An Induction Reactor-combustion

Transcript of An Induction Reactor-combustion

-

8/12/2019 An Induction Reactor-combustion

1/8

An induction reactor for studying crude-oil oxidation relevant to in situ combustion

Mohammad Bazargan, Alexandre Lapene, Bo Chen, Louis M. Castanier, and Anthony R. Kovscek

Citation: Review of Scientific Instruments 84, 075115 (2013); doi: 10.1063/1.4815827View online: http://dx.doi.org/10.1063/1.4815827

View Table of Contents: http://scitation.aip.org/content/aip/journal/rsi/84/7?ver=pdfcov

Published by the AIP Publishing

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitationnew.aip.org/termsconditions. Downloaded

177.20.130.9 On: Tue, 10 Dec 2013 18:34:33

http://scitation.aip.org/search?value1=Mohammad+Bazargan&option1=authorhttp://scitation.aip.org/search?value1=Alexandre+Lapene&option1=authorhttp://scitation.aip.org/search?value1=Bo+Chen&option1=authorhttp://scitation.aip.org/search?value1=Louis+M.+Castanier&option1=authorhttp://scitation.aip.org/search?value1=Anthony+R.+Kovscek&option1=authorhttp://scitation.aip.org/content/aip/journal/rsi?ver=pdfcovhttp://dx.doi.org/10.1063/1.4815827http://scitation.aip.org/content/aip/journal/rsi/84/7?ver=pdfcovhttp://scitation.aip.org/content/aip?ver=pdfcovhttp://scitation.aip.org/content/aip?ver=pdfcovhttp://scitation.aip.org/content/aip/journal/rsi/84/7?ver=pdfcovhttp://dx.doi.org/10.1063/1.4815827http://scitation.aip.org/content/aip/journal/rsi?ver=pdfcovhttp://scitation.aip.org/search?value1=Anthony+R.+Kovscek&option1=authorhttp://scitation.aip.org/search?value1=Louis+M.+Castanier&option1=authorhttp://scitation.aip.org/search?value1=Bo+Chen&option1=authorhttp://scitation.aip.org/search?value1=Alexandre+Lapene&option1=authorhttp://scitation.aip.org/search?value1=Mohammad+Bazargan&option1=authorhttp://oasc12039.247realmedia.com/RealMedia/ads/click_lx.ads/www.aip.org/pt/adcenter/pdfcover_test/L-37/662712509/x01/AIP-PT/Janis_RSIArticleDL_120413/JanisResearch_PDF_DownloadCover_banner120413.jpg/5532386d4f314a53757a6b4144615953?xhttp://scitation.aip.org/content/aip/journal/rsi?ver=pdfcov -

8/12/2019 An Induction Reactor-combustion

2/8

REVIEW OF SCIENTIFIC INSTRUMENTS 84, 075115 (2013)

An induction reactor for studying crude-oil oxidation relevant toin situcombustion

Mohammad Bazargan, Alexandre Lapene,a) Bo Chen, Louis M. Castanier,and Anthony R. Kovscekb)

Energy Resources Engineering Department, Stanford University, Stanford, California 94305-4007, USA

(Received 21 February 2013; accepted 1 July 2013; published online 24 July 2013)

In a conventional ramped temperature oxidation kinetics cell experiment, an electrical furnace isused to ramp temperature at a prescribed rate. Thus, the heating rate of a kinetics cell experiment

is limited by furnace performance to heating rates of about 0.53 C/min. A new reactor has been

designed to overcome this limit. It uses an induction heating method to ramp temperature. Induction

heating is fast and easily controlled. The new reactor covers heating rates from 1 to 30 C/min.

