An Experimental Investigation of Wallinterference Effects for Parachutes in Closed Wind Tunnels

-

Upload

ravikrishna -

Category

Documents

-

view

12 -

download

1

description

Transcript of An Experimental Investigation of Wallinterference Effects for Parachutes in Closed Wind Tunnels

SAND89- 1485 • U C - 6 0 0 Unlimited Release Printed September 1989

An Experimental Investigation of Wall-Interference Effects for Parachutes in Closed Wind Tunnels

J. Michael Macha, Robert J. Buffington

Prepared by Sandia National Laboratories Albuquerque, New Mexico 87185 and Livermore, California 94550 for the United States Department of Energy under Contract DE-AC04-76DP00789

4)-'

JL .1.4 / &7e?

f \ / f ^1 . I.LI AKJ^J

. .1989

Issued b Departm NOTIC1 agency o: ment noi contractc or implie complete disclosed Referenc trade na constitut United S subcontr: *„„ „ state or reflect those of the any of their contractors or

the United States

rk sponsored by an ited States Govern-!S, nor any of their y warranty, express y for the accuracy, product, or process 'ately owned rights, acess, or service by )es not necessarily or favoring by the ;heir contractors or do not necessarily

United States Government, any agency thereof or subcontractors.

L I N D A H A L L L I B R A R Y

O A k / l t^OOCVA

Printed in the United States of America. This report has been reproduced directly from the best available copy.

Available to DOE and DOE contractors from Office of Scientific and Technical Information PO Box 62 Oak Ridge, TN 37831

Prices available from (615) 576-8401, PTS 626-8401

Available to the public from National Technical Information Service US Department of Commerce 5285 Port Royal Rd Springfield, VA 22161

NTIS price codes Printed copy: A02 Microfiche copy: A01

LINDA HALL LIBRARY

3 3690 00614 9271

SAND89-1485 Distribution Unlimited Release Category UC —600

Printed September 1989

An Experimental Investigation of Wall-Interference Effects for Parachutes

in Closed Wind Tunnels

J. Michael Macha Parachute Systems Division

Robert J. Buffington Experimental Aerodynamics Division

Sandia National Laboratories Albuquerque, NM 87185

Abstract A set of 6-ft-diameter ribbon parachutes (geometric porosities of 7 %, 15 %, and 30 %) was tested in various subsonic wind tunnels covering a range of geometric blockages from 2 % to 35 %. Drag, base pressure, and inflated geometry were measured under full-open, steady-flow conditions. The resulting drag areas and pressure coefficients were correlated with the bluff-body blockage parameter (i.e., drag area divided by tunnel cross-sectional area) according to the blockage theory of Maskell. The data show that the Maskell theory provides a simple, accurate correction for the effective increase in dynamic pressure caused by wall constraint for both single parachutes and clusters. For single parachutes, the empirically derived blockage factor KM has the value of 1.85, independent of canopy porosity. Derived values of KM for two- and three-parachute clusters are 1.35 and 1.59, respectively. Based on the photometric data, there was no deformation of the inflated shape of the single parachutes up to a geometric blockage of 22%. In the case of the three-parachute cluster, decreases in both the inflated diameter and the spacing among member parachutes were observed at a geometric blockage of 35%.

3

Acknowledgements The authors are grateful to Messrs. Brazfield, Peepers, Powers, Smith, Stark, Tate

and Whinery of Sandia Laboratories for their involvement with the models and experiments. We also acknowledge NASA for providing tunnel time at the Ames, Langley, and Lewis Research Centers.

Contents Acknowledgements 4 Summary 7 Nomenclature 8 Introduction 9 Theory of Wall Corrections 9 Experimental Program 11

General Procedure 11 Models and Tunnel Installation 11 Measurement Uncertainty 13

Experimental Results 14 Model Inflated Geometry 14 Drag Area and Pressure Coefficient 16

Wall-Interference Correction 19 Single Parachutes 19 Parachute Clusters 20

Conclusions 21 References 21

Figures 1 Parachute dimensional data 12 2 Wind-tunnel installation details 13 3 Inflated shape of the 30%-porous model in Tunnel No. 4 14 4 View from downstream of the two-parachute cluster in Tunnel No. 2 15 5 View from downstream of the three-parachute cluster iff Tunnel No. 2 16 6 Variation in single-parachute uncorrected drag area with the Maskell bluff-body blockage

parameter 17 7 Variation in uncorrected base-pressure coefficient with the Maskell bluff-body blockage parameter 18 8 Variation in cluster uncorrected drag area with the Maskell bluff-body blockage parameter 19 9 Correction to dynamic pressure for single parachutes 20

Tables 1 Wind Tunnels Used in the Blockage Study 11 2 Data Summary for the Single Parachutes 17 3 Data Summary for the Clusters 18

LINDA HALL LIBRARY 5"6

KANSAS CITY, MO

Summary An extensive wind tunnel investigation was con

ducted to gather information on wall-interference effects for parachutes. A set of ribbon parachutes with geometric porosities of 7 %, 15 %, and 30 % was tested in six, solid-wall, subsonic wind tunnels covering a range of geometric blockages from 2 % to 35 %. Both single parachutes and clusters of two and three parachutes were studied.

The ultimate effect of the constraint imposed by the tunnel walls is an increase in airstream velocity in the vicinity of the parachute. Reference flow conditions must be corrected to reflect this higher velocity to avoid substantial errors in aerodynamic coefficients derived from wind tunnel measurements. The study discussed in this report was prompted by the lack of existing wall-interference data specifically applicable to parachutes and by the need for a correction method of verified accuracy.

