ANNUAL SAFETY CONFERENCE · applications, including fire suppression, aerosol cleaning and...

Transcript of ANNUAL SAFETY CONFERENCE · applications, including fire suppression, aerosol cleaning and...

SAFER SOLVENTS THROUGHOUT INDUSTRY(EPA / OSHA Changes For Solvents Used in Manufacturing Operations)

Presented by Joe McChesney

ANNUAL SAFETY CONFERENCE

KYZEN is…

KYZEN is the leading provider of green engineered fluids and

processes for precision cleaning applications in high-reliability manufacturing environments.

Global Operations

• Metal Finishing

• Electronics

• Advanced Packaging

• Optics & Glass

Markets

State-of-the-Art Laboratories

Who is Joe McChesney?

Professional Attributes• Involved in various seminars/projects with EPA, OSHA, universities, and numerous state

organizations involving Clean Air Regulations, Clean Water Act.• Worked with EPA Triangle Park to define/establish initial air permit rules / regulations for

National Emission Standards for Hazardous Air Pollutants (NESHAP).• Holds several US patents for process/equipment design related to solvent cleaning and

recovery processes, regulated hazardous air pollutants, and waste stream management.

Honors/Awards• 1993 selected by University of Tennessee to serve on EPA/Clean Air Advisory Board• 1996 selected to serve on State of Kentucky International Trade Association Advisory

Board• Patent # 6,076,537 awarded for vacuum extraction cleaning system for solvent in a

closed vessel• Patent #7,611,564 B2 awarded in 2009 for nPB solvent recovery using a carbon

adsorption process• Patent pending – filed 2013 - for new DuoSolvent cleaning equipment to replace

banned solvents and/or existing solvents facing more strict regulations or phase out.

40 years of experience with solvent and aqueous cleaning processes from conceptual design through field operation.

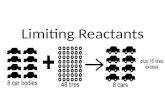

Cleaning Basics

In today’s manufacturing world most items are cleaned! (Several Times in Some Cases)

• Critical Performance

• Reliability

• Process Requirements

• Personnel Safety

“Soils/contaminants/etc. must be removed!”

• Cleaning Performance

• Compatibility With Substrates

• Process Efficiency

• Environmental Impact

• Worker Safety (EH&S)

Cleaning Process Requirements

Cleaning Overview• Increased demands for QUALITY &

RELIABILITY calls for continuous improvements in many manufacturing processes, including cleaning.

• End product must meet specifications to assure success of operations.

• Cleaning methods must meet EH&S concerns as well as “get the job done!”

Cleaning Process

Cleaning Synergy Soils

Heat Exposure

Part Geometry

Agent

Cleaning Equipment

Energy

Cleaning Factors • Simple water flush (rare in manufacturing world!)

• Aqueous chemical agents: Alkaline “pH” Neutral Acid

• Solvents Chlorines / bromines / fluoro-chemicals Alcohols / modified alcohols and Hydrocarbons

• Thermal

• Cleanliness specifications for precision and critical cleaning requires no contaminant or rinse water residue on the end product.

• Solvent usage is continually growingdue to inability of water to perform in certain criteria, component spacing, and restrictive drying process.

• Materials compatibility is a major area for concern where solvent is superior! (Example: Multiple metals and lubes).

Why Solvents?

• Multi-metals compatibility

• Multiple elastomers compatibility

• Multiple lubes removal compatibility

• Ease of application

• Assured drying

• Residue free cleaning

• Energy saving

Solvent Advantages

Choosing Solvent vs. Aqueous

• End-user confidence of cleaning results

• In some cases, one process is generally perceived or proven as superior

This is also why the government recognized the need for solvent cleaning and enacted

certain laws to preserve this process until a better method is discovered.

Choosing Solvent vs. Aqueous

• Favorable environmental properties

• Operational temperature (lower = less energy consumed)

• Global Warming Potential Rating(lower = less global warming effect)

• Surface tension (wettability)(lower=better penetration/fast drying)

• Personnel Exposure Limits (OSHA)(higher = safer products, safer workplace)

New vs. Older Solvents

Users today are evaluating these new options in order to

provide a safer workplace.

New vs. Older Solvents • The main difference is environmental and health

characteristics of the solvent being used!

• Most solvents (old and new) can clean, that is what they do. However a lot of solvents are being phased out or becoming more regulated in terms of personnel exposure limits and air emissions.

BE SAFE – YOU HAVE A RIGHT TO KNOW!

HAZARD COMMUNICATION STANDARDS (HCS) is OSHA’s way of ensuring safety to employees who potentially come in contact with hazardous chemicals.

Using Solvents?

