AMIF2014 – [Nautica] Andreas Echtermeyer, Compositi in applicazioni navali e off-shore

AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di...

-

Upload

arti-puglia -

Category

Automotive

-

view

166 -

download

6

description

Transcript of AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di...

![Page 1: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/1.jpg)

Advanced materials in Transmissions design and manufacturing. The GETRAG Bari plant experience.

C. Maselli, September 17th 2014

![Page 2: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/2.jpg)

April 12, 2023

Agenda

1. The GETRAG group

2. The Bari plant

3. The Bari plant: R&D capabilities

4. The Bari plant: ME capabilities

5. Materials in 6DCT250 (examples)

6. Carbon facing in Synchro-rings

7. Optimized steel and treatments for gearset components

8. Advanced materials in manufacturing processes

9. Conclusions

2 E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA

![Page 3: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/3.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA3

The GETRAG groupKey facts 2013

24 locations worldwide in Europe, North America and Asia

14 individual companies

3.2 Billion EUR 3.9 Million transmissions

Sales Global production

13,250

Employees

![Page 4: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/4.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA4

The Bari plant

Starting from green field (Dec.)

1.000.000 tm’s (Giu)

SOP 28x (Aug.)

Capacity inst. 28x: 728.000/year (2.600/day)

Total investments: ~ (250 + 130) mil € Shift pattern: 4 shifts (6 h/d - 6 dd/week)

28x FWD-Transaxle 5 speed Manual Transmission for gasoline and diesel engines – up to 280 Nm

SOP DCT250RSA (Apr.)

SOP Gear sets DCT250 (July)

Contract closure 28x (Dec.)sold transmissions 3.558.000

DCT250 Power Shiftfor gasoline and diesel engines – up to 250 Nm

SOP DCT250 Ford (May)

Capacity inst. DCT250: 380.000/year (~1.350/day)

1.000.000 tm’s (Jun)

SOP DCT250 EDISON

1996 – 1998 – 2000 – 2002 – 2004 – 2006 – 2008 – 2010 – 2011 – 2012 – 2013 – 2014 1996 – 1998 – 2000 – 2002 – 2004 – 2006 – 2008 – 2010 – 2011 – 2012 – 2013 – 2014

Certifications: ISO TS 16949, ISO 14001:2004, OHSAS 18001:1999, EMAS

![Page 5: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/5.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA

R&D capabilities

5

The Bari plant

Engineering Team

Production Support

Design of new components & variants

Continuous improvements (shiftability, durability, material…)

Testing

NVH testing, durability & shiftability

Software calibration

High speed and endurance testing

Synchronization durability testing

Material characterization

Research Centre

Base and applied Research

Innovation & new technologies

The Research & Development dpt. is organized in 3 Teams:

![Page 6: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/6.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA

Technologies & Processes

6

The Bari plant

Gears & Shafts Al-cases

Labs

for

qual

ity c

ontr

ols

Softtechnologies

Milling - Turning – Shaping – Pointing – Hobbing – Splines Rolling – Deburring – Chamfering – Drilling – LASER welding – Washing

Low Pressure Carburizing

Quenching & Tempering

Straightening – Shot peening – Hard Turning - Grinding OD/ID – Gear grinding – Power honing - Polishing La

bs fo

r qu

ality

con

trol

s

Machining center1

Deburring 2

Washing3

Leak test4

Assembly & Testing

• Transmissions assembly• EOL 100% testing

Heattreatment

Hardtechnologies

![Page 7: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/7.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA

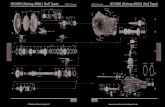

Materials in 6DCT250 (examples)

7

Optional Topline. Arial Regular 14pt, single-row only with 1.0 spacing

Component Material Technology Surface treatment

Housings Aluminum alloy Pressure die cast

Gears Mn steel Cold forging raw Shot peened (specific derivatives)

Shafts Mn steel Cold or warm forging raw

Diff case Cast iron / Aluminum Sand Casting / Die casting

Diff pin Steel alloy Rolling Carbo nitrided / Nickel or Phospated coated

Diff gears Steel alloy Warm forging Phospated coated

Sy-rings Steel alloy Cold forging Carbon facing / Molibdenum based coating

Shift gears, Sy- Hubs Sinter metal Sintering

Washer TORLON Polyamide TORLON property -

Fasteners Steel alloy Cold rolling Anti rust coatings

Sealant Loctite Defined roughness properties of flanges

TCU, E-motors Electronics Electronics

Clutch Carbon facing LuK property

![Page 8: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/8.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA8

