Anergy Thermograhy Solutions

-

Upload

ruwan-wijemanne -

Category

Documents

-

view

4 -

download

0

description

Transcript of Anergy Thermograhy Solutions

7/18/2019 Anergy Thermograhy Solutions

http://slidepdf.com/reader/full/anergy-thermograhy-solutions 1/3

THERMOGRAPHY

Dare you imagine a failure of a component to interrupt the whole electrical distribution

system? Can you afford the downtime of your critical machines?

If you say "no" to the above questions, you definitely need infrared thermography

electrical inspection service. Infrared thermography electrical inspection is a new preventive

maintenance service offered by us. It is considered as the most effective way to maintain an

electrical system. The aim to promote uninterrupted system operation, extend the service life of

equipment as well as prevent damage to property and personal injuries is the concept behind

this inspection.

Introduction

Thermography is a method of inspecting electrical and mechanical equipment by

obtaining heat distribution pictures. This inspection method is based on the fact that most

components in a system show an increase in temperature when malfunctioning. The increase

in temperature in an electrical circuit could be due to loose connections or a worn bearing in

the case of mechanical equipment. By observing the heat patterns in operational system

components, faults can be located and their seriousness evaluated.

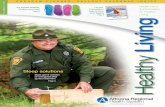

What you see, What themographer See,.

Thermography test

Maximize Safety Efficiency Availability Performance

Minimize Risk Losses Breakdowns

Applications

ot Spot: There may be a looseconnection, phaseunbalance or an overloading. Need tocheck with clip-onmeter, Immediate

7/18/2019 Anergy Thermograhy Solutions

http://slidepdf.com/reader/full/anergy-thermograhy-solutions 2/3

Electrical

Most electrical problems are manifested or are

accompanied by temperature changes. Infrared

thermography inspection is done with an infrared

camera to provide an infrared thermography of the

energy emitted by the electrical components which

otherwise is not visible to the human eyes.

Following appliances are critical components in

electrical system to be checked annually,

Transformers

Circuit breakers

Bus bars

Switchgear

Fuses

Relays

Insulators

Capacitors

A comprehensive scanning of suspected hot spots that might be overlooked by visual inspections

and traditional inspection by pointer thermometer

Verify whether the electrical connections are properly made and maintained.

Interpret the images acquired to determine equipment condition and the possible causes of

temperature deviations.

A clear and concise report to illustrate all the problem areas found, including load

readings, live and thermal images.

Recommendations to rectify the problems and suggestions of your maintenance schedule

The inspection will be carried out while the electrical

system is under load and can be performed at any

time without shutting down the facilities. Therefore, no

disruption to the normal operative routine will be

made.

Rotating Mechanics

7/18/2019 Anergy Thermograhy Solutions

http://slidepdf.com/reader/full/anergy-thermograhy-solutions 3/3

Failures of continuous rotating mechanisms can be identified by a thermography test

prior to the severe breakdown

which will damage to the entire

process.

Bearings

Gears

Drive Belts

Couplings

Shafts

Pumps

Other Thermal Applications

Electric Arc FurnacesLadles

Heat Treatment Furnaces

Glass Furnaces

Rotary Kilns

Dryers

Building

Damaged, missing or wet insulation costs money,

this money is spent on the extra energy needed to heator cool your buildings, without insulation heat can escape

quicker than it would to if insulation was there. Damaged

insulation through damp or roof leaks can speed up the

thermal conduction process by providing a highly

conductive path for cool to escape.

Building thermal imaging has been successfully

used in the finding missing or damaged insulation in

domestic buildings and commercial, this information can be

used to tackle heat loss problems head on saving moneyby only treating the areas you have problems with..