Ancient Food Technology (Technology and Change in History)(Gnv64)

Click here to load reader

-

Upload

jorge-dillon -

Category

Documents

-

view

383 -

download

79

Transcript of Ancient Food Technology (Technology and Change in History)(Gnv64)

TECHNOLOGY AND CHANGE IN HISTORY

Ancient Food TechnologyRobet I. Curtis

BRILL

S ( ) R ( ) R I

ANCIENT FOOD TECHNOLOGY

B Y

ROBERT I. CURTIS

' י 8 6 / '

BRILL L E I D E N · B O S T O N · K Ö L N

2001

This 1)(1e)k is printed on acid-free paper.

L i b r a r y o f C o n g r e s s C a t a l o g i n g - i n - P u b l i c a t i o n D a t a

T h e Library of Congress Cataloging-in-Publication Data is also available.

D i e D e u t s c h e B i b l i o t h e k - C I P - E i n h e i t s a u f n a h m e

C u r t i s , R o b e r t I.s Anc ient food technology / by Robert I. Curtis. Leiden ; Boston ; Köln : Brill, 2001

(Technology and change in history ; Vol. 5) ISBN 90 0 1 09681 7

ISSN 1385-920X ISBN 90 04 0 9 6 8 1 7

© Copyright '2001 by Koninklijke Brill .NV, Leiden, The Netherlands

All rights reserved. .No /)art of this publication may be reproduced, translated, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior written

permission from the publisher.

Authorization to photocopy items for internal or personal use is granted by Brill provided that

!lie appropriate fees are paid directly to The Copyright Clearance Center, '222 Rosewood Drive. Suite 910

DanversMA 01923, USA. Fees are subject to change.

I'RINTKl) IN ΙΊΙΙ M.Hn.KI.AM)S

TABLE O F C O N T E N T S

List of Abbreviations xi List of Figures xiii List of Plates xv List of Maps xvii Acknowledgements xix Foreword xxiii

PART O N E

P R E H I S T O R Y

Chapter One: Lower and Middle Paleolithic Periods 3 A. Hominids and Their Tools 4 B. Early Hominid Subsistence Strategies 20 C. Hominid Intelligence 32

Chapter Two: Upper Paleolithic and Neolithic Periods 35 A. Upper Paleolithic Period 35 B. Last Glacial Maximum 48 C. Epipaleolithic Period and the Rise of Agriculture 57 D. Neolithic Period 65

1. Southwest Asia 65 2. Europe 74 3. Egypt 77

Summary and Conclusions to Part One 81

PAR T T W O

EGYPT AND T H E N E A R EAST

Chapter Three: Egypt 1 93 A. Cereal Processing 99

1. Storage 99 2. Bread and Beer 105

TABLE OF CON TENTS VI11

a. Milling 114 b. Bread Making 117 c. Beer Production 131

Chapter Four: Egypt II 142 B. Wine 142 C. Oil 164 D. Animal Processing 165

1. Butchery 165 2. Dairy Products 173 3. Fish 173

E. Sweeteners 176

Chapter Five: T h e Ancient Near East 178 A. Prehistoric Period 180

1. Cereal Processing 183 2. Wine 184 3. Oil 187

B. Historic Period 189 1. Food Technology and the Rise of the State 190 2. Cereal Processing 195

a. Storage 195 b. Milling 199 c. Bread Making 205 d. Beer Production 210

3. Wine 219 4. Oil 226 5. Animal Processing 233

a. Butchery 233 b. Dairy Products 234 c. Fish 238

6. Sweeteners 240

Summary and Conclusions to Part Two 243

TABLE OF CONTENTS IX

P A R T T H R E E

M E D I T E R R A N E A N C I V I L I Z A T I O N S

Chapter Six: The Greek World: Bronze Age Through the Hellenistic Period 259

A. Bronze Age 259 1. Cereals 260 2. Wine and Olive Oil 267 3. Miscellaneous Processes 274

B. Classical and Hellenistic Periods 275 1. Cereal Processing 276

a. Storage 276 b. Milling 279 c. Bread Making 289 d. Beer Production 294

4. Wine 294 5. Olive 303 6. Animal Processing 313

a. Butchery 313 b. Dairy Products 315 c. Fish 316

7. Sweeteners 322

Chapter Seven: Rome I 323 A. Cereal Processing 325

1. Storage 325 2. Milling 335 3. Bread Making 358 4. Beer Production 370

B. Wine 372 C. Oil 380

Chapter Eight: Rome II 395 1). Animal Processing 395

1. Butchery 395 2. Dairy Products 399 3. Fish 402

E. Sweeteners 417 F. Refrigeration 419 ο

Summary and Conclusions to Part Three 420

Select Bibliography 435

Index 467

Plates

LIS׳!' O F ABBREVIATIONS

Abbreviations of modern works follow those listed either in the most recent issue of L'Année Philologique, or in the American Journal of Archaeology 95, no. 1 (Jan. 1991). In general, abbreviations of ancient Greek and Roman authors conform to those listed in the Oxford Classical Dictionary, 3r<l edition (Oxford: Oxford Universi-ty Press, 1998). Abbreviations of papyri and ostraca conform to those listed in Checklist of Editions of Greek Papyri and Ostraca. Supplement No. 4 of Bulletin of the American Society of Papyrologists. J ohn F. Oates, Roger S. Bagnall, William H. Willis, and K. A. Worp, eds. 3,{l ed. (Atlanta: Scholars Press, 1985). Attention is particularly drawn to the following:

The African Archaeological Review American Journal ()) Physical Anthropology American Anthropologist Ancient Near Eastern Texts Relating to the Old Testament. James B. Pritchard, ed. 3rd ed. Princeton, N . J . : Princeton University Press, 1969. L'Année Epigraphique Annual Review of Anthropology A rchaeological Review from Cambridge Biblical A rchaeologist Bulletin of Sumerian Agriculture Cambridge Ancient History Dictionnaire des antiquités grecques et romaines. C. Daremberg and FI Saglio, eds. 10 Vols. Paris: Hachette, 1877 1918. John M. Edmonds, ed., The Fragments of Attic Comedy. 4 Vols. Leiden: E.J. Brill, 1957-1961. Human Evolution Inscriptiones Graecae Ad Res Romanas Pertinentes. René Cagnat et al, eds. 4 Vols. Paris: E. Leroux, 1911-27.

Journal of Anthropological Research Journal of A rchaeological Research Journal of Archaeological Science Journal of Cuneiform Studies

Afr Archaeol Rev AJPA AmerAnthr A N E T

L'AnnEp. AnnRAnthr Archaeol RevCamb BiblArch BullSumAgri CAM Dar.-Sag.

Edmonds

H um Ε vol IG R R

JAnthrRes J Arch Res JArchSci J O S

I.IST OF ABBREVIATIONS

Journal of Human Evolution Journal of World Prehistory Lexikon der Ägyptologie. Wolfgang Helck, Eberhard Otto, and Wolfhart Westendorf, eds. 6 Vols. Wiesbaden: Ot to Harrassowitz, 1975— 1986. Mitteilungen des Deutschen Archäologischen Instituts. (A=Athenische Abteilung; B=Baghdader Abteiling; I=Istanbuler Abteilung; Κ=Kai ro Abteilung; M=Madr ide r Abteilung; R=Römische Abteilung) Realencyclopädie der classischen Altertumswissenschaft. A. Pauly, G. Wissowa, and W. Kroll, eds. Stuttgart: J . B. Metzler, 1894-1980. Review of Paleobotany and Paly no logy Reallexikon der Assyriologie und vorderasiatischen Archäologie. Berlin: W. de Gruyter & Co., 1928 . M. I. Rostovtzeff, The Social and Economic History of the Hellenistic World. 3 Vols. Oxford: Oxford University Press, 1941. /

x i i

JHumEvol JWorld Prehist LÄ

M D AI

R E

RevPalaeobotPalynology RIA

S E H H W

LIST O F F I G U R E S

1. Cladogram of hominid evolution, with associated tool kits 12 2. Oldowan Tools 13 3. Acheulian Tools 16 4. Mousterian Tools 38 5. Final Perigordian tools (blade and bone) 39 6. Egyptian domed granaries 102 7. Hieroglyphic symbols associated with food technology 109 8. Fifth-Dynasty T o m b of Rec-em-Kuy, at Saqqara 113 9. Bakery-Brewery model from Twelfth-Dynasty T o m b of Meket-re, al

Thebes 126 10. T o m b of Rameses III 128 11. T o m b o f N a k h t 152 12. Egyptian wall paintings showing grape treading and pressing with bag

press 155 13. Bag press in frame 159 14. Assyrian camp 204 15. Sumerograms for kaš, šim, and ninda 206 16. Lcver-and-weight press from Ekron, Israel 230 17. Milking frieze from Temple of Ninhursag, at Ubaid 236 18. Cretan Hieroglyphic Form 116, for wine 268 19. Megarian Bowl, from Thebes 283 20. Hopper mill, from Olynthus 285 21. Archaic bakery model 292 22. Hero's weight-and-drum press, according to Drachmann 312 23. North granary in Roman fort at Housesteads 332 24. Morgantina and Pompeian rotary mills 342 25. Pompeian rotary donkey mill 346 26. Barberai water mill 354 27. Gearing for water mill 356 28. Relief from the T o m b of Eurysaces 359 29. Kneadinsr machine 364 30. Miliarium, from Stabiae 375 31. Trapetum, from Pompeii 383 32. Wedge press, from Herculaneum 386 33. Cato's lever-and-drum press 387