Carbon facing in Sy-rings STRIPS BONDING ON SINTERED BODY

SINTERED BODY

CARBON LAY-UPSTRIPS CUTTING

CARBON LAYER

Optimum reached by proper definition of:

- Physical properties (lining composition, specific Rz parameters for the load carrying surface)

- Attributes verification (value and behavior of friction coefficient, lubrication capability)

output GN 904319

ISstate

DOE

NEW state

RedEx

VALIDATION

TARGET: Material definition for optimized synchro capability at all temperatures

![Page 9: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/9.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA9

Optimized steel and treatments for gearset components

The automotive market is always demanding a product with higher performance at a lower cost: the OEM’s suppliers must accept this challenge

Since the operational integrity of the product as well as any other characteristics requested by the Customer has not to be affected, cost saving can only be obtained: with the use of new steel alloys, sometimes necessary also for environmental

protection reasons by means of the heat thermo-chemical treatment recipe optimization

An example of components steel alloy change is the one realized in GETRAG during the year 2006: from 20MoCrS4 to 20MnCrS5

Each steel alloy needs a customized heat treatment recipe. The target is the realization of fixed metallurgical characteristics (%C profile, case depth, case hardness, core hardness) inside the components, to be obtained in a shorter time and with less energy consumpion.

![Page 10: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/10.jpg)

April 12, 2023

10

Optimized steel and treatments for gearset components

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA

Example of heat treatment recipe optimization is the one made on the low pressure carburizing phase: evaluation of the carburizing gas (from propane to acetylene) and carburizing steps (number and the duration) of the carburizing gas injections

3D thermo-mechanical numerical simulations of the component complete heat treatment are massively used, in order to realize factorial plans that allow the identification of process parameters (temperature, time, gas pressure) to be used to minimize time and costs

Carbon content profile is monitored at different time instants of the vacuum carburizing process, as well as the metallurgical phases proportion (ferrite/perlite, upper/lower bainite, martensite, austenite) and the residual stress after final tempering

Results are validated by metallurgical lab measurement and by testing campaigns

![Page 11: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/11.jpg)

April 12, 2023

11

Optimized steel and treatments for gearset components

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA

Testing of the most interesting variants used in the factorial plan is anyway performed, including variants that are also subjected to a shot peening superficial treatment (the components are put in a machine where steel spheres hit the surface and increase the surface residual compressive stress)

Wöhler or SN curves are generated for each variants, in order to verify the behavior in regards to gear bending and contact fatigue

Lots of specimens are produced for each variant and subjected to different load levels at special test rigs, in order to determine the number of cycles to failure

Test results are then converted into mathematical laws, to be assessed by the design departments

After completing the design review, the solution is assessed in regards to any other influencing aspect

Once all the affected departments approve the change, the target becomes its implementation in the mass production

Equipment for gear bending investigations

![Page 12: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/12.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA12

Optimized steel and treatments for gearset components

In-house specification, with reduced tolerances in composition, allow less scattering in Jominy curve for minimum scattering in mechanical behavior and less distortive heat treatment

![Page 13: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/13.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA13

Heat Treatment: low pressure carburizing (furnace supplier: ECM)

source: http://www.ecm-furnaces.com/low-pressure-carburising

![Page 14: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/14.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA14

Advanced materials in manufacturing processes

Tooling:

Hobbing: Hard metal hobs coated Al-Ti oxides. High performance at high temperature

Hard turning: CBN insert, high wear resistance

Grinding: CBN electro-deposited grinding wheels, high wear resistance at high

temperature. Coolant pure oil

Ceramic CBN grinding wheels, high wear resistance at high

temperature. Coolant water-oil mix

Composite quills: high stiffness

![Page 15: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/15.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA15

Hobbing: Hard metal hobs coated Al-Ti oxides

Hard turning: CBN insert

Advanced materials in manufacturing processesTooling:

![Page 16: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/16.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA16

Grinding: CBN electro-deposited grinding wheels

Composite quills Ceramic CBN grinding wheels

Tooling:

Advanced materials in manufacturing processes

![Page 17: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/17.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA17

Advanced materials in manufacturing processesTooling:

Heat treatment: 3D carbon fibers jigs: high mechanical resistance at high temperature

Alloy jigs (mancellium): highest mechanical resistance at high

temperature for a metal alloy.