Those who manufacture or import chemicals must assess their hazards, as well as create labels and [provide you with safety data sheets (SDS) to inform their customers of the potential DANGERS!

Where Can I find more Information?

Employers MUST Provide a Safe and Hazard Free

Workplace !

• Environmental and Ecology

• EPA / OSHA /ACGIH Compliance

• VOC Content

• Global Warming Potential (Greenhouse Effect)

• Carbon Footprint (Energy Consumed)

BIG “E” Concerns

Gone and Going Solvent List!

AK225…………..GONE!

nPB (toxic concerns)….Going Fast!

TCE (toxic concerns)……Going Fast!

HFCs – use “unacceptable by EPA”

• Recently, the U.S. DoD, GSA and NASA issued a final rule amending the Federal Acquisition Regulation (FAR) to implement the President’s Climate Action Plan.

• Final rule impacts high GWP HFCs used in many common applications, including fire suppression, aerosol cleaning and precision cleaning.

• The United States is making substantial progress in limiting use and reducing emissions of high global warming potential (GWP) hydrofluorocarbons (HFCs). The U.S. Environmental Protection Agency (EPA) recently changed the status of HFCs to “unacceptable” for certain uses under its Significant New Alternatives Policy (SNAP).

HFC deemed “Unacceptable” By EPA!

ENVIRONMENTAL NEWS ALERT: Nov. 2, 2016 - TCE: “Known Human Carcinogen”

(Abbreviated from: CHEMICAL REGULATION REPORTER)IT’S OFFICIAL: TRICHLOROETHYLENE (TCE), a chlorinated solvent will be listed as a “known human carcinogen” to be published in Federal Report on Carcinogens – Nov 3, 2016.

The Dept. of Health and Human Services, which issues the report, upgraded trichloroethylene (TCE) from a “reasonably anticipated to be” to a “known human carcinogen.”

The U.S. Environmental Protection Agency (EPA) is proposing 2 rules that would restrict the use of TCE.1. First rule would restrict, ban, or otherwise address health risks identified with

commercial vapor degreasing operations.2. Second rule would address health risks with dry cleaning & aerosol spray

degreasers.3. More info: National Toxicology Program Nov 3 Federal Register Notice

SEPT 11, 2017 –NIOSH Adds 9 Chemicals To Skin Notation Profiles (Abbreviated from: EHS TODAY)

“Because of the significent risk of chemicals in the workplace, niosh has published new skin notation profiles to alert workers and employers to the health risk of skin exposure to chemicals in the workplace.”

These profiles are meant to better protect workers from the risks of skin contact with the chemicals of interest.

Two (2) of the 9 are:

1-BROMOPROPANE (nPB)

TRICHLOROETHYLENE (TCE)

ENVIRONMENTAL NEWS ALERT:

1992 1994 1996 2003 2015 2016 ?

SOLVENTS Timeline of EPA Phase-outs

CFC-113 nPBTCE

HCFC 225

Montreal Protocol

HFC Final RuleSolvay 365

Vertrel 4310

HCFC 141B1-1-1 Tri

OSHA Occupational Exposure Limits EHS – Characteristics and Concerns

100 100 0.1

800

100

200

100

200

800

PERC TCE NPB HFE AK225 HFC-4310 HFC-365 TRANS BLEND HFO

PEL based on 8 hours TWA

Perm

issib

leEx

posu

re L

imits

(PEL

)

Higher allowable ppm levels = User preferred levels

AC

GIH

reco

mm

enda

tions

TOXIC !!!

Ban

ned

by th

e fe

dera

l gov

ernm

ent

• The increased volumes of carbon dioxide and other greenhouse gases released by the burning of fossil fuels, land clearing, agriculture, and other human activities, are believed to be the primary sources of the global warming that has occurred over the past 50 years. * Life Science article

GLOBAL WARMING ALERT !

Perc TCE nPB HFE AK225 HFC-4310 HFC-365 Trans Blend HFOSeries 1 800 140 0.31 320 370 1500 890 148 1

800

140

0.31

320370

1500

890

148

1

GLOBAL WARMING POTENTIAL (GWP)

Ban

ned

by th

e fe

dera

l go

vern

men

t

Lower = less global warming effect

Boiling Point = Energy Consumption (Carbon Footprint Contributor)

250

188

160142

130 130105 110

66

Perc TCE nPB HFE AK225 HFC-4310 HFC-365 Trans Blend HFO

Ban

ned

by th

e fe

dera

l go

vern

men

t

A carbon footprint is defined as: The total amount of greenhouse gases produced to directly and indirectly support human activities, usually expressed

in equivalent tons of carbon dioxide (CO2).