Measurements of drag and canopy base pressure were correlated with the ratio of drag area to tunnel cross section according to an existing bluff-body blockage theory. The resulting equation for the in

crease in airstream dynamic pressure caused by wall constraint is

± - i + K ^ qu c

where qu is the as-measured, uncorrected dynamic pressure, CDSU the uncorrected drag area of the parachute, and C the cross-sectional area of the wind tunnel. The blockage factor, KM, has been evaluated from the experimental data base.

For the single parachutes, KM = 1.85 independent of canopy porosity. Derived values of KM for the two-and three-parachute clusters are 1.35 and 1.59, respectively. The invariance of the blockage factor with respect to geometric porosity suggests that the derived values of KM may be applied to circular and conical canopies in general. Photometric data show that single parachutes can be tested at geometric blockages as great as 22% without model deformation. In the case of the three-parachute cluster, significant distortion of the inflated shape was observed at a geometric blockage of 35 %.

7

Nomenclature c LDS

cP D

Dc

KM

Lr

Ls

N

P

Ps

q

sP

tunnel cross-sectional area

model drag area, D/q

pressure coefficient, (p — ps)/q

model drag force

Canopy constructed diameter, ~ 6 ft

Maskeli bluff body blockage factor

riser length

suspension line length, 6 ft

number of parachutes in a cluster

canopy surface pressure

free-stream static pressure

free-stream dynamic pressure

model frontal projected area

Subscripts

u uncorrected for wall interference

/

8

An Experimental Investigation of Wall-Interference Effects for Parachutes

in Closed Wind Tunnels

Introduction Because of the complexity of the fluid dynamics

involved, advances in parachute technology rely heavily on experimentation. Conventional, solid-wall wind tunnels are often used as an alternative to flight testing, especially when the objective of the investigation is steady-state performance. However, because aerodynamic measurements made in a wind tunnel are subject to errors caused by the flow-constraining influence of the tunnel walls, prudent testing practice dictates that the size of the parachute relative to that of the tunnel be consistent with the ability to correct for this effect. In the past, no generally accepted procedure for treating wall interference for parachutes existed; individual investigators applied corrections on an ad hoc basis, often using adaptations of methods developed for other types of models.

The applicability of the various correction methods used and the accuracy of the reported data should be viewed with some skepticism because of the unique features of a parachute compared with other aerodynamic devices. For example, the large wake emanating from the canopy causes the interference to be greater for a parachute than for a streamlined body with the same frontal area, thus precluding the use of simple methods based on potential theory. In addition, the inflated shape of a parachute will be distorted if the wall constraint is severe enough. And in the case of multiple-parachute clusters, the measured performance may be further in error because of a change in the spacing among members of the cluster. Finally, the relatively large dimensional tolerances associated with fabric construction and the requirement to replicate material elastic properties place a practical limit on the miniaturization of parachutes. This restriction on model scale often makes it difficult to observe even a modest upper limit on geometric blockage (i.e., the ratio of the inflated frontal area of the model to the area of the tunnel) except in the few largest wind tunnels in existence.

The purpose of this investigation was to generate an adequate experimental data base for single parachutes and multiple-parachute clusters with which to formulate and validate an accurate blockage correction method. The models used were of ribbon design covering a range of geometric porosities, but the results are believed to be applicable to any parachute of circular or conical construction. Use of the correction method should significantly increase confidence in future steady-state wind tunnel data and may stimulate a more extensive use of wind tunnels by increasing the acceptable upper limit on geometric blockage.

Theory of Wall Corrections In a solid-wall test section, the blocking effect of

the wall on the free displacement of streamlines causes velocities in the vicinity of a model to increase. If the resulting extraneous pressure gradient over the length of the model is not too great, the character of the viscous flow (i.e., the boundary layer thickness and locations of flow separation) remains essentially the same as in an unconstrained airstream. Under these conditions, model force and pressure measurements can be adequately corrected on the basis of the average increase in dynamic pressure along the tunnel centerline. That is, in incompressible flow,

^ D ° U (1 — Cpu)

"C^S" = (1 - Cp) P,u/ _ _q_ (D

Here, q is the dynamic pressure of the airstream, CDS the model's drag area (i.e., drag divided by q), and Cp

the pressure coefficient at any point on the model. The subscript "u" denotes as-measured, uncorrected quantities; variables without subscript are corrected quantities.

The ability to predict the increase in dynamic pressure is directly related to how amenable the flow

around the body is to mathematical description. For streamlined shapes, the interference velocity field is readily determined from a representation of the walls, the body, and the narrow trailing wake with potential flow singularities. The computational part of this approach has been reduced to a chart look-up procedure as presented in Reference 1.

In the case of a bluff body such as a parachute, the large wake dominates the flow field and the wall-constraint problem. The internal mechanics of the wake are not well enough understood to be accurately modeled by singularities without additional flow-field measurements such as the static pressure distribution along the tunnel wall. The evolution of this "pressure signature" method has been documented by Hackett,2

and there is no reason to doubt its applicability to parachutes. However, the pressure signature method requires tunnel instrumentation and on-line computing resources that are not yet in place at most wind tunnels. In the interim, there exists a need for an approximate, explicit correction procedure of acceptable and verified accuracy. Quantitative information on the deformation of individual parachutes and parachute clusters at high blockages is also needed, since a change in model geometry makes any attempt at wall correction a dubious undertaking.