This is the first time that the oxidation profiles of a crude oil are available over such a wide range

of heating rate. The results from an induction reactor and a conventional kinetics cell at roughly

2 C/min are compared to illustrate consistency between the two reactors. The results at low heating

rate are the same as the conventional kinetics cell. As presented in the paper, the new reactor couples

well with the isoconversional method for interpretation of reaction kinetics. 2013 AIP Publishing

LLC.[http://dx.doi.org/10.1063/1.4815827]

I. INTRODUCTIONIn situ combustion (ISC) is a thermal enhanced oil re-

covery (EOR) method that uses air injection to generate heat

inside the reservoir. It has been successfully applied in numer-

ous oil fields.14 Ignition is usually initiated using gas burners

or electrical heaters.5 The air burns a small portion of the oil

but gives, in return, significant amounts of heat and produces

combustion gases. Heat significantly reduces the viscosity of

the heavy oil and combustion gases push the oil toward the

producer thereby increasing recovery.6

In situ combustion is implemented at lab scale in an ex-

periment known as a combustion tube.7 The combustion

tube experiment is a one-dimensional process. This exper-

iment is also valuable for screening field candidates. Even

though it provides useful information, however, it is difficult

to distinguish and quantify various phenomena such as trans-

port and chemical reactions. Dedicated experiments are re-

quired especially for kinetics study.8

Various techniques have been applied to study the kinet-

ics of combustion. Tadema9 was the first to use a differential

thermal analysis (DTA) method to study the combustion ki-

netics of the crude oil. In this experiment, the temperature dif-

ferences between an oil/sand sample and a blank sand sample

are measured while they are heated under the same conditions

of heating rate and air flow.

Thermo-gravimetric analysis (TGA) is another experi-ment to measure oxidation kinetics. It uses the amount and

rate of the change in the weight of the oil/sand sample as a

function of the temperature. The advantage of TGA is that it

requires less time. But TGA uses a small sample size and it is

sensitive to mass transfer effects.10

a)Present address: TOTAL - EP/DEV/GIS/SIM, Avenue Larribau, 64018Pau, France.

b)Electronic mail:[email protected]

Bae11

used both DTA and TGA to analyze the combus-tion behavior of different crude oil samples. The derivative of

thermo-gravimetric curves (DTG) is used by Vossoughi and

Shoubary12 together with TGA to investigate the effect of dif-

ferent parameters such as specific surface area and oxygen

partial pressure on coke combustion.

Differential scanning calorimetry (DSC) is yet another

technique to study the kinetics of combustion. DSC monitors

differential heat flow of the sample as a function of tempera-

ture. Kok13 used DSC together with TG/DTG to characterize

the combustion behavior of two crude oil samples.

Yannimaras et al.14 introduced accelerating rate

calorimetry (ARC) to probe oxidation of crude oils. The

ARC method consists of a small spherical sample holdersubjected to accurate temperature and heat supply control.

Yannimaras and Tiffin15 used the modified accelerating

rate calorimeter to characterize the combustion behavior of

different heavy and medium crude oil samples based on the

continuity of the ARC trace ties.

Finally, ramped temperature oxidation (RTO)16 is an-

other technique that aims to study the combustion kinetics of

crude oil. Among kinetics experiments, RTO has been mostly

used by the authors and others to propose reaction models to

simulate in situcombustion processes.1720

A. Kinetics cell experiment

In a RTO kinetics cell experiment, a mixture of crude oil,

water, sand (reservoir rock), and clay is placed in the cell that

is subjected to a controlled temperature program. The air is in-

jected at a constant flow rate from the bottom of the cell. The

furnace is programmed to ramp temperature and the tempera-

ture of the cell is measured continuously. The composition of

the produced gas is measured using a gas analyzer. Figure1

shows a schematic of a furnace kinetics cell and the result for

a 13 API 21 oil sample at a temperature ramp of 2.77 C/min.

0034-6748/2013/84(7)/075115/7/$30.00 2013 AIP Publishing LLC84, 075115-1

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http:/ /scitationnew.aip.org/termsconditions. Downloaded

177.20.130.9 On: Tue, 10 Dec 2013 18:34:33

http://dx.doi.org/10.1063/1.4815827http://dx.doi.org/10.1063/1.4815827http://dx.doi.org/10.1063/1.4815827http://dx.doi.org/10.1063/1.4815827http://dx.doi.org/10.1063/1.4815827mailto:%[email protected]://crossmark.crossref.org/dialog/?doi=10.1063/1.4815827&domain=pdf&date_stamp=2013-07-24mailto:%[email protected]://dx.doi.org/10.1063/1.4815827http://dx.doi.org/10.1063/1.4815827http://dx.doi.org/10.1063/1.4815827 -

8/12/2019 An Induction Reactor-combustion

3/8

075115-2 Bazarganet al. Rev. Sci. Instrum.84, 075115 (2013)

FIG. 1. Schematic of a furnace kinetics cell design (left) and a result for a 13 API oil sample at a temperature ramp of 2.77 C/min (right).