![Page 18: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/18.jpg)

April 12, 2023

E. Camarda, D. Paradiso, C. Maselli, N. Achille, N. De Vito - GETRAG SpA18

Conclusions

Advanced materials constitute the base for technological excellence and continuous improvement, to meet constantly increasing market challenges.

GETRAG S.p.A. is an user of a wide range of materials for the production of dual clutch transmissions

GETRAG S.p.A. has Engineering and Manufacturing capabilities to support improvements in terms of materials definition (and their treatments), in order to meet the requirement of the final customer in terms of quality and costs.

For any information visit us at: www.getrag.com

![Page 19: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/19.jpg)

Thank you for your attention

![Page 20: AMIF2014 – [Automotive] Ettore Camarda, Materiali innovativi nella progettazione e produzione di trasmissioni. L’esperienza dello Stabilimento GETRAG di Bari](https://reader035.fdocuments.in/reader035/viewer/2022081505/5562bc2bd8b42a09618b4bcb/html5/thumbnails/20.jpg)

![AMIF2014 – [Nautica] Andreas Echtermeyer, Compositi in applicazioni navali e off-shore](https://static.fdocuments.in/doc/165x107/5562bc7cd8b42a595e8b4c9d/amif2014-nautica-andreas-echtermeyer-compositi-in-applicazioni-navali-e-off-shore.jpg)

![AMIF2014 – [Aerospazio] Umberto Galietti, Termografia per la manutenzione predittiva di componenti meccanici, elettrici e di elementi strutturali in materiale composito](https://static.fdocuments.in/doc/165x107/5562bd0bd8b42aaf178b478d/amif2014-aerospazio-umberto-galietti-termografia-per-la-manutenzione-predittiva-di-componenti-meccanici-elettrici-e-di-elementi-strutturali-in-materiale-composito.jpg)

![AMIF2014 – [Aerospazio] Marco Protti, Sviluppi nell'applicazione dei compositi nel settore dell’aeronautica](https://static.fdocuments.in/doc/165x107/5562bc28d8b42a09618b4bc9/amif2014-aerospazio-marco-protti-sviluppi-nellapplicazione-dei-compositi-nel-settore-dellaeronautica.jpg)

![AMIF2014 – [Automotive] Nevio di Giusto, Materiali avanzati per l’alleggerimento delle strutture automobilistiche](https://static.fdocuments.in/doc/165x107/5562bc35d8b42a09618b4bcf/amif2014-automotive-nevio-di-giusto-materiali-avanzati-per-lalleggerimento-delle-strutture-automobilistiche.jpg)

![AMIF2014 – [Aerospazio] Silvio Pappadà, Componenti per elicottero, in materiale composito termoplastico](https://static.fdocuments.in/doc/165x107/5562bbccd8b42a13618b4b71/amif2014-aerospazio-silvio-pappada-componenti-per-elicottero-in-materiale-composito-termoplastico.jpg)

![AMIF2014 – [Plenaria] Marco Vittori Antisari, Innovazione dei materiali per il trasporto sostenibile - Il contributo dell'ENEA](https://static.fdocuments.in/doc/165x107/5562bbc2d8b42a13618b4b69/amif2014-plenaria-marco-vittori-antisari-innovazione-dei-materiali-per-il-trasporto-sostenibile-il-contributo-dellenea.jpg)

![AMIF2014 – [Automotive] Pankaj Mallick, Materiali attuali e futuri per automobili leggere](https://static.fdocuments.in/doc/165x107/558cd8d8d8b42a885e8b4600/amif2014-automotive-pankaj-mallick-materiali-attuali-e-futuri-per-automobili-leggere.jpg)

![AMIF2014 – [Nautica] Riccardo Gennaro, Processi a basso costo per componenti in composito ad alte prestazioni](https://static.fdocuments.in/doc/165x107/5562bc78d8b42a595e8b4c9b/amif2014-nautica-riccardo-gennaro-processi-a-basso-costo-per-componenti-in-composito-ad-alte-prestazioni.jpg)

![AMIF2014 – [Plenaria] Marco Falzetti, Tendenze nei materiali per il sistema dei trasporti](https://static.fdocuments.in/doc/165x107/5562bbc5d8b42a13618b4b6d/amif2014-plenaria-marco-falzetti-tendenze-nei-materiali-per-il-sistema-dei-trasporti.jpg)