An approximate correction method of proven accuracy for a variety of nonlifting two- and three-dimensional bluff bodies has been developed by Maskell.3 His approach is based on the premise that the form of the pressure distribution about a model is not altered by the proximity of the tunnel walls (i.e., Eq (1)). This assumption is essentially satisfied if there is no displacement of the flow-separation line and, in the case of a flexible model, no deformation. Maskell amplified the relation between model drag and base pressure by applying the momentum equation to the control volume bounded by the tunnel walls, the body, and the constant-pressure surface delimiting the near wake. To complete the set of equations defining the blocking effect of the walls, Maskell introduced a relation that accounts for the distortion of the wake. The form of this auxiliary relation, which was corroborated by experimental data obtained with a series of square plates, is presumed to hold generally for bluff bodies in incompressible flow.

According to Maskell, the effective increase in dynamic pressure is given by

where C is the cross-sectional area of the wind tunnel and KM is the bluff-body blockage factor for the model shape of interest. Since KM is independent of the degree of wall constraint and the geometric blockage does not appear explicitly, Eq (2) is especially suited to on-line correction during data acquisition for parachutes where the inflated shape may not be known a priori.

According to additional details of Maskell's theory,3 KM is equal to the negative reciprocal of the average near-wake pressure coefficient in an unconstrained flow. That is,

KM = - — ^ • (3) p, base avg.

For the body shapes originally considered by Maskell (i.e., thin, square plates normal to the flow), the near wake is a region of nearly constant pressure. In this case, Eqs (1) to (3) can be used to determine KM

from measurements of CDSU and a single pressure somewhere on the base of the model.

For bluff shapes with appreciable depth in the flow direction, Eq (2) is still valid, but the relationship between KM and the average base pressure may require modification. In a study of two-dimensional rectangular prisms, Awbi4 found it was necessary to include a multiplicative factor, A, on the right-hand side of Eq (3). As the depth-to-height ratio of the prism increased from near zero (i.e., a thin plate), A first increased to values greater than 1.0 and then monotonically decreased to values less than 1.0.

For some bluff bodies, including parachutes, pressure is not uniform over the base so the average value must be determined from a survey of the surface. In practice, other constraints on model design often prevent the incorporation of a sufficient number of measurement orifices.

In any event, KM can be evaluated for a particular body or family of similar bodies by directly fitting Eqs (1) and (2) to pressure or drag measurements made on models over a range of geometric blockages. This approach has been used previously by Pass5 for triangular plates and by Awbi and Tan6 for spheres.

The unique feature of a parachute compared to other bluff bodies is its flexibility, and the fact that the inflated shape is determined by a state of equilibrium between internal stresses and surface pressures. To maintain a constant geometry in any experimental wall-effects study, it is necessary to keep constant the ratio of corrected dynamic pressure to the elastic moduli of the fabric components of the model. At

10

geometric blockages below which model distortion occurs, the blockage factor, KM, for an individual parachute should then depend on the physical characteristics that influence the inflated shape; these may include canopy type (solid, ribbon, guide surface, cruciform, etc.) and the stage of inflation (i.e., full-open or reefed). The value of KM for a cluster of parachutes should depend on the collective shape presented to the airstream, which may be influenced by the length of risers used as well as canopy type.

Experimental Program

General Procedure The experimental procedure consisted of measur

ing drag, base pressure, and airstream properties for a set of non-reefed parachutes in wind tunnels of different sizes. Compared to the alternate approach of testing different-size but geometrically similar parachutes in a single wind tunnel, the procedure used has the advantage of eliminating extraneous scale effects that might obscure the true wall-interference effects. Specifically, the difficulty during model fabrication of maintaining precise geometric similarity among canopies of different diameters was avoided. Furthermore, by testing one size of parachute at a fixed drag level, the corrected airstream velocity is necessarily constant regardless of the tunnel size. Then, the dynamic similarity parameters which are functions of velocity and which determine the aerodynamic performance and inflated geometry of the parachute (i.e., Mach and Reynolds numbers and the elasticity parameters) are duplicated as well.

The variable among the set of models was geometric porosity. Single parachutes were tested in each wind tunnel at a fixed drag level of 250 lb, or equiva-lently, at corrected dynamic pressures of 13 to 19 psf depending on their porosity. The same method was used for the clusters of two and three parachutes, with

the drag set at 500 lb and 750 lb, respectively. Movie and still cameras recorded model geometry.

The cross-sectional areas of the solid-wall wind tunnels used in the study and the resulting approximate geometric blockage ratios for a single parachute are listed in Table 1. For convenience, specific wind tunnels will be cited by number in the following discussions. Except for Tunnel No. 4, the test sections were rectangular in cross section; Tunnel No. 4 was rectangular with 45-deg filleted corners. Single-parachute configurations were tested in all six of the wind tunnels, whereas the clusters of two and three parachutes were tested in Tunnel Nos. 1, 2, and 3, only.

Table 1. Wind Tunnels Used in the Blockage Study

c Wind Tunnel (sq ft) Sp/C

1. Lockheed 30X26 ft 780.0 0.019 2. NASA Langley 14x22 ft 315.4 0.048 3. NASA Lewis 9X15 ft 130.5 0.116 4. General Dynamics 8X12 ft 91.5 0.166 5. NASA Ames 7X10 ft 70.4 0.217 6. V o u g h t 7 X l 0 f t 70.0 0.217

Models and Tunnel Installation The models used in the tests were 6-ft-diameter,

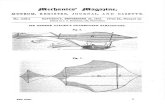

12-gore ribbon parachutes with a 20-deg constructed cone angle. Typical model dimensions are shown in Figure 1. Spacing between the l-in.-wide ribbons was adjusted to provide a uniform geometric porosity from vent to skirt of 7%, 15%, or 30%. Canopy materials were nylon tape (MIL-T-5038, Type III) with sufficient strength to limit elastic elongation to less than 1 % at the test dynamic pressure. The Kevlar suspension lines (MIL-C-87129, Type IV, 400 lb) were 6 ft long.

