -- Tangential Measurements for CylindricalGears.]

This standard provides tolerances for different gear accuracy grades from A2 to A11 forunassembled spur and helical gears. Applicable definitions are provided.

The purpose is to provide a common basis for specifying accuracy, and for the procurementof unassembled gears. It is not a designmanual for determining the specific quality levels fora given application.

AGMA 390.03 of 1973 was a consolidation of several AGMA publications, including:

AGMA 235.02 (Feb. 1966), Information Sheet for Master Gears

AGMA 239.01 (Oct. 1965), Measuring Methods and Practices Manual for Control ofSpur, Helical and Herringbone Gears

AGMA 239.01A (Sept. 1966), Measuring Methods and Practices Manual for Control ofBevel and Hypoid Gears, and parts of

AGMA 236.05 (ASA B6.11, June 1956), Inspection of Fine--Pitch Gears

AGMA 390.02 (Sept. 1964), Gear Classification Manual originally published as AGMA390.01 (1961)

Data was added for Gear Rack and Fine--PitchWorms andWormgears. The former AGMA390.02 for Coarse--Pitch and Fine--Pitch Spur, Helical and Herringbone Gearing wasenhanced to offer a single, compatible classification system. The tolerance identifier �Q�was added to indicate that the tolerances in 390.03 apply. If Q is not used as a prefix in thequality number, tolerances in AGMA 390.01 and 390.02 applied.

ANSI/AGMA 2000--A88 was an update of those sections from AGMA 390.03 for parallelaxis gears only. Additionally, the formulas stated the tolerances in metric terms. Thecontent was revised, but basic tolerance levels were unchanged from AGMA 390.03. Theother material in AGMA 390.03 on Bevels and Worms was replaced by ANSI/AGMA2009--A99 and ANSI/AGMA 2011--A98, respectively. ANSI/AGMA 2000 was approved byAGMAmembership in January 1988, and as a American National Standard Institute (ANSI)standard on March 31, 1988.

The user of this American National Standard is alerted that differences exist between it andANSI/AGMA 2000--A88. Differences include, but are not limited to:

-- Accuracy grade numbering system is reversed, such that the smallest numberrepresents the smallest tolerance;

-- Relative magnitudes of elemental tolerances for a single grade are in a differentproportion;

-- The �helix evaluation range�, where the tolerances are applied, are defined for lessflank area than in ANSI/AGMA 2000--A88;

-- The �K Chart� is not used for the permissible tolerance values;

-- Runout is not included as one of the elements with a tolerance;

-- Concepts of �mean measurement trace�, �design profile�, �slope deviation� and�form deviation� are added, similar to ISO 1328--1.

Therefore, the user of ANSI/AGMA 2015--1--A01 must be very careful when comparingtolerance values formerly specified using ANSI/AGMA 2000--A88.

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

v

ANSI/AGMA 2015--1--A01 is a replacement for ANSI/AGMA 2000--A88 and ANSI/AGMAISO 1328--1. It is a complete revision, including accuracy grades, in order to be morecompatible with ISO. It combines the grading system of ISO 1328--1 with the methods ofANSI/AGMA 2000--A88, and adds concepts of accuracy grade grouping for minimummeasurement requirements, filtering, data density, and roughness limits to form deviations.

This revision was started by the AGMA Inspection and Handbook Committee in 1997. Itwas approved by the AGMA membership in June, 2001. It was approved as an AmericanNational Standard on August 1, 2002.

Suggestions for improvement of this standard will be welcome. They should be sent to theAmerican Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria,Virginia 22314.

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

vi

PERSONNEL of the AGMA Inspection and Handbook Committee

Chairman: Edward Lawson M&M Precision Systems Corp.. . . . . . . . . . . . . . . . . . . . . . . . . . .

ACTIVE MEMBERS

W.A. Bradley Consultant. . . .D.R. Choiniere Profile Engineering, Inc.. .J. Clatworthy Gear Metrology, Inc.. . . .B.L. Cox BWXT Y--12, LLC. . . . . . .T.C. Glasener Xtek, Incorporated. . .G.G. Grana The Gleason Works. . . . .B. Hofrichter Arrow Gear Company. . . .I. Laskin Consultant. . . . . . . .

S. Lindley The Falk Corporation. . . . . .M. May The Gleason Works. . . . . . . . .D.A. McCarroll ZF Industries. .D.R. McVittie Gear Engineers, Inc.. . . .S. Moore Martin Sprocket & Gear, Inc.. . . . . . .L.J. Smith Consultant. . . . . .R.E. Smith R.E. Smith & Company, Inc.. . . . . .

ASSOCIATE MEMBERS

M. Antosiewicz The Falk Corporation. .M.J. Barron Gear Motions, Inc.. . . . .D. Behling Hamilton Sundstrand Aero.. . . . . .M.K. Considine Considine Associates. .R. Considine Considine Associates. . . .J.S. Cowan Eaton Corporation. . . . .M.E. Cowan Process Equipment Co.. . . .B. Cowley Mahr Corporation. . . . . .C. Dick The Horsburgh & Scott Co.. . . . . . . . .H.D. Dodd Caterpillar, Inc.. . . . . .R. Green R--7 Group, Gear Consultants. . . . . . .D. Gregory Gear Products, Inc.. . . . .B. Gudates Fairfield Manufacturing Co., Inc.. . . . .J.S. Hamilton Regal--Beloit Corporation. . .H. Harary NIST. . . . . . .D. Heinrich Xtek, Incorporated. . . . .G. Henriot Consultant. . . . . .J. Horwell Brown & Sharpe. . . . . .S. Johnson The Gear Works -- Seattle, Inc.. . . . .T. Klemm Liebherr. . . . . . .D.E. Kosal National Broach & Machine Co.. . . . . .J. Koshiol Columbia Gear Corporation. . . . . .

W.E. Lake MitsubishiGearTech.Center (AG). . . . . .A.J. Lemanski Penn State University. . .G.A. Luetkemeier Rockwell Automation/DodgeD. Matzo Northwest Gears, Inc.. . . . . . .P.A. McNamara Caterpillar, Inc..W.J. Michaels Sundstrand Corporation. . .M. Milam Amarillo Gear Company. . . . . . .T. Miller The Cincinnati Gear Company. . . . . . . .M. Nanlawala IIT Research Institute/INFAC. . .M. Octrue Centre Technique Des Ind. Mec.. . . . . .T. Okamoto Nippon Gear Company, Ltd.. . . . .J.A. Pennell Univ. of Newcastle--Upon--Tyne. . . . .K.R. Price Eastman Kodak Company. . . . . .R.S. Ramberg The Gear Works -- Seattle, Inc.. . .V.Z. Rychlinski Brad Foote Gear Works, Inc.. .D.H. Senkfor Precision Gear Company. . . .S. Shariff PMI Food Equipment Group. . . . . . .E. Storm Consultant. . . . . . .T. Waldie Philadelphia Gear Corporation. . . . . . .R.F. Wasilewski Arrow Gear Company.F.M. Young Forest City Gear Company. . . . .P. Zwart Caterpillar, Inc.. . . . . . .

1

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

American National Standard --

Accuracy ClassificationSystem -- TangentialMeasurements forCylindrical Gears

1 Scope

This part of ANSI/AGMA 2015 establishes anaccuracy grade system relevant to tangential mea-surements on flanks of individual cylindrical involutegears.

It specifies definitions for gear tooth accuracy terms,the structure of the gear accuracy grade system, andallowable values.

It is strongly recommended that any user of this partof ANSI/AGMA 2015 be very familiar with themethods and procedures outlined in AGMA915--1--A02. Use of techniques other than those ofAGMA 915--1--A02 combined with the limits de-scribed in this part of ANSI/AGMA 2015 may not besuitable.

This standard provides the gear manufacturer andthe gear buyer with a mutually advantageousreference for uniform tolerances. Ten accuracygrades are defined in this standard, numbered A2through A11, in order of decreasing precision.

1.1 Equations for tolerances

Equations for tolerances and their ranges of validityare provided in 7.2 for the defined accuracy ofgearing. In general, these tolerances cover thefollowing ranges:

5 ≤ z≤ 1000 or 10 000/mn whichever is less5 mm ≤ D ≤ 10 000 mm0.5 ≤ mn ≤ 504 mm ≤ b ≤ 1000 mmβ ≤ 45°

where

D is pitch diameter;

mn is normal module;

b is facewidth (axial);

z is number of teeth;

β is helix angle.