LIST OF FIGURES XIV

34. Composite drawing of Tripolitanian oil press 389 35. Pliny's second lever-and-screw press, according to Drachmann . . . 392

LIST O F PLATES

1. Limestone mortars and pestle, from VVadi Kubbaniya 2. Quern and rubber, from Wadi Kubbaniya 3. Basalt mortar and pestle, from Jericho 4. Fifth-Dynasty granary models, from Giza 5. Reed and rush sieve, from Lisht 6. Fifth-Dynasty servant statue of woman grinding grain, from Giza 7. Bakery-brewery model from Twelfth-Dynasty T o m b of Meket-re, from

Thebes 8. Bread loaves from Eleventh-Dynasty tomb, from Thebes 9. Fifth-Dynasty servant statue of man baking bread, from Giza

10. Relief of royal kitchen, from Amarna 1 1. Sixth-Dynasty servant statue of a "Brewer," from Giza 12. Eleventh-Dynasty servant statues of men making beer, from Deir el-

Bersheh 13. Sixth-Dynasty beer vat, from Giza 14. Eighteenth-Dynasty stela of Syrian drinking beer with siphon, from

Amarna 15. VVine amphorae from Tomb, of Tutankhamun 16. Model of butcher's shop from T o m b of Meket-re, from Thebes 17. Saddle quern and rubber, from Jericho 18. Neo-Babylonian cuneiform tablet discussing brewing techniques 19. Impression of banquet scene on Early Dynastic 111 cylinder seal 20. Granary model from Geometric II tomb, from Athens 21. Hopper-rubbers, from Olynthus 22. Black-figure vase showing satyrs treading grapes, from Athens 23. Black-figure vase showing two men operating oil press, from Athens 24. Stone-spouted press bed, from Olynthus 25. Salt-fish (.salsamentum), from Corinth 26. Roman rotary handmill from Roman fort at Chesters 27. Pompeian rotary donkey mills from bakery (Reg. VII.ii.22) in Pompeii 28. Funerary relief of P. Nonius Zethus, from Ostia 29. Barbegal water mill 30. Sarcophagus of M. Annius Octavius Valerianus 31. Kneading machine from bakery at Reg. VII.ii.22 in Pompeii 32. Roman relief showing grape treading, from Rome

LIST OF PLATES XVI

33. Roman relief showing the boiling of musturn to make defrutum 34. Roman rotary crushing basin (trapetum), from Boscoreale 35. Reconstructed lever-and-drum press in Villa of the Mysteries, near

Pompeii 36. Relief of butcher shop, f rom Ostia 37. Altar of Atimetus, from Rome 38. Cheese press from Roman fort at Balmuildy, on Antonine Wall, Scotland 39. Late fourth-century A. D. salting vats at Santa Pola, Spain

LIST O F MAPS

1. East and South Africa 5

2. Europe and Southwest Asia 37

3. Egypt and Southwest Asia 96

4. Ancient Near East 179

5. Eastern Mediterranean 261

6. Western Roman Empire 324

AC K N ( )WLEI )GEX I EN1 ׳ S

An author must inevitably assume full responsibility for his work, but the final product is always more than just the result of his efforts alone. I gladly and with-out reservation acknowledge the assistance of numerous individuals and institu-dons without whose support this book would neither have been finished nor would have attained what value readers may judge to reside in it. When acknowledging one's debt to those who have contributed in one way or another, an author invariably runs the risk of omitting someone deserving of mention. Should there be any in this category, I hereby warmly thank them and apologize for the unintended omission. Many individuals and institutions provided timely and valuable assistance. Some offered advice and suggestions, freely given, and received by me with much appreciation, even if not always followed. Others gave encouragement not only at the beginning when the project was first under-taken but, most importantly, throughout the period of research and writing when at times my energy and spirits flagged. And still others, in a spirit of pro-fessional collegiality, materially assisted in obtaining illustrations and permis-sions to publish them. All in their own way significantly contributed to the final product; none but myself, however, is accountable for it. T o all I concede a tremendous debt of gratitude and offer my sincere thanks in hopes that the book in its final form to some degree finds favor with them.

I would like to thank Ervan Garrison, Elizabeth Kann, Ja red Klein, Dan Robie, and Gay Robins, who read portions of the book in manuscript, thereby saving me from mistakes of commission and omission, keeping me focused on the topic at hand, and providing guidance and timely suggestions on where the book might be improved. Where imperfections of any kind remain, the fault lies where it should, with the author. Other individuals were instrumental in provid-ing a visual component to the book. These include Lindsay Allason-Jones, Francesco Buranelli, Richard Fazzini, Robert Foley, Seymour Gitin, Sue Hutchison, Lawrence Keppie, David Mattingly, Mark J. Meister, Georgina Plowright, Scott Sanders, Guy Sanders, Stacey H. Savatsky, Bettina Schmitz,

Joan Tucker, Fred Wendorf, Brandon Wester, Donald White, and Larry Zim-merman. I would especially like to thank Catharine Roehrig, who during my visit to the Department of Egyptian Antiquities in the Metropolitan Museum of Art, in New York, gave of her time and expertise in assisting my research, mak-ing the trip a memorable and successful one. T o Susan Morris and the staff of the Interlibrary Loan Office of the University of Georgia Libraries, I extend a

A( :Κ NOW I ,ED Ci Ε M ENTS XX

warm note of thanks for their skill and professionalism in tracking down many and obscure books and articles. Among those whose conversation on specific aspects of ancient food technology or linguistic matters always provided grist for the mill, I particularly wish to recognize my colleagues Bob Harris, Ja red Klein, and Benedict Lowe. I would specifically like to thank Julian Deahl, Senior Acquisitions Editor, at Brill Academic Publishers, for his encouragement throughout the writing of this book, his sympathetic understanding in periods of personal crisis for the author, which intervened to slow progress on the book, and for his seemingly eternal patience.

Many institutions graciously provided photographs and line drawings and permissions to publish them, often with nominal or no charge at all. These include Ägyptisches Museum of the Staatliche Museen zu Berlin; the American School of Classical Studies in Athens, both the Agora and Corinth Excavations; the Archaeological Institute of America; Ashmolean Museum, Oxford; British Museum; Brooklyn Museum of Art; Michael C. Carlos Museum of Emory Uni-versity; Centre Camille Ju l l i an-CNRS; Direzione Generale Musei Vaticani; English Heritage; Griffith Institute, Ashmolean Museum; Hargrett Collection of the University of Georgia; Hunter ian Museum of the University of Glasgow;

Jona than P. Rosen Collection, New York; Metropolitan Museum, New York, both the Egyptian and Ancient Near Eastern Collections; Museum of Fine Arts, Boston; the Museum of Antiquities of the University and Society of Antiquaries of Newcastle Upon Tyne; the Oriental Institute, Chicago; Pelizaeus Museum, Hildesheim; and the Saalburg Museum. Among publishers who gave permission to use illustrations from works published by them are Academic Press, American Journal of Archaeology, Antiquity, the British School of Archaeology in Iraq, Chrysalis Books Group, The Johns Hopkins University Press, McGraw-Hill Companies, Oxford Journal of Archaeology, and Routledge.

The writing of this book was immeasurably supported through two Senior Research grants from the Vice President for Research of the University of Geor-gia, with additional financial assistance from Wyatt Anderson, Dean of Arts and Sciences, and Richard A. LaFleur, Head of the Department of Classics. I would also like to thank the Department of Classics at the University of Leeds, which granted me the teaching position of Visiting Professor of Classics during the fall of 1997, and provided lodging and library assistance, plus gracious camaraderie, while I was conducting research in England.

My final, and most heartfelt, appreciation goes to my wife, Susan, and daugh-ter, Julia. Susan, a professional librarian, contributed her expertise in ferreting out the most obscure references. O n one occasion in particular, when other more enjoyable activities beckoned, she spent her free time in Boston perusing the collection of the Museum of Fine Arts looking for any art historical material

XXI ACKNOWLEDGEMENTS

related to ancient food technology. Julia, though disappointed, was always understanding when, on too many occasions, her father begged off participating in other activities in order to spend time on the book. Both had for many months 011 end to endure my long absences, both of mind and body, and to walk around and step over books, papers, and photographs scattered about the house. Without their patience and generosity my task would have been far more onerous than it otherwise was.

F O R E W O R D

In January 1939, while excavating in the northern section of the Archaic cerne-tery at Saqqara, Walter B. Emery discovered a rather humble tomb dating to the Second Dynasty (early third millennium B. C.).1 Denoted T o m b 3477, in size and intrinsic value of its contents it was rather unremarkable save in one respect. It had lain undisturbed from the time of the burial in it of a woman of about sixty years of age. Emery found there an almost perfectly preserved meal, laid out on dishes of pottery, alabaster, and diorite. Here was a near pristine example of a funerary meal found in other Early Dynastic burials, though none preserved so well as this nor so elaborate. Emery was excited because he believed that it proved what he had long suspected, that is, that early Egyptians as part of the funerary ritual included cooked meals with the deceased.2 Later tombs contained not only examples of food items but more frequently paintings, sculpture, and models of food and drink, which, apparently through a magical transformation, were intended to serve as gifts to the gods or as sustenance for the deceased throughout eternity.:i

Emery's interest lay more in the meal's symbolic importance than in the indi-vidual food items and what they can tell us about the state of Egyptian food technology. Foods found in T o m b 3477 fell into two general categories, those which were eaten in their natural state, whether cooked or raw, and those which had been processed in some fashion. In the former category were stewed fruit (possibly figs) and berries. Processed foods included grape wine, a triangu-lar loaf of bread made from emmer wheat, circular honey-cakes, a sort of por-ridge of ground barley, various cuts and portions of beef, cleaned and dressed fish and fowl, a pigeon stew, and perhaps cheese.1 These processed foods show Egyptian knowledge of the principles of butchery, fermentation, milling, and cooking. Already, at the dawn of the historical period in Egypt, nearly 5,000 years ago, the Egyptian diet was both varied and technologically sophisticated.

