Analysis of Electrical Characteristics of AlGaN/GaN … HYUN-SOO LEE et al : ANALYSIS OF ELECTRICAL...

Transcript of Analysis of Electrical Characteristics of AlGaN/GaN … HYUN-SOO LEE et al : ANALYSIS OF ELECTRICAL...

-

JOURNAL OF SEMICONDUCTOR TECHNOLOGY AND SCIENCE, VOL.17, NO.3, JUNE, 2017 ISSN(Print) 1598-1657 https://doi.org/10.5573/JSTS.2017.17.3.354 ISSN(Online) 2233-4866

Manuscript received May. 18, 2016; accepted Dec. 25, 2016 Electronics and Telecommunications Research Institute (ETRI), GaN Power Electronics Research Section, Daejeon 34129, Korea E-mail : [email protected]

Analysis of Electrical Characteristics of AlGaN/GaN on Si Large SBD by Changing Structure

Hyun-Soo Lee, Dong Yun Jung, Youngrak Park, Hyun-Gyu Jang, Hyung-Seok Lee, Chi-Hoon Jun,

Junbo Park, Jae Kyoung Mun, Sang-Ouk Ryu, Sang Choon Ko, and Eun Soo Nam

AbstractWe investigated the improvement in electrical characteristics of large AlGaN/GaN on Si Schottky barrier diode (SBD) induced by structural change to achieve a better trade-off between the forward and reverse performance to obtain high power conversion efficiency in PFC converter. Using an optimized dry etch condition for a large device, we fabricated three-types of SBD with 63 mm channel width: conventional, recessed, recessed dual-anode-metal SBD. The recessed dual-anode-metal SBD exhibited a very low turn-on voltage of 0.34 V, a high forward current of 1.63 A at 1.5 V, a leakage current of 114 A at -15 V, a breakdown voltage of 794 V. Index TermsGaN, Schottky barrier diode, low turn-on voltage, recess, large SBD

I. INTRODUCTION

Wide-bandgap III-nitride semiconductors are a promising candidate for both short wavelength optoelectronics and power electronic devices because of the intrinsic advantages of materials such as direct bandgap and high electron peak velocity [1, 2]. Most of the Gallium Nitride (GaN)-based power devices are fabricated on the AlGaN/GaN heterostructure grown on Si because of the availability of its large wafer size and cost effectiveness [3, 4]. The high switching speed of a GaN power device can be used to reduce the size and the

complexity of a power conversion system, and its high power density and low leakage current enhances the power conversion efficiency at the same time [5]. Conventional AlGaN/GaN planar Schottky barrier diode (SBD) exhibits a high turn-on voltage, leading to a considerable conduction loss [6]. A SBD can be used for a rectifier and freewheeling diode in power electronics fields. The turn-on voltage of the SBD is one of the most important parameters. In switching operation, low turn-on voltage of the SBD minimizes power loss and it improves efficiency of a power conversion system. In this paper, we propose recessed dual-anode metal structure for low turn-on voltage of the SBD. So, recently, various studies have been carried out to improve characteristics of AlGaN/GaN SBD. The structural change to reduce on-resistance [7, 8] and surface passivation to reduce surface leakage current, such as SiO2, SiNx, Al2O3, SiCN dielectric film, have been investigated [9, 10]. Recess etch in anode region and recess depth controls have been actively investigated as well [11-14]. However, finding a dry etch condition that can achieve uniform etching profile with a reproducible etch rate and little plasma damage is difficult. And hence fabrication of large dimension device needed for power conversion application is challenging. In addition, the damage occurred during the etching process may seriously degrade the device performance [15]. To reduce the turn-on voltage, the anode of the SBD was replaced with a dual anode metal to take advantage of the different work functions of the two metals [16]. In those studies, however, although the forward characteristics of dual anode metal SBD were improved, the reverse characteristics were degraded. So, to improve both the

-

JOURNAL OF SEMICONDUCTOR TECHNOLOGY AND SCIENCE, VOL.17, NO.3, JUNE, 2017 355

forward and the reverse characteristics, a gated ohmic anode SBD together with a recessed and dual metal has been suggested [17]. However, previous research has been carried out on small lateral-SBD. We have suffered from low forward current level because of the small size dimension with ring-type geometry structure.