As shown in Fig. 1, the oxygen consumption curve (in

mole percent) shows two peaks. The first peak is referred to

as low temperature oxidation (LTO) and the second peak ashigh temperature oxidation (HTO).16 These two peaks are as-

sociated with two deviations in the linear temperature profile

of the kinetics cell. In a kinetics cell experiment (from now

on, referred to as a furnace kinetics cell), the temperature

of the furnace, and not the temperature of the kinetics cell,

is commonly controlled (Fig. 1). The system possesses sig-

nificant thermal inertia due to the thick (order cm) walls of

the kinetics cell itself and the furnace elements. Large heating

rates that are accurately controlled are virtually precluded for

exothermic reactions. Furnace kinetics cell experiments are

usually operated in the maximum heating range of 3 C/min.

B. The importance of heating rate

Furnace kinetics cell experimental results are mostly used

to screen ISC candidates and propose a lumped reaction

model. The reaction model is only a part of the full field

model.

The combustion tube experiment, which is used as an

intermediate scale experiment between the kinetics cell and

the field, can be availed for validating a given reaction model

by comparing combustion tube simulations and experimental

results.

Figure2 shows a temperature profile along the combus-

tion tube in a successful in situ combustion process. Eachcurve in Fig.2 corresponds to a thermocouple that has been

placed at a fixed position along the tube. Each thermocou-

ple is separated by roughly 4 cm. The temperature peak is

called the combustion front (or fire front). As the front moves,

the temperature at each position increases smoothly and then

the rate of increase slows down. This is the time period

where the water vaporizes. After the vaporization of water, the

combustion front arrives, the temperature increases quickly,

and the temperature peaks. After the front passes each posi-

tion, the temperature of that position starts decreasing.

Figure3shows the rates of temperature increase (heating

rates) versus time at several positions along the combustion

tube. As suggested in Fig. 3,the heating rates in the reaction

zone are between 15 and 30 C/min. The range of heating at

the combustion front (Fig.3) is much larger than the workinglimit of the heating rate in a furnace kinetics cell. This does

not necessarily mean that the kinetics of combustion change

with the heating rate. But the predictability of the pseudo

reaction model that has been proposed based on the furnace

study is questionable.

The induction kinetics cell has been designed to work at

wider ranges of heating rate including the heating rate at the

combustion front, as described next. It also aims to enable us

to quench the reaction at different stages and analyze the reac-

tant remaining in the sample. This capability should be useful

for examining the reaction intermediates that are important to

understanding ISC.22

II. INDUCTION REACTOR

A. Induction heating

Induction heating has found many industrial applications

of annealing, brazing, bonding, forging, and so on. It has

FIG. 2. Temperature profiles for a combustion tube test of a 13 API oil

sample. The legend gives the location of each thermocouple.

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http:/ /scitationnew.aip.org/termsconditions. Downloaded

177.20.130.9 On: Tue, 10 Dec 2013 18:34:33

-

8/12/2019 An Induction Reactor-combustion

4/8

075115-3 Bazarganet al. Rev. Sci. Instrum.84, 075115 (2013)

