Aluminium Conductor

-

Upload

leader-cable -

Category

Documents

-

view

265 -

download

11

description

Transcript of Aluminium Conductor

1

CONTENTINTrOduCTION ________________________________________________2

ALuMINIuM & ALLuMINIuM ALLOY CONduCTOrS __________________3

CONduCTOrS _________________________________________________4

ALuMINIuM ___________________________________________________4

ALuMINIuM CONduCTOrS ______________________________________5

BArE ALL ALuMINIuM CONduCTOr (AAC) ________________________6

BArE ALL ALuMINIuM ALLOY CONduCTOr (BArE AAAC) __________10

BArE ALuMINIuM CONduCTOr STEEL rEINFOrCEd (ACSr) _______13

PVC - COVErEd ALuMINIuM CONduCTOrS_______________________19

AErIAL BuNdLE CABLE _______________________________________20

OPGW CABLE ________________________________________________29

2

INTrOduCTIONLeader Cable Industry Berhad, incorporated in 1976 has grown steadily to become the country’s single largest cable manufacturer today since its 1990 merger with Universal Cable (M) Berhad under the flagship of its parent, Leader Universal Holdings Berhad (LEADER).

Through its far sighted planning and unceasing product and service innovation, LCIB has successfully cultivated a manufacturing profile of an extensive range of cable and wire products.

From household cables, XLPE cables, telecommunication cables for both domestic and export markets, LCIB has achieved a distinguished reputation as a leading supplier of power and telecommunication cables to major corporations both local and foreign.

This catalogue serves as a guide to LCIB’s manufacturing processes and standards in the manufacturing of aluminium conductors, cables and OPGW.

3

ALuMINIuM & ALLuMINIuM

ALLOY CONduCTOrS

Aluminium & aluminium alloy conductors are the preferred and dominant

conductors in several areas of power transmission and distribution. The

major areas dominated by aluminium and aluminium alloy conductors are

non-insulated overhead power transmission, insulated overhead power

transmission and non overhead power distribution.

4

CONduCTOrS

ALuMINIuM

This dominance is due to the excellent overall properties of aluminium and aluminium alloy conductors. Aluminium and aluminium alloy conductors offer good conductivity, light weight, excellent resistance to corrosion, good bending properties, greater tensile strength than copper and excellent compatibility with most common insulation used by the wire and cable industry.

These conductors now command a significant share of the insulated, interior wire market particularly in the larger dimensions (i.e heavy current installations) where weight and ease of handling are important factors.

This trend is due to their excellent overall properties. Principally these are listed as :

1. Conductivity In excess of twice that of copper by unit weight.

2. Strength A range of strengths from dead soft to that of mild steel,depending on the required temperature of aluminium alloy.

3. Workability Permitting a wide range of processing from wire drawing to stranding. This offers excellent bend quality.

4. Light Weight Ease of handling, low installation costs, longer spans and more distance between pull-ins.

5. Corrosion Resistance Most industrial, marine and chemical atmospheres cause corrosion. In addition, the corrosion resistance of all alloys can be further improved by anodizing.

6. Compatibility With Insulation Does not adhere to or combine with usual insulating materials. No tin-coating required: clean stripping.

5

ALuMINIuM CONduCTOrS

Aluminium and aluminium alloy electrical conductors are made by various processes from wire-drawing (i.e rod breakdown to fine wire) to wire stranding from a large diameter of redraw aluminium and aluminium alloy rods.

With strong and consistent emphasis on quality, Leader Cable continues to strive for improvement in the production of our aluminium and aluminium alloy conductors to better

meet customer requirements and expectations.

6

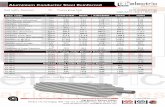

BArE ALL ALuMINIuM CONduCTOr (AAC)

The stranded Bare All Aluminium Conductor (AAC) are made up of concentric-lay-stranded aluminium wires only. The

conductor may be made up of 7, 19, 37, 61 or more wires in 1, 2, 3, 4 or mre layers around a central wire. Each successive

layer shall have six more wires than the layer immediately beneath. For a given cross-sectional area, the conductor becomes

more flexible as the number of wires is increased (with a corresponding decrease in size of each wire).

When All Aluminium Conductors are to be used in overheaded lines, full hard drawn temper wires are used. The illustration

below show some typical stranding patterns.