In this paper, in order to obtain high efficiency in the PFC converter via SBD with lower turn-on voltage together improved other forward properties without degradation of reverse characteristics. All three types of

devices with different anode structure were fabricated on the same wafer. We describe the AlGaN/GaN on Si SBDs with 63 mm channel using the optimized dry etch condition [18] for a large device to obtain a uniform etch profile, an accurate etch rate, and very little plasma damage. In contrast to previous studies which focused on small devices with limited power capacity, we analyse electrical characteristics of large dimension SBDs that can be used directly in a power switching system.

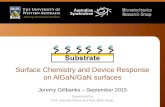

Fig. 1. Process flow for three kinds of SBD and The fabricated SBD structure (C-SBD = Conventional SBD, R-SBD = RecessedSBD, RDA-SBD = Recessed dual anode SBD).

-

356 HYUN-SOO LEE et al : ANALYSIS OF ELECTRICAL CHARACTERISTICS OF ALGAN/GAN ON SI LARGE SBD BY CHANGING

II. DEVICE FABRICATION

The GaN-SBD devices were fabricated on an AlGaN/GaN heterostructure sample, grown by MOCVD on a 4-in Si (111) substrate. The epi-sturcture consists of a 3-to-4-m GaN buffer layer, a 20-nm Al0.25G0.75N barrier, a 1.25-nm undoped GaN layer. A mesa isolation step with an etching depth of 300 nm was carried out by inductively coupled plasma reactive ion etching (ICP RIE) using a BCl3/Cl2 gas mixture [18]. To measure electrical characteristics of AlGaN/GaN SBD in a consistent manner, SBDs of different structure, three kinds of SBD Conventional SBD (C-SBD), Recessed SBD (R-SBD), and Recessed dual-anode-metal SBD (RDA-SBD)- were fabricated on the same wafer. Fig. 1 shows each process flow for three-type of SBD fabrication and the structure of a completed AlGaN/GaN SBD.

A Ti/Al/Ni/Au ohmic metal was deposited using e-beam evaporation as an ohmic contact in cathode and anode. Then, rapid thermal annealing carried out at 900 C for 50 s in N2 ambient. Atomic force microscope (AFM) measurement results of small devices verified that the etching profile is very uniform across the whole wafer and that the etch rate reproducible. Usually, etching profile is not uniform in larger devices, and therefore we expect high device-to-device variation. Also, uneven etch surface morphology can result in increased surface leakage current. So, in order to obtain inductively coupled plasma reactive-ion etching (ICP-RIE) dry etch condition with a uniform etch profile, accurate etch rate, very low plasma damage, and even surface morphology, we optimized dry etch condition by changing the ICP power, the RF power, the gas feed rate, the chamber pressure. The ICP RIE conditions used to fabricate a large GaN SBD were the following: ICP power = 50 W, RF power = 3 W, flow (BCl3/Cl2) = (16/3) sccm, pressure = 10 mTorr. Using the optimized dry etch condition, we obtain an RMS roughness of the etched surface to be 0.29 nm and an etch rate of ~0.3 /s. The low RMS roughness of the etched surface can decrease the surface leakage current, and the etch rate of ~0.3 /s allows the recess depth to be accurately controlled. R-SBD and RDA-SBD were etched using the same etch condition. The recess depth d measured by AFM was

16 nm. Fig. 2 shows measured AFM profile of the recessed region and recess surface morphology.

In structures with fully recessed anode, it is obvious that direct contact to the two-dimensional electron gas (2DEG) makes the Schottky barrier height to drop, causing lower onset voltage. However, we studied that the SBD which has a remaining AlGaN layer exhibited the lowest turn-on voltage than that of fully recessed SBD, because the residual AlGaN layer helps in the creation of small amounts of 2DEG, which can participate in electron movement [13]. And the leakage current is effectively controlled by the selectively reducing the 2DEG density under the Schottky metal of the anode region. To effectively control the leakage current and obtain the lower turn-on voltage, more than half of the AlGaN layer of the anode region should be etched [19]. Subsequently, a Ni/Au Schottky metal as the anode metal was deposited, and then, a 700-nm-thick SiO2 passivation layer was deposited by plasma enhanced chemical vapor deposition (PECVD). After removing the SiO2 passivation layer in the anode and cathode region using buffered oxide etch (BOE), finally, a 3-m-thick Ti/Au metal was plated as the contact metal. A channel width is a summation of total width of active area, which is 63 mm. An electrode gap (LAC) is distance between anode and cathode, which is 15 m in our device.