FIG. 3. Heating rate at several positions for the combustion tube test of a

13 API oil sample.

a high heating speed and good efficiency. Quick response

makes the induction heating process precisely controllable.23

A current (dc or ac) passing through a solenoid coil cre-

ates a magnetic field around the coil. When a magnetic solid

bar is placed inside the coil, the induced magnetic field be-

comes stronger. Relative permeability (r) indicates the abil-

ity of the material (that is placed inside the coil) to conduct

magnetic flux better than a vacuum or air.24

According to Faradays law, alternating voltage applied

to a solenoid coil produces a time variable magnetic field

that has the same frequency as the coil current.25 This mag-

netic field induces eddy currents (Foucault currents) in the

work-piece placed inside the coil.26 These eddy currents pro-

duce heat by Joules law.27 Larger relative permeability and

resistivity of the work-piece make induction heating more

efficient.28 TableIshows the electrical resistivity, relative per-

meability, and melting point of several metals. The list helps

us to choose the best metal to be used in the induction reactor.

B. Reactor design

Figure4 shows the elements of the induction reactor. A

1.2 kW-100 kHz induction generator (The Roy-1200, FLUX-

EON) has been used to heat a carbon-steel tube. Carbon-steel

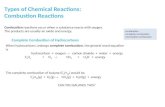

TABLE I. Electrical resistivity,29 relative permeability,30 and melting

point31 of several metals.

Metal Resistivity Relative permeability Melting temperature

( m) (r) (C)

Stainless steel 316 7.0 107 1.02 1510

Silver 1.60 108 0.99 761

Copper 1.70 108 0.99 1083

Gold 2.30 108 0.90 1063

Aluminum 2.80 108 1.00 660

Carbon-steel 1.60 107 3800 1540

Iron 1.0 107 4500 1536

Cobalt 6.20 108 255 1495

Nickel 6.80 108 600 1495

FIG. 4. Induction reactor design.

has very good features for use as the induction heating work-

piece. It has high melting temperature, relative permeabil-

ity, and resistivity (Table I). The oxidation of carbon-steel

is reduced by coating the tube with multilayers of silicon

(SilcolloyTM 1000). The tube is 12 cm long, has an OD of

1.91 cm, and wall thickness of 2.11 mm. The mixture thatcontains the oil sample is placed in the middle of the tube.

It fills 3 cm of the tube in the middle. This corresponds to

about 7 g of the mixture (depending on its composition). The

amount of sample in the tube is chosen accurately as a com-

promise to minimize temperature gradient along the sample,

as shown later, and maximize the oxygen consumption. The

rest of the tube on both sides is filled with sand. The sand on

the inlet side helps to preheat the injected gas.

The temperature of the sample is measured with a J type

thermocouple. To control the temperature, we use a temper-

ature controller that is connected to the induction generator

through a double pole double throw (DPDT) ice cube re-

lay (LY series, OMEGA). The induction generator is attachedto the coil. The coil is a copper tube with OD of 0.64 cm

and has 11 loops with a diameter of 5.08 cm. Cooling water

passes through the coil. The tube has been placed exactly in

the middle of the coil using a side arm. The reactor is wrapped

with insulation. Insulation does not affect the induced mag-

netic field. An efficient heating mechanism and small thermal

mass enable us to achieve all of our desired heating rates while

consuming less than 300 W.

C. Process design

Figure5demonstrates the different parts of the system.

Two inlets are considered for injection: One for air and onefor other gases (e.g., N2). The flow rate of each stream is con-

trolled by mass flow controllers (SLA5800 series, Brooks In-

strument). The injected gas passes through the reactor and en-

ters the liquid trap. Any particular matter is separated from

the flue gas using filters. A back pressure regulator controls

the system pressure. Eventually, a flow of 0.2 SLPM is sent to

the compact gas analyzer (4200 series, SERVOMEX).

III. RESULT

The mixture for testing consists of 1.5 g of the crude-oil

sample (optimal mass depends on the oil), 3.76 g of water,

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http:/ /scitationnew.aip.org/termsconditions. Downloaded

177.20.130.9 On: Tue, 10 Dec 2013 18:34:33

-

8/12/2019 An Induction Reactor-combustion

5/8

075115-4 Bazarganet al. Rev. Sci. Instrum.84, 075115 (2013)

FIG. 5. Process design.