127(1+6+12+18+24+30+36)

37(1+6+12+18)

96(1+6+12+18+24+30)

19(1+6+12)

61(1+6+12+18+24)

7(1+6)

7

STrANdEd HArd - drAWN ALL ALuMINIuM CONduCTOr (AAC) (BS 215, PArT 1)

Code Name

Nominalarea

Construction, Number/ Wire

diameter

Calculatedarea

Approx.overall

diameter

Approx.weight

Calculatedbreaking

load

CalculatedDC

resistanceat 20˚ C

Hard-drawncopper

equivalentarea

mm2 No./mm mm2 mm kg/km kN ohm/km mm2

MidgeAntFly

WaspHornetChafer

CockroachButterfly

Centipede

225060

100150200

250300400

7/2.067/3.107/3.40

7/4.3919/3.2519/3.78

19/4.2219/4.6537/3.78

23.3352.8363.55

106.0157.6213.2

265.7322.7415.2

6.189.30

10.20

13.1716.2518.90

21.1023.2526.46

64145174

290434587

731888

1,145

3.998.289.90

16.0024.7032.40

40.4048.7563.10

1.2270.54190.4504

0.27020.18250.1349

0.10830.089160.06944

14.6533.1839.91

66.5798.97133.9

166.9202.7260.7

STrANdEd HArd - drAWN ALL ALuMINIuM CONduCTOr (AAC) (AS 1531, Part 1)

Code NameConstruction,

No./Wirediameter

Calculatedsectional

area

Approx.overall

diameter

Approx.weight

Calculatedminimum

breaking load

CalculatedDC

resistanceat 20˚ C

Hard-drawncopper

equivalentarea

No./mm mm2 mm kg/km kN ohm/km mm2

GeminiJupiter

Leo

LibraMars

Mercury

MoonNeptune

Pluto

SaturnTaurusTriton

UranusVenusVirgo

7/1.757/2.257/2.50

7/3.007/3.757/4.50

7/4.7519/3.2519/3.75

37/3.0019/4.7537/3.75

61/3.2561/3.7591/4.50

16./8427.8334.36

49.4877.31111.3

124.0157.6209.8

261.5336.7408.7

506.0673.71,447

5.256.757.50

9.0011.313.5

14.316.318.8

21.023.826.3

29.333.849.5

46.175.994.3

135212305

340433578

721926

1,130

1,4001,8604,010

3.014.765.75

7.9111.916.8

18.824.732.3

41.850.962.9

75.298.3207

1.711.03

0.833

0.5790.3700.258

0.2320.1830.137

0.1100.08570.0706

0.05720.04290.0200

10.2817.4821.58

31.0748.5569.90

77.8798.97131.8

164.2211.4256.7

317.8423.1908.7

8

STrANdEd HArd - drAWN ALL ALuMINIuM CONduCTOr (AAC)(dIN 48201, PArT 5)

Nominal AreaConstruction,

No./Wirediameter

Calculatedarea

Approx.overall

diameter

StandardWeight

Calculatedbreakingstrength

CalculatedDC

resistanceat 20˚ C

Hard-drawncopper

equivalentarea

mm2 No./mm mm2 mm kg/km kN ohm/km mm2

162535

505070

95120150

185240300

7/1.77/2.17/2.5

7/3.019/1.819/2.1

19/2.519/2.837/2.25

37/2.5061/2.2561/2.50

15.924.234.4

49.548.365.8

93.2117147

182243299

5.16.37.5

9.09.0

10.5

12.514.015.8

17.520.322.5

43.466.393.9

135.2132.5180.4

255.5321406

501670827

287434581

840874

1,178

1,5771,9952,664

3,0714,3925,063

1.8071.1870.845

0.5860.5990.435

0.3090.2460.196

0.1580.1180.096

10.015.221.6

31.130.441.4

58.673.692.5

114153188

STrANdEd HArd - drAWN ALL ALuMINIuM CONduCTOr (AAC)(ASTM B 231)