III. RESULTS AND DISCUSSION

As shown in Fig. 2, the anode region dry etched using the optimized etch condition with uniform etch profile and low plasma damage and accurate etch rate. Large devices were free of adverse effect that can arise from the dry etching process. Fig. 3 shows the forward

Fig. 2. AFM image of recessed region (left), RMS roughness ofrecessed surface (right).

-

JOURNAL OF SEMICONDUCTOR TECHNOLOGY AND SCIENCE, VOL.17, NO.3, JUNE, 2017 357

current-voltage (I-V) characteristics of the fabricated large SBDs with various structures.

In Fig. 3, R-SBD by comparison with C-SBD exhibited a reduced turn-on voltage and on-resistance by having the Schottky metal near 2DEG channel [11]. On the other hand, electrons can flow through the ohmic contact portion of the anode at small bias voltage, thereby greatly improving the turn-on voltage in RDA-SBD in comparison to R-SBD. When the forward bias voltage is increased above a threshold value, electrons can flow through the Schottky contact region as well. When the device is completely turned on, extra current flowing through the ohmic contact region in the anode increases the total forward current [17].

Fig. 4 shows the measured reverse I-V characteristics. We observed that, as shown in Fig. 4, R-SBD exhibited the lowest leakage current by effectively controlling the conduction between the Schottky metal and the 2DEG channel. In RDA-SBD, the majority of the voltage drop develops across the Schottky recess metal and the cathode metal. Therefore, the additional ohmic contact region introduced in the anode does not contribute much to increasing the leakage current. The leakage current of RDA-SBD was more slightly increased than that of R-SBD. However, in consideration of a trade-off between the forward and the reverse characteristics, the increased leakage current is acceptable because the forward performance of RDA-SBD was greatly improved. Also, the breakdown voltages were not changed by changing

the anode structure. We can see that 16-nm recessed dual-anode-metal SBD has a lower VT than other recessed SBD due to the ohmic-to-ohmic junction effect as shown from 0 V to 0.2 V in Fig. 3 (inset) and from -2 V to 0 V in Fig. 4. Consequently, forward and reverse characteristics of the RDA-SBD are simultaneously improved compared to that of C-SBD. Also, when comparing the ON-resistance, the slope of forward I-V curve, of three type SBDs, the RDA-SBD exhibit the lowest On-resistance in Fig. 3. Because electrical characteristics of RDA-SBD can minimize energy loss at energy conversion systems, when apply this device to high power/switching application, high energy conversion efficiency can be obtained. The electrical characteristics of the fabricated devices are summarized in Table 1. Fig. 5 is a picture of the fabricated GaN-SBD with 63 mm channel width and top view of the fabricated three kinds of SBD is the same. Fabricated devices were designed to obtain longer channel width in same dimension.

Fig. 3. Linear scale I-V curve is obtained by Tektronix 370A (anode voltage sweep from 0 V to 1.6 V), measuring in the high current regime and Log scale (Inset) I-V curve is measured by HP4155 (anode voltage sweep from 0 V to 1.5 V), to accurately measure the turn-on voltage values at low current regime.

Fig. 4. Reverse characteristics measured by HP4155 and Breakdown voltage measured by Tektronix 370A.

Table 1. Device Characteristics Characteristics C-SBD R-SBD RDA-SBD

VT 0.85 V 0.45 V 0.34 V IF (at 1.5 V) 0.7 A 1.45 A 1.63 A IR (at -15 V) 865 A 84 A 114 A

VB 803 V 802 V 794 V

-

358 HYUN-SOO LEE et al : ANALYSIS OF ELECTRICAL CHARACTERISTICS OF ALGAN/GAN ON SI LARGE SBD BY CHANGING

IV. CONCLUSION

The most of traditional structures of SBD were realized in small devices that could not be readily used in a power conversion system because the same structure could not scale up to a larger dimension. Problems such as epitaxial defects, non-uniform and uneven etch condition have plagued larger devices. In this study, using the optimized dry etch condition, such as uniform etch profile, accurate etch rate, very low plasma damage in anode region, we fabricated three different structure type GaN-SBD with 63 mm-long channel. In contrast with previous devices that focused on small scale devices, we investigated large dimension SBDs that can be used directly in power system. Recessed dual-anode-metal structure exhibited excellent electrical characteristics, such as ultra-low turn-on voltage, high forward current, low leakage current, and breakdown voltage without degradation, among fabricated devices with different structures. The recessed dual-anode-structure is suitable for usage in a rectifier and freewheeling diode in the PFC converter with high power conversion efficiency.