2.00 g of clay, and 50.00 g of the cooked sand. The sand isfirst mixed with clay and then water is added. The oil sample

is then added and mixed thoroughly. The induction reactor

needs to be fed with about 10.00 g (corresponds to 3.00 cm

in the middle of the tube) of the prepared mixture for each

experiment. Sand is packed adjacent to the sample.

The temperature controller applies the heating program.

The oxygen consumption associated with the sample, at the

given heating rate, must be enough to be detected accu-

rately by the gas analyzer. This means that if less of the

sample is used, the injection rate must be accordingly de-

creased. Also, the sample amount should not be excessive,

as it causes deviation from linearity in the temperature his-

tory. The amount of sample is kept constant for all tests at allheating rates to compare oxygen consumption. The amount

of sample needed, however, decreases as the heating rate in-

creases. For 30 C/min, 2.00 g of sample (0.6 cm in the middle

of the tube) is enough.

Figure 6 shows the temperature profile and associated

oxygen consumption of a 9 API oil sample at a heating rate

of 2.60 C/min. The pressure is kept constant at 100 psi while

FIG. 6. Temperature profile (left axis) and associated oxygen consumption

(right axis) of a 9 API oil sample at heating rate of 2.60 C/min and air flow

of 1 SLPM.

air is injected at the flow rate of 2 SLPM. Figure6shows thatoxygen consumption is as expected displaying LTO and HTO

regions. Figure6 also represents the capability of the device

to maintain an accurate heating rate.

Fast response of the induction heating system minimizes

the difference between the programmed temperature and ki-

netics cell temperature. So not only a RTO function, but any

other temperature history may also be achieved by the device.

This provides a unique opportunity for kinetics reaction mod-

els to test their ability to predict the reaction at combustion

tube conditions.

A. Repeatability

In order to demonstrate the repeatability achieved by the

induction reactor, two experiments at a low heating rate of

2.84 C/min were conducted. A total amount of 10.13 g of

mixture was used in each experiment. Figure7shows the oxy-

gen consumption of these two experiments. The two curves in

Fig.7almost perfectly overlap, and demonstrate repeatability

of the induction kinetics cell.

FIG. 7. Repeatability of the induction kinetics cell: Two experiments have

been conducted at heating rate of 2.84 C/min and air flow of 1 SLPM on an

identical 9 API oil sample.

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http:/ /scitationnew.aip.org/termsconditions. Downloaded

177.20.130.9 On: Tue, 10 Dec 2013 18:34:33

-

8/12/2019 An Induction Reactor-combustion

6/8

075115-5 Bazarganet al. Rev. Sci. Instrum.84, 075115 (2013)

FIG. 8. Temperature is measured along the sample through thermal well and

across the sample by thermocouples with ceramic insulator.

B. Homogeneous temperature condition

The accuracy of a RTO kinetics study depends on the

reactor achieving a homogenous temperature distribution.32

Fast heating and heat transfer in the induction reactor allow

it to work in homogenous conditions close to a constant tem-perature profile along the reactor.

The temperature of the sample and of the outside sur-

face of the reactor wall are each measured by thermocou-

ples. Because temperature measurement on the outside sur-

face of the reactor wall is disturbed by eddy currents that are

formed during induction heating, thermocouples are covered

in OMEGATITE 450 ceramic insulator. The accuracy of the

temperature measurement by a thermocouple encased in ce-

ramic insulator was verified. This was achieved by removing

the insulation and using a Raytek MI3 infrared temperature

sensor (reported accuracy of1 C) together with the thermo-

couple with ceramic insulation. Hence, the temperature along

and across the sample (Fig.8) is measured. Figure9 shows themaximum temperature difference inside the sample at differ-

ent heating rates. The x-axis in Fig.9is the temperature of the

sample and the y-axis is the maximum temperature difference

inside the reactor.

FIG. 9. Temperature difference inside the sample versus temperature of the

sample at different heating rates for the induction reactor using a 13 API oil

sample and an air flow of 1 SLPM.