See clause 4 for required and optional measuringmethods.

1.2 Exceptions

This standard does not apply to enclosed gear unitassemblies, including speed reducers or increasers,gear motors, shaft mounted reducers, high speedunits, or other enclosed gear units which aremanufactured for a given power, speed, ratio orapplication.

Gear design is beyond the scope of this standard.The use of the accuracy grades for the determinationof gear performance requires extensive experiencewith specific applications. Therefore, the users ofthis standard are cautioned against the directapplication of tolerance values to a projected perfor-mance of unassembled (loose) gears when they areassembled. Refer to the latest AGMA PublicationsIndex for applicable standards.

NOTE: Tolerance values for gears outside the limitsstated in this standard should be established by deter-mining the specific application requirements. Thismayrequire setting a tolerance smaller than calculated bythe formulas in this standard.

2 Normative references

The following standards contain provisions which,through reference in this text, constitute provisions ofthis American National Standard. At the time ofpublication, the editions indicated were valid. Allstandards are subject to revision, and parties toagreements based on this American NationalStandard are encouraged to investigate the possibil-ity of applying the most recent editions of thestandards indicated below.

AGMA 915--1--A02, Inspection Practices -- Part 1:Cylindrical Gears -- Tangential Measurements

AGMA 915--3--A99, Inspection Practices -- GearBlanks, Shaft Center Distance and Parallelism

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

2

ANSI/AGMA 1012--F90, Gear Nomenclature,Definitions of Terms with Symbols

ANSI/AGMA 2110--A94, Measuring InstrumentCalibration -- Part I, Involute Measurement (Metric)

ANSI/AGMA 2113--A97, Measuring InstrumentCalibration, Gear Tooth Alignment Measurement

ANSI/AGMA 2114--A98, Measuring InstrumentCalibration, Gear Pitch and Runout Measurements

ISO 701:1998, International gear notation --Symbols for geometrical data

3 Symbols, terminology and definitions

The symbols, terminology and definitions pertainingto the tolerances and inspection of spur and helicalgear teeth are listed here for use in this standard. Forother definitions of geometric terms related togearing, see ANSI/AGMA 1012--F90.

NOTE: Some of the symbols and terminology con-tained in this document may differ from those used inother documents and AGMA standards. Users of thisstandard should assure themselves that they are usingthe symbols, terminology and definitions in themannerindicated herein.

3.1 Fundamental terms and symbols

The terminology and symbols used in this standardare listed alphabetically by term in table 1, andalphabetically by symbol in table 2.

3.2 Definitions

cumulative pitch deviation, total, Fp The largestalgebraic difference between the index deviationvalues for a specified flank.

Distinction is not made as to the direction oralgebraic sign of this reading. Such a distinctionwould require a purely arbitrary specification of adirection (clockwise or counterclockwise) traveledbetween the two teeth comprising the total cumula-tive pitch deviation.

Table 1 -- Alphabetical table of terms with symbols, by terms

Terms Symbol Units Where usedAccuracy grade A -- -- 7.1.2Accuracy grade identifier prefix A -- -- 1Contact pattern measurement cp -- -- Table 3Cumulative pitch deviation, total Fp mm 3.2Cumulative pitch deviation tolerance, total FpT mm 7.2.2Design outside diameter Do mm Eq 2Diameter, pitch D mm 1.1Facewidth (axial) b mm 1.1Functional profile length Lαc mm 3.2Gear form filter cutoff λg mm Eq 1Helix angle β deg 1.1Helix deviation, total Fβ mm 3.2Helix evaluation range Lβ mm 3.2Helix form deviation ffβ mm 3.2Helix form tolerance ffβT mm 7.2.6.3Helix slope deviation fHβ mm 3.2Helix slope tolerance fHβT mm 7.2.6.2Helix tolerance, total FβT mm 7.2.6.1Normal module mn mm 1.1Number of teeth z -- -- 1.1Number of pitches in a sector k -- -- Figure 4Pitch, transverse circular pt mm Figure 4Profile deviation, total Fα mm 3.2Profile form deviation ffα mm 3.2Profile form tolerance ffαT mm 7.2.5.3Profile slope deviation fHα mm 3.2Profile slope tolerance fHαT mm 7.2.5.2

(continued)

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

3

Table 1 (concluded)

Terms Symbol Units Where usedProfile tolerance, total FαT mm 7.2.5.1Single flank composite deviation, tooth--to--tooth (filtered) fis mm 3.2Single flank composite deviation, total Fis mm 3.2Single flank composite tolerance, tooth--to--tooth fisT mm 7.2.3Single flank composite tolerance, total FisT mm 7.2.4Single pitch deviation fpt mm 3.2Single pitch deviation tolerance fptT mm 7.2.1Tolerance diameter dT mm 3.2Tooth thickness measurement s -- -- Table 3

Table 2 -- Alphabetical table of symbols with terms, by symbols

Symbol Terms Units Where usedA Accuracy grade identifier prefix -- -- 1A Accuracy grade -- -- 7.1.2b Facewidth (axial) mm 1.1cp Contact pattern measurement -- -- Table 3D Diameter, pitch mm 1.1Do Design outside diameter mm Eq 2dT Tolerance diameter mm 3.2Fis Single flank composite deviation, total mm 3.2FisT Single flank composite tolerance, total mm 7.2.4Fp Cumulative pitch deviation, total mm 3.2FpT Cumulative pitch deviation tolerance, total mm 7.2.2Fα Profile deviation, total mm 3.2FαT Profile tolerance, total mm 7.2.5.1Fβ Helix deviation, total mm 3.2FβT Helix tolerance, total mm 7.2.6.1ffα Profile form deviation mm 3.2ffαT Profile form tolerance mm 7.2.5.3ffβ Helix form deviation mm 3.2ffβT Helix form tolerance mm 7.2.6.3fHα Profile slope deviation mm 3.2fHαT Profile slope tolerance mm 7.2.5.2fHβ Helix slope deviation mm 3.2fHβT Helix slope tolerance mm 7.2.6.2fis Single flank composite deviation, tooth--to--tooth (filtered) mm 3.2fisT Single flank composite tolerance, tooth--to--tooth mm 7.2.3fpt Single pitch deviation mm 3.2fptT Single pitch deviation tolerance mm 7.2.1k Number of pitches in a sector -- -- Figure 4Lαc Functional profile length mm 3.2Lβ Helix evaluation range mm 3.2mn Normal module mm 1.1pt Pitch, transverse circular mm Figure 4s Tooth thickness measurement -- -- Table 3z Number of teeth -- -- 1.1β Helix angle deg 1.1λg Gear form filter cutoff mm Eq 1

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

4

This standard specifies direction of tolerancing fortotal cumulative pitch deviation to be along the arc ofthe tolerance diameter, dT, circle within the trans-verse plane. Tolerances for total cumulative pitchdeviation are provided by the formula in 7.2.2 of thisstandard.

datum axis The datum axis of the gear is defined by

the datum surfaces. It is the axis to which the geardetails, and in particular the pitch, profile, and helixtolerances are defined. See AGMA 915--3--A99.

design helix The helix specified by the designer asshown on the design specification. When notspecified, it is an unmodified helix. See figure 1.

--

+

--

+

--

+

+

--

--

+

--

+

--

+

b) Helix form deviationa) Total helix deviation c) Helix slope deviation

--

+

--

+

Key

: Design helix : Measured helix : Mean helix line

i) Design helix: unmodified helixMeasured helix: with minus material outside the evaluation range

ii) Design helix: modified helix (example)Measured helix: with minus material outside the evaluation range

iii) Design helix: modified helix (example)Measured helix: with excess of material outside the evaluation range

i)

ii)

iii)

Fβ

Fβ

f fβf fβ

f Hβ

f Hβ

Lβ

Lβ

b

b

Lβ

Lβ

b

b

Lβ

Lβ

b

b

Fβ

f fβ

Lβ

b

Lβ

b

Lβ

b

f Hβ

Figure 1 -- Helix deviations

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

5

design profile The profile specified by the designeras shown on the design specification. When notspecified, it is an unmodified involute. See figure 2.

functional profile That portion of the tooth flankbetween the profile control diameter and the start oftip break, see figure 3.