ACKNOWLEDGMENTS

This work was supported by Institute for Information

& communications Technology Promotion (IITP) grant funded by the Korea government (MSIP) (No. B0132-15-1006, Development of High Efficiency GaN-based Key Components and Modules for Base and Mobile Stations) and by the Korea Institute of Energy Technology Evaluation and Planning(KETEP) and the Ministry of Trade, Industry & Energy(MOTIE) of the Republic of Korea (No. 20152020105940).

REFERENCES

[1] Y.-F. Wu, D. Kapolnek, J. P. Ibbetson, P. Parikh, B. P. Keller, U. K. Mishra, Very-high power density AlGaN/GaN HEMTs, IEEE Electron Device Lett., Vol. 48, No. 3, pp. 586-590, Mar., 2001.

[2] J. H. Lee, D. Y. Lee, B. W. Oh, J. H. Lee, Comp-arison of InGaN-Based LEDs Grown on Conventi-onal Sapphire and Cone-Shape-Patterned Sapphire Substrate, IEEE Trans. Electron Devices, Vol. 57, No. 1, pp. 157-163, Jan., 2010.

[3] F. Semond, P. Lorenzini, N. Grandjean, J. Massies, High-electron-mobility AlGaN/GaN heterostruct-ures grown on Si(111) by molecular-beam epita-xy, Appl. Phys. Lett., Vol. 78, No. 3, pp. 335-337, Jan., 2001.

[4] K. Cheng, M. Leys, S. Degroote, B. Van Daele, S. Boeykens, J. Derluyn, M. Germain, G. Van Tende-loo, J. Engelen, G. Borghs, Flat GaN epitaxial layers grown on Si(111) by metalorganic vapor phase epitaxy using step-graded AlGaN intermedi-ate layers, J. Electron. Mater., Vol. 35, No. 4, pp. 592-598, Apr., 2006.

[5] S. Iwakami, O. Machia, I. Yoshimichi, B. Ryohei, Y. Masataka, E. Toshihiro, K. Nobuo, G. Hirokazu, I. Akio, Evaluation of AlGaN/GaN Heterostruc-ture Field-Effect Transistors on Si Substrate in Power Factor Correction Circuit, Jpn. J. Appl. Phys., Vol. 46, No. 2, pp. L721-L723, Jul., 2007.

[6] G.-Y. Lee, H.-H. Liu, and J.-I. Chyi, High-Performance AlGaN/GaN Schottky Diodes With an AlGaN/AlN Buffer Layer, IEEE Electron Device Lett., Vol. 32, No. 11, pp. 1519-1521, Nov., 2011.

[7] J.-H. Lee, C.-H. Park, K.-S. Im, J.-H. Lee, AlGaN/GaN-Based Lateral-Type Schottky Barrier Diode With Very Low Reverse Recovery Charge at High Temperature, IEEE Trans. Electron Device, Vol. 60, No. 10, pp. 3032-3039, Oct., 2013.

Fig. 5. Microscope image of the fabricated 2 x 2 mm2 GaN-SBD with 63 mm channel width and 15 m electrode gap (channel width: a summation of total width of active area, electrode gap: distance between anode and cathode).

-

JOURNAL OF SEMICONDUCTOR TECHNOLOGY AND SCIENCE, VOL.17, NO.3, JUNE, 2017 359

[8] E. Matioli, B. Lu, T. Palacios, Ultralow Leakage Current AlGaN/GaN Schottky Diodes With 3-D Anode Structure, IEEE Trans. Electron Device, Vol. 60, No. 10, pp. 3365-3370, Oct., 2013.

[9] H. Kambayashi, T. Nomura, H. Ueda, K. Harada, Y. Morozumi, K. Hasebe, A. Teramoto, S. Sugawa, T. Ohmi, High Quality SiO2/Al2O3 Gate Stack for GaN MetalOxideSemiconductor Field-Effect Transistor, Jpn. J. Appl. Phys., Vol. 52, No. 4S, pp. 04CF09-1-04CF09-6, Mar., 2013.