11

CONSTRUCTED CANOPY SHAPE

Figure 1. Parachute dimensional data

A pressure orifice was located on the outside centerline of each gore, 12 in, from the apex. Examination of data reported by Pepper and Reed7 for parachutes of similar construction had shown that the pressure at this location is approximately equal to the radially averaged pressure. The orifices consisted of 0.035-in.- diameter holes drilled in 0.5-in.-diameter by 0.125-in.-thick rigid plastic disks firmly sewn to the outer surface of the canopy. The twelve orifices were manifolded together with flexible tubing and connected to a single length of tubing attached to one of the suspension lines.

The same method of model installation was used in each facility and was designed to minimize structure volume and associated flow interference. The parachutes were attached to a single-component load cell mounted inside a 3.2-in.-diameter by 18-in.-long ogive-cylinder support body. The support body was suspended on the centerline of the tunnel by four 0.125-in.-diameter steel cables. The drag of the system was reacted by a cable or steel rod from the nose of the support body to a yoke, and then by a pair of 0.25-in.-diameter cables to the tunnel side walls. The plastic tubing from the manifolded pressure orifices was routed across the load cell and down one of the support-body centering cables to a transducer outside the test section. General features of the installation are illustrated in Figure 2.

For the single parachutes, the actual coupling of the suspension lines to the load cell was through

I- 18.1 in. 1

TYPICAL GORE DETAIL

twelve individual attachment points on a circle of 1.25-in. radius. Under load, this scheme produced sufficient torsional resistance to prevent the parachutes from rotating because of slight asymmetries in their construction.

The cluster configurations were composed of two or three of the 15 % -porous parachutes. Risers were added between the confluence point of the suspension lines and the load-cell assembly, with the length of the risers relative to that of the suspension lines given by the equation

- I = VH - 1 , (4) J-'s

where N is the number of parachutes in the cluster. To prevent members of a cluster from rotating about each other, the parachutes were tethered together at the skirt with 2-ft lengths of cord. In the first test of the series (Tunnel No. 2), it was found necessary to attach an additional tether from one of the parachutes to the tunnel floor to prevent rotation of the cluster as a unit. In subsequent tests, a rotary bearing was added to the base of the load-cell assembly to allow the clusters to rotate at will. It should be noted that the clusters did not rotate continuously; occasionally, part of one revolution would occur with a return to a stable geometry. With the addition of the swivel, it was not possible to measure canopy surface pressures for the clusters.

12

1 - T W 0 1 / 4 INCH STEEL CABLES 2 - FOUR 1/8 INCH STEEL CABLES 3 - 2 INCH OIA., 5.4 INCH LONG YOKE 4 - 3.2 INCH DIA., 1 . 75 INCH LONG

SUPPORT BODY 5 - 6 FOOT CONSTRUCTED DIA., PARACHUTE 6 - TUNNEL THROAT

7 - DISTANCE FROM YOKE TO CENTER BODY VOUGHT 7X10 5' ROD NASA AMES 7X10 5' ROD GENERAL DYNAMICS 8X11 SINGLE 1/4"

CABLE (NO YOKE) NASA LEWIS 9X15 8' ROD NASA LANGLEY 14.5X21.8 7.3' ROD LOCKHEED, GA. 30X26 4' - 1/4" CABLE

8 - VOUGHT, NASA AMES I GENERAL DYNAMICS X < 6 INCHES

NASA LEWIS X = 6 8 INCHES LOCKHEED, GA X = 19' NASA LANGLEY X = 213 INCHES TURNBUCKLES AND EYEBOLTS

Figure 2. Wind-tunnel installation details

Measurement Uncertainty The uncorrected dynamic pressure at the model

location was measured in terms of the pressure difference between two sets of wall orifices ahead of the test section. Typically, the downstream set was at or near the end of the contraction. If a model is sufficiently large, its presence may affect the static pressure in this region. The resulting error in qu would obscure the genuine wall-interference effects. A supplemental investigation of the effects of the proximity of the model to the wall orifices was conducted in Tunnel No. 6. The results confirmed that the orifices were far enough removed from the models to accurately determine qu in all of the facilities used.

Based on demonstrated transducer accuracy, the uncertainty in all pressure measurements, including

those used to determine airspeed, was ±0.1 psf. The instrument uncertainty in the measurement of model drag was ± 1 lb. The propagation of uncertainties in results calculated from these measurements was estimated using the method of Kline and McClintock (see, e.g., Reference 8). The maximum uncertainties in the reported data, as a percentage of the quoted values, are as follows: drag area, ±1.5%; pressure coefficient, ±4%. The inflated diameters of the models, which were determined from photometric data, have an estimated uncertainty of ±1.5%.

The overall quality of the data was enhanced by averaging values over an appropriate time scale and, for most configurations, by obtaining multiple measurements at each blockage from two or three identical parachute models and/or repeated measurements from the same model.

13

Experimental Results

Model Inflated Geometry Analysis of the photometric data for the single-

parachute configurations showed that there was no change in inflated shape over the range of geometric blockages investigated. The mid-gore diameters of the 7%-, 15%-, and 30%-porous models were 54.5, 55.1, and 52.3 in., respectively. Figure 3 illustrates the inflated shape of the 30 % -porous model from orthogonal views; the general features shown are typical of the 7%- and 15%-porous models as well.

The maximum geometric blockage investigated for the cluster of two 15%-porous parachutes was 0.232 in Tunnel No. 3. There was no observable effect

HHB.;.*

Figure 3. Inflated shape of the 30%-porous model in Tunnel

of wall constraint on either the inflated shape of a member parachute or the spatial relation between the two parachutes. The canopies remained in contact with each other as shown in Figure 4, with the risers making an angle of ~ 3 0 deg.