-- +

CD

+--

TB TB

CD

+--

CD

-- + +-- +--

+-- -- +

Key: Design profile : Measured profile : Mean profile line

TB Start of tip breakCD Profile control diameter

i) Design profile: unmodified involuteMeasured profile: with minus material outside the evaluation range

ii) Design profile: modified involute (example with tip relief only)Measured profile: with minus material outside the evaluation range

iii) Design profile: modified involute (example with full contour)Measured profile: with excess of material near the tip

Fα

Fα

Fα

L αc

i)

ii)

iii)

ffα

ffα

ffα

fHα

fHα

fHα

+--L αc

L αc

L αc

L αc

L αc

L αc

L αc

L αc

CD

TB TB

CD

TB

CD

CD

TB TB

CD

TB

CD

TB

a) Total profile deviation b) Profile form deviation c) Profile slope deviation

Figure 2 -- Profile deviations

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

6

Functionalprofile

Internaltooth

Base circleInside diameter

Start of tip break

Pitch diameter

Profile controldiameter

Root diameter

Externaltooth

Functionalprofile

Base circleRoot diameter

Profile controldiameter

Pitch diameter

Start of tip break

Outside diameter

Figure 3 -- Functional profile

functional profile length, Lαc The differencebetween the roll path lengths at the points that definethe limits of the functional profile.

gear form filter cutoff, λg The wavelength at whicheither involute profile or helix measurement data aresegregated by the low--pass filter, thereby includingonly longer wavelength deviations.

This filter cutoff should be stated in terms of roll pathlength. It shall be calculated as follows:

λg =Lαc30

but not less than 0.25 mm (1)

where

λg is the gear form filter cutoff, mm.

helix deviation Amount by which a measured helixdeviates from the design helix. Deviations causedby plus material outside the helix evaluation rangemust be included in the calculation of helix formdeviation, ffβ, and total helix deviation, Fβ. Minusmaterial outside the helix evaluation range may beignored. This standard specifies the direction oftolerancing for helix deviation to be in a transverseplane, on a line tangent to the base circle.

helix deviation, total, Fββββ Distance between twodesign helix lines which enclose the actual helixtrace over the evaluation range, Lβ, see figure 1a.

helix evaluation range, Lβ Unless otherwisespecified, the helix length of trace shortened at eachend by the smaller of the following two values: 5% ofthe helix length of trace, or the length equal to onemodule.

NOTE: It is the responsibility of the geardesigner to as-sure that the helix evaluation range is adequate for theapplication.

helix form deviation, ffβ Distance between twofacsimiles of the mean helix line, which are eachplaced with constant separation from the mean helixline, so as to enclose the actual helix trace over theevaluation range, Lβ, see figure 1b.

helix length of trace Unless otherwise specified,full facewidth is limited toward the ends of the teethby the end faces or, if present, the start of endchamfers, rounds, or other modification intended toexclude that portion of the tooth from engagement.The helix length of trace should be stated as the axialcomponent of the helix.

helix slope deviation, fHβ Distance between twodesign helix lines which intersect the mean helix lineat the end points of the evaluation range, Lβ, seefigure 1c.

Deviations are deemed to be positive when helixangles are larger and negativewhen helix angles aresmaller, than the designed helix angle. The helixdeviations of spur gears if other than zero areindicated by the subscripts �R� and �L�, instead of analgebraic sign, implying deviations in the sense ofright or left helices respectively.

index deviation The displacement of any toothflank from its theoretical position, relative to a datumtooth flank, see figure 4.

Distinction is made as to the direction and algebraicsign of this reading. A condition wherein the actualtooth flank position was nearer to the datum toothflank, in the specified measuring path direction(clockwise or counterclockwise), than the theoreticalposition would be considered a minus (--) deviation.A condition wherein the actual tooth flank positionwas farther from the datum tooth flank, in thespecified measuring path direction, than the theoret-ical position would be considered a plus (+) devi-ation.

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

7

Indexdeviation

theoreticalactual

pt

+fpt

k ⋅ pt

Figure 4 -- Pitch deviations

This standard specifies direction of tolerancing forindex deviation to be along the arc of the tolerancediameter, dT, circle within the transverse plane.

mean helix line A line (or curve) that has the sameshape as the design helix, but aligned with themeasured trace. It is developed by subtracting theordinates of a straight--line gradient from the ordi-nates of the design helix. Within the evaluationrange, Lβ, the straight--line gradient is found byapplying the least squaresmethod to the deviation ofthe measured helix trace from the specified designhelix.

NOTE: This helix is an aid in the determination of thedeviations ffβ (figure 1b) and fHβ (figure 1c).

meanprofile line A line (or curve) that has the sameshape as the design profile, but aligned with themeasured trace. It is developed by subtracting theordinates of a straight--line gradient from the ordi-nates of the design profile. Within the functionalprofile length, Lαc, the straight--line gradient is foundby applying the least squares method to the devi-ation of themeasured profile trace from the specifieddesign profile.

NOTE: This profile is an aid in the determination of ffα(figure 2b) and fHα (figure 2c).

profile control diameter A specified diameter ofthe circle beyond which the tooth profile mustconform to the specified involute curve. Seefunctional profile.

profile deviation Amount by which a measuredprofile deviates from the design profile. Deviationscaused by plus material beyond the tip break must

be included in the calculation of the profile formdeviation, ffα, and total profile deviation, Fα. Minusmaterial beyond the tip break may be ignored. Thisstandard specifies the direction of tolerancing forprofile deviation to be in a transverse plane, on a linetangent to the base circle.

profile deviation, total, Fαααα Distance between twodesign profile lines which enclose the actual profiletrace over the functional profile length, Lαc, seefigure 2a.

profile evaluation range The profile is evaluatedover the specified functional profile length.

profile form deviation, ffαααα Distance between twofacsimiles of the mean profile line, which are eachplaced with constant separation from the meanprofile line, so as to enclose the actual profile traceover the functional profile length, Lαc, see figure 2b.

profile slope deviation, fHαααα Distance between twodesign profile lines which intersect the mean profileline at the endpoints of the functional profile length,Lαc, see figure 2c.

The profile slope deviation is deemed to be positiveand the corresponding pressure angle deviation isdeemed to be negative when the mean profile lineshows an increase in material toward the tooth tip,relative to the design profile.

roll path length The linear distance along a basetangent line from its intersection with the base circleto the given point on the involute curve in thetransverse plane.

NOTE: Roll path length is an alternative to roll angle forspecification of selected diameter positions on an invo-lute profile.

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

8

single flank composite test A test of transmissionerror, performed where mating gears are rolledtogether, at their proper center distance, withbacklash, and with only the driving and driven flanksin contact. Deviations are measured in terms ofangular displacement and converted to linear dis-placement at the pitch radius.

single flank composite deviation, tooth--to--tooth (filtered), fis The value of the greatest singleflank composite deviation over any one pitch (360/z),after removal of the long term component (sinusoidaleffect of eccentricity), during a single flank compos-ite test, when the gear is moved through onerevolution.

single flank composite deviation, total, Fis Themaximum measured transmission error range, dur-ing a single flank composite test, when the gear ismoved through one revolution.

single pitch deviation, fpt The displacement of anytooth flank from its theoretical position relative to thecorresponding flank of an adjacent tooth, seefigure 4.

Distinction is made as to the algebraic sign of thisreading. Thus, a condition wherein the actual toothflank position was nearer to the adjacent tooth flankthan the theoretical position would be considered aminus (--) deviation. A condition wherein the actualtooth flank position was farther from the adjacenttooth flank than the theoretical position would beconsidered a plus (+) deviation.

This standard specifies tolerancing direction ofmeasurement for single pitch deviation to be alongthe arc of the tolerance diameter, dT, circle within thetransverse plane. Tolerances for single pitch devi-ation are provided by the formula in 7.2.1 of thisstandard.

start of tip break Minimum specified diameter atwhich the tip break can occur. See ANSI/AGMA1012--F90.

tolerance diameter, dT The diameter located onenormal module below the design outside diameter,thereby being approximately at mid--height.

dT = Do− 2mn (2)

where:

dT is tolerance diameter, mm;

Do is design outside diameter, mm;

mn is normal module, mm.

