Angela Sparks Resume 2-2016

-

Upload

angela-sparks -

Category

Documents

-

view

82 -

download

0

Transcript of Angela Sparks Resume 2-2016

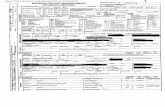

A N G E L A S P A R K S5 6 1 P E R E G R I N E C I R C L E , L O N G M O N T , C O 8 0 5 0 4

P H O N E 3 0 3 - 9 4 9 - 0 7 2 3 • E - M A I L S P A R K S A N G E L A @ L I V E . C O M

SUMMARY OF QUALIFICATIONS Senior Optical Engineer: Subcontract Procurement Administration,

Optical Analysis, Hardware Support Hardware Quality Engineer: Requirement Verification, Root

Cause/Corrective Action Management, Hardware Inspection Security Clearances: SCI Top Secret and DOD Secret

EDUCATIONBS in Physics, Minor in Engineering

PROFESSIONAL EXPERIENCEBall Aerospace & Technologies Corp. -- Boulder, CO

December 1997-Present

Integration and Test Lead for fast moving, multi-build optical bench- Developing and maintaining test procedures and schedules, managing

personnel and hardware resources Hardware Quality Engineer for Detector Technology Center

- Cross functional management of root cause and corrective actions, optical and focal plane assembly specific vendor source inspection, vendor development

Manager for multimillion dollar IR blackbody assembly procurement- Specified optical component and sub-assembly requirements including

Statement of Work, Product Specification, and Component Drawings. Procurement lead and point of contact for suppliers to track and maintain cost, schedule, and risk. Worked with cross-functional internal and external teams to build and verify flight assemblies including component integration and test procedure development resulting in requirement validation and verification. Ensured compliance to requirements and negotiate deviations. Worked with vendor and internal teams to resolve deficiencies resulting in root cause and corrective action plans. Daily and weekly reporting of progress to upper level management.

- Guided vendor in development of flight cleanliness standards, flight part control, component and assembly performance testing, and facility upgrades including M&P concerns.

- Successfully presented design development and vendor progress to government customers at the Critical Design Review.

Optical department functional lead - Quarterly reviews for lower level staff including comprehensive

interviews with fellow team members on the employee’s performance, knowledge, and work ethic.

- Presentation of reviews to employees with focus on performance and career development.

Optical test conductor and procedure author for multi-spectral Operational Land Imaging (OLI) instrument- Co-authored Focal Plane Alignment, Wavefront Error, Polarization, and

Spectral Flight Test Procedures.

- Performed lead test conductor activities including management and execution of flight performance testing, maintaining test paperwork, and reporting to next level assembly.

- Worked with multi-disciplinary engineering team: Quality Assurance, Systems, Mechanical, M&P engineering, and NASA customers.

Technical lead for flight procurement and mechanical integration of the field flattener lenses on the NASA Discovery Mission Kepler Photometer- Interfaced with vendor to ensure compliance with specifications,

worked to resolve issues of conflict or uncertainty, and tracked vendor schedule performance.

- Performed optical source inspections at the vendor for optical substrate and coating requirements.

- Coordinated with a cross-functional team: mechanical engineering, M&P engineering, systems engineering, quality assurance, production engineering, procurement, and optical resources in order to receive, inspect, and test the field flattener lenses.

- Led and coordinated final cleaning, mechanical assembly bonding, inspection, and performance testing of all lens assemblies in preparation for integration with focal plane CCD modules and final delivery to the focal plane array assembly Integrated Product Team.

- Led Material Review Board activities pertaining to discrepancies with the field flattener lenses – with both internal and external customer reviewers.

- Supported Failure Review Board activities with specific emphasis on optical bond failures with resolution ending in improved optical cleaning processes and bonding techniques which were implemented company wide.

- Part of large optic (> 1 meter diameter) bonding team, personally responsible for procedure development, execution, and test.

Optical Analyst developing and maintaining detailed tolerance analysis for Kepler subsystems and components- Supported optical design, optical simulation and performance

characterization. Also worked with mechanical, structural, systems, M&P, and quality engineers to resolve issues and develop a working tolerance budget that met optical, mechanical, and system needs.

- Performed tolerance analysis, flowed down requirements and provided specifications to vendors for entire optical train including 1.4 meter mirror, 0.95 meter lens, and 25 field flattener lenses.

- Modified optical design files and documented “as-built” telescope system and test configurations.

Kepler optical specification author. Documentation QA for Shuttle Tracker specializing in end-item-data

packages and production certification logs. Calipso Optical Component Lead

- Responsible for optical path performance and tolerance analyses, specification generation, procurement, vendor supervision, receiving and inspection.

- Supervised bonding of all the optics for the Calipso optical bench and beam expander optics.

- Responsible for design, performance, and tolerancing of the beam expander optics.

OMPS Optical Performance and Tolerance Analyst- Supported the build-up and testing of the breadboard spectrometer.

- Analyzed the optical systems including thermal, alignment, and fabrication tolerancing and system performance.

- Developed component specifications.- Maintained significant vendor interaction.

CERTIFICATIONS AND SOFTWARE Test Conductor ESD Cleanroom Beryllium Handling Laser Safety Hazardous Waste Management CODEV Optical Design and Analysis Microsoft Office Suite including Word, Excel, Project, and Visio SharePoint, Velocity, and AGILE software