The greatest geometric blockage for the cluster of three parachutes was 0.348, also in Tunnel No. 3. At the lower blockage ratios in Tunnels No. 1 and 2, the cone angle formed by the risers was approximately 29 deg; in Tunnel No. 3, the cone angle decreased to approximately 26.5 deg and the mid-gore diameter of a member parachute decreased to 53.2 in. This change in geometry represents a 12% decrease in the area of a circle circumscribing the three canopies. Figure 5 shows the geometry of the three-parachute cluster in Tunnel No. 2.

Figure 4. View from downstream of the two-parachute cluster in Tunnel No. 2

15

• * • « * • »

/ * f * - .

• • - \ . - C * - . ' . - ? * T £

Figure 5. View from downstream of the three-parachute cluster in Tunnel No. 2

Drag Area and Pressure Coefficient

The uncorrected drag areas determined for the single parachutes are listed in Table 2. Where multiple measurements were made, both the mean value and the standard deviation are given. For all three canopy porosities, the trend is for CDSU to increase as tunnel size decreases. There is a notable discrepancy between the data from Tunnel Nos. 5 and 6 for the 7 % - and 15 % -porous canopies. Although the geometric blockages are essentially the same, the uncorrected drag areas from Tunnel No. 6 are lower by amounts that are significantly larger than the standard deviations observed in any of tunnels. The discrepancy may be the result of subtle differences between the two facilities, such as the location and design of the breather at the downstream end of the test section and the degree to which the test section proper was sealed from the atmosphere. It is probable that these features would begin to influence the flow around a bluff model at high blockages.

In Figure 6, the uncorrected drag areas for single parachutes are plotted as a function of the Maskell blockage parameter (i.e., uncorrected drag area divided by the tunnel cross-sectional area). As predicted by Eqs (1) and (2), the data exhibit a linear dependence within measurement accuracy.

Canopy pressures were measured for the single-parachute configurations in Tunnel Nos. 2-5, and are listed in Table 2 in coefficient form. As shown in Figure 7, these data also exhibit a linear dependence on the Maskell blockage parameter.

Drag-area measurements for the cluster configurations are summarized in Table 3. In Figure 8, these data are represented by the solid symbols. The three data points for the two-parachute cluster clearly establish a linear variation with the Maskell blockage parameter. In the case of the three-parachute cluster, the test results at the largest blockage ratio must be discounted because of the geometry change discussed previously. The open symbols are inferred from the single parachute data, and are discussed in a following section.

16

Table 2. Data Summary for the Single Parachutes

Canopy Porosity

7%

15%

30%

Tunnel No.

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

CJJSJ

Mean

20.37 20.98 25.81 31.96 38.58 35.57

18.18 18.64 22.70 27.85 32.26 30.84

13.84 14.15 16.44 18.49 20.40 19.70

,(sq ft)

SD

0.06 0.22 0.05 0.25 0.64 —

0.43 0.28 —

0.31 0.52 —

0.07 0.20 0.29 0.52 —

1 _

Mean

— 1.688 1.968 2.427 2.913

—

1.699 1.941 2.401 2.756

—

1.635 1.843 2.114 2.258

—

^ p , u

SD

— 0.005 0.018 0.009 0.020

—

0.013 —

0.011 0.002

—

— •— — — —

CDSu (sq ft)

«#u

30

20

10

^^jur'

i

^ ^ k^

i i

5^

./" +

^/*-

CANOPY POROSITY

+ 7% A 15% * 30%

I I

0.10 0.20 0.30

CDSu

0.40 0.50 0.60

Figure 6. Variation in single-parachute uncorrected drag area with the Maskell bluff-body blockage parameter

17

1~Cp,u

3.00

2.60

2.20

I

1.80

1.40

1.40

1.40

-

-

- ^ ^

-

^ - - + }

. / "A ^

* ^ ^

—^ 1 _ J

+^-

CANOPY POROSITY

+ 7% A 15% ® 30%

i i

0 0.10 0.20 0.30 0.40 0.50 0.60

Figure 7. Variation in uncorrected base-pressure coefficient with the Maskell bluff-body blockage parameter

Table 3. Data Summary for the Clusters

N Tunnel

No. (sq ft)

1 2 3

1 2 3

36.35 39.93 52.88

56.39 67.89

102.10

18

C D S u (sq ft)

1 i U

100

80

60

40

20

-

-

3-CHUTE CLUSTER KM = 1.59

. , - " "

^ _ ^ - ^ r ^ " ^ ^

— 1 1 1 i

s*

^ ^

2-CHUTE CLUSTER KH = 1.35

1 1 !..__

- " "

•

0.10 0.20 0.30 0.40 0.50

D5u

0.60 0.70 0.80

Figure 8. Variation in cluster uncorrected drag area with the Maskell bluff-body blockage parameter

Wall-Interference Correction

Single Parachutes Linear, least-squares approximations were made

to the variations of CyS,, and 1 — Cpu with the Maskell blockage parameter as indicated by the solid lines in Figures 6 and 7. The vertical-axis intercepts represent values corrected for the effects of wall constraint. The corrected drag areas in units of square feet are 19.J, 17.1, and 13.3 for canopy porosities of 7%, 15%, and 30%, respectively. Corresponding corrected pressure coefficients are -0 .49 , - 0 . 5 1 , and -0 .52 . Although the slight increase in the magnitude of Cp with increasing porosity is marginally within the measurement uncertainty, the trend is consistent with pressure measurements on porous rigid disks reported in Reference 9. Assuming the pressures at the measurement location are representative of the average base pressures, Maskell's theory (i.e., Eq (3)) gives KM « 2.0.