The location of pitch and helix measurements shallbe at the tolerance diameter. See 4.3.3.

transmission error The deviation of the position ofthe driven gear, for a given angular position of thedriving gear, from the position that the driven gearwould occupy if the gears were geometricallyperfect.

4 Manufacturing and purchasingconsiderations

This standard provides classification tolerances andmeasuring methods for unassembled gears. Thisclause presents considerations for control of thevarious phases of manufacturing, including therecommended methods of measurement control.

These methods provide the manufacturer andpurchaser with recommendations for verifying theaccuracy of a manufactured product, as well asinformation relative to the interpretation of measure-ment data.

Some design and application considerations maywarrant measuring or documentation not normallyavailable in standard manufacturing processes.Specific requirements are to be stated in thecontractual documents.

In the previous (AGMA 2000--A88) classificationsystem, higher AGMA accuracy numbers desig-nated higher precision. In this standard, lowerAGMA accuracy grades designate higher precisionin order to be consistent with international standards.To avoid confusion, the designator �A� shall be usedwhen specifying accuracy grades from thisstandard.

4.1 Manufacturing certification

Certification of variations in accordance with thegear�s specific AGMA accuracy grade and inspec-tion charts or data can be requested as part of thepurchase contract.

The manufacturing of gearing to a specified accura-cy may or may not include specific measurements.When applications warrant, detailed specificmeasurements, data analysis, and additionalconsiderations may be necessary to establishacceptance criteria for a gear. The specific methodsof measurement, documentation of accuracy grade,and other geometric tolerances of a gear are

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

9

normally considered items which are to be mutuallyagreed upon between manufacturer and purchaser.

For information on the use of statistical processcontrol (SPC), see annex C.

NOTE: Specifying an AGMA accuracy grade or mea-surement criteria that requires closer tolerances thanrequired by the application may increase the costunnecessarily.

4.2 Process control

Process control is defined as the method by whichgear accuracy is maintained through control of eachindividual step of the manufacturing process. Uponcompletion of all manufacturing operations, a spe-cific gear has been given an inherent level ofaccuracy; this level of accuracy was establishedduring the manufacturing process, and it is totallyindependent of any final inspection.

Process control includes elements such asmanufacturing planning, maintenance of machinetools, cutting tool selection and maintenance, heattreatment control, and accuracy assurance pro-grams, as needed, to achieve and maintain thenecessary gear accuracy. When properly applied,gears manufactured by specific control techniqueswill be found to be of uniform accuracy. Therefore,little or no final inspection may be necessary for agear, particularly in some classification levels; assur-

ance of the necessary accuracy having been built--inthrough careful manufacturing control at each step.

NOTE: Documentation may be deemed unnecessaryfor productsmanufactured under process control wheninspection records are not specified in the purchasecontract.

With proper application of process control, relativelyfew measurements may be made on any one gear.For example, tooth size may be evaluated by ameasurement on only two or three sections of agiven gear. It is assumed that these measurementsare representative of all the teeth on the gear. Gearsmade in quantity may be inspected at various stepsin their manufacturing process on a sampling basis.It is possible that a specific gear can pass throughthe entire production process without ever havingbeen measured. Based on appropriate confidencein the applied process control, the manufacturer ofthat gear must be able to certify that its accuracy isequal to those gears that were measured.

4.3 Measurement methods

Gear geometry may be measured by a number ofalternatemethods as shown in table 3. The selectionof the particul

ar method depends on the magnitude of thetolerance, the size of the gear, the productionquantities, equipment available, accuracy of gearblanks, and measurement costs.

Table 3 -- Reference for methods and tolerances

Parametersymbol

Measurement descriptionLocation of

tolerance (clause)Elemental:FpfptFαffαfHαFβffβfHβ

Cumulative pitch, totalSingle pitchProfile, totalProfile formProfile slopeHelix, totalHelix formHelix slope

7.2.27.2.17.2.5.17.2.5.37.2.5.27.2.6.17.2.6.37.2.6.2

Composite:Fisfiscp

Single flank composite, totalSingle flank composite, tooth--to--toothContact pattern

7.2.47.2.3-- --

Size:s Tooth thickness -- --

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

10

The manufacturer or the purchaser may wish tomeasure one or more of the geometric features of agear to verify its accuracy grade. A gear which isspecified to an AGMA accuracy grade must meet allthe individual tolerance requirements applicable tothe particular accuracy grade and size as noted intables 4 and 5. Unless otherwise specified, allmeasurements are taken and evaluated at the

tolerance diameter, dT, as specified in 3.2.

Normally the tolerances apply to both sides of theteeth unless only one side is specified as the loadedside. In some cases, the loaded side may specifyhigher accuracy than the nonloaded or minimum--loaded side; if applicable, this information is to bespecified on the gear engineering drawing (see4.4.6).

Table 4 -- Gear types and measurement methods

Accuracy group Grade designatorMinimum acceptable

parametersAlternative method

Group MLow (L) A10--A11 Fp, fpt, s Group H( ) p, fpt,

s, radial method1)

Medium (M) A6--A9 Fp, fpt, s, Fα, Fβ Group H

High (H) A2--A5Fp, fpt, sFα, ffα, fHαFβ, ffβ, fHβ

cp, Fis, fis, s

NOTE:1) See ANSI/AGMA ISO 1328--2.

Table 5 -- Minimum number of measurements

Method designatorTypical measuring Minimum number of requirements for1)

Method designatoryp g

method Group L Group M Group H

Elemental:Fp: Cumulative pitch, total

Two probeSingle probe

All teethAll teeth

All teethAll teeth

All teethAll teeth

fpt: Single pitchTwo probeSingle probe

All teethAll teeth

All teethAll teeth

All teethAll teeth

Fα: Profile, totalffα: Profile formfHα: Profile slope

Profile test -- -- 3 teeth 4 teeth

Fβ: Helix, totalffβ: Helix formfHβ: Helix slope

Helix test -- -- 3 teeth 4 teeth

Composite:Fis: Single flank composite, total All teeth All teeth All teethfis: Single flank composite,

tooth--to--toothAll teeth All teeth All teeth

cp: Contact pattern 3 places 3 places 3 placesSizes:s: Tooth thickness Tooth caliper

Measurement over orbetween pinsSpan measurementComposite action test

2 teeth1 place

1 placeAll teeth

3 teeth1 place

2 placesAll teeth

4 teeth2 places

3 placesAll teeth

NOTE:1) See 4.3 for location of measurements.

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

11

If prior agreement between the manufacturer andpurchaser specifies measurement of gears, unlessotherwise specified, the manufacturer may select:

-- the measurement method to be used fromamong the applicable methods described inAGMA 915--1--A02 and summarized in table 4;

-- the piece of measurement equipment to beused by the selected measurement method, pro-vided it is in proper calibration;

-- the individual teeth to be measured, as longas they are approximately equally spaced andmeet the minimum number required by themethod as summarized in table 5.

NOTE: This standard provides tolerances for unas-sembled gears. Themeasurement of gearingmated inan assembly for a specific application is beyond thescope of this document.

4.3.1 Equipment verification

Equipment used for the elemental measurement ofproduct gears should be verified periodically accord-ing to standard calibration procedures such as thosein ANSI/AGMA 2110--A94, ANSI/AGMA 2113--A97and ANSI/AGMA 2114--A98. This should alsoinclude a determination of the uncertainty of themeasuring process.

4.3.2 Recommended measurement controlmethods

The recommended methods of measurement con-trol for each AGMA accuracy grade and type ofmeasurement are listed in tables 4 and 5.

NOTE: No particularmethod ofmeasurement or docu-mentation is considered mandatory unless specificallyagreed upon between manufacturer and purchaser.When applications require measurements beyondthose recommended in this standard, specialmeasure-ment methods must be negotiated prior to manufactur-ing the gear.

4.3.3 Considerations for elementalmeasurements

Before elemental measurement values can becompared with tolerance values, certain operationalparameters of the measurement instrument must beknown. This includes:

-- datum axis;

-- direction of measurement;

-- direction of tolerancing;

-- tolerancing diameter;

-- data filtering;

-- data density.

In some cases, measurement instruments follow theminimum requirements by default. When otherconditions exist, it is required that causes of theresulting measurement differences are known andcompensated.

