AC 65-15A - Airframe & Powerplant Mechanics - Airframe Handbook

AMD INTERNATIONAL TECHNOLOGIES, LLC.AMD...

Transcript of AMD INTERNATIONAL TECHNOLOGIES, LLC.AMD...

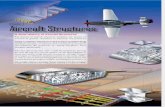

Manufacturer of Airframe Structural Components & Assemblies

Precision Sheet Metal Fabrication & Machining

Process & Product Development * Value Engineering

What We Do

AMD INTERNATIONAL TECHNOLOGIES, LLC.AMD INTERNATIONAL TECHNOLOGIES, LLC.AMD INTERNATIONAL TECHNOLOGIES, LLC.AMD INTERNATIONAL TECHNOLOGIES, LLC.

Established 1994 * DUNS Number: 926010760 * Cage Code: 00WV8

NAICS Codes 332322: Sheet Metal Work Manufacturing * 332710: Machine Shops

336412: Aircraft Engine and Engine Parts Manufacturing 336413: Other Aircraft Parts and Auxiliary Equipment Manufacturing

336414, 336415, 336419: Guided Missile and Space Vehicle Manufacturing

FSC Code 1560: Airframe Structural Components * 1680: Misc. Aircraft Accessories and Components

Certifications SBA 8A – Small Disadvantaged Business AS9100 REV C * ISO 9001:2008 – QUALITY

Company Designations

AMD International Technologies, LLC. 1725 South Campus Ave. Ontario, CA 91761 USA

Phone No. 909-985-8300 Fax No. 909-985-8388

Web Page www.amdinttech.com

Who We Are

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

AMD International Technologies, LLC.

Who We Are

Our Services

Mission Statement

Mission Statement Our Services

Our values reflect who we are. They are the pillars of our culture. AMD International Technologies cul-

ture draws on our core values of leadership, people, service, diversity, accountability, and partnerships.

At AMD International Technologies, we are committed to being the best at what we do. Building and

maintaining strong relationships with our customers, vendors and employees is critical to the way we

operate.

It is our goal to always develop and respect collaborative partnerships. We do this by delivering what we

promise when we promise it, providing innovative solutions that address the specific needs of our cus-

tomers, and creating a working environment that makes our employees proud, while always striving to

improve and exceed expectations, all at the same time maintaining our core values.

Who We Are

Sheet Metal Fabrication

• Single Part Processing

• Assembly Processing

Stretch Forming

• Skin Fabrication

Extrusion Stretch Forming

• Extrusion Forming

Hydro-Forming

• Hydro-Form Fabrication

Precision Machining

• Production Machining

• Tool Manufacturing

Multi Part Assembly Processing

• Fabricated Assemblies

• Machined Assemblies

Program Management

• Engineering Design

• Quality Assurance

• Process Control

AMD International Technologies mission is

to exceed our Customers expectations in

innovation, quality, cost and delivery

through continuous improvement, employ-

ees’ involvement, supplier participation

and customer interaction.

Sheet Metal Fabrication

Single Part Processing

Assembly Processing

Engineering Process Control Processing

Materials Equipment

Fabrication, Cutting, Shearing,

Blanking, Stamping, Brake Forming,

Hydro-Forming, Stretch Forming,

Roll Forming, Routing Trimming,

Check & Straighten, Deburring,

Multi Part Assembly Processing,

Tooling Designed & Built In-house

ISO9001: 2008/AS9100C Approved,

Written Planning & Process Controls,

CAD / CAM Engineering,

Model Based Definition (MBD),

All Major CAD Software Supported,

CATIA, Siemens NX, Solid Works,

Verisurf, Master CAM, CompareVidia,

Quality Assurance, CMM Inspection

Sheers, Cutoff Saws,

Brake Form Presses,

Hydro-Form Presses,

Stretch Form Presses,

Turret Punch Presses,

Roll Form 20 foot Cap,

Deburring Equipment,

Assembly Presses

Wide Range of Materials

Aluminum, Steel,

Stainless Steel,

High Temperature Alloys,

Titanium, Copper, Brass,

Bronze, Non-Metallics

Sheet Metal Fabrication

AMD International Technologies is committed to the highest standards of quality and productivity in the industry. Our

well trained team of professionals are results oriented with quality as our main focus. Innovative lean processes

make us very competitive. From a simple flat pattern part to complete assemblies, our engineering and process con-

trol assures reliability.

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

Stretch Forming

Skin Fabrication

Part Configuration Equipment

Materials Engineering Tooling

Skin Stretch Press 150 Ton

64" x 120", 150 Ton

Skin Stretch Press 300 Ton

120" x 160", 300 Ton

Covers, Doors, Panels,

Leading Edges, Skins, Shells,

Any Sheet Metal Part Requiring

Contoured Forming

Value Engineering

Short Run Tools & Shop Aids

Long Run Class "A" Tools

Designed & Built In-house

Aluminum, Steel,

Stainless Steel,

High Temperature Alloys

Stretch Forming Process

The stretch forming process is ideal for producing a wide range of parts requiring contour surfaces such as door

panels, nose sections, skin sections and wing leading edges, due to lower non-recurring costs associated with the

process. The variety of shapes and cross sections that can be stretch formed is almost unlimited. The process in-

volves the sheet material to be held in place and the use of hydraulic rams to force a form tool into the sheet,

stretching it to shape.