' Wal ter B. Emery, A Funerary Repast in an Egyptian Tomb of the Archaic Period Leiden: Nederlands Instituut voor hot Nabije Oosten, 1962).

- T h e typicality of a such a sumptuous meal is debatable. Cf. Hilary W ilson, Egyptian Food and Drink (Bucks: Shire Publications Ltd., 1988), p. 11.

5 Emery, Funerary Repast, p. 2. 1 Ibid., pp. 6 7. There was also an unidentifiable liquid made of some fatty substance. The

food items were identified by Alfred Lucas, at that t ime chemical advisor for the Egyptian Amiq-uities Service.

FOREWORD XXVI11

They were, however, neither the first to apply technology to food nor the last to do so.

All species of animals must have food to survive. Herbivores graze on grasses, forage off bushes or trees, and dig for roots and bulbs. Carnivores hunt or ambush and kill their prey, or scavenge previously killed animals. Omnivores participate in some or all of these activities. Although animals exhibit greater or lesser large and small motor dexterity, visual, aural and olfactory acuteness, speed, strength, ingenuity, patience, endurance, and, in pack animals, coopéra-tion, none of these food procuring activities rely on technology per se. If by the term food technology one understands simply a method of acquiring something to eat or drink through solving a specific technical problem, then clearly many animals engage in food technology. So, for instance, over thirty years ago J a n e Goodall demonstrated that chimpanzees, whose diet is basically frugivorous, that is, made up of fruits, leaves, bark, and pith, sometimes made and used sim-pie tools, such as sticks, stems, and small twigs, to catch and eat termites and ants. They also use leaves as a drinking tool, and, at certain times of the year exploit stone hammer and anvil technology to get at meat in nuts. Indeed, out-side of the use of weapons, most habitual tool-use behavior of chimpanzees cen-ters on subsistence. Tufted capuchin monkeys were observed to produce simple stone tools for cutting and hammering. T h e "archer fish" projects water spouts at insects, spiders, and other small creatures to knock them into the water and so render them more readily available to eat. Likewise, various south Pacific birds use small twigs held in their bill to probe for insect larvae in trees, and sea otters while floating on their backs place stones on their chest and pound hard-shell mollusks against them to crack the shell.5 The conclusion seems inescapable. Humans are not the only animals to make and use tools and were probably not the first to create tools to exploit opportunities for obtaining food. The question is, of course, more complicated than this when humans are involved.

Not all foods require processing to be edible; fruits, many nuts, and most veg-etables come readily to mind. These and even uncooked meat were basic food items for prehistoric humans. Other foods for a variety of reasons required some

J י a n e Goodal l , "Too l -us ing a n d A i m e d T h r o w i n g in a C o m m u n i t y of Free-living C h i m -panzees , " Nature '201 (2» Mar. , ' 1964): 1264-66 ; B e n j a m i n B. Beck, Animal Tool Behavior: Vie Use and Manufacture of Tools by Animals (New York: G a r l a n d S T P M Press, 1980), esp. pp. 20 105, 109 15; G rego ry Cha r l e s Wes te rgaa rd a n d S t e p h e n J . Suomi , "A Simple Stone-tool Technology in Monkeys , " JHumEvol 27 (1994): 3 9 9 - 4 0 4 ; Elisabetta Visalberghi , " C a p u c h i n Monkeys: A W i n -dow into T o o l Use in Apes a n d H u m a n s , " in Tools, Language and Cognition in Human Evolution. K a d i -lcen R. Gibson a n d T i m Ingold, cds. (Cambr idge : C a m b r i d g e University Press, 1993), p p . 138 50; Wil l iam C . M c G r c w , " T h e Intelligent Use of Tools : T w e n t y Proposi t ions," in ibid., pp. 154 -57 .

XXVI1 FOREWORD

degree of alteration. Some foods, for example, demand processing to render them more palatable or easier to digest. Others, poisonous in their natural state, can be made safe when properly treated or rendered into a different form. When processed in some fashion to achieve these purposes, the number and variety of available foods expand and more food becomes available for more people. Excess foods or those needed as a safeguard against future want can be stored for short or long periods of time when properly processed. They can also be transported if necessary or desired. Additionally, some foods in processed form have a value beyond alleviating hunger. Fermented grain, grapes, and dates, for example, in the form of alcoholic beverages, through their mind-alter-ing characteristics, give pleasure beyond being merely tasteful or safe. This rais-es two questions. What exactly does the term "food technology" mean, and what was ancient man's contribution to it? The former question can be fairly precisely defined; the answer to the latter will occupy the remainder of this book.

Food technology concerns the knowledge and practical application of the principles of food science to the preservation, processing, preparation, packag-ing, storage, and transportation of food.'׳ While this definition fits well in the modern, complex world, and, as will become clear, serves as the basis for defin-ing the scope of this book, it does not entirely encompass the ancient view of technology, or at least the Greek view of it.7 T h e modern world has severed the link between technology and technique. Knowledge of the principles of tool use (technology), for example, has been separated from the skilled use of the tool itself (technique). The latter embodies specific and practical know-how gained primarily through observing and copying procedures. The former, on the other hand, is theoretical knowledge capable of general application.8 So, today, to consider an activity as technical is to imply that its focus is narrow and its perfor-mance is perfunctory, requiring little or no general or theoretical knowledge. One thinks of the difference between an electrician and an electrical engineer, or between a cook and a food scientist. This dichotomy is foreign to the Graeco-Roman view of technology in general and serves only to obscure our knowledge of the changing relationship between man and his diet.

The term technology derives from the Greek τέχνη, meaning craft, skill, and cunning of hand; it can also refer to the process of doing or making something

Dictionary of Nutrition and Food Technology. Arno ׳' ld E. Bender , cd. 6th cd. (London: But terworths , 1990), p. 114."

7 W e have little in fo rmat ion on w h a t p reced ing cul tures thought abou t it, if they p o n d e r e d the quest ion at all.

8 T i m Ingold, "Tool -use , Sociality a n d Intel l igence," in Tools, Language and Cognition, pp. 433-36.

FOREWORD XXVI11

related to art or craft. The term μηχανή, artificial contrivance or machine, simi-larly assumes the manual operation of some apparatus to assist the application of τέχνη. Inherent in both these terms is the idea that the craftsman utilizes knowl-edge to effect something practical or meaningful. For the ancients, therefore, knowledge and technique go hand in hand. I should also add that the ancient would include what we would call superstition as a natural concomitant to tech-nique.9 In the modern world, the tool, an instrument manipulated by human agency, is distinguished from the machine that is not manually operated but runs upon some non-human power, such as electricity. Although much of ancient technology does depend upon working by hand, it will become clear that in the area of food the ancient world progressed from the use of simple hand tools to complex machines operated by animal or water power designed to produce more and better products more efficiently. The journey from simple tool to complex machine, however, was a long one, and many of the old hand techniques contin-ued in use long after new mechanical apparatus had appeared on the sccne. The reasons for this vary, and involve differences of economic status, the speed and methods by which technical knowledge was transferred, and the degree to which new methods and tools replaced the old. I propose to look at food technology from the ancient perspective, focussing not only 011 the theoretical principles employed, even if not completely understood, by them but also on who applied them, why, under what conditions, to what practical application they were put, and what products they produced.

Technological innovation in antiquity did not develop in a vacuum anymore than it docs today. Just as it arises within a certain environment so it also many times alters the society from which it springs. The conclusion about technologi-cal change that Frances and Joseph Gies have ascribed to the Medieval period applies equally to the ancient world:10

The most momentous changes are now understood not as single, explicit inven-lions but as gradual, imperceptible revolutions . . . taking place through incremen-tal improvements, large or small, in tools, techniques, and the organization of work. This new view is part of a broader change in historical theory that has come to perceive technological innovation in all ages as primarily a social process rather than a disconnected series of individual initiatives.

G יי e o r g e W . H o u s t o n , " T h e Sta te of the Art: C u r r e n t W o r k in the T e c h n o l o g y of Ancien t R o m e , " C J 8 5 (1989): 80.

1(1 Prances a n d J o s e p h Gics, Cathedral, Forge, and Waterwheel. Technology and Invention in the Middle Ages (Ν. Y.: H a i p e r Collins, 1994), p. 2. Cf. for the R o m a n per iod , Kevin G r e e n e , " T h e Study of R o m a n Techno logy : S o m e Theoretical Cons t ra in t s , " in Theoretical Roman Archaeology: First Confer-ence Proceedings. E leanor Scott , ed. (Aldershot: Avebury , 1993), pp . 39 47.

XXVI1 FOREWORD

In this book, therefore, I propose to describe and discuss not only the technolo-gies applied by ancient man to food processing but also to place these innova-tions within their social, economic, and political context. Food technology, for example, played a role in religion, the rise of the state, the creation of bureau-cratic institutions, even the development of writing itself. Going one step further, I will focus on the ramifications of these innovations upon ancient society at large. 111 other words, what led to these advances in food technology and what were their influences, intended 01־ not, upon that society?