It is important to distinguish between measurementlocation (the tolerance diameter), measurementdirection, and tolerancing direction. In this standard,the tolerancing direction for pitch measurements isalong the arc of the tolerance diameter, dT, circlewithin the transverse plane, while the tolerancingdirection for helix is tangent to the base circle withinthe transverse plane.

4.3.3.1 Datum axis

Specification of the design profile, design helix, anddesign pitch requires definition of an appropriatereference axis of rotation, called the datum axis. It isdefined by specification of datum surfaces. SeeAGMA 915--3--A99.

The datum axis determines tooth geometry, therebybeing the reference for measurements and associat-ed tolerances. The location and orientation of thetolerance diameter circle are determined by thedatum axis.

4.3.3.2 Direction of measurement

Measurements of the shape or the position of anysurface can be made in a direction normal to thatsurface, inclined at some angle, or along the arc of aspecified circle.

Common metrology practice is to measure in adirection normal to the surface being tested. At anypoint on a gear tooth surface, the normal vector isoriented 1) tangent to the base cylinder of the gear,and 2) inclined relative to the transverse plane at thebase helix angle. Measurements taken in thisdirection have the following characteristics:

-- Measurements will always be the smallestwhen the direction of measurement is normal tothe surface. Measurements at any otherinclination will be larger.

-- Measurements made in the normal directionare not affected by the tolerancing diameterselected by the test operator.

-- Measurements taken in other directions maybe affected by force vectors acting upon the probemechanism.

-- As gear teeth move through mesh, the lines(or points) of contact between mating tooth

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

12

surfaces proceed along lines of action within theplane of action. Measurements made in thenormal direction coincide with this direction oftooth meshing motion. When converted to angu-lar units of measure, they correlate well withtransmission errors.

It is important to understand that various gearmeasuring instruments use different testing proce-dures, some measuring in the normal direction,some measuring in other directions.

4.3.3.3 Direction of tolerancing

Tolerances on the shape or the position of gear toothsurfaces must specify the direction in which givenmeasurements are to be considered. This specifieddirection, called the tolerancing direction, may benormal to that surface, inclined at some angle, oralong the arc of a specified circle. When thetolerancing direction is inclined at some angle to thenormal direction, it is specified by two parameters:

-- the diameter to which the measurementsshall be tangent;

-- the angle of inclination, relative to thetransverse plane.

In this standard the tolerancing direction varies withthe given toleranced elemental parameter. Toler-ancing direction requirements are listed in 3.2.Originalmeasurement valuesmust be compensatedif the actualmeasurement direction and the toleranc-ing direction specified for the given parameter aredifferent.

When the measurement instrument�s direction ofmeasurement is normal and the tolerancing direc-tion is other than normal, measurement values mustbe increased before analysis and comparison totolerances. Typically, the factor for this adjustment isthe cosine of the angle between the normal directionand the specified tolerancing direction. For exam-ple, when testing helix with a normal direction ofmeasurement (within the base tangent plane) themeasurement values must be divided by the cosineof the base helix angle to compensate those valuesto the transverse plane as required by clauses 3 and7.

Measurement values from elemental test instru-ments that measure in a direction other than normaland not in the specified tolerancing direction, requiremore complex adjustments before comparison totolerances.

4.3.3.4 Tolerance diameter

This standard specifies the tolerance diameter, dT,as defined in 3.2 as the location for measurement ofhelix and pitch parameters. Also see 4.3.3.2 and4.3.3.3.

4.3.3.5 Measurement data filtering

Any tooth surface will exhibit a wide spectrum ofdeviations from the specified tooth flank form. Thisincludes, at one extreme, those of long duration,such as a general concavity. At the other end of thespectrum are short duration irregularities, such assurface roughness. Measurement and control ofshort duration roughness is beyond the scope of thisstandard. See ISO/TR 10064--4.

This standard requires modification of original mea-surement values for involute profile and helix param-eters so as to include only long duration irregularitiesbefore analysis and comparison to tolerances. Thismodification is called low--pass filtering. It willminimize or exclude all irregularities with wave-lengths shorter than the specified filter cutoff wave-length. The filter cutoff specified by this standard isthe gear form filter cutoff, λg, as defined in 3.2.

The actual filter type and attenuation should beindicated on the data sheet. A Gaussian type filterwith 50% attenuation of cut--off is recommended.

See Annex D for additional information.

4.3.3.6 Measurement data density

Measurement data density is closely related tomeasurement data filtering in that the data samplingrate limits the wavelength of surface irregularitiesthat can be observed. The number of data pointsincluded in the evaluation length should be shown onthe inspection record. This standard thereforerequires that involute profile measurement data setsinclude a minimum of 200 samples. Helix measure-ment data sets include aminimum of 200 samples or5Lβ / λg, whichever is greater, in order to ensure thatthe filter is effective.

4.3.4 Tooth contact pattern inspections

Checking tooth contact patterns with a mate ormaster gear is a method of inspection of eitherassembled gears, or gears mounted on a geartesting machine. It provides an indication of compat-ible tooth shape, both up and down the tooth profile,and lengthwise on the tooth. It evaluates that portionof the gear tooth surface which actually makescontact with its mate. With this technique, the areasthat contact can be observed by coating the teethwith a very thin layer of marking compound and

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

13

meshing the gears, see AGMA 915--1--A02. Ajudgement of compatibility may be made by theposition and size of the contact area. It does notnecessarily indicate compatible tooth shape forloaded conditions. Axial runout may also beindicated by a shifting of the tooth contact from sideto side, progressively around the gear. This test caninclude the effect of tooth element variations, suchas a variation in helix. This standard does notprovide tolerances relating these tests to gearaccuracy.

4.3.5 Inspection by sound test

The accuracy of a pair of gears may also beevaluated by running them in a suitable soundtesting machine. The acceptability is characterizedby periodic variation in sound during each revolution,or high levels of noise. This standard does notprovide specific limits for this test, which is normallybased on experience.

4.4 Additional considerations

When specifying the accuracy of a gear, there areadditional or special considerations that must bereviewed. These considerations may include itemssuch as:

-- backlash allowances in tooth thickness;

-- materials furnished by the purchaser;

-- matching gears as sets;

-- master gears for composite measurement;

-- replacement gearing;

-- modified AGMA accuracy grade;

-- center distance and backlash markings ongear and pinion;

-- record of tooth contact patterns byphotographs, transfer tapes, etc.

The listed items and other special considerations areto be reviewed and agreed upon by themanufacturerand purchaser.

4.4.1 Backlash

An individual gear does not have backlash. Back-lash is only present when one gear mates withanother. The backlash of a gear set is based on thetooth thickness of each member in mesh, as well asthe center distance at which the gears areassembled. The functional backlash is dependentupon the tolerances of tooth thickness, runout, toothgeometry, and center distance.

The methods of determining the backlash requiredfor individual applications are beyond the scope ofthis standard (for additional information see ANSI/AGMA 2002--B88).

4.4.2 Material furnished by the purchaser

When heat treating operations are required, the gearmanufacturer shall assume the responsibility for thefinal accuracy only when the material furnished is inaccordance with the agreed uponmaterial specifica-tions.

4.4.3 Matching gears as sets

Matched sets can be provided, usually at extra cost,and are required in many applications. In such acase, the purchaser must agree on the details of theadditional specifications concerning how the match-ing is to be performed and verified. Applicationsrequiring high accuracy gearingmay necessitate thematching, or modifying, of pinion and gear profilesand helix such that thematched set is satisfactory forthe application.

NOTE: This standard provides tolerances for unas-sembledgears only. The inspectionofgearingmated inan assembly for a specific application is beyond thescope of this standard. Thematching process for suchgears sold as pairs assumes greater importance thanthe individual absolute measurements.

4.4.4 Master gears for composite action tests

A master gear may be used for single flankcomposite tests. A master gear is a gear of knownaccuracy, designed specifically to mesh with thegear to be inspected for composite variation. Thedesign, accuracy, and cost of a master gear must benegotiated between the manufacturer and purchas-er. Usually, a specific master is required for eachdifferent production gear design. Providing ormanufacturing a special master gear must bescheduled to be available when the manufacturedgear is to be inspected by compositemeasurements.