A strictly empirical evaluation of KM which makes use of the drag-area measurements as well as the pressure measurements is achieved by directly fitting Nqs (J) and (2) to the data. The result of this proce

dure is shown in Figure 9. The same type of symbol has been used for both drag area and canopy pressure for a given porosity, as indicated by the pair of symbols'*^ each value of the blockage parameter. The data illustrate a high degree of conformity between the independent measurements of drag area and base pressure in determining the effective increase in dynamic pressure. The best-fit value of KM to the composite data for all three canopy porosities is 1.85. A plausible explanation for the small discrepancy between this value and the 2.0 based on Eq (3) is a slight difference between the locally measured and average base pressures, or possibly the failure to include an appropriate A-factor as suggested by Awbi.4

The derived blockage factor of 1.85 for parachutes compares favorably to those of 2.8 for a nonporous disk (evaluated from data reported in Reference 10) and of 3.6 for a sphere in subcritical flow.6 Generally, KM is greater for shapes with lower drag coefficients. The corrected drag coefficient based on solid frontal area of the inflated canopy (i.e., excluding the fraction of open area between ribbons) was approximately 1.35 for all three porosities. Tn comparison, typical values of the drag coefficient for a disk and a sphere are 1.1.8 and 0.46, respectively.

19

1.20

1.00

0.80

q-q, ^ u 0.60

0.40

0.20

-

-

-

-

s^*

/*>

A +/ / ^ *

CANOPY

+ A ©

H " 1 " 8 5

POROSITY

7% 15% 30%

0.10 0.20 0.30

CDSU

0.40 0.50 0.60

Figure 9. Correction to dynamic pressure for single parachutes

Parachute Clusters The drag area measurements for the cluster con

figurations were analyzed in the same manner as those for the single parachutes. The lower set of data in Figure 8 shows a linear relation between uncorrected drag area and the bluff-body blockage parameter for the two-parachute cluster. The best-fit value of KM for the three data points represented by the solid triangles is 1.35. Data from the wind tunnel investigation of cluster performance by Baca11 have been re-examined in light of the present wall-interference results. For riser lengths given by Eq (4), those data now show that the drag area of a cluster of N parachutes is equal to N times the drag area of a single parachute, within an estimated measurement uncertainty of ± 3 % . The frequently observed reduction in drag efficiency as the number of parachutes in a cluster increases only occurs with risers shorter than those used in the present study. The open triangle on the vertical axis of Figure 8 represents twice the corrected drag area of a single 15%-porous canopy from Figure 6. The excellent agreement between the single-parachute and cluster data is reassuring, given the relatively small number of data points for the cluster.

The upper set of data in Figure 8 is for the three-parachute cluster. The data point at the greatest

blockage has been ignored in evaluating the Maskell blockage factor because of the geometry distortion described earlier. For the two remaining data points, KM = 1.59. Again, the excellent agreement between the extrapolation of the cluster data to zero blockage and triple the corrected drag area of a single parachute represented by the open circle gives the required credibility to the cluster data.

Based on the available data, only a tentative discussion of the relationship among the values of KM

for the single parachute and the cluster configurations is possible. It might be argued that the two-parachute cluster illustrated in Figure 3 presents a shape with a higher aspect ratio than does the single parachute. The concurrent decrease in KM from 1.85 to 1.35 is qualitatively in agreement with the effect of increasing aspect ratio for rectangular plates reported by Maskell.3 This reasoning projects that the effective aspect ratio of the three-parachute cluster fell between the other two model configurations. Typically, the average base pressure coefficient increases in magnitude with aspect ratio. Had it been possible to obtain canopy pressure measurements for the clusters, the connection between Cp and KM suggested by Eq (3) might have provided greater insight into this question.

20

Conclusions An extensive wind tunnel investigation was con

ducted to gather information on wall-interference effects for parachutes. A set of non-reefed ribbon parachutes of 7%, 15%, and 30% geometric porosity was tested in six different subsonic wind tunnels, covering a range of geometric blockages from 2 % to 35 %. In addition to single-parachute configurations, clusters of two and three parachutes were studied. The resulting measurements of drag and canopy base pressure were correlated with the ratio of drag area to tunnel cross section, according to the bluff-body blockage theory of Maskell. Analysis of the experimental data leads to the following conclusions:

1. The Maskell wall-correction equation (i.e., Eq (2)) was shown to accurately reflect the effective increase in tunnel dynamic pressure for both single parachutes and parachute clusters.

2. For single parachutes, the Maskell blockage factor KM has a value of 1.85, independent of canopy porosity. Photometric data showed that there was no deformation of the inflated geometry up to the maximum geometric blockage ratio of 0.217.

3. Derived values of KM for the two- and three-parachute clusters were 1.35 and 1.59, respectively. In the case of the three-parachute cluster, changes in model geometry as a result of wall constraint were detected at the highest geometric blockage ratio of 0.348; both the inflated diameter and the spacing among member parachutes decreased significantly.

The invariance of the Maskell blockage factor with respect to the porosity of the ribbon parachutes used in this study suggests that the derived values of KM may be applied to circular and conical canopies in general. And although the reported data are for full-open canopies, the corrections are probably adequate for moderately reefed configurations as well. On the other hand, considering the variation in the blockage factor between a disk and a sphere, tentatively setting KM « 3.0 may be more appropriate for very highly reefed, single parachutes. The present data afford no grounds to extrapolate to clusters with more than three parachutes. The data do show that the upper limit on geometric blockage for testing parachutes without significant model deformation resulting from wall constraint lies between 23 % and 35 %.