111 approaching this subject I had to answer several questions. First and fore-most was the question of where to begin. Where, for instance, does agriculture or husbandry end and food technology begin? The answer is not an easy one, but is not altogether arbitrary. Agriculture is closely allied to food processing, since both deal directly with food and neither particularly require skilled individ-uals. Nevertheless, a clear distinction can and should be drawn between these two activities. The selection of plants to be grown, the preparing of the soil for planting, the sowing of seeds, the care of the plants during growing, and the liar-vesting of the produce all fall clearly under agriculture. If foods consumed in their natural state without further processing, as nuts, fresh vegetables, fruits, and milk often are, are not in some way altered after harvesting, they do not fall under the category of food technology. The grape and olive, however, most often receive further treatment after picking, and grains are only selected for their various uses after they have been separated from the stalk through thresh-ing. Food technology begins at the point when these plant foods undergo specif-ic processes to change their form in some way (such as milling grain into Hour) or to so alter them as to create a different food product altogether (for instance, fermenting grapes into wine). In other words, for the grape and olive it is 111 the vat; for grain, it is 011 the threshing room floor. T h e care, raising, and feeding of animals as well as the use of their byproducts, such as wool, skin, horn, and so on, plainly belong to animal husbandry. I would also include in the same cate-gory the raising of bees for their honey and the milking of cows, sheep, and goats for their milk. But the processing of the honey and the production of but-ter, cheese, or yogurt from milk fall into the realm of food processing. So also butchery of the animal, which precedes preservation of the meat, qualifies for inclusion. And finally, (lie methods and tools for catching fish are not part of food processing, but what one does to preserve the fish for later consumption, whether salting, smoking, drying, or fermenting, clearly is.

The second question involved what to do with those subjects that affected food technology but were not part of it. Here, I mean, for example, grain stor-age and long-distance transportation of finished pre )ducts. HcW ing no 1ntcnt10n<il effect 011 the food item, nevertheless, storage of cereals as an alternative to

FOREWORD XXVI11

immediate processing docs play a role in the decision of when to process. Like-wise, storage and transportation of a food item after processing also constitute a continuation of that process. Here, I am thinking particularly of the racking of wine or the storage of preserved fish and their subsequent delivery to market. I have, therefore, classed storage and transport containers as part of food technol-ogy in accordance with the modern definition of the term. And, finally, the invention of pottery led directly to important innovations in cooking and other techniques to alter food. But pottery has many other uses. I have, therefore, restricted my discussion to particular containers that were developed specifically to process foods, and have left to others to treat pottery more widely.

The present book is essentially a handbook, and as such, claims only modest aims. It neither breaks new ground nor advances a particular thesis about the subject. It does, however, seek to synthesize the vast amount of work accom-plished on the topic and to present the state of the question on ancient food tech-nology as it exists in A. D. 2000. Food technology has never received the atten-tion it deserves, being usually relegated to a minor sidelight in a discussion of agriculture or as an afterthought to general discussions on ancient technology where pride of place goes to engineering, metallurgy, or water power. R. J. Forbes, in Studies in Ancient Technology, for example, devoted comparatively little space to food processing and preservation, and scattered this information among several different volumes." He relied almost exclusively on literary sources, and did not attempt to place the role of food technology in its societal context. This book, therefore, will for the first time focus specifically on ancient food technolo-gy, and will bring to bear literary, archaeological, epigraphic, art historical, and scientific evidence upon the subject. In doing so, it goes beyond previous general histories of ancient technology by showing the interrelationship of food technolo-gy with ancient society, believing that the former cannot with profit be isolated from the latter. I have also sought to point out areas where controversy continues and in which further work is necessary. T o take only one example, food technolo-gy, more so than any other area of ancient technology, involved the active partie-ipation of women, since they were in all places and at all times intimately con-nected with its function. In some instances, they may have been the instigators of technical innovation if not of invention itself. Because the information on ancient

11 R . J . Forbes, Studies in Ancient Technology. 9 Vols. (Leiden: E . J . Brill, 1955-1964) . Forbes dis-tr ibutes his discussion of food technology in four different volumes, with a por t ion of V o l u m e T h r e e con ta in ing the bulk of the mater ia l . H e also wro t e the chap t e r on food technology in Char l e s Singer , E . J . H o l m y a r d , a n d A. R. Hal l , eds., A History of Technology. 8 Vols. (Oxford : O x f o r d Universi ty Press, 1954 84), I: '238 98, bu t even here he lumps chemicals a n d cosmetics a long with food.

XXVI1 FOREWORD

food technology is so scattered and because this is the first attempt to bring it all together, I have provided full, though not exhaustive, documentation of both pri-mary and secondary sources. Considering the rate of archaeological discovery and evaluation, some of what is contained between these two covers may be in need of revision by the time it is published. So, for example, as this book was going to press, Cambridge University Press brought out a book entitled Ancient Egyptian Materials and Technology, too late for me to consult.12

A word needs to be said on the organization of the book. 111 organizing the book along chronological and geographic lines while focussing on products that received processing, I have departed somewhat from the usual topical organiza-tion of handbooks in this series. Food technology tended to be associated with certain plant foods, such as the cereals, grapes, and olives, the Mediterranean triad as they have come to be known, but not others, and a few animals, such as cattle, goats, sheep, and pigs, desirable for their meat or dairy by-products. Food technology does not lend itself well to discussion of its separate principles, since several technological applications are often applicable to a single product. So, for instance, grain milling could involve four separate processes: parching, pounding, grinding, and sieving. Fermentation plays a primary role in the pro-duction of wine, but so does treading and pressing. T o concentrate on each activity or principle separately would, I believe, result in a loss of understanding of the whole, thereby giving a false impression of the technology itself. Addition-ally, to treat the subject strictly topically would, I believe, have hindered, if not prevented, accomplishing a major goal, that of placing food technology within ancient society. So, for example, Forbes' topical treatment of the subject tends to mix Egyptian, ancient Near Eastern, Greek, and Roman contributions in a way that obscures the role of innovation within each society. My choice has been to approach the topic by culture and chronologically within each one. The geographical areas include the ancient Near East, Egypt, and both the eastern and western Mediterranean. Time and space constraints, unfortunately, require omission of the Far East and the New World. The chronological periods under review span the years from the appearance of genus homo, ca. two and one-half million years ago, to the period of the late Roman Empire. Three overlapping time periods structure the work: the prehistoric period, the historical period of Egypt and the ancient Near East, and the Graeco-Roman period. I have com-posed each of the three parts as self-contained units, so that each can be read separate from the others. I have, however, provided cross-references and have

1'-' Paul T . Nicholson a n d Ian Shaw, eds., Ancient Egyptian Materials and Technology (Cambr idge : C a m b r i d g e Universi ty Press, 2000).

FOREWORD XXVI11

designated subsections so that someone interested in, say, milling or wine mak-ing could read those parts only of each section. This has, of course, necessitated some repetition across cultures. Effort has been made to keep this to a mini-mum, though I have not hesitated to include a moderate amount where it seemed necessary for the discussion at hand. Comparison of ancient and mod-ern production methods and description of physical and chemical changes undergone by the product when processed, for example, have been placed where the technology is first discussed in detail. The quantity and quality of evi-dence available, however, has determined where that discussion comes in the book. So, for instance, modern wine making and the chemical and physical changes inherent in the process first receive full treatment in the chapter on Egypt, even though Egyptian knowledge of the process apparently came from inhabitants of Southwest Asia. The latter people likely acquired it from popula-tions farther to the east where evidence for wine making precedes that in Egypt by nearly a thousand years. While information for wine making in those areas is not plentiful, it is for Egypt. Methods for salting fish, though probably practiced by peoples of the Near East and definitely by Greeks, are more clearly under-stood from evidence dating to the Roman period. And finally, I have appended to each section a chapter summarizing the technological innovations arising from the cultures discussed. A reader desiring a rapid overview of ancient food technology, therefore, could read these summary chapters. I hope that they will also encourage the reader to investigate the other chapters to learn the role of food technology in each ancient culture.

P A R T O N E

P R E H I S T O R Y

C H A P TER O N E

T H E L O W E R AND M I D D L E P A L E O L I T H I C P E R I O D S

T o undertake a study of the development of ancient food technology wc must first know where and when man began and how he evolved. This is not an easy task. Practitioners of paleontology and paleoanthropology study fossil evidence, such as bones, or artifacts that betray behavior, such as tools, weapons, and jew-elry, and compare them with modern data to create hypotheses to explain the evolutionary history of man. The evidence, however, does not remain static. Archaeological finds increase almost daily, and scientific instruments become ever more accurate and precise in measuring various aspects of the evidence. So, for example, no sooner have archaeologists announced the discovery in one place of the oldest fossil evidence for early man, than in another location comes the claim for a still older fossil. This generates reinterpretation of evidence and reconsideration of theories once considered strong. Theories are constantly being produced, altered, refined, and sometimes discarded. Changing interpre-tations of often contradictory evidence begets controversy and characterizes a field continually in (lux. Nevertheless, as competing theories arise and contend with each other, dead ends are met, new directions are taken, our understanding of man's beginnings becomes clearer.