[10] J.-H. Lee, J.-H. Jeong, J.-H. Lee, Enhanced Electrical Characteristics of AlGaN-Based SBD With In Situ Deposited Silicon Carbon Nitride Cap Layer, IEEE Electron Device Lett., Vol. 33, No. 4, pp. 492-494, Apr., 2012.

[11] E. Bahat-Treidel, O. Hilt, R. Zhytnytska, A. Wentzel, C. Meliani, J. Wurfl, G. Trankle, Fast-Switching GaN-Based Lateral Power Schottky Barrier Diodes With Low Onset Voltage and Strong Reverse Blocking, IEEE Electron Device Lett., Vol. 33, No. 3, pp. 357-359, Mar., 2012.

[12] M. Zhu, B. Song, M. Qi, Z. Hu, K. Nomoto, X. Yan, Y. Cao, W. Johnson, E. Kohn, D. Jena, H. G. Xing, 1.9-kV AlGaN/GaN Lateral Schottky Barrier Diodes on Silicon, IEEE Electron Device Lett., Vol. 36, No. 4, pp. 375-377, Apr., 2015.

[13] Y. R. Park, J.-J. Kim, W. J. Chang, H.-G. Jang, J. H. Na, H. S. Lee, C.-H. Jun, H.-Y. Cha, J. K. Mun, S. C. Ko, E. S. Nam, Low onset voltage of GaN on Si Schottky barrier diode using various recess depths, Electron. Lett., Vol. 50, No. 16, pp. 1164-1165, Jul., 2014.

[14] Y. R. Park, J. J. Kim, W. J. Chang, D. Y. Jung, S. B. Bae, J. K. Mun, C.-H. Jun, S. C. Ko, E. S. Nam, Normally-off GaN MIS-HEMT using a combi-nation of recessed-gate structure and CF4 plasma treatment, Phys. Status Solidi A, Vol. 212, No. 5, pp. 1170-1173, May., 2015.

[15] S. Tripathy, A. Ramam, S. J. Chua, J. S. Pan and A. Huan, Characterization of inductively coupled plasma etched surface of GaN using Cl2/BCl3Cl2/ BCl3 chemistry, J. Vac. Sci. Technol. A, Vol. 19, No. 5, pp. 2522-2532, Jun., 2001.

[16] T.-Fu. Chang, C.-F. Huang, T.-Yu. Yang, C.-W. Chiu, T.-Yi. Huang, K.-Y. Lee, F. Zhao, Low Turn-on voltage dual metal AlGaN/GaN Schottky barrier diode, Solid-State Electron., Vol. 105, pp.

12-15, Mar., 2015. [17] J.-G. Lee, B.-R. Park, C.-H. Cho, K.-S. Seo, H.-Y.

Cha, Low Turn-On Voltage AlGaN/GaN-on-Si Rectifier With Gated Ohmic Anode, IEEE Electron Device Lett., Vol. 34, No. 2, pp. 214-216, Feb., 2013.

[18] H.-S. Lee, D.Y. Jung, Y. Park, J. Na, H.-G. Jang, H.-S. Lee, C.-H. Jun, J. Park, S.-O. Ryu, S.C. Ko, E.S. Nam, 0.34VT AlGaN/GaN-on-Si Large Schottky Barrier Diode With Recessed Dual Anode Metal, IEEE Electron Device Lett., Vol. 36, No. 11. pp. 1132-1134, Nov., 2015.

[19] W. Saito, Y. Takada, M. Kuraguchi, K. Tsuda, I. Omura, Recessed-gate structure approach toward normally off high-Voltage AlGaN/GaN HEMT for power electronics applications. IEEE Trans. Electron Devices, Vol. 53, No. 2, pp. 356-362, Feb., 2006.

Hyun-Soo Lee received his B.S. degree in Electronics Engineering from Dankook University, Cheonan, Korea in 2014. He received his M.S. in Electricity and Electronic Engi-neering from Dankook University, Youngin, Korea in 2016. In 2016, he

joined Electronics and Telecommunication Research Institute (ETRI) as a research scientist. His research interest includes power electronics module, and power device fabrication. He is currently focused on GaN power devices.

