An overview to push & pull systems By: Tiruvannamalai R. S. Date: 11/16/2001.

Transcript of An overview to push & pull systems By: Tiruvannamalai R. S. Date: 11/16/2001.

An overview to push & pull systems

By: Tiruvannamalai R. S.

Date: 11/16/2001

• Objective

• Definitions

• Comparison of push & pull systems

• AHP for push & pull system

• POLCA - A case study

• Hybrid push/pull systems

• Conclusion

• References

Agenda

Objective

To provide an overview to

• Push production systems

• Pull production systems

• POLCA

• Hybrid push/pull systems

Definitions

3

Pull: Production is triggered only in response to actual

consumption of inventory.

Push: Production is triggered based on due dates of customer

orders or desired restocking to inventory levels.FORECASTFORECAST

DEMANDDEMAND

Comparison between pull and push systems

WIP WIPWIP

Cell 1 Cell 4Cell 3Cell 2

Material Flow

Withdrawals trigger production

Pull System:

2

Information FlowCustomeCustome

r r

demanddemand

WIP WIPWIP

Cell 1 Cell 4Cell 3Cell 2

Information Flow

Material Flow

Push System:

MRP schedule triggers production

Forecast ?Forecast ?

Characteristics of push and pull systems

Parameters Push Pull

Historical data Customer demand

Same as material flow Opposite to material flow

Make to stock Make to order

Forecasting errors Fluctuation in customer demand

Planning

information

Flow of

information

Manufacturing

techniqueInventory level

affected by

2, 3, & 4

Comparison between push and pull systems

Parameters Push PullLead Time

Manufacturing cost

Inventory, WIP level

Customer service

Throughput

Changing product mix and variety

Machine utilization

Product introduction

Demand fluctuation

Manufacturing environment

Suitable

Suitable

Not suitable

Not suitable

Faster Slower

Repetitive Customized

1, 3, 4, 5, & 6

Methodology for selection of

push & pull systems

Methodology for selection

Analytic Hierarchy Process(AHP) approach:

A simple decision-making tool

• To deal with complex, unstructured and multi-attribute

problems

• To classify push, pull and hybrid push-pull systems in

production planning

• To analyze push-pull systems using quantitative and qualitative

criteria

• To devise a 3D state-space model

• To simulate multiple environments

8

Three-dimensional state-space model (AHP model)

High

High

HighLow

Low

Low

Unreliable

suppliers &

lead timeServiceability,

Commitment, & Costs

Demand Fluctuation

11

55

33

77 88

44

22

66

1 & 5 - Uses pull systems

2, 4, 6, 7 & 8 - Uses push systems

3 - Employs push/pull systems

8

POLCA

POLCA

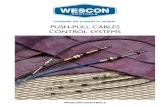

• Paired-cell Overlapping Loops of Cards with Authorization

• “Novel material control strategy used in QRM, which

combines the best of push and pull methods to limit

congestion while at the same time providing a high degree of

flexibility.”

9

POLCA (contd.)

Where does POLCA work?

• High level material requirement planning system

(HL/MRP)

• Cellular organization

• Flat BOM’s

9

POLCA (contd.)

Key featuresKey features:

• To release authorizations by HL/MRP

• To control card based on material control methods

• To produce control cards (POLCA cards)

• To use POLCA cards for each pair of cells

9

Case study- CFP corporation

• Products- Customized faceplates & nameplates

• Features- Printing, holes, notches, bends

• Strength- Small batches for specialized markets

• Uses cell concept to satisfy highly varied markets

9

Applying POLCA-CFP Corporation (contd.)

Printing cellsPrinting cells Fabrication cellsFabrication cells Assembly cellsAssembly cells Shipping cellShipping cell

P1P1

P2P2

F3F3

A1A1

F2F2

F1F1

A2A2

A3A3

S1S1

P1/F2 LoopP1/F2 Loop

A3/S1 LoopA3/S1 Loop

F2/A3 LoopF2/A3 Loop

9

Applying POLCA-CFP Corporation (contd.)

P1P1

F2F2

P1/F2P1/F2

P1/F2P1/F2

P1/F2 LoopP1/F2 Loop

F2/A3F2/A3P1/F2P1/F2

A3A3

F2/A3F2/A3

F2/A3F2/A3F2/A3F2/A3

F2/A4 LoopF2/A4 Loop

P1/F2P1/F2

P1/F2P1/F2

9

9

Advantages of POLCA over push-pull systems

• Assures that each cell only works on jobs that are

destined for downstream cells

• Uses of HL/MRP authorization to prevent buildup of

unnecessary inventory

• Flows in longer flexible loops

• Overlapping loops gives greater degree of flexibility

Hybrid push/pull

Issues – 1. When to push ?

2. When to pull?

Hybrid push-pull:

•Pushes through certain manufacturing stages and pulls else where based on the characteristics and value addition in stages

•Draws a demarcation for determining stages in production that needs to work in push and those in pull

Hybrid push/pull

Delayed differentiation strategy:

A method to combine push and pull systems within a production line

Push strategyPush strategy Pull strategyPull strategy

Push-pull boundaryPush-pull boundary

Customer Customer

demanddemandForecastForecast

7

Hybrid push/pull (contd.)

Advantages:

• Allows to realize advantages of both push & pull

approaches

• Helps to improve economies of scale

• Helps to reduce FGI

• Caters to a wide range of customer demands

• Provides better shop floor control

7

Hybrid push/pull (contd.)

Area of research:

• Locating the push-pull boundary

• Looking for more than one possible differentiation

pointWork done so far:

• Literature review

• Determined the various stages in a multi stage

production line

Hybrid push/pull (contd.)

Work planned ahead:

• Model a multi stage production line with hybrid

push/pull system

• Determining the push pull boundary line

Summary

• Comparisons between push & pull systems

• Methodology for selecting push & pull systems

• POLCA

• Hybrid push pull

• Area of research

• Future work

References

1) APICS International Conference & Exposition-Oct 28-31, 2001.

2) Black, JT. (1991). The design of the factory with a future. New York: McGraw Hill,Inc.

3) Bonney, M. C. , Zhang, Z. , Head, M. A. , Tien, C. C. , & Barson, R. J. (1999). Are push and

pull systems really so different? International Journal of Production Economics, 59, 53-64.

4) Grosfeld-Nir, A. , Magazine, M. , & Vanberkel, A. (2000). Push and pull strategies for

controlling multistage production systems. International Journal of Production Research, 38,

11, 2361-2375.

5) Huang, C. C. , & Kusiak, A. (1998). Manufacturing control with a push-pull approach.

International Journal of Production Research, 36, 1, 251-275.

6) Krishnamurthy, A. , & Suri, R. Push can perform better than pull for flexible manufacturing

systems with multiple products. Center for Quick Response Manufacturing.

7) Levi, D. S. , Kaminsky, P. , & Levi, E. S. (2000). Designing and managing the supply chain.

New York: McGraw Hill,Inc.

8) Razmi, J. , Rahnejat, H. , & Khan, M.K. (1998). Use of analytic hierarchy process approach

in classification of push, pull and hybrid push-pull systems for production planning.

International Journal of Operations & Production Management, 11, 1134-1151.

9) Suri, R. (1998). Quick response manufacturing. Portland, Oregon: Productivity press.