FIG. 10. Oxygen consumption profiles at five different heating rates ver-

sus time for the induction reactor and a 13 API oil sample and air flow of

0.6 SLPM.

C. Comparison with furnace kinetics cell

Before increasing the heating rates, we show the consis-

tency of the induction reactor with results from a conventional

furnace kinetics cell. We use the isoconversional method18 for

comparison. To perform isoconversional analysis, several ex-

periments at different heating rates are needed. The isoconver-

sional method provides a model-free apparent activation en-

ergy versus conversion.18 If two reactors are consistent, they

should yield a similar apparent activation energy curve versus

conversion.

Figure10shows oxygen consumption profiles at five dif-

ferent heating rates (Fig.11) for a 13 API oil sample and air

flow of 0.6 SLPM. Figure 12shows the apparent activation

energy (isoconversional fingerprint) obtained by the induction

reactor and the conventional furnace kinetics cell. The shaded

region in Fig.12 represents the confidence region of 95% of

the result after taking into account measurement uncertain-

ties (primarily temperature) coming from induction reactor.

Figure12 demonstrates that the two devices give consistent

isoconversional fingerprints.

FIG. 11. Temperature profiles at five different heating rates versus time in

the induction reactor and a 13 API oil sample and air flow of 0.6 SLPM.

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http:/ /scitationnew.aip.org/termsconditions. Downloaded

177.20.130.9 On: Tue, 10 Dec 2013 18:34:33

-

8/12/2019 An Induction Reactor-combustion

7/8

075115-6 Bazarganet al. Rev. Sci. Instrum.84, 075115 (2013)

FIG. 12. Apparent activation energy curves of a 13 API oil sample obtained

by induction reactor and a conventional furnace kinetics cell.

D. Large heating rate

As mentioned earlier, the induction reactor is able to op-erate at wide ranges of heating rate. Figure13shows the oxy-

gen consumption (right axis) and temperature profiles (left

axis Figure 13) at heating rates of 2, 5, 8, 12, 16, 20, 25,

30 C/min. This is the first time that such data are avail-

able over such a broad range of heating rates for crude oil

oxidation.

FIG. 14. Oxygen consumption versus time at heating rates of 8, 12, 16, 20,

25, 30 C/min for a 13 API oil sample and air flow of 0.6 SLPM.

There are several interesting observations suggested by

these figures. First, for heating rates greater than 5

C/min,oxygen consumption is not complete even at 750 C. This

means that the heating rate is greater than the reaction rate.

Consequently, oxidation reactions continue even after the

peak temperature. Second, LTO and HTO peaks merge at

larger heating rates. Figure 14 depicts oxygen consumption

versus time for heating rates of 8, 12, 16, 20, 25, 30 C/min.

FIG. 13. (a)(h) Temperature profile (left axis) and associated oxygen consumption (right axis) versus time for the induction reactor and a 13 API oil

sample at an air flow of 0.6 SLPM.

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http:/ /scitationnew.aip.org/termsconditions. Downloaded

177.20.130.9 On: Tue, 10 Dec 2013 18:34:33

-

8/12/2019 An Induction Reactor-combustion

8/8

075115-7 Bazarganet al. Rev. Sci. Instrum.84, 075115 (2013)

TABLE II. Total oxygen consumption at different heating rates.

Heating rate (C/min) Oxygen consumption (102 SL)

2 66.58

5 67.01

8 65.89

12 67.22

16 66.19

20 65.9625 64.55

30 66.39

It shows that LTO and HTO peaks merge together as heat-

ing rate increases. At 30 C/min, just one peak is observed

meaning that LTO and HTO are completely merged. Third,

the total amounts of oxygen consumption (Table II) is the

same within measurement error for all heating rates. This has

been confirmed using different crude-oil samples.33

IV. CONCLUSION

A new RTO kinetics reactor has been designed. It en-

ables us to study the kinetics of crude-oil oxidation at a wider

range of heating rates, covering the entire range of the fire-

front zone in a combustion tube experiment. This helps us to

evaluate better the predictability of reaction models for simu-

lating the combustion propagation front. By using the isocon-

versional method, the consistency of the induction reactor and

the furnace kinetics cell results has been verified. Finally, the

results of ramped temperature oxidation of a crude-oil sample

have been shown. The results suggest:

At low heating rates, less than 3 C/min, the new re-

actor gives the same result as the conventional kinetics

cell experiment. A wide range of heating rates is achieved by the new

reactor. For the first time, the oxidation profiles of

crude oil at large heating rates up to 30 C/min are

shown. The new reactor appears to exhibit heating rates suffi-

cient to achieve rate-limiting oxidation of crude oil.