Dong Yun Jung received the B.S. degree in Electronics and Materials Engineering (First class honors) from Kwangwoon University, Seoul, Korea, in 2001, and the M.S. and Ph.D. degrees (excellence graduate) in Electrical Engineering from Korea

Advanced Institute of Science and Technology(KAIST), Korea, in 2003 and 2009, respectively. He studied the broadband IC for optical communications and low-power CMOS receiver circuits and 3-D module using low temperature co-fired ceramic (LTCC) technologies for

-

360 HYUN-SOO LEE et al : ANALYSIS OF ELECTRICAL CHARACTERISTICS OF ALGAN/GAN ON SI LARGE SBD BY CHANGING

millimeter-wave applications. He joined the Electronics and Telecommunications Research Institute (ETRI) in 2003 as a member of the engineering researcher. From 2009 to 2014, he was with the R&D Center of Samsung Electronics, as a senior engineer, where he contributed to the development of millimeter-wave IC. Since 2014, he has been with the ETRI as a member of the senior researcher. His research interests include power electronics semiconductor devices and high-speed, high-efficiency power electronics conversions for high power and energy applications. Dr. Jung received Best Paper Award from KAIST in 2007 and 2008, respectively. He received a Silver Award in SAMSUNG Best Paper Award 2012.

Youngrak Park was born in Ulsan, Korea, in 1986. He received the B.S. degree in information and communi- cations engineering from the Korea Advanced Institute of Science and Technology (KAIST), Daejeon, Korea, in 2008, the M.S degree in

electrical engineering from the Seoul National University, Seoul, Korea, in 2011. He studied the design of Radio Frequency Power amplifier and millimeter-wave ICs and. Since February 2011, he has been with the Electronics and Telecommunications Research Institute (ETRI), Daejeon, Korea. His research activities include the fabrication and design of GaN devices.

Hyun-Gyu Jang received the B.S. degree in electronics engineering from Korea Polytechnic University, Siheung, Korea, in 2013, and the M.S. in Advanced Device Technology from University of Science, UST, Korea, in 2015. He studied the

Gallium nitride power devices. In 2015, he joined Electronics and Telecommunications Research Institute (ETRI), located in Daejeon, Republic of Korea, as a Research Engineer. His current research interests include the design, fabrication, and characterization of electronic devices based on compound semiconductors and the design of power supply unit such as inverter and converter.

Hyung-Seok Lee received the B.S. and M.S. degrees in electrical engineering from Korea University, Seoul, Korea, in 2000 and 2002, respectively, and the Tech. Lic. And Ph.D. degrees from the Royal Institute of Technology (KTH),

Stockholm, Sweden, in 2005 and 2008, respectively. From 2001 to 2002, he was a Researcher with Samsung SDI Central R&D Center, Suwon, Korea. From 2007 to 2008, he was a Researcher with Fairchild, Stockholm, Sweden (TranSiC AB). From 2008 to 2013, he was a Postdoc in Massachusetts Institute of Technology (MIT)-Microsystems Technology Laboratories (MTL), Cambridge, MA, US. In 2013, he was a Senior Researcher with Samsung Corning R&D Center, Asan, Korea. Since 2014, he has been a Senior Researcher with Electronics and Telecommunications Research Institute (ETRI), Daejeon, Korea. His research interests include the process technology and device design of high-power devices in wide-bandgap materials, as well as low power device of Si/SiGe devices. He contributed more than 60 publications including international journals and conference proceedings.

Chi-Hoon Jun was born in Daegu, Republic of Korea, in 1959. He received the M.S. degree in Mechanical Engineering and the Ph.D. degree in Metallurgical Engi- neering from Kyungpook National University, Daegu, Korea, in 1984

and 1997, respectively. He joined the Electronics and Telecommunications Research Institute (ETRI), Daejeon, Korea in 1985 as a member of the engineering staff. He became a senior member in 1991 and a principal member in 1999. He also served as a team leader of the microsystem team from 2001 to 2002. His primary research interests are in GaN power devices, power packaging, energy harvesting, optical MEMS for telecommunication, bioMEMS/microfluidics, physical sensors, bio chips, surface micromachining, DRAM metallization, CVD/MOCVD processes for advanced semiconductors.