T o impose order on the mass of archaeological material dating to the early Chronological

periods of man's history — there is, of course, no written evidence — and to fiameumk

relate it to cultural developments down to historic times, prehistorians have defined subdivisions of time based upon observed changes in the most frequently found and widely-spread artifacts, stone tools. So, for instance, the period encompassed by the use of the first tools received the name Paleolithic and, in general terms, spanned the period from roughly '2.5 million years B. P. to about 10,000 years B. P. By convention, these arc further subdivided into Early, or Lower, Paleolithic, Middle Paleolithic, and Late, or Upper, Paleolithic. The term "Stone Age" has been attached to archaeological time sequences to distin-guish tool development in Sub-Saharan Africa from what transpired in Europe and Eurasia. The division points are roughly identical, except that the Middle Stone Age began about 100,000 years earlier than the Middle Paleolithic. The final 10,000 years, roughly 20,000 10,500 B. P., are now in some areas, such as North Africa and the Middle East, frequently denoted Epipaleolithic. In geolog-ic terms, the period coincides with the years stretching from the Late Pliocene

CHAPTER ONE 4

epoch to the Late, or Upper , Pleistocene. T h e subsequent period, falling geolog-ically into the Early Holocene, is styled Neolithic, or "New Stone" age, and is characterized not only by the manufacture of polished stone implements, but more importantly by its dominant cultural activity, the practice of agriculture and the domestication of plants and animals. T h e term Mesolithic, sometimes limited to northwestern Europe but frequently applied more broadly, designates the period in the Early Holocene just preceding the arrival of agriculture. One needs to keep in mind that, although, as will be shown later, the Paleolithic era began in East Africa and the Neolithic period arose in Southwest Asia, these cul-tural activities may have occurred at different times elsewhere, and, although the sequences of development may be similar, they need not be synchronous. Additionally, every stage of development observed in one area may not always appear in another. This can result from, among other factors, the momentum and direction of the spread of the culture with its technology from one area to another and the rate of adaptation of the innovation in a different environment. O u r understanding of the relationship of cultural development in various geo-graphic areas may also be hampered by the degree of archaeological work accomplished in one place compared to that in another.1

A. Hominids and Their Tools

Ausiralopiihecines Most everyone agrees that man began in Africa, where ca. five or six million years ago (mya) he became genetically separated from the great apes, particularly chim-panzees.2 Until recently, evidence placed the earliest hominid population in Ethiopia, at Hadar, where in 1974 archaeologists discovered Australopithecus afaren-sis, familiarly called "Lucy," a small creature with a rather ape-like head who lived perhaps 3.5 mya.3 Lucy was not the first hominid identified in Africa, but she was

1 G r a h a m e Clark , World Prehistory. In New Perspective. 3rd cd. (Cambr idge : C a m b r i d g e Universi ty Press, 1977), pp. 24—25; 1). Bruce Dickson, Ancient Preludes. World Prehistory from the Perspectives of Archaeology, Geology, and Paleoecolog}׳ (Minneapo l i s / St. Paul: Wes t Publishing Co. , 1993), pp . 192-93, '

- R i c h a r d G . Kle in , " A n a t o m y , Behavior , a n d M o d e r n H u m a n Or ig ins , " JWorldPrehisl 9, no. 2 (1995): 1(59; P. V. Tob ias , " T h e Env i ronmen ta l Background of H o m i n i d E m e r g e n c e a n d the A p p e a r a n c e of the G e n u s Homo," JHumEvol 6, no. 2 (1991): 135.

3 D o n a l d C . J o h a n s o n a n d Ma i t l and A. Edcy, Lucy. The Beginnings of Humankind (New York: S imon a n d Schuster , 1981). A convenient s u m m a r y of the physical characterist ics of the various Plio-Pleistocenc homin ids a n d the in te rpre ta t ions of their evolut ion can be found in Alan Bilsbor-ough , "Diversi ty, Evolut ion a n d Adap t ion in Early H o m i n i d s , " in Stone Age Prehistory. Studies in Memory of Charles McBurney. G . Ν. Bailey a n d P. Cal low, eds. (Cambr idge : C a m b r i d g e Universi ty Press, 1986), pp . 1 9 7 - 2 2 0 .

THF, !.()WER AND MIDDLE PALEOLITHIC PERIODS כ

1. East and South Africa

CHAPTER ONE 6

the oldest up to that time.4 Fossil evidence discovered in 1992-1993, however, indicates that the earliest known hominid population inhabited Aramis, Middle Awash, Ethiopia, about 4.4 mya. Termed Ardipithecus ramidus, this hominid differs significantly from apes in its dental, cranial, and post-cranial characteristics, and to a lesser extent from Australopithecus, with which it may be a sister taxon.5 Shortly after Ard. ramidusי discovery, another find, Australopithecus anamensis, from Kanapoi and Allia Bay, Kenya, near Lake Turkana, was announced. Dating between 3.9 and 4.2 mya, this is the earliest hominid which reliable evidence shows to have walked upright at least part of the time.6 A. anamensis may prove to have been an intermediary in a direct lineage between Ard. ramidus and A. afarensis. There is, however, controversy over whether these are linear species or examples of the radiation of several different species, some of which were contemporary with each other and only one of which eventually led to humans.7

In addition to Hadar, A. afarensis fossils have been unearthed at Laetoli in Tan-zania and in the early 1990s at Maka and Fejej in Ethiopia, the latter find possi-bly extending the A. afarensis population back to 4.0-4.18 mya.8 T o judge from bones and fossil footprints, this hominid was especially suited for walking upright, though it retained an essentially ape-like rib cage.9 Whether linearly derived from

4 Australopithecus africanus was first d iscovered in 1925 at T a t i n g in South Africa, while a robust fo rm, A. hoisei, was discovered in 1959 in n o r t h e r n T a n z a n i a on the western edge of the eastern Rift Valley at O lduva i Gorge . P. V. Tobias, Olduvai Gorge. Vol. 4 (Cambr idge : C a m b r i d g e Uni -versity Press, 1991), p. 17. Var ious robust a n d gracile aust ra lopi thecines have come to light at o the r places in Sou th Africa, such as Sterkfonte in , M a k a p a n s g a t , Swar tkrans , a n d D r o m d r a a i . See R i c h a r d G . Klein, " T h e S tone Age Prehis tory of Sou the rn Afr ica ," AnnRAnth 12 (1983): Be ;־48 25 rna rd A. W o o d a n d M . Ellis, "Ev idence for Die tary Special ization in the 'Robus t ' Aus-t ra lopi thecines ," in Fossil Man. New Facts — New Idea. V lad imi r V. Novo tny a n d Alcna Mizerova , eds. (Brno: A n t h r o p o s Ins t i tu te -Moravian M u s e u m , 1986), pp . 102-03 .

5 T i m 1). Whi te , G e n Suwa , a n d B e r h a n e Asfaw, "Australopithecus ramidus, a N e w Species of Early H o m i n i d f rom Aramis , E th iop ia , " Nature 371 (22 Sept. 1994): 306 12; terminology revised in Nature 375 (4 M a y 1995): 88.

6 M e a v e G . Leakey, C r a i g S. Feibcl, I an McDouga l l , a n d Alan Walker , " N e w Four-mill ion-year-old H o m i n i d Species f r o m K a n a p o i a n d Allia Bay, K e n y a , " Nature 376 (17 Aug. 1995): 565 7 1. Since as yet lower skeletal remains of the strongly ape-like hominid Ard. ramidus have not c o m e to light, o n e canno t speculate on the degree of bipedali ty of this spccies. "Earliest Bipedal Ances tor?" Archaeology (Nov. Dec . 1995): 18.

7 El izabeth Culo t ta , " N e w H o m i n i d C r o w d s the Field," Science 269 (18 Aug. 1995): 918; D e a n Falk, T i m o t h y B. G a g e , Bruce Dudek , a n d T o d d R. Olson , "Did M o r e T h a n O n e Specics of H o m i n i d Coexist Before 3.0 M a ? Evidence f r o m Blood a n d T e e t h , " JHumEvol 29 (1995): 591 600; Klein, " A n a t o m y , Behavior , a n d M o d e r n H u m a n Or ig ins , " pp. 169 70.

B J o h n K a p p e l m a n , Ca r l C . Swisher , III, J o h n G . Fleagle, So lomon Yirga, T h o m a s M . Brown, a n d Muluge t a Feseha , "Age of Australopithecus afarensis f r o m Fejej, E th iop ia , " JHumEvol 30 (1996): 139-46 .

!1 T i m 1). Whi t e , G e n Suwa, Wil l iam K. H a r t , Rober t G. Wal te r , G iday WoldeGabr ie l , J e a n de Heinzel ln , J . D e s m o n d Clark , Be rhane Asfaw, a n d Elisabeth V r b a , " N e w Discoveries of Aus-

כTHF, ! . ( )WER AND MIDDLE PALEOLITHIC PERIODS

Ard. ramidus or one of several contemporaneous hominids, A. afarensis seems to have been the ancestor of all later hominids. Somewhere around 3.0 2.5 mya A afarensis split into two general directions. T h e first, which proved a dead end, con-stituted the robust australopithecines, usually denominated P[aranthr0pus) aethiopi-eus, P. robustus, and P. boisei. The second, or gracile, form, named A. africanus, known only from southern Africa, may have led directly to the genus Homo. The recent discovery in the Hata Beds of the Middle Awash Valley of Ethiopia of a new species, Australopithecus garhi, thus far known only from craniodental remains and dated to 2.5 mya, has now challenged this conclusion. Although clearly descended from A. afarensis, this hominid possesses some dental features similar to those of early genus Homo. This has led its discoverers to suggest that A. garhi is a prime candidate for the nearest ancestor of our own species.10

Major site locations for fossil remains of the earliest example of the genus demis H o m o

Homo include Olduvai Gorge in Tanzania , in Ethiopia in the vicinity of Lake Turkana, and especially in Kenya, on the northeast shore of Lake Turkana at Koobi Fora and at Chemeron to the south." The genus Homo can be anatomi-

tralopithecus at M a k a in E th iop ia , " Nature 366 (18 Nov . 1993): 261 65; R i c h a r d Leakey, 771e Origin of Humankind{ N e w York: Basic Books, 1994), pp. 55 56; Michae l H . Day , " H o m i n i d Locomot ion

F rom T a t i n g to the Lactoli Footpr in ts , " in Hominid Evolution. Past, Present, and Future. Phillip V. Tob ias , ed. (New York: Alan R. Liss, Ltd., 1985), pp . 115-27 .