4.4.5 Replacement gearing

For replacement gearing, the performance obtainedfrom the previous gearing should be evaluated. Ifsatisfactory, replace with similar material and accu-racy. If improved performance is desired, modifica-tions of material, heat treatment, and accuracy levelshould be considered. Consult with the manufactur-er for appropriate recommendations.

4.4.6 Modified AGMA accuracy grade

Conditions may require that one or more of theindividual elements or composite tolerances be of alower or higher accuracy grade than the other

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

14

tolerances. In such cases, it is possible tomodify theaccuracy grade to include an accuracy grade foreach gear element or composite tolerance.

4.4.7 Additional criteria

Gear blank dimensions supplied by the purchasermust be mutually agreed upon to permit the gearmanufacturer to hold the tolerances for the specifiedaccuracy grade. See AGMA 915--3--A99.

4.5 Acceptance criteria

The tolerances, methods, and definitions containedin this standard prevail unless contractual agree-ments between the manufacturer and purchasercontain specific exceptions.

4.5.1 Evaluation of accuracy grade

The overall accuracy grade of a gear is determinedby the largest accuracy grade number measured forany toleranced parameter specified for the gear bythis standard.

5 Application of the AGMA classificationsystem

5.1 Basis of classification system

TheAGMA classification system is an alpha numericcode which contains two items, accuracy grade andprefix. The AGMA classification number shallconsist of a prefix letter �A� identifying the tolerancesource, and an accuracy grade identifying thespecific tolerances. An example of how to establishan AGMA classification number for a given set ofconditions is presented in figure 5.

Ten accuracy grades are provided in this standard,numbered A2 through A11 in order of decreasingprecision.

5.2 Additional characteristics

In certain applications there may be additionalcharacteristics that may require tolerances in orderto assure satisfactory performance. For example, ifdimensions for tooth thickness or surface finishtolerances are desirable in order to assure satisfac-tory performance in special applications, suchdimensions and tolerances should appear on draw-ings or purchase specifications. Methods ofmeasur-ing some of these characteristics are discussed inAGMA 915--1--A02, and in the annexes.

5.3 Accuracy tolerances

The tolerances for each item that govern theaccuracy of gears are calculated by the equationsgiven in clause 7.

6 Measuring methods and practices

The measuring methods and practices for spur andhelical gears can be found in AGMA 915--1--A02.

7 Tolerance values

The tolerance values for each item that govern theaccuracy are calculated by the equations given in7.2. For convenience, some tolerance tables areprovided in annex A, and additional tables coveringall tolerances, grades, and sizes in both metric andU.S. customary units are available in the Supple-mental Tables for AGMA 2015/915--1--A02.

Tolerance source identifier

Indicates the tolerances in ANSI/AGMA 2015--1--A01. The letter Q was used todesignate tolerances from AGMA 2000--A88 and 390.03. If no letter is shown,tolerances in AGMA 390.01 or 390.02 apply. (See clauses 1 and 4.)

Accuracy grade

This integer (ranging from 2 through 11) identifies the accuracy level of the tolerances.(See clauses 6 and 7.)

Accuracygrade

Typical AGMA grade number A 5

Figure 5 -- Illustration of AGMA classification number

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

15

Values outside the limits of the equations are beyondthe scope of this standard and are not to beextrapolated. The specific tolerances for such gearsare to be agreed upon by the buyer and the seller.

7.1 Use of equations

7.1.1 Range of application

Unless otherwise stated, the range of the applicationis as per 1.1.

7.1.2 Step factor

The step factor between two consecutive grades is

2 . Values of the next higher (or lower) grade are

determined by multiplying (or dividing) by 2 . Therequired value for any accuracy grade may bedetermined by multiplying the unrounded calculated

value for grade 5 by 2A−5

where A is the numberof the required accuracy grade.

7.1.3 Rounding rules

Values calculated from the equations in 7.2 are to berounded as follows:

-- If greater than 10 micrometers, round to thenearest integer micrometer;

-- If 5.0 micrometers or greater but less than orequal to 10 micrometers, round to the nearest 0.5micrometer;

-- If less than 5.0 micrometers, round to thenearest 0.1 micrometer.

NOTE: If the measuring instrument reads in inches,values calculated from the equations in 7.2 are to beconverted to ten thousandths of an inch and thenrounded according to the rules for micrometers (i.e.,substitute the word tenths for micrometers in the rulesabove).

7.2 Tolerance equations

The single pitch deviation tolerance and total cumu-lative pitch deviation tolerance equations for diame-ters greater than 400 mm are identical to thecorresponding equations in ISO 1328--1, except inall cases, the actual values for module, diameter andface width shall be used (in all equations) rather thanthe geometrical mean values which are used togenerate the tolerance tables in ISO 1328--1. Forsmaller gears the change in tolerance as diameterdecreases is less than ISO 1328--1, with theresulting value slightly higher for a given diameter.

The equations for the single flank composite toler-ances are different from the corresponding tangen-tial composite equations in ISO 1328--1. Calculatedvalues for tooth--to--tooth single flank compositetolerance have been reduced to account for thefiltered analysis used within this standard.

7.2.1 Single pitch deviation tolerance, fptT

Single pitch deviation, fptT, is to be calculatedaccording to equation 3 or 4.

For gears with 5≤ dT ≤ 400 mm

fptT = 0.3mn+ 0.003dT+ 5.2 × 2 A−5

(3)

For gears with 400 < dT ≤ 10 000 mm

fptT = 0.3mn+ 0.12 dT + 4 × 2 A−5

(4)

where the range of application is restricted asfollows:

Accuracy grades A2 through A110.5≤ mn ≤ 505≤ z≤ 1000 or 10 000/mn whichever is less5≤ dT ≤ 10 000 mm

7.2.2 Cumulative pitch deviation tolerance,total, FpT

Total cumulative pitch deviation tolerance, FpT, is tobe calculated according to equation 5 or 6.

For gears with 5≤ dT ≤ 400 mm

FpT = 0.3mn+ 0.03dT+ 20 × 2 A−5

(5)

For gears with 400 < dT ≤ 10 000 mm

FpT = 0.3mn+ 1.25 dT + 7 × 2 A−5

(6)

where the range of application is restricted asfollows:

Accuracy grades A2 through A110.5≤ mn ≤ 505≤ z≤ 1000 or 10 000/mn whichever is less5≤ dT ≤ 10 000 mm

7.2.3 Single flank composite tolerance,tooth--to--tooth, fisT

Single flank composite tolerance, tooth--to--tooth,fisT, is to be calculated according to equation 7.

fisT = 0.03mn+ 0.003dT+ 2 × 2 A−5

(7)

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

16

where the range of application is restricted as followsif fisT is specified:

Accuracy grades A2 through A110.5≤ mn ≤ 505≤ z≤ 1000 or 10 000/mn whichever is less5≤ dT ≤ 2500 mm

7.2.4 Single flank composite tolerance,total, FisT

Single flank composite tolerance, total, FisT, is to becalculated according to equation 8.

FisT = 0.33mn+ 0.033dT+ 22 × 2 A−5

(8)

where the range of application is restricted as followsif FisT is specified:

Accuracy grades A2 through A110.5≤ mn ≤ 505≤ z≤ 1000 or 10 000/mn whichever is less5≤ dT ≤ 2500 mm

7.2.5 Profile tolerances

The range of profile tolerance application isrestricted as follows:

Accuracy grades A2 through A110.5≤ mn ≤ 505≤ z≤ 1000 or 10 000/mn whichever is less5≤ dT ≤ 10 000 mm

7.2.5.1 Profile tolerance, total, FααααT

Total profile tolerance, FαT, is to be calculatedaccording to equation 9.

FαT = 3.2 mn + 0.22 dT + 0.7 × 2 A−5

(9)

7.2.5.2 Profile slope tolerance, fHααααT

Profile slope tolerance, fHαT, is to be calculatedaccording to equation 10.

fHαT = 2 mn + 0.14 dT + 0.5 × 2

A−5

(10)

7.2.5.3 Profile form tolerance, ffααααT

Profile form tolerance, ffαT, is to be calculatedaccording to equation 11.

ffαT = 2.5 mn + 0.17 dT + 0.5 × 2

A−5

(11)

7.2.6 Helix tolerances

The range of helix tolerance application is restrictedas follows:

Accuracy grades A2 through A110.5≤ mn ≤ 505≤ z≤ 1000 or 10 000/mn whichever is less5≤ dT ≤ 4000 mm4≤ b≤ 1000 mm

7.2.6.1 Helix tolerance, total, FβT

Total helix tolerance, FβT, is to be calculatedaccording to equation 12.