References 'W. H. Rae and A. Pope, Low-Speed Wind Tunnel

Testing, 2nd ed. John Wiley & Sons, New York, 1984, Chap. 6.

2J. E. Hackett, "Living with Solid-Walled Wind Tunnels," AIAA Paper 82-0583, presented at AIAA 12th Aerodynamic Testing Conference, Williamsburg, VA, March 22-24, 1982.

3E. C. Maskell, A Theory of the Blockage Effects on Bluff Bodies and Stalled Wings in a Closed Wind Tunnel, Royal Aircraft Establishment Report No. Aero 2685, UK, November 1963.

4H. B. Awbi, "Wind Tunnel Wall Constraint on Two-Dimensional Rectangular-Section Prisms," J. Industrial Aerodynamics, Vol. 3, No. 4, 1978, pp. 285-306.

5C. Q. Pass, "A Wake Blockage Correction Method for Small Subsonic Wind Tunnels," AIAA Paper 87-0294, presented at AIAA 25th Aerospace Sciences Meeting, Reno, NV, January 12-15, 1987.

6H. B. Awbi, and S. H. Tan, "Effect of Wind-Tunnel Walls on the Drag of a Sphere," J. Fluids Engineering, Vol. 103, September 1981, pp. 461-465.

7W. B. Pepper, and J. F. Reed, "Parametric Study of Parachute Pressure Distribution by Wind Tunnel Testing," J. Aircraft, Vol. 10, No. 11, November 1976, pp. 895-900.

8J. P. Holman, and W. J. Gajda, Experimental Methods for Engineers, 4th ed. McGraw-Hill, New York, 1984, Chap,^.

9S. A. Peshchenko, "Aerodynamic Characteristics of Permeable Disks at Subsonic Free-Stream Flow Velocities," Trans, from Russian in Fluid Dynamics, Vol. 21, No. 4, 1986, pp. 610-615.

10H. Hoist, "Wind Tunnel Wall Interference in Closed, Ventilated and Adaptive Test Sections," in Wind Tunnel Wall Interference Assessement and Correction, Ed. by P. A. Newman and R. W. Barnwell, NASA CP-2319, Washington, 1984, pp. 61-78.

HB. K. Baca, An Experimental Study of the Performance of Clustered Parachutes in a Low-Speed Wind Tunnel, Sandia Report SAND85-0813, Sandia National Laboratories, Albuquerque, NM, December 1985.

21

DISTRIBUTION:

1 Boeing Commercial Airplane Company Attn: R. A. Day

Mail Stop 1W-82 PO Box 3707 Seattle, WA 98124

1 Boeing Vertol Company Attn: D. Bevan

Mail Stop P38-07 PO Box 16858 Philadelphia, PA 19142

1 Calspan Corporation Transonic Wind Tunnel Attn: C. Reid PO Box 400 Buffalo, NY 14225

1 California Institute of Technology Attn: Taras Kiceniuk

Mail Code 205-45 1201 East California Boulevard Pasadena, CA 91125

1 Chrysler Corporation Aerodynamic Engineering Office Attn: G. F. Romberg

CIMS 413-03-06 PO Box 1118 Detroit, MI 48228

1 Colorado State University Fluid Dynamics and Diffusion Laboratory Attn: J. E. Cermak Fort Collins, CO 80523

1 Fluidyne Engineering Corporation Attn: D. P. Saari 5900 Olson Memorial Highway Minneapolis, MN 55422

1 Ford Motor Company Wind Tunnel Building Attn: R. R. Lord PO Box 2053 Dearborn, MI 48121

1 General Dynamics/Convair Division Attn: R. E. Attlesey

Mail Zone 86-6660 PO Box 85377 San Diego, CA 92138

1 General Motors Technical Center Aerodynamics Laboratory Attn: P. S. Beebe 6363 East 12-Mile Road Warren, MI 48090

1 Georgia Institute of Technology School of Aerospace Engineering Attn: P. Hellsten Atlanta, GA 30332

1 Grumman Aerospace Corporation Attn: F. Blomback

Mail Stop C25/05 South Oyster Bay Road Bethpage, NY 11714

1 University of Illinois Attn: K. R. Sivier 104 S. Mathews, Room 102 Urbana,IL 61801

2 Lockheed Aeronautical Systems Division Low Speed Wind Tunnel Attn: G. A. Pounds

D. J. Wilsden 1055 Richardson Road Smyrna, GA 30080

1 LTV Wind Tunnel Laboratories Low Speed Wind Tunnel Attn: R. H. Oldenbuttel PO Box 531046 Grand Prairie, TX 75053

1 University of Maryland Glenn L. Martin Wind Tunnel Attn: J. B. Barlow

Building 081, Room 1102 College Park, MD 20742

1 McDonnell Aircraft Company Attn: M. Pershall

Dept. 254 PO Box 516 St. Louis, MO 63166

1 Massachusetts Institute of Technology Wright Brothers Wind Tunnel Attn: F. Durgin

Building 17-100 Cambridge, MA 02139

22

DISTRIBUTION (continued):

2 NASA Ames Research Center Attn: C. T. Snyder

Mail Stop 200-3 J. V. Kirk Mail Stop 247-3

Moffett Field, CA 94035

4 NASA Langley Research Center Attn: R. V. Harris

Mail Stop 116 A. E. Phelps, III Mail Stop 286 F. P. Quinto Mail Stop 286 R. A. Kilgore Mail Stop 287