10 R icha rd G. Klein, The Human Career. Human Biological and Cultural Origins (Chicago: T h e Uni -versity of Ch icago Press, 1989), pp. 158 62; idem, "Ana tomy , Behavior, a n d M o d e r n H u m a n Or i -gins," p. 170; H e n r y M . M c H c n r y a n d Randal l R. Skelton, "Is Australopithecus africanus Ancestral to Homo?" in Hominid Evolution, pp . 221 26; a n d Tobias , Olduvai Gorge, Vol . 4, pp . 8 11, 820 27; Bils-bo rough , "Diversity, Evolution a n d Adap t ion , " pp. 210 13. T h e lineage of Homo remains cont ro-versial. Dona ld C . J o h a n s o n argues that A. afarensis was the ances tor of all later hominids, but con-siders it m o r e likely tha t A. africanus led to P. robustus/bosei a n d was not a precursor to Homo. H e thinks that that link has yet to be discovered. Dona ld C . J o h a n s o n , " T h e Most Primitive Australop-ithecus," in Hominid Evolution, pp . 203 21. For A. garhi, see Berhane Asfaw, T i m Whi te , O w e n Lovejoy, Bruce Lat imer , Scott Simpson, a n d G e n Suwa, "Austalopithecus garlic. A N e w Species of Early H o m i n i d f r o m Ethiopia, ' 5 Science 284 (23 April 1999): 629 35. Its bra incase size of ca. 450 cc. is well below that of H. habilis at ca. 640 cc. Cf. also Leakey, The Origin of Humankind, pp . 21 36.

11 T h a t / / . habilis, t he earliest identif iable example of Homo, represents a single taxon is strongly ma in t a ined by Tob ias , " E n v i r o n m e n t a l Backg round , " 129 42, a n d idem, Olduvai Gorge. Vol. 4, pp. 3 49. O the r s , however , assert that , because of significant ana tomica l var iat ions seen in fossils f rom different sites, the earliest representat ives of this genus m a y actually represent three different species of Homo. So, for instance, differences 111 endocran ia l capaci ty a n d tooth size incline some scholars to believe tha t Π habilis at O lduva i G o r g e differs f rom Homo finds at K o o b i Fo ra a n d so postulate th ree separa te species: H. habilis sensu stricto, II. rudolfensis, a n d II. ergaster. See, e.g., Be rna rd W o o d , "Or ig in a n d Evolut ion of the G e n u s Homo" Nature 355 (27 Feb. 1992): 783 90; idem, "Ear ly H o m i n i d Species a n d Specia t ion ," JHumEvol 22 (1992): 351 65; Daniel L. Lieber-m a n , Berna rd A. W o o d , a n d David R. P i lbeam, " H o m o p l a s y a n d Early Homo: an Analysis of the Evolut ionary Rela t ionships of II. habilis sensu stricto a n d II. rudolfensis," JHumEvol 30 (1996): 97 120; a n d G. Philip Righ tmi re , "Var ia t ion A m o n g Early Homo C r a n i a f r o m Olduva i G o r g e a n d the Koob i Fora Reg ion , " AJPA 90 (1993): 1 33. '

CHAPTER ONE 8

cally differentiated from Australopithecus in a number of ways, but most clearly by possession of a cranial capacity ranging from two to five times larger.12 The dif-ferential between P. robustus, with an average endocranial capacity of 530 cc, and the earliest Homo, H. habilis, with 640 cc, is quite small. The slightly younger and more widely dispersed contemporary, H. erectus, however, had a significantly larger endocranial capacity, averaging 1,043 cc.13 Although increased brain size is important, brain structure seems more critical in processing, learning, and retaining information. Increased mental complexity and processing capacity affect linguistic skills, tool use, and social intelligence. 14

12 Aust ra lopi thecine c ran ia vary f r o m 380 cc to 530 cc, while the earliest Homo had a capaci ty of f rom 600 cc to 752 cc. Homo erectus, ;1 later f o r m found at sites ex tend ing f rom Africa to C h i n a over a long span of t ime, weighs in with a crania l capaci ty vary ing be tween 700 cc a n d 1250 cc. By compar i son , the bra in of m o d e r n m a n , Homo sapiens sapiens, varies be tween 1,000 cc a n d 2,000 cc. T o b i a s gives slightly varying figures for the m e a n endocran ia l capacit ies for early hominids , bu t they a re relatively close. See T o b i a s , Olduvai Gorge, Vol . 4, p. 708, T a b l e 181, a n d pp. 799 801. Frank E. Poirier, Understanding Human Evolution. 2 n d ed. (Englewood Cliffs, N . J . : Pren-tice Hall , 1990), pp . 139-42 , 211; Dickson, Ancient Preludes, pp . 185 86; J o h n YVymcr, The Palae-olithic Age (New York: St. M a r t i n ' s Press, 1982), pp. 46 47.

13 Figures given by Phillip V7. Tob ias , in Lar ry Trask , Phillip V . Tob ias , T h o m a s W y n n , lain Davidson, Wil l iam Noble , a n d Paul Mellars , " T h e Or ig ins of S p e e c h , " CArchJ 8, η θ . 1 (1998): 75. Homo habilis may u p o n fu r the r investigation p rove to be m o r e an end-s tage of aus t ra lopi thecine deve lopment than the first example of genus Homo. Cf . Clark , World Prehistory, p. 22. A hominid similar to II. habilis of eas tern Afr ica a n d p e r h a p s a p recur so r to II. erectus has been discovered at Longgupo in S ichuan , C h i n a a n d dates to ca. 500 ,000 years af ter the a p p e a r a n c e of II. habilis in Africa. Roy Larick a n d Russell C h i c h o n , " T h e First Asians," Archaeology ( Jan . -Feb . 1996): 5 1 - 5 3 . H. erectus fossils have been recorded in Nor th a n d East Afr ica (Algeria a n d Olduva i Gorge , for example) , Southeas t Asia (Java), a n d C h i n a . W h e t h e r II. erectus m a d e it to E u r o p e is open to ques-tion. They d i sappea r f r o m the fossil records abou t 300 ,000 B. P., a l though some m a y have sur-vived as late as 27 ,000 B.P. in J a v a . C . C . Swisher , III, W . J . Rink, S. C . An ton , H. P. Schwarcz , G . H. Curt is , A. Supr i jo , a n d Wid ia smoro , "Latest Homo erectus of J a v a : Potential C o n t e m p o r a n e -ity with Homo sapiens in Southeas t Asia," Science 274 (13 Dec. 1996): 1870-74 ; A n n Gibbons , "Homo erectus in J a v a : A 2 5 0 , 0 0 0 - Y e a r A n a c h r o n i s m , " Science 274 (13 Dec. 1996): 1841-42; Dick-soil, Ancient Preludes, pp . 187 90; W y m e r , Palaeolithic Age, pp. 46, 138 39; J o h n A. J . Gowlet t , Ascent to Civilization. The Archaeology of Early Humans. 2nd ed. (New York: M c G r a w - H i l l , Inc., 1993), pp. 84- 85, 100-09; Kle in , Human Carier, pp . 183 223.

" Klein, " A n a t o m y , Behavior , a n d M o d e r n H u m a n Orig ins ," p. 169; Poirier, Understanding Human Evolution, pp. 140 42; Ka th leen R. Gibson , "Too l Use, L a n g u a g e a n d Social Behavior in Rela t ionship to In fo rma t ion Processing Capac i t i es , " in Tools, Language and Cognition in Human Evo-lution. Ka th leen R. Gibson a n d T i m Ingold, cds. (Cambr idge : C a m b r i d g e Universi ty Press, 1993), pp . 251 69; Chr i s St r inger , " H u m a n Evolution a n d Biological Adap ta t ion in the Pleistocene," in Hominid Evolution and Community Ecology. Prehistoric Human Adaption in Biological Perspective. Rober t Foley, ed. (London: A c a d e m i c Press, 1984), pp . 77 78. W h y the bra in size of Homo increased as it did, the reby init iating an ever widen ing d i f ference be tween it a n d o the r early hominids , r emains u n k n o w n . O n e line of thought associates the evolut ion of bipedal ism with the deve lopment of a blood-f low system in the bra in that al lowed for an increased cool ing capabil i ty du r ing hyper ther -mia the reby al lowing for larger b ra in size a n d increased menta l capaci ty . See D e a n Falk, "En la rged Occ ip i t a l / Marg ina l Sinuses a n d Emissary Fo ramina : T h e i r Significance in H o m i n i d

כTHF, ! . ( )WER AND MIDDLE PALEOLITHIC PERIODS

The Chemeron site in Kenya has yielded the oldest evidence thus far for the H. habilis and

genus Homo. T h e date o f c a . 2.5 mya established for H. habilis, or "skillful man," stone tools

is contemporaneous with dating of stone tools found in Ethiopia at Kada Gona and West Gona. At Hadar archaeologists have uncovered remains of genus Homo, dated by potassium-argon dating of volcanic ash to ca. 2.33 mya, in the same strata as finds of stone flakes and chopping tools of the Oldowan lithic industry.15 Recent studies showing tool making and tool-use among modern monkeys and chimpanzees, however, cause some hesitation in attributing the first tool use to Homo. If tool behavior of modern apes is any indication of early hominid activities, australopithecines may have used simple tools, particularly wooden ones, which would have left no archaeological trace. But, stone tools made by modern apes are clearly inferior to those that began to appear at this time in East Africa.16 The flaking skill evident in Oldowan tools found at Gona implies a much earlier development of the knowledge of stone-tool manufacture, but the identification of the hominid who made the tools remains unknown. Time and location, however, make A. garhi a prime contender for the tool mak-