FβT = 0.1 dT + 0.63 b + 4.2 × 2 A−5

(12)

7.2.6.2 Helix slope tolerance, fHβT

Helix slope tolerance, fHβT, is to be calculatedaccording to equation 13.

fHβT = 0.07 dT + 0.45 b + 3 × 2 A−5

(13)

7.2.6.3 Helix form tolerance, ffβT

Helix form tolerance, ffβT, is to be calculatedaccording to equation 14.

ffβT = 0.07 dT + 0.45 b + 3 × 2 A−5

(14)

8 Master gears

Master gears are used mainly for composite errortesting. The determining of individual deviations incylindrical gears calls for special equipment. Inaddition, the master gears can also be used forverifying gear testers.

The calibration certificates of master gears shallcontain detailed results of all the required measuredvalues, uncertainty for each measured value, andthe measurement conditions. Master gears shallconform to clause 7 tolerances, for accuracy grade2, 3 or 4.

Master gears of accuracy grade 2 are recommendedfor verifying gear testers and checking productiongears primarily of grades 4 and 5. Master gears ofgrade 3 are recommended for checking gearsprimarily of grade 6 and 7. Master gears of grade 4are recommended for checking gears of grade 8 andhigher.

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

17

Annex A(informative)

Tolerance tables

[The foreword, footnotes and annexes, if any, are provided for informational purposes only and should not beconstrued as a part of ANSI/AGMA 2015--1--A01, Accuracy Classification System -- Tangential Measurements forCylindrical Gears.]

A.1 Purpose

This annex provides a graphical presentation of thevalues for tolerances of accuracy grade 5. Thesetables are calculated from the equations in 7.2, but

should not be interpolated or extrapolated. For moredetailed tables of diameter, number of teeth andmodule, see Supplemental Tables for AGMA2015/915--1--A02.

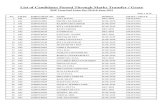

Table A.1 -- Spur and helical gear classification, single pitch deviation tolerance, fptT, grade 5Table values in micrometers

Tooth size Tolerance diameter, mmDiametralpitch

Module 100 200 300 400 600 800 1000

50.8 0.5 5.5 6.0 -- -- -- -- --25.4 1 6.0 6.0 6.5 6.5 -- -- --12.7 2 6.0 6.5 6.5 7.0 7.5 8.0 --8.5 3 6.5 6.5 7.0 7.5 8.0 8.5 8.56.4 4 6.5 7.0 7.5 7.5 8.0 8.5 9.05.1 5 7.0 7.5 7.5 8.0 8.5 9.0 9.54.2 6 7.5 7.5 8.0 8.0 8.5 9.0 9.53.6 7 7.5 8.0 8.0 8.5 9.0 9.5 103.2 8 8.0 8.0 8.5 9.0 9.5 10 102.8 9 8.0 8.5 9.0 9.0 9.5 10 102.5 10 8.5 9.0 9.0 9.5 10 10 111.7 15 10 11 11 11 11 12 121.3 20 12 12 12 12 13 13 141.0 25 -- 14 14 14 14 15 150.5 50 -- -- 21 21 22 22 23

Tolerance diameter, mm

f ptT,m

icrometers

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000

1 module20 module50 module

Figure A.1 -- Spur and helical gear classification, single pitch deviation tolerance, grade 5

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

18

Table A.2 -- Spur and helical gear classification, cumulative pitch deviation tolerance, total, FpT,grade 5

Table values in micrometers

Tooth size Tolerance diameter, mmDiametralpitch

Module 100 200 300 400 600 800 1000

50.8 0.5 23 26 -- -- -- -- --25.4 1 23 26 29 32 -- -- --12.7 2 24 27 30 33 38 43 --8.5 3 24 27 30 33 39 43 476.4 4 24 27 30 33 39 44 485.1 5 25 28 31 34 39 44 484.2 6 25 28 31 34 39 44 483.6 7 25 28 31 34 40 44 493.2 8 25 28 31 34 40 45 492.8 9 26 29 32 35 40 45 492.5 10 26 29 32 35 41 45 501.7 15 28 31 34 37 42 47 511.3 20 29 32 35 38 44 48 531.0 25 -- 34 37 40 45 50 540.5 50 -- -- 44 47 53 57 62

0

10

20

30

40

50

60

70

80

0 100 200 300 400 500 600 700 800 900 1000

Tolerance diameter, mm

FpT,m

icrometers

1 module20 module50 module

Figure A.2 -- Spur and helical gear classification, cumulative pitch deviation tolerance, total, grade 5

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

19

Table A.3 -- Spur and helical gear classification, single flank composite tolerance, tooth to tooth,fisT, grade 5

Table values in micrometers

Tooth size Tolerance diameter, mmDiametralpitch

Module 80 200 400 600 800 1000 1200 1400 1600 1800 2000

50.8 0.5 -- -- -- -- -- -- -- -- -- -- --25.4 1 2.3 2.6 3.2 -- -- -- -- -- -- -- --12.7 2 2.3 2.7 3.3 3.9 4.5 -- -- -- -- -- --8.5 3 2.3 2.7 3.3 3.9 4.5 5.0 5.5 -- -- -- --6.4 4 2.4 2.7 3.3 3.9 4.5 5.0 5.5 6.5 7.0 -- --5.1 5 2.4 2.8 3.4 4.0 4.6 5.0 6.0 6.5 7.0 7.5 8.04.2 6 2.4 2.8 3.4 4.0 4.6 5.0 6.0 6.5 7.0 7.5 8.03.6 7 2.5 2.8 3.4 4.0 4.6 5.0 6.0 6.5 7.0 7.5 8.03.2 8 2.5 2.8 3.4 4.0 4.6 5.0 6.0 6.5 7.0 7.5 8.02.8 9 2.5 2.9 3.5 4.1 4.7 5.5 6.0 6.5 7.0 7.5 8.52.5 10 2.5 2.9 3.7 4.1 4.7 5.5 6.0 6.5 7.0 7.5 8.51.7 15 2.7 3.1 3.8 4.3 4.9 5.5 6.0 6.5 7.5 8.0 8.51.3 20 2.8 3.2 3.8 4.4 5.0 5.5 6.0 7.0 7.5 8.0 8.51.0 25 -- 3.4 4.0 4.6 5.0 6.0 6.5 7.0 7.5 8.0 9.00.5 50 -- -- 4.7 5.5 6.0 6.5 7.0 7.5 8.5 9.0 9.5

0

2

4

6

8

10

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Tolerance diameter, mm

f isT,m

icrometers

1 module20 module50 module

Figure A.3 -- Spur and helical gear classification, single flank composite tolerance, tooth to tooth,grade 5

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

20

Table A.4 -- Spur and helical gear classification, single flank composite tolerance, total, FisT,grade 5

Table values in micrometers

Tooth size Tolerance diameter, mmDiametralpitch

Module 80 200 400 600 800 1000 1200 1400 1600 1800 2000

50.8 0.5 -- -- -- -- -- -- -- -- -- -- --25.4 1 25 29 36 -- -- -- -- -- -- -- --12.7 2 25 29 36 42 49 -- -- -- -- -- --8.5 3 26 30 36 43 49 56 63 -- -- -- --6.4 4 26 30 37 43 50 56 63 70 76 -- --5.1 5 26 30 37 43 50 57 63 70 76 83 904.2 6 27 31 37 44 50 57 64 70 77 83 903.6 7 27 31 38 44 51 57 64 71 77 84 903.2 8 27 31 38 44 51 58 64 71 77 84 912.8 9 28 32 38 45 51 58 65 71 78 84 912.5 10 28 32 39 45 52 58 65 72 78 85 911.7 15 30 34 40 47 53 60 67 73 80 86 931.3 20 31 35 42 48 55 62 68 75 81 88 951.0 25 -- 37 43 50 57 63 70 76 83 90 960.5 50 -- -- 52 58 65 72 78 85 91 98 105

0

20

40

60

80

100

120

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Tolerance diameter, mm

FisT,m

icrometers

1 module20 module50 module

Figure A.4 -- Spur and helical gear classification, single flank composite tolerance, total, grade 5

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

21

Annex B(informative)

Tolerance system development and comparison

[The foreword, footnotes and annexes, if any, are provided for informational purposes only and should not beconstrued as a part of ANSI/AGMA 2015--1--A01, Accuracy Classification System -- Tangential Measurements forCylindrical Gears.]