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

Extrusion Stretch Forming

Extrusion Forming

Part Configuration Equipment

Materials Engineering Tooling

Horizontal Stretch Press 25 Ton

300 In., 25 Ton

Horizontal Stretch Press 35 Ton

264 In., 35 Ton

Angels, Formers, Longerons, Ribs,

Stringers, Supports, Tees,

Any Extruded or Formed Metal Part

Requiring Contoured Forming

Value Engineering

Short Run Tools & Shop Aids

Long Run Class "A" Tools

Designed & Built In-house

Engineered Shapes in

Aluminum, Stainless Steel,

High Temperature Alloys,

Titanium

Extrusion Stretch Forming Process

The extrusion stretch forming process is ideal for producing a wide range of parts requiring contour shapes such as

Angels, Formers, Longerons, Ribs, Stringers, Supports, Tees, because this process has typically lower non-

recurring costs. The variety of shapes that can be formed is almost unlimited. The process involves the brake formed

or extruded material to be held in place and with the use of hydraulic rams and manipulators a form tool is driven into

the material to achieve the forming process.

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

Hydro-Forming

Hydro-Form Fabrication

Part Configuration Equipment

Materials Engineering Tooling

Hydro-Form Press 500 Ton

36" x 36" x 36" 500 Ton

Hydro-Form Press 600 Ton

48" x 52" x 18", 600 Ton

Formers, Longerons, Robs, Stiffeners

Any Thin Metal Part

Requiring Forming

Simple to Complex Shapes

Value Engineering

Short Run Tools & Shop Aids

Long Run Class "A" Tools

Designed & Built In-house

Aluminum, Steel,

Stainless Steel,

High Temperature Alloys,

Titanium, Brass, Copper

The Hydro-Forming Process

Hydro-Forming is a metal forming and fabricating process developed to provide a cost effective means to produce irregular contours that do not lend themselves well to stamping. This can be a single stage, or a multi stage process saving labor, tools, and materials. Sheet Hydro-Forming uses a form die and a sheet of metal. The blank sheet is driven into the die forming the desired shape. Virtually all metals capable of cold forming can be hydro-Formed. The process is very cost effective when it comes too small and medium quantity requirements along with complex shapes.

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

Precision Machining

Production Machining

Tool Manufacturing

Engineering Programing Processing

Materials Equipment

3 Axis Milling, 4 Axis Milling, 5 Axis Milling,

5 Axis Profiling, Long & Short Run Production,

Form Tooling, Trim Jigs and Fixtures

CAD / CAM Engineering Programming, Model Based Definition (MBD),

Master CAM Programming All Major CAD Software Supported, CATIA, Siemens NX, Solid Works, Verisurf, (CompareVidia Validation)

Machining Center CNC 3 Axis, HASS VF-4

X50, Y20, Z25, 10,000 RPM

Machining Center CNC 4 Axis, HASS VF-7

X84, Y32, Z30, 15,000 RPM

Machining Center CNC 3 Axis, HASS VF-8

X64, Y40, Z30, 10,000 RPM

Router / Profiler CNC 5 AXIS, DMS

X144, Y72, Z48, 15,000 RPM

Wide Range of Materials

Aluminum,

Steel, Stainless Steel,

High Temperature Alloys,

Titanium,

Copper, Brass, Bronze,

Non-Metallics, Wood, Plastic

Machining Process

AMD International Technologies utilizes late model, well maintained CNC machine tools and equipment to assure product quality and repeatability. Our machining department is well adapted to support the needs of our fabrication shop. It serves as a source for tooling used in the forming and fabrication process along with the processing of pro-duction parts that range from extruded shapes, thin metal components and hog out parts produced from a wide range of materials. We use the latest software compatible with most major CAD data. Our well trained team of pro-fessionals is results oriented with quality as our main focus. Innovative lean processes make us very competitive.

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

Multi Part Assembly Processing

Fabricated Assemblies

Machined Assemblies

Part Configuration Processing

Nut Plates, Huck bolts, Lock bolts, Eddie Bolts, Hi-Lok, Hi-Shear, Self-Clinching Hardware

Mechanical and Sub-Assemblies Installation

Riveting, Pressing

Staking, Sizing

Cutting Trimming Fitting

Sealing and Touchup

Multi Part Assembly

Structural Assembly

Bracket Assembly

Precision Mechanical Assemblies

Assembly Processing

The multi part assembly process is one of our core service offerings. We manufacture the components gather spec

hardware and bring it all together to produce the complete assembly. Written engineering instructions help assure a

proper assembly process and high quality results. Assembly personnel are well trained and experienced. When re-

quired custom tooling is designed and built in support of the assembly process.