Evolu t ion ," in Evolutionary History 0J the "Robust" Australopithecus. Freder ick E. Gr ine , ed . (New York: Aldi ne de Gruy te r , 1988), pp . 85 96, a n d Steven Mid ien , 77ie Prehistory of the Mind. A Search for the Origins of Art, Religion and Science (London: T h a m e s a n d H u d s o n , 1996), pp . 2 0 4 - 0 6 . A second idea, re fer red to as the "energet ic a p p r o a c h , " suggests that a shift f rom an essentially vegetar ian diet to o n e based on mea t , a n d so one m o r e easily digestible, allowed for smaller gut tissue. T h i s permi t -ted a n evolut ion whe reby energy, otherwise utilized for a larger gut to digest plant foods, was diverted to the bra in . T h e ext ra energy went in to suppor t ing a larger bra in . T h e r e may also be a correlat ion be tween increased brain size a n d tin־ extra energy acqui red by a m o t h e r whose diet began to be m o r e heavily mea t based. T h e mo the r ' s a d d e d energy was passed on to her fetus whose bra in size thereby increased. See A n n G i b b o n , "Solving the Brain 's Energy Crisis," Science 280, 29) 5 3 6 M ח״. 8 a y 1998): 1345 47. But cf. C . M . Hladk , b . J . Chivers , a n d P. Pasquet , " O n Diet a n d Gut Size in N o n - h u m a n Pr imates a n d H u m a n s : Is there a Rela t ionship to Brain Size?" CurrAnth 40, nM. 5 (Dec. 1999): 695 97.

S. S '־' e m a w , P. R e n n e , J . W . K. Harr is , C . S. Feibel, R. L. Bernor , N . Fesseha, a n d K. M o w -bray , "2.5-mil l ion-year-old Stone Tools f r o m G o n a , E th iop ia , " Nature 385 (23 J a n . 1997): 333-36. W h o m a d e the tools at G o n a is u n k n o w n . See also A. M . H. S., "Earliest R e m a i n s of G e n u s H o m o , " Archaeology 50, 1 (Jan. Feb. 1997): 26; Tob ia s , " E n v i r o n m e n t a l Background of H o m i n i d E m e r g e n c e , " p. 138; idem, Olduvai Gorge, Vol . 4, pp. 830 32; A n d r e w Hill, Steven W a r d , Alan D e m o , Garniss Curt is , a n d R o b e r t Drake , "Earliest H o m o , " Nature 355 (20 Feb. 1992): 719 22; G lynn Isaac, " T h e Archaeology of H u m a n Origins: Studies of the Lower Pleistocene in East Afr ica 1971 1981," in The Archaeology of Human Origins. B a r b a r a Isaac, cd. (Cambr idge : C a m -br idge Universi ty Press, 1989), pp . 126 '27.

Gregory Char ׳" l e s Wes te rgaa rd a n d S tephen J . Suomi , "A Simple Stone-tool Technolog) in ׳Monkeys , " JHumEvol 17 (1994): 403. T h e viability of rel iance on compar i sons be tween observed behaviors 111 m o d e r n ch impanzees a n d o the r apes a n d assumed behaviors in early homin ids is not shared by all paleoanthropologis ts . Dissenters p re fe r to rely upon fossil evidence alone. Cf. R i c h a r d Polls, " H o m i n i d Hun te r s? Prob lems of Ident i fying the Earliest H u n t e r / Ga the re r s , " in Hominid Evolution and Community Ecology, pp. 129 66.

CHAPTER ONE 1 0

crs of Gona. Bones of an antelope and of a three-toed horse, found in close proximity to the bones of A. garhi, bear cut marks indicative of butchery with stone tools. That this hominid may have engaged in behavior to this point char-acteristic of genus Homo alone further supports the suggestion that A. garhi was ancestor to H. habilis.7י The proposition that tool making was species specific, therefore, may have to be altered if these finds in the Hata beds bear further scrutiny. Credit for the earliest stone tools, however, must continue to reside for the moment with H. habilis rather than with any australopithecine. The former possessed a greater brain size and assumed increased brain structure, and his thumb placement allowed for more precise grasping than the chimpanzee-like thumb of, for instance, A. afarensisAdditionally, although the brain capacity and thumb placement of P. robustus are similar to those of Ii. habilis, there has been no firm evidence for stone tools in relation to finds of P. robustus.{9

The appearance of genus Homo at around 2.5 mya coincided with several important events. Physiological changes from the australopithecines include increased brain capacity and complexity, which led to an increased level of cog-nitive intelligence. Dentocranial variances, such as decreased posterior teeth size and enamel thickness relative to australopithecines (slightly with respect to Ii. habilis but significantly in H. erectus), as well as a less developed jaw musculature in comparison with that of Paranthropus indicate differences in diet.20 And finally,

17 El izabeth Culo t t a , "A N e w H u m a n Ances tor?" Science 284 (23 April 1999): 5 7 2 - 7 3 ; J e a n de Heinzel ln , J . D e s m o n d Clark , T i m Whi te , Will iam H a r t , Paul R e n n e , G iday WoldeGabr i e l , Y o n a s Beyene, a n d Elisabeth V r b a , " E n v i r o n m e n t a n d Behavior of 2 .5-Mil l ion-Year-Old Bouri Homin ids , " Science 284 (23 April 1999): 6 2 5 . 2 9 ־

18 T h e endocran ia l capaci ty of H. habilis is ca. 190 cc greater than that of A. garhi and 226 cc grea ter than that of A afarensis. Postcranial bones of A. garhi have yet to be discovered. See Tobias , Olduvai Gorge, Vol. 4, p. 709, Fig. 49, a n d p. 799; Asfaw et al, "Australopithecus garhi," p. 632. T h e issue of w h o m a d e the first tools, II. habilis, the robust australopithecines, or both, remains con-tentious. Sec T i m D . Whi te , " T h e C o m p a r a t i v e Biology of 'robust'Australopithecus: Clues f rom C o n -text ," in Evolutionaly History, p. 464; a n d Bilsborough, "Diversity, Evolution and Adap t ion , " p. 215.

19 W . C . M c G r e w , M a r k W . H a m r i c k , S a n d r a E. Inouye , J a m e s C . O h m a n , Melissa Slanina , Gail Baker, R o b e r t P. M e n s f o r t h , a n d Randa l l L. S u s m a n , " T h u m b s , Tools , a n d Early H u m a n s , " Science 2 6 8 (28 April 1995): 586 89; Klein, " A n a t o m y , Behavior , a n d M o d e r n H u m a n Or ig ins , " pp. 172- 75; idem, Human Career, pp . 1 6 9 7 ־ 0 . Randa l l S u s m a n , on the o ther h a n d , argues tha t I'. robustus did possess precision grasp ing capabili t ies a n d p robab ly m a d e a n d used tools app rop r i a t e for his basically vegetar ian diet. Randa l l L. S u s m a n , " N e w Postcranial R e m a i n s f rom Swar tk rans a n d T h e i r Bear ing on the Funct ional M o r p h o l o g y a n d Behavior of Paranthropus robustus," in Evolutionary History, pp. 149 72; idem, " H a n d of Paranthropus robustus f rom M e m b e r 1, Swar tkrans : Fossil Evidence for Too l Behavior ," Science 240 (6 M a y 1988): 781 -84 ; a n d idem, " W h o M a d e the O l d o w a n Tools? Fossil Evidence for Too l Behavior in Plio-Pleistocene Homin ids , , ) JAnthRes 47 י S u m m e r 1991): 129-51 .

20 H e n r y M . M c H e n r y , " N e w Est imates of Body Weigh t in Early H o m i n i d s a n d T h e i r Signifi-cance to Encephal iza t ion a n d M c g a d o n t i a in ' R o b u s t ' Aust ra lopi thecines ," in Evolutionary History,

THF, ! . ( )WER AND MIDDLE PALEOLITHIC PERIODS כ

postcranial elements show marked changes. Homo developed a more efficient thumb placement on his hand, thereby allowing for increased grasping and manipulation skills. He differed significantly as well from the more ape-like aus-tralopithecines in bone structure of the shoulders, rib cage, and waist, so that the bipedalism of Homo was more agile and quick.1־ /VII these developments seem fortuitous with the simultaneous appearance of the first stone tools.

T h e spread of the use of stone tools was not a gradual process. Once knowl- Stone ״tool kits״

edge of how to construct tools was discovered and analyzed, diffusion of the skill probably occurred rather rapidly, and the sophistication of the objects and the complexity of the processes used to produce them depended upon the proficien-cy of the individual tool makers. Archaeologists conventionally group these tool "kits" into lithic "industries," typified by the technological process used to pro-duce them, by the specific materials from which they were made, and by the use to which they were put, and named for the particular site where first discovered. The range of tool industries for the entire Paleolithic period varies considerably from one area to another, and many local variants can be identified. In general, however, Paleolithic tools can be classified into four general types based on the technology used to produce them and further correlated with specific time peri-ods and with particular hominid groups (Fig. I).22 These include the Oldowan, Acheulian, Mousterian, and Blade industries.