-

JOURNAL OF SEMICONDUCTOR TECHNOLOGY AND SCIENCE, VOL.17, NO.3, JUNE, 2017 361

Junbo Park received his B.S. degree in Physics from Harvey Mudd College in 2008. He received his Ph.D. in Applied Physics from Cornell University in 2014. In 2015, he joined Electronics and Teleco- mmunication Research Institute as a

research scientist. His research interest includes power electronics module, and power device fabrication. He is currently focused on SiC power devices.

Jae Kyoung Mun received his BS degree in materials science and engineering from Ajou University, Suwon, Rep. of Korea, in 1990 and his MS and PhD degrees in materials science and engineering from the Korea Advanced Institute of Science

and Technology, Daejeon, Rep. of Korea, in 1992 and 2006, respectively. In 1992, he began working at ETRI. His research interests included the development of GaAs MMIC front- and backside processes, reliability, and failure mechanisms. From 2004, he worked on designing RF and millimeterwave band MMIC switches. From 2006 to 2009, he worked as an adjunct associated professor at Daejeon University, Rep. of Korea. From 2009 to 2010, he worked as a consultant at Bell Labs, Murray Hill, NJ, USA. From 2011 to 2013, he was in charge of GaN RF & power devices R&D group. From 2013, he was also a professor with the Department of Advanced Device Engineering, Korea University of Science and Technology, Daejeon, Rep. of Korea. His main research interests are GaN devices and Au-free CMOS compatible process developments. He received the Best Student Award from Ajou University upon his graduation in 1990. He received scholarships from the Ministry of Science & Technology in 1990 and 1991. He has published 52 SCI papers and 41 international conference proceedings. Besides this, he has over 51 US patents and 66 Korean patents.

Sang-Ouk Ryu received the M.S., degree from Univ. of Missouri-rolla, USA and Ph.D in the Department of Electrical Engineering from Virginia Tech, Blacksburg, USA in 1994 and 1999, respectively. In 2000, he joined Electronics and Telecommunications

Research Institute (ETRI) where he worked in the area of non-volatile memory and MEMS devices. In 2006 he became an assistant professor in Dankook University and now he is a full professor in the university. His interests include organic solar cell devices and reliability issues of organic based display devices.

Sang Choon Ko received B.S. degree in electrical engineering from Sungkyunkwan University, Korea in 1994, and got MS degree there in 1996. From 1990 to 1991 he has done military service of Army Korea. After MS degree he moved to

Tohoku University. He received Ph.D. from Tohoku University in March 1999. In 1999, he joined Microsystem Technology (MST) Laboratory of Daimler Chrysler Co. as a visiting researcher. At the same time he was a research associate at the Department of Mechatronics and Electronics in Tohoku University. In 2000, he joined Pohang University of Science and Technology (POSTECH) as a post-doctoral position. From October 2001 he is working at Microsystem Team of Electronics and Telecommunications Research Institute (ETRI), Daejeon, Korea. He has studied on the projects for piezoelectric acoustic device, condenser microphone, and MEMS optical switch. From 2011, he joined the development of GaN-based discrete devices, e.g., SBD and FET. Now, he is working for GaN power device and applications as section-leader of GaN power device section in ETRI.

-

362 HYUN-SOO LEE et al : ANALYSIS OF ELECTRICAL CHARACTERISTICS OF ALGAN/GAN ON SI LARGE SBD BY CHANGING

Eun Soo Nam received the B.Sc. degree in Physics from Kyung-Pook National University, Daegu, Korea in 1983, and M.Sc. and Ph.D. degrees in Physics from the State University of New York, Buffalo, USA, in 1992 and 1994, respectively. Since 1985,

he has been with the Electronics and Telecommuni- cations Research Institute (ETRI), Daejeon, Korea. In 2006, he was a Visting Scholar with the Division of Engineering and Applied Sciences (now the School of Engineering and Applied Sciences), Harvard Universtity, Cambridge, MA. He is currently the Head of the Components & Materials Research Laboratory of ETRI, as a Senoir Vice President. Dr. Nam holds over 50 patents and has published over 100 papers in several fields, including compound semiconductors, microwave monolithic integrated circuits (MMICs), long wavelength InP semiconductor photonic devices, and optoelectronic integrated circuits (OEICs).