B.1 Purpose

This annex gives the reasoning leading to the spurand helical gear classification system of this stan-dard, and comparisons of pitch tolerances andcumulative pitch tolerances with other systems.

B.2 Development

The gear classification system was changed fromthe previous AGMA 2000--A88 for several reasons:

-- The nonlinear formulas and tables madeinterpolation of values within the applied rangesdifficult;

-- The tolerance trends did not relate well totypical manufacturing capabilities for very smallgears;

-- The old system was outdated for gearmanufacturer�s and customer�s applications.

The committee agreed that a new gear classificationsystem was needed: one that used more linearformulas, was easier to understand by users, andallowed for an expanded range of application (butonly with agreement between manufacturer anduser).

In addition to AGMA 2000--A88, the committeestudied the other cylindrical gear classificationsystem, ISO 1328--1:1995. It was noted that formany typical gears (100 mm to 800 mm diameterand 2 to 20 module), relatively small differencesoccurred between the classification systems. In bothsystems, the classes or grades are separated by asquare root of 2 stepping factor.

Initial investigations by the committee for ANSI/AGMA 2009--A99 (bevel gears) indicated that atolerance system in which the tolerance curves werelinear with changes in diameter may have beenappropriate. The following formulas were thendeveloped:

fptT = 0.003 dT+ 0.3 mn+ 5 × 2 A−5

(B.1)

FpT = 0.03 dT+ 0.3 mn+ 19 × 2 A−5

(B.2)

The committee then elected to adopt the toleranceformulas from ISO 1328--1 and ISO 1328--2, withmodifications for the smaller diameters. Thisassured some harmony with existing internationalstandards and eliminated the difficulties associatedwith interpolating some non--linear values fromAGMA 2000--A88.

The limits were established to set the tolerances atpoints the committee thought were valid. The singleflank tolerances are different than those given inannex A of ISO 1328--1:1995. Based on committeeexperience, the single flank tolerances shown in thisstandard are more appropriate for functional consid-erations.

After much study and discussion, the classificationsystem in this standard was agreed upon. Thesystem of classifying very accurate gears with a lownumber, instead of retaining the method of AGMA390.03, was done for two reasons:

-- The system is established internationally byISO and other standards;

-- A new labeling system was necessary todistinguish the difference of the new tolerancegrades and those of AGMA 2000--A88.

A general comparison between the new system andAGMA 2000--A88 systems may be made by sub-tracting the class or grade number of one systemfrom 17 to find an approximate class or gradenumber for the other system.

B.3 Comparison

See figures B.1 through B.18 for a comparison of thenew systemwith AGMA 2000--A88 and ISO 1328--1.Tolerance values from ISO 1328--1 are plotted asstep functions as per the standard�s tables.

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

22

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000Tolerance diameter, mm

ANSI/AGMA 2015--1--A01, A6 AGMA 2000--A88,runout, Q12

ISO 1328--1, 6

FpT,m

icrometers

Figure B.1 -- Tolerance comparison, cumulative pitch deviation, total,class Q12 and grade A6 for module 12.7

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000Tolerance diameter, mm

ANSI/AGMA 2015--1--A01, A5 AGMA 2000--A88,runout, Q12

ISO 1328--1, 5

FpT,m

icrometers

Figure B.2 -- Tolerance comparison, cumulative pitch deviation, totalclass Q12 and grade A5 for module 12.7

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

23

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A5 AGMA 2000--A88,runout, Q12

ISO 1328--1, 5Tolerance diameter, mm

FpT,m

icrometers

Figure B.3 -- Tolerance comparison, cumulative pitch deviation, total,class Q12 and grade A5 for module 6.4

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A5 AGMA 2000--A88,runout, Q12

ISO 1328--1, 5Tolerance diameter, mm

FpT,m

icrometers

Figure B.4 -- Tolerance comparison, cumulative pitch deviation, total,class Q12 and grade A5 for module 1.6

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

24

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A7 AGMA 2000--A88,runout, Q10

ISO 1328--1, 7Tolerance diameter, mm

FpT,m

icrometers

Figure B.5 -- Tolerance comparison, cumulative pitch deviation, total,class Q10 and grade A7 for module 12.7

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A7 AGMA 2000--A88,runout, Q10

ISO 1328--1, 7Tolerance diameter, mm

FpT,m

icrometers

Figure B.6 -- Tolerance comparison, cumulative pitch deviation, total,class Q10 and grade A7 for module 6.4

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

25

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A7 AGMA 2000--A88,runout, Q10

ISO 1328--1, 7Tolerance diameter, mm

FpT,m

icrometers

Figure B.7 -- Tolerance comparison, cumulative pitch deviation, total,class Q10 and grade A7 for module 1.6

0

20

40

60

80

100

120

140

160

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A8 AGMA 2000--A88,runout, Q9

ISO 1328--1, 8Tolerance diameter, mm

FpT,m

icrometers

Figure B.8 -- Tolerance comparison, cumulative pitch deviation, total,class Q9 and grade A8 for module 12.7

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

26

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A8 AGMA 2000--A88,runout, Q9

ISO 1328--1, 8

Tolerance diameter, mm

FpT,m

icrometers

Figure B.9 -- Tolerance comparison, cumulative pitch deviation, total,class Q9 and grade A8 for module 6.4

ISO 1328--1, 5ANSI/AGMA 2015--1--A01, A5 AGMA 2000--A88,pitch, Q12

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000Tolerance diameter, mm

f ptT,m

icrometers

Figure B.10 -- Tolerance comparison, allowable single pitch deviation,class Q12 and grade A5 for module 12.7

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

27

ANSI/AGMA 2015--1--A01, A5 AGMA 2000--A88,pitch, Q12

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 5

Figure B.11 -- Tolerance comparison, allowable single pitch deviation,class Q12 and grade A5 for module 6.4

ANSI/AGMA 2015--1--A01, A5 AGMA 2000--A88,pitch, Q12

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000

Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 5

Figure B.12 -- Tolerance comparison, allowable single pitch deviation,class Q12 and grade A5 for module 1.6

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

28

ANSI/AGMA 2015--1--A01, A7 AGMA 2000--A88pitch, Q10

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 7

Figure B.13 -- Tolerance comparison, allowable single pitch deviation,class Q10 and grade A7 for module 12.7

ANSI/AGMA 2015--1--A01, A7 AGMA 2000--A88pitch, Q10

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 7

Figure B.14 -- Tolerance comparison, allowable single pitch deviation,class Q10 and grade A7 for module 6.4

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

29

ANSI/AGMA 2015--1--A01, A7 AGMA 2000--A88pitch, Q10

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000

Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 7

Figure B.15 -- Tolerance comparison, allowable single pitch deviation,class Q10 and grade A7 for module 1.6

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A8 AGMA 2000--A88pitch, Q9

Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 8

Figure B.16 -- Tolerance comparison, allowable single pitch deviation,class Q9 and grade A8 for module 12.7

ANSI/AGMA 2015--1--A01 AMERICAN NATIONAL STANDARD

30

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000

ANSI/AGMA 2015--1--A01, A8 AGMA 2000--A88pitch, Q9

Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 8

Figure B.17 -- Tolerance comparison, allowable single pitch deviation,class Q9 and grade A8 for module 6.4

ANSI/AGMA 2015--1--A01, A8 AGMA 2000--A88pitch, Q9

0

5

10

15

20

25

30

35

0 100 200 300 400 500 600 700 800 900 1000Tolerance diameter, mm

f ptT,m

icrometers

ISO 1328--1, 8

Figure B.18 -- Tolerance comparison, allowable single pitch deviation,class Q9and grade A8 for module 1.6

ANSI/AGMA 2015--1--A01AMERICAN NATIONAL STANDARD

31

Annex C(informative)

Example of statistical process control (SPC) application

[The foreword, footnotes and annexes, if any, are provided for informational purposes only and should not beconstrued as a part of ANSI/AGMA 2015--1--A01, Accuracy Classification System -- Tangential Measurements forCylindrical Gears.]