Boiling temperature in ⁰F

Lower Boiling Point = Less Energy Consumed

Emerging Solvents

HFO – (M6920)

SCAQMD ApprovedNASA Approved

CC

CF3

H

H

Cl

Environmental

VOC exempt by EPA and SCAQMDGWP =1 (100-year ITH)

High Degree of SolvencySurface tension 12.7 dynes/cm

• Excellent Metal and plastic compatibility

• No stabilizers required –no monitoring

Performance

Stability/Compatibility

Hydrofluoro-OlefinTechnology

Key BenefitsGREEN VOC Exempt Low Global Warming Potential (1) Low Carbon Footprint (low energy consumption) Superior solvency @ low temps

Safe Highest Exposure Limits (OEL/PEL) @ 800ppm Non-flammable Pure molecule – no additives SCAQMD APPROVED ! NASA APPROVED !

HFO SOLVENTVapor Degreasing / Cold Cleaning

Emerging Solvents

Modified AlcoholRefined Hydrocarbon

No Chlorine or Bromine or Fluorine

Key Benefits– Better Cleaning

• Low Surface Tension• Continuous Removal of Contaminants• Polar and Non-Polar Soils

– Lower Operating Costs• Lower Energy and Chemical Consumption• Stability

– Green• Zero Emissions Under Vacuum Operation

– Safe• TOTAL ENCLOSURE = Reduces Human Exposure

Modified AlcoholVacuum Vapor Degreasing

Key Benefits– Better Cleaning

• Heavy soil loading removal (oils / greases / waxes)• Continuous Removal of Contaminants (Non-Polar only)• Low surface tension

– Lower Operating Costs• Low Chemical Consumption• Stability

– Green• Zero Emissions Under Vacuum Operation

– Safe• TOTAL ENCLOSURE = Reduces Human Exposure

HYDROCARBONsVacuum Vapor Degreasing

Emerging SOLVENT ProcessVacuum Degreasing Systems

Rating Based On: Highest PEL Limits for Personnel Safety Lowest Global Warming Potential Lowest Surface Tension VOC FREE or Very Low Rating Non-flammable Carbon Footprint Contribution Operation Temperature Multi-metals / Lubes Compatibility Rapid Drying – Generally Residue Free Stability

Highest Rated New Solvents

• HFOs• MODIFIED ALCOHOLS• REFINED HYDROCARBONS

Note: Each of These Solvents Have Different Characteristics That Need To Be Reviewed To Meet Your Specific Applications and Process Specifications.

These GREEN SOLVENTS currently comply with regulations and are being used across the

WORLD!

Recommended New Solvents(No Particular Order)

• Today’s new solvent’s are replacing the older generation at a fairly rapid pace.

• WHY? Mostly EH&S Conditions (Corporate and Gov)

• Some due to compatibility of new components.

• Progress in new degreasing systems that: use considerable less solvent generate very low emissions to the atmosphere isolate the operator from process usually incorporate automation for process control

Sustainable Development For The Future

• Move to Environmentally GREEN CLEANING Processes Move away from PERC, TCE, nPB, HFCs, and flammables Move away from Water-based cleaning due to residue/drying,

water consumption, energy required, discharge and emissions restrictions

Move toward Closed Vacuum Systems – New Solvents• Key Benefits

Low emissions Low chemical consumption and waste Less energy consumed Compact foot print (wash/rinse/dry @ one system) Concentration of soil (Not throwing away cleaning chemistry)

Low VOC emissions Low worker exposure (Safety Plus) Non-flammability

SOLVENT Market Trends

• The old adage that solvent cleans better, faster, and in more restrictive places than water can ever reach - is still true!

• The fact that today’s cleanliness specifications for precision and critical cleaning cannot have any contaminant residue or rinse water residue on the end product… still drives some users toward solvent.

WHY SOLVENT?

Summary• Today’s new solvents are developed for maximum cleaning

performance.• They provide lower GWP, carbon footprint, and energy

consumption.• Feature highest worker safety ratings !!!!!• Approved by U.S. Government and other organizations.

• There is an abundance of information available in today’s world to consider the best cleaning method to suit your needs.

• From government resources, environmental organizations, equipment suppliers, chemical suppliers, to technical papers and consultants.

• There are companies that will perform cleaning analysis of your parts using a specific process to verify the results before you make a commitment. Most are free!

• Use these resources to supplement your decision.

Get Informed!

Strategic Alliances

• Trade Associations such as PMA

• Customers

• Distributors & Representatives

• Contaminant Vendors

• Cleaning Equipment Manufacturers

• Enablers of Technology

Thank You/QuestionsFor more information, contact:Joe McChesney KYZEN Global Products Line Manager, SolventsEmail: [email protected]: 615-831-0888