Hampton, VA 23665

2 NASA Lewis Research Center Attn: F. Katina

Mail Stop 6-8 G. Neimer Mail Stop 6-2

21000 Brookpark Road Cleveland, OH 44135

1 Northrop Corporation Aircraft Division Attn: F. W. Peitzman

Org. 3840/64 1 Northrop Avenue Hawthorne, CA 90250

1 University of Notre Dame Aerospace and Mechanical Engineering Attn: R. G. Nelson Notre Dame, IN 46556

1 Naval Ship Research and Development Center Aviation Department Attn: D. R. Chaddock

Code 1662 Bethesda, MA 20084

1 Pennsylvania State University Applied Research Laboratory Attn: A. L. Treaster P.O. Mux 30 Stale College, PA 16804

1 Princeton University Subsonic Wind Tunnel Attn: H. C. Curtiss MAE Department Princeton, NJ 08540

1 Rockwell International Corporation North American Aircraft Attn: R. B. Russell PO Box 92098 Los Angeles, CA 90009

1 Sverdrup Advanced Technology Attn: M. O. Varner PO Box 884 Tullahoma, TN 37388

1 Texas A&M University Low Speed Wind Tunnel Attn: O. W. Nicks Easterwood Airport College Station, TX 77843

1 University of Texas BRC Wind Tunnel Attn: J. C. Westkaemper 10100 Burnet Road, Bldg. 7 Austin, TX 78758

1 United Technologies Research Center Attn: A. Fasano Silver Lane East Hartford, CT 06108

1 USAF Wright Aeronautical Laboratories Attn: T. Tighe

AFWAL/FIMM Wright-Patterson AFB, OH 45433

1 US Air Force Academy Attn: Major V. Parisi

USAFA/DFAN Colorado Springs, CO 80840

1 US Army Aviation Research & Technology Activity

Attn: E. Austin SAVRT-TY-ATA

Fort Eustis, VA 23604

1 US Naval Academy Aerospace Engineering Department Attn: J. E. Allen Annapolis, MD 21402

23

DISTRIBUTION (continued):

1 University of Washington Department of Aeronautics & Astronautics Attn: W. H. Rae, Jr. Seattle, WA 98195

1 Wichita State University Wind Tunnel Operations Attn: M. L. Davidson Wichita, KS 67208

1 DSMA International, Inc. Attn: G. M. Elfstrom 6655 Airport Road Missassauga, Ontario LV4 1V8 CANADA

1 National Research Council Canada NAE Low Speed Aerodynamics Laboratory Attn: M. Nituch Bldg. M-2, Montreal Road Ottawa, Ontario K1A 0R6 CANADA

1 University of Western Ontario Boundary Layer Wind Tunnel Laboratory Attn: D. Surry London, Ontario N6A 5B6 CANADA

1 British Maritime Technology, Ltd Applied Fluid Mechanics Division Attn: J. F. Maybrey 67 Stanton Avenue Teddington, Middlesex TW 11 OJJ ENGLAND

1 Motor Industry Research Association Aerodynamics Department Attn: G. W. Carr Watling Street Nuneaton, Warwickshire CV10 OTU ENGLAND

1 Royal Aerospace Establishment 5-Metre Wind Tunnel Attn: K. Dolman Farnborough, Hants GU14 6TD ENGLAND

1 ONERA Large Wind Tunnels DPT (GME) Experimental Aerodynamics Division Attn: H. G. Consigny

B P 7 2 92 322 Chatillon Cedex FRANCE

1 Technion-Israel Institute of Technology Department of Aeronautical Engineering Attn: A. Seginer 32000 Haifa ISRAEL

1 Fiat Auto S.P.A. D.T.-S.P.-Gallerie Aerodinamiche E Climatiche Attn: B. V. Bonis Via F. Coppi 2 10043 Orbassano (Torino) ITALY

1 Industrie Pininfarina S.P.A. Galleria del Vento Attn: A. Cogotti Via Lesna 78 10095 Grugliasco (Torino) ITALY

1 FFA, Aeronautical Research Institute of Sweden Attn: K. Widing Box 11021 S-161, 11 Bromma SWEDEN

1 Volvo Car Corporation Climatic Wind Tunnel, PVT Attn: F. M. Christensen S-40508 Goteborg SWEDEN

1 Duits-Nederlandse Wind Tunnel Attn: A. H. Runge Voorsterweg 31 8316 PR MARKNESS THE NETHERLANDS

1 Daimler-Benz Aktiengesellschaft Attn: A. Kuhn Abt. ZFPA, Postfach 202 D-7000 Stuttgart 60 WEST GERMANY

1 Porsche Aktiengesellschaft Dept. EASS, MeBzentrum fur Aerodynamik Attn: J. D. Vagt Porschestrasse 7251 Weissach WEST GERMANY

24

DISTRIBUTION (continued):

1 Technical Hochschule, Darmstadt Attn: B. Ewald Petersenstrasse 30 6100 Darmstadt WEST GERMANY

1 Volkswagenwerk AG FO-AT-Klimawindkanal Attn: R. Buchheim Postfach 3180 Wofsburg WEST GERMANY

1 1 1 1 1 1

10 1 1 1 1 1

10 30

1 5 8

3

400 1510 1520 1530 1550 1551 1552 1553 1554 1555 1556 6225 1554 1552 8524 3141 3141-1

3151

R. C. Maydew J. W. Nunziato L. W. Davison D. B. Hayes C. W. Peterson J. K. Cole D. D. McBride and Staff W. L. Hermina D. P. Aeschliman W. R. Barton W. L. Oberkampf D. C. Reda R. J. Buffington J. M. Macha J. A. Wackerly S. A. Landenberger C. L. Ward For DOE/OSTI W. I. Klein