Solid Rivets, Blind Rivets, Drive Rivet, Cherry Max, Cherry Lock, Semi-Tubular, Full Tubular

Rivet Fastening Assembly

Treaded Inserts, Helicoil Insert, Keensert, Slimsert, Rosan Fittings, Blind Nut, Lock Wire Safety Wire

Threaded Fastener Installation

Bearing installation, Staking, Swaging, Roller Swaging, Chisel Staking, Ball Staking, V-groove Staking

Precision Part Assembly

Press-Fit, Shrink Fit, Sizing After Installation, Lee Plug Installation

Bushing Installation

Primers, Sealant, Loctite, Silicone and Adhesive sealing to Specifications

Sealing and Touchup

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

AOG priority

AOG priority, (Aircraft On Ground) applies to spare parts that are needed im-mediately for an aircraft to return to service. AOG is a term in aviation indicat-ing that a problem is serious enough to prevent an aircraft from flying. Gener-ally there is a rush to acquire the parts to put the aircraft back into service, and prevent further delays to operation.

Expedited Processing Service

EPS Service

AMD International Technologies has available to its customers that require it. Expedited Pro-cessing Service (EPS). We have a system in place that allows us to take on jobs and man-ufacture them in a short period of time. We utilize innovative technics to produce and pro-cess parts per engineering requirements with-out the need to build expensive tooling.

Expedited Processing Service

AOG Priority Service

Aircraft On Ground

Customers requiring parts under an AOG priority can get parts in days or weeks rather than months. Fabrication, special process such as heat treat, NDT inspection, plating and painting are all hand carried and walked through the process for fast turnaround.

Depending on your requirement, we can help you out as well.

Computerized Order Administration

Comprehensive Contract Review

Comprehensive Engineering

Comprehensive Operational Procedures

Step by Step Process Planning

Dedicated Project Management

Quality Assurance Inspection and Review

Production Control and Scheduling

Material Control

Special Tool Control

Program Management

Engineering Design

Quality Assurance

Process Control

AMD International Technologies has available for its engineers the latest software packages in the industry.

We are able to work with most types of CAD / CAM Engineering data including, CATIA, Siemens NX, Solid

Works, Verisurf, Master CAM, and CompareVidia. We have in place a documented process to control digital

product definition (DPD).

Our team of degreed engineers work very closely with manufacturing production to provide clear and accu-

rate engineering and planning. We work hard to develop cost-cutting innovative solutions without compromis-

ing quality.

Engineering Design

Quality System: Our quality assurance system is well implemented throughout our manufacturing process. We are ISO 9001:2008 / AS 9100:Rev. C Certified. Our commitment to quality goes far beyond the inspec-

tion of parts. From contract review to shop travelers, onto first article, in process and final inspection, our

quality department is involved in the entire process.

Continuous improvement efforts: Lean Manufacturing & Six Sigma Principles * Continuous Training for All Employees * Acquisitioning State-of-the-Art Inspection Equipment * Continuous improvement and value-

added activities focused on results * Root-cause analysis of challenges

Experience Counts: Because of our many years of experience we are well adapted to work with all type of inspection and engineering requirements. From full scale mylars to full 3D model CMM inspection, we pro-

duce results that meet our Customer's expectations.

Quality Assurance

Process control is a discipline that deals with all aspects of a process for maintaining the output of a specific

process within a desired range. At AMD we believe in controlling the process from start to finish. Below is a

list of controls we have in place to maximize our ability to produce a positive outcome for our customers.

Process Control

DPD Control

Mistake Proofing

Lot Control

Inventory Control

Lean Manufacturing

Cost Accounting

Customer Support and Service

Outsourcing Control Measures

Equipment Preventive Maintenance Program

ISO 9001:2008 / AS 9100:Rev. C Certified

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com

Doing Business With Us

Prime Customers

Programs

Contact Us

Quotes & Technical Review Turn Times Manufacturing Production Turn Times

Expedited Processing Service, AOG Priority

Standard Production Lead Time 10 to 16 Wks

Long Term Agreements Going Out 5 to 10 Yrs

Expedite Quotes 24 Hours Standard Quotes 2 to 5 days Large Packages 1 to 4 weeks

LTA Packages 4 Weeks

The Boeing Company Lockheed Martin

Northrop Grumman Nordam

US Government Department of The Navy

DLA Defense Logistics Agency

Prime Customer Relationships

Boeing B-52 Stratofortress Lockheed C-130 Hercules Lockheed C-141 Starlifter

Boeing KC-135 Stratotanker Boeing KC-767 Tanker

McDonnell Douglas F-15 Eagle General Dynamics F-16 Fighting Falcon

McDonnell Douglas F/A-18 Hornet Northrop T-38 Talon

Northrop F-5 Freedom Fighter Lockheed P-3 Orion

List of Aircraft Programs we Have Supported

Ravi Joshi President

Contact any of our qualified Estimators and Program Managers for assistance.

Lou Pattengell General Manager

George Ruben Program Manager

AMD International Technologies, LLC. Manufacturer of Airframe Structural Components & Assemblies * AS9100 Approved

1725 South Campus Ave. * Ontario, CA 91761 * Ph. # 909-985-8300 * Web Page www.amdinttech.com