1C. P. Gadelle, J. G. Burger, C. P. Bardon, V. Machedon, A. Carcoana, and

V. Petcovici, Heavy-oil recovery by in situcombustion: Two field cases in

Romania,J. Pet. Technol. 33, 2057 (1981).2G. Moritis, EOR oil production up slightly, Oil Gas J. 96(16), 4956

(1998).3T. M. Counihan, A successful in situ combustion pilot in the Midway-

Sunset field, California, in Proceedings of the SPE California Regional

Meeting, Bakersfield, California, 1977.4D. M. Marjerrison and M. R. Fassihi, Performance of Morgan pressure

cyclingin situ combustion project, in Proceedings of the SPE/DOE Im-

proved Oil Recovery Symposium, Tulsa, Oklahoma 1994.5P. S. Sarathi, In situ combustion handbook: Principles and practices,

Technical Report No. DOE/PC/91008-0374(National Petroleum Technol-

ogy Office, U.S. Department of Energy, 1999).

6M. Prats, Thermal recovery, Society of Petroleum Engineers Monograph

No. 7 (Society of Petroleum Engineers, 1982).7W. L. Penberthy and H. J. Ramey, Design and operation of laboratory

combustion tubes,SPE J. 6(2), 183198 (1966).8C. Y. Lin, W. H. Chen, S. T. Lee, and W. E. Culham, Numerical simula-

tion of combustion tube experiments and the associated kinetics ofin situ

combustion processes,SPE J. 24(6), 657666 (1984).9H. J. Tadema, Mechanism of oil production of underground combustion,

in Proceedings of the World Petroleum Conference, 1959.10A. Jess and A. K. Andresen, Influence of mass transfer on thermogravi-

metric analysis of combustion and gasification reactivity of coke,Fuel89,1541 (2010).

11J. H. Bae, Characterization of crude-oil for fireflooding using thermal

analysis method,SPE J. 17(3), 211218 (1977).12S. Vossoughi and Y. E. Shoubary, Kinetics of crude-oil coke combustion,

SPE J. 4(2), 201206 (1989).13M. V. Kok, Use of thermal equipment to evaluate crude oils, Ther-

mochim. Acta214(2), 315324 (1993).14D. V. Yannimaras, A. H. Sufi, and M. R. Fassihi, The case for air injection

into deep light oil reservoir, in Proceedings of the 6th European Sympo-

sium on Improved Oil Recovery, 1991.15D. V. Yannimaras and D. L. Tiffin, Screening of oil forin situ combustion

at reservoir conditions by accelerating-rate calorimetry,SPE J. 10(1), 36

39 (1995).16B. C. Burger and J. G. Sahuquet, Chemical aspects ofin situcombustion-

heat of combustion and kinetics,SPE J. 12(5), 410422 (1972).17

A. Lapene, G. Debenest, M. Quintard, L. M. Castanier, M. G. Gerritsen,and A. R. Kovscek, Kinetics oxidation of heavy oil. 1. Compositional and

full equation of state model,Energy Fuels 25(11), pp. 48864895 (2011).18M. Cinar, L. M. Castanier, and A. R. Kovscek, Isoconversional kinetic

analysis of the combustion of heavy hydrocarbons,Energy Fuels 23, 4003

(2009).19D. D. Mamora, New findings in low-temperature oxidation of crude-oil,

in Proceedings of the SPE Asia Pacific Oil and Gas Conference, 1995.20M. R. Fassihi, W. E. Brigham, and H. J. Ramey, Reaction kinetics ofin

situ combustion: Part 2Modeling,SPE J. 24(4), 408416 (1984).21API is a measure how heavy or light a petroleum fluid is compared to water.