The type of tools used at Olduvai Gorge in the lower Paleolithic period in contexts of H. habilis finds are usually classed as Oldowan (Fig. 2) and comprise H. habilis and the what has been termed the "chopper-core" or "cobble-tool" industry. Made prin- Oldowan tool kit

cipally of basalt and quartzite, Oldowan tools, while assuming no clearly pre-conceived form, served diverse purposes. The basic Oldowan tool was a pebble or cobblestone chipped on one side (unifacial) to produce a chopper. Later, Developed Oldowan tools included bifacial chopping implements and core and flake scrapers. One cannot always be sure whether the larger stone, which has been chipped, is the intended tool or the flakes struck from it. Modern experi-ments with recreating Oldowan-type tools indicate that the cores were good for

pp . 133 48; Wil l iam L. Hy lande r , " Impl ica t ions of In Vivo Exper imen t s for In te rpre ta t ing the Func t iona l Signif icance of ' R o b u s t ' Aust ra lopi thecine J a w s , " in Evolutionary History, pp . 5 5 - 8 3 ; Frederick E. G r i n e a n d Lawrence B. M a r t i n , " E n a m e l Thickness a n d Deve lopmen t in Australo-pithecus a n d Paranthropus," in Evolutionary History, pp. 3 42; Klein, " A n a t o m y , Behaviour a n d M o d -ern H u m a n Or ig ins , " 172 75, csp. Fig. 3, p. 174; idem, Human Career, pp . 138 58. O n the rcla-t ionship be tween tooth size a n d dietary adap ta t ion in genera l , see W o o d a n d Ellis, "Ev idence for Die tary Special izat ion," in Fossil Man, pp. 1 1 4 . 1 ־ 6

21 Leakey, Origin 0J Humankind, pp. 55 57. 22 In o t h e r words , homin id technology follows a similar evolut ionary process as homin id mor -

phology. Sec R o b e r t Foley, " H o m i n i d Species a n d Stone-tool Assemblages: H o w a re they Relat-ed?" Antiquity 61, no. 233 (Nov. 1987): 3 8 0 - 9 2 .

1 2 CHAFFER ONE

Hi © I

Ô

Anatomically modern H. sapiens (Africa )

0 African archaic H.sapiens

@ European 'Neanderthals '

^ European archaic H sapiens

? SE Asian H. erect us

φ SE Asian archaic M sapiens φ Ε Asian Η. erectus

fy Ε Asian archaic H. sapiens

^ Early African Η erectus

0 3 sp.

ft H. habilis

I A robustus

A. crasstdens A boisei

A. aethiopicus (?)

A. africanus

A afarensis

\\(m Pan

KEY

Termite 'fishing sticks '

Hammerstones

Digging sticks

Oldowan

Ach eu lea η

Asian pebble-tools

Leva!lois Mousterian

African MSA

Blade technology

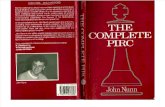

Fig. 1. Cladogram of hominid evolution with associated tool kits. From Foley, "Hominid Species and Stone-tool Assemblages,1' p. 38b, Fig. 2. Reprinted by permission of Robert Foley and Antiquity Publications Ltd.

כTHF, ! . ( )WER AND MIDDLE PALEOLITHIC PERIODS

Fig. 2. Oldowan Tools: 1 and 2. Chopping tools, from Olduvai Gorge; 3. Tool f rom Sterkfontein, S. Africa; 4. Choppe r f rom Vallonet cave, Provence, France, contemporary with Beds 1 and 2 at Olduvai. Bordes, Old Stone Age, Fig. 10. Courtesy of McGraw-Hil l Companies .

CHAPTER ONE 1 4

cutting branches or for dismemberment and breaking of animal bones. T h e small, thin Hakes, often retouched, possessed sharp edges useful for skinning and scraping or for precise cutting in butchery.23 Whether they were actually used for those purposes is another question.

One other event, roughly coincident with the appearance of H. habilis, proba-bly played an important role in human evolution. Strong evidence suggests the occurrence of a global climatic change, which in Africa was characterized by a shift f rom a wet, hot environment to a cooler, drier one, with the concomitant alteration of the ecosystem from generally forest and woodlands to a more open area of savannah and shrubs.24 Coming as it does at the point of a branching of the hominid line into the robust australopithecines going off in one direction and Homo in another, the climatic changes may have played a role in intensify-ing observable evolutionary responses of the different lines.25 This certainly seems the case in regard to habitat and diet. Homo prospered in different envi-ronments, such as along rivers and lakes, in wooded areas, and in dry open grasslands, and developed a more generalized, omnivorous diet. The robust aus-tralopithecines seem tied to open grassland near rivers and to a predominantly herbivorous diet.26

H. erectus and die This climatic change may have spurred development of the second species of Acheulian tool kit Homo. Known earlier as "Java M a n " (Pithecanthropus erectus) from finds in Java

and "Peking M a n " (Sinanthropus pekinensis) from fossils discovered near Peking (now Beijing), China, especially Zhoukoudian, H. erectus arose first at Koobi Fora near Lake Turkana in northern Kenya ca. 1.8-1.7 mya. He is also attested at

23 A l though some scholars a rgue for the p re fe rence of def ined shapes, such as spheroids, dis-coids, a n d po lyhedrons , O l d o w a n tool shapes d e p e n d e d on the cha rac t e r of the s tone a n d on the n u m b e r a n d sequence of flakes de t ached . Sec M i t h e n , Prehistory of the Mind, pp ־ 98 96 . , a n d Iain Davidson a n d Wil l iam Noble , "Tools a n d L a n g u a g e in H u m a n Evolu t ion ," in Tools, Language and Cognition, p p . 3 6 7 - 6 9 . Cf. W y m e r , Palaeolithic Age, p. 55; Dickson, Ancient Preludes, pp . 193-95; Isaac, "Archaeo logy of H u m a n Or ig ins , " pp. 129-31; Gowlet t , Ascent to Civilization, pp. 3 8 - 3 9 , 5 2 - 5 3 ; Klein, Human Career, pp. 165-82 .

24 Elisabeth S. V r b a , "La te Pliocene Cl imat ic Events a n d H o m i n i d Evolut ion ," in Evolutionary History, pp. 4 0 5 - 2 6 ; Michae l L. Prent ice a n d George H . D e n t o n , " T h e Deep -Sea Oxygen Isotope Record , T h e Global Ice Sheet System a n d H o m i n i d Evolu t ion ," in ibid., pp . 3 8 3 - 4 0 3 ; Tob ias , "Env i ronmen ta l Background , " pp . 137 38; R i c h a r d L. Hay , "O lduva i Gorge ; A Case His tory in the In te rp re ta t ion of H o m i n i d Pa leoenv i ronment s in East Af r ia , " in Establishment of a Geologic Framework for Paleoanthropology. Leo F. Lapor te , ed. Special P a p e r 242 (Boulder, Co. : T h e Gcologi-cal Society of Amer ica , Inc., 1990), pp . 2 3 - 3 7 ; a n d Bilsborough, "Diversity, Evolution a n d Adap -t ion," p. 213.

25 Elisabeth S. V r b a , "Cl imate , H e t e r o c h r o n y a n d H u m a n E v o l u t i o n / ' JAnthRes 52 (Spring 1996): 1 - 2 8 .

26 V r b a 5 "La te Pliocene Cl imat ic Events ," pp. 418 20; Pat S h i p m a n a n d J o h n M . Harr is , " H a b i t a t Prefe rence a n d Palcoecology of Australopithecus boisei in Eastern Afr ica ," in Evolutionary History, pp . 343 81.

כTHF, ! . ( )WER AND MIDDLE PALEOLITHIC PERIODS

other African sites, such as Beds II and IV at Olduvai Gorge in Tanzania and Bodo in Ethiopia. Perhaps ancestral to modern humans, H. erectus was probably the first hominid to depend almost entirely on bipedalism.27 Reliance upon this new mode of travel, which freed him from attachment to an arboreal or semiar-boreal existence, a significantly increased brain capacity and complexity leading to advances in cultural adaptations, and development of more sophisticated and efficient tools, doubtless contributed to his spread first to Southwest Asia, at Ubeidiya in the Jordan Valley of Israel, as early as 1.4—1.3 mya, then to the Far East and, perhaps, subsequently to Europe.28

The first important innovation in the prehistoric tool kit beyond the unspe-cializcd Oldowan industry was the so-called Acheulian industry (Fig. 3), com-posed of bifacial tools, such as cleavers, and, most characteristically, the hand-axe. The earliest Acheulian handaxes are closely associated with African H. erec-tus, sometimes called H. ergaster. Acheulian-type tools have been found over nearly all the Old World, and the industry lasted probably well beyond 200,000 years B. P.29 Crude forms appear in the early levels at Olduvai Gorge, but once in use advances in sophistication came rapidly. The handaxe, made from a core or retouched large flake, was in its later, most elegant form (after ca. 250,000 B. P.) pre-shaped on the core and then struck off in what has been called the Levai-lois technique. The handaxe makes an efficient tool for butchering large ani-mais, while the clcaver outperforms the simple flake tool in cutting wood and splitting hides.

For a long time scholars believed that while hominids were developing in H. erectus and H. sapiens

27 Klein, " M o d e r n H u m a n Or ig ins , " pp . 175-79; idem, Human Career, pp . 183-223; Poirier , Understanding Human Evolution, pp. 221 51; Hay , " O l d u v a i Gorge : A Case His tory ," pp . 23 37. R igh tmi re believes that H. erectus m a y have been a distinct species r a the r than a stage of evolution leading directly to H. sapiens sapiens. Cf. G . Philip R igh tmi re , " H o m o erectus a n d Later Midd le Pleistocene H u m a n s , " AnnRevAnthr 17 (1988): 2 3 9 - 5 9 ; idem, The Evolution of Homo Erectus ( C a m -bridge: C a m b r i d g e Universi ty Press, 1990), pp. 180 237.