CodeName

NominalSize

Hard-drawncopper

equivalentarea

Strandingclass*

Construction,No./Wirediameter

Calculatedarea

Approx.diameter

Standardweight

Calculatedbreakingstrength

CalculatedDC

resistanceat 20˚ C

AWG/MCM AWG/MCM No./mm mm2 mm kg/km kN ohm/ km

PeachbellRoseIrisPansy

PoppyAsterPhloxOxlip

SneezewortValerianDaisyLaurel

PeonyTulipDaffodilCanna

GoldentuftCosmosSyringaZinnia

6421

1/02/03/04/0

250250

266.8266.8

300336.4350

397.5

450477477500

8643

21

1/02/0

157.2157.23/03/0

188.34/0220250

283300300314

AAAA,AAA,A

AA,AAA,AAA,AAA,A

AAAAAA

AAAAA,A

AAAAAAA

7/1.567/1.967/2.477/2.78

7/3.127/3.507/3.937/4.42

7/4.8019/2.917/4.96

19/3.01

19/3.1919/3.3819/3.4519/3.67

19/3.7119/4.0237/2.8819/4.12

13.321.133.642.4

53.567.485.0

107.2

126.7126.7135.2135.2

152.0170.5177.3201.4

228.0241.7241.7253.3

4.685.887.418.34

9.3610.511.813.3

14.414.614.915.1

16.016.917.318.4

19.620.120.220.6

36.758.292.6116.9

147.5185.8234.4295.6

349.3349.3372.8372.8

419.1470.1488.8555.3

628.6666.4666.4698.4

2.493.955.977.12

8.7311.013.517.0

20.120.621.421.4

24.027.028.031.8

35.037.138.538.9

2.171.370.8580.680

0.5390.4280.3390.269

0.2280.2280.2130.213

0.1900.1690.1630.143

0.1260.1190.1190.114

9

STrANdEd HArd - drAWN ALL ALuMINIuM CONduCTOr (AAC) (ASTM B 231) - continued

CodeName

NominalSize

Hard-drawncopper

equivalentarea

Strandingclass*

Construction,No./Wirediameter

Calculatedarea

Approx.diameter

Standardweight

Calculatedbreakingstrength

CalculatedDC

resistanceat 20˚ C

AWG/MCM AWG/MCM No./mm mm2 mm kg/km kN ohm/ km

HyacinthDahliaMistletoeMeadowsweet

OrchidHeucheraVerbenaFlag

VioletNasturtiumPetuniaCattail

ArbutusLilacCockscombSnapdragon

MagnoliaGoldenrodHawkweedCamelia

BluebellLarkspurMarigoldHawthorn

NarcissusColumbineCarnationGladiolus

CoreopsisJessamineCowslipSagebrush

LupineBitterrootTrilliumBluebonnet

500556.5556.5600

636650700700

715.5715.5750750

795795900900

95495410001000

1033103311131192

1272135114311510

1590175020002250

25000275030003500

314350350377

400409440440

450450472472

500500566566

600600629629

650650700750

800850900950

1000110112601415

1570173018902200

AAAAAA,A

AA,AAAAAA

AAAAAA

AAAAAA

AAAAAA

AAAAA, AAA, A

AA, AAA, AAA, AAA, A

AAAAAA

AAAA

37/2.9519/4.3537/3.1137/3.23

37/3.3337/3.3737/3.4961/2.72

37/3.5361/2.7537/3.6261/2.82

37/3.7261/2.9037/3.9661/3.09

37/4.0861/3.1837/4.1861/3.25

37/4.2561/3.3161/3.4361/3.55

61/3.6761/3.7861/3.8961/4.00

61/4.1061/4.3091/3.7791/3.99

91/4.2191/4.42

127/3.90127/4.22

253.3282.0282.0304.0

322.3329.4354.7354.7

362.6362.6380.0380.0

402.8402.8456.0456.0

483.4483.4506.7506.7

523.7523.7564.0604.2

644.5694.8725.1765.4

805.7886.710131140

1267139315201773

20.721.821.822.6

23.323.624.424.5

24.724.825.325.4

26.026.127.727.8

28.628.629.329.3

29.829.830.932.0

33.034.035.036.0

36.938.741.543.9

46.348.650.754.9

698.4777.5777.5838.2

888.6908.2977.9977.9

1000999.710481048

1111111112571257

1333133313971397

1444144415551666

1777191619992110

2221244528203174

3527387842734984

40.343.343.647.0

49.951.054.957.5

56.158.758.859.9

62.363.468.569.8

72.674.076.177.5

78.680.186.392.4

98.6103108114

120132149167

186205223260

0.1140.1020.1020.0948

0.08940.08750.08130.0813

0.07950.07950.07590.0759

0.07160.07160.06320.0632

0.05960.05960.05690.0569

0.05500.05500.05110.0477

0.04470.04150.03980.0377

0.03580.03250.02870.0255

0.02300.02090.01930.0166

* NOTE : AA - For bare conductors usually used in overhead lines A - For conductors to be covered with weather - resistant, slow - burning materials and for bare conductors where greater flexibility than is afforded by Class AA is required

10

BArE ALL ALuMINIuM ALLOY CONduCTOr (BArE AAAC)Aluminium alloy (AAAC) contains a small percentage (about 0.6%) of silicon and magnesium elements. It provides several benefits for overhead lines.