API gravity of a petroleum fluid is related to its specific gravity() at 60 F

by: API = 141.5 131.5.

22R. G. Moore, J. D. M. Belgrave, R. Mehta, M. Ursenbach, C. C. J. Lau-

reshen, and K. Xi, Some insights into the low-temperature and high-

temperaturein situ combustion kinetics, in Proceedings of the SPE/DOE

Enhanced Oil Recovery Symposium, 1992.23V. Rundev, D. Loveless, R. Cook, and M. Black, Handbook of Induction

Heating(Marcel Dekker, 2003).24S. Zinn and S. L. Semiatin, Elements of Induction Heating: Design, Con-

trol, and Applications(ASM International, 1988).25D. C. Giancoli, Physics: Principles with Applications, 6th ed. (Prentice

Hall, 2004).26H. D. Young, R. A. Freedman, T. R. Sandin, and A. L. Ford, Sear and

Zemanskys University Physics: With Modern Physics, 12th ed. (Pearson

Addison-Wesley, 2007).27W. Watson, A Text-Book of Physics: Including a Collection of Examples

and Questions, 7th ed. (Longmans, CO, 2007).28E. Rapoport and Y. Pleshivtseva, Optimal Control of Induction Heating

Processes(Taylor and Francis Group, 2007).29R. A. Serway and J. W. Jewett,Principles of Physics (with PhysicsNow and

InfoTrac), 4th ed. (Thomson, 2003).30

C. Moosbrugger and F. Cverna, ASM Ready Reference: Electrical andMagnetic Properties of Metals (ASM International, 2000).31D. J. Young,High Temperature Oxidation and Corrosion of Metals (Else-

vier, 2008).32J. Hepola, Construction and operation of an isothermal flow reactor sys-

tem for study of SO2 removal by injected limestone sorbents, Rev. Sci.

Instrum.61, 2682 (1990).33M. Bazargan, Measurement of in situ combustion reaction kinetics with

high fidelity and consistent upscaling for reservoir simulation, Ph.D. the-

sis, Stanford University, Stanford, CA, 94305-4007, USA, 2013.

This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http:/ /scitationnew.aip.org/termsconditions. Downloaded

http://dx.doi.org/10.2118/8905-PAhttp://dx.doi.org/10.2172/3175http://dx.doi.org/10.2118/1290-PAhttp://dx.doi.org/10.2118/11074-PAhttp://dx.doi.org/10.1016/j.fuel.2009.09.002http://dx.doi.org/10.2118/6173-PAhttp://dx.doi.org/10.2118/16268-PAhttp://dx.doi.org/10.1016/0040-6031(93)80068-Lhttp://dx.doi.org/10.1016/0040-6031(93)80068-Lhttp://dx.doi.org/10.2118/27791-PAhttp://dx.doi.org/10.2118/3599-PAhttp://dx.doi.org/10.1021/ef200365yhttp://dx.doi.org/10.1021/ef900222whttp://dx.doi.org/10.2118/9454-PAhttp://dx.doi.org/10.1063/1.1141860http://dx.doi.org/10.1063/1.1141860http://dx.doi.org/10.1063/1.1141860http://dx.doi.org/10.1063/1.1141860http://dx.doi.org/10.2118/9454-PAhttp://dx.doi.org/10.1021/ef900222whttp://dx.doi.org/10.1021/ef200365yhttp://dx.doi.org/10.2118/3599-PAhttp://dx.doi.org/10.2118/27791-PAhttp://dx.doi.org/10.1016/0040-6031(93)80068-Lhttp://dx.doi.org/10.1016/0040-6031(93)80068-Lhttp://dx.doi.org/10.2118/16268-PAhttp://dx.doi.org/10.2118/6173-PAhttp://dx.doi.org/10.1016/j.fuel.2009.09.002http://dx.doi.org/10.2118/11074-PAhttp://dx.doi.org/10.2118/1290-PAhttp://dx.doi.org/10.2172/3175http://dx.doi.org/10.2118/8905-PA