(i) Strength - About twice that of aluminium 1350 (EC)

(ii) Weight - 20% (approx.) lighter than ACSR conductor of equal diameter.

(iii) Corrosion resistance - It has a high resistance to atmospheric corrosion which is suitable for coastal and industrial areas.

(iv) Surface hardness - AAAC’s surface is significantly harder than aluminium 1350. It is lesss liable to damage during installation which is an important advantage of EHV transmission lines where corona and radio interference is a major consideration.

(v) Termination - Much simpler jointing accessories required compared to ACSR.

(vi) AC Resistance - AAAC is a non-magnetic material. It doed not exhibit the magnetic core losses found in ACSR conductor.

127(1+6+12+18+24+30+36)

37(1+6+12+18)

96(1+6+12+18+24+30)

19(1+6+12)

61(1+6+12+18+24)

7(1+6)

11

BArE STrANdEd ALL ALuMINIuM ALLOY CONduCTOr (AAAC) (BS 3242)

CodeName

Nominalaluminium

area

Construction,No./Wirediameter

Sectionalarea

Approx.overal

diameter

Approx.weight

Calculatedbreaking

load

CalculatedDC

resistanceat 20˚ C

mm2 No./mm mm2 mm kg/km kN ohm/km

AlmondCedar

Fir

HazelOakAsh

ElmUpas

253040

50100150

175300

7/2.347/2.547/2.95

7/3.307/4.65

19/3.48

19/3.7637/3.53

30.1035.4747.84

59.87118.9180.7

211.0362.1

7.027.628.85

9.9013.9517.40

18.8024.71

8297

131

164325497

580997

8.449.94

13.40

16.8033.3050.65

59.10101.5

1.0940.92810.6880

0.54980.27690.1830

0.15680.09155

BArE STrANdEd ALL ALuMINIuM ALLOY CONduCTOr (AAAC) (AS 1531, Part2)

CodeName

Construction,No./Wirediameter

Sectionalarea

Calculatedequivalentaluminium

area

Approx.overal

diameter

Approx.weight

Calculatedminimumbreaking

load

CalculatedDC

resistanceat 20˚ C

No./mm mm2 mm2 mm kg/km kN kg/km

AgateAmenthystDiamond

EmeraldGarnetJade

JasperOpalPearl

RubyRutile

Sapphire

SpinelTopazZircon

7/1.757/2.257/2.50

7/3.007/3.757/4.50

7/4.7519/3.2519/3.75

37/3.0019/4.7537/3.75

61/3.2561/3.7591/4.50

16.8427.8334.36

49.4877.31111.3

124.0157.6209.8

261.5336.7408.7

506.0673.71,447

14.32.7

29.3

42.165.894.8

106134178

221285345

426568

1,220

5.256.757.50

9.0011.313.5

14.316.318.8

21.023.826.3

29.333.849.5

46.175.994.3

135211304

339433576

721924

1,120

1,4001,8604,000

4.717.789.64

13.921.731.2

34.844.258.8

73.594.4115

135179384

1.971.19

0.967

0.6710.4300.298

0.2680.2120.159

0.1280.09910.0819

0.06620.04980.0232

12

BArE STrANdEd HArd-drAWN ALL ALuMINIuM ALLOY CONduCTOr (AAAC) (dIN 48201, PArT 5)

Nominal areaConstruction,

No./Wirediameter

Calculatedarea

Approx.overall

diameter

Standardweight

Calculatedbreaking strength

Calculatedresistance at

20˚ C

mm2 No./mm mm2 mm kg/km kg ohm/km

16253550

507095120

150185240300

4005006258001000

7/1.77/2.17/2.57/3.0

19/1.819/2.119/2.519/2.8

37/2.2537/2.5061/2.2561/2.50

61/2.8961/3.2391/2.9691/3.2591/3.74

15.8924.2534.3649.48

48.3665.8293.27117.0

147.1181.6242.5299.4

400.1499.8626.2802.1999.7

5.16.37.59.0

9.010.512.514.0

15.717.520.222.5

26.029.132.636.841.1

446794

135

133181256322

405501670827

1,1051,3811,7332,2192,766

450690980

1,410

1,3801,8752,6603,335

4,1905,1756,9108,535

11,40014,24517,84522,86028,490

2.09101.37030.96680.6714

0.69050.50730.35790.2854

0.22740.18420.13830.1120

0.08380.06710.05370.04190.0336

BArE STrANdEd ALL ALuMINIuM ALLOY CONduCTOr (AAAC) (ASTM B 399M)

Code Name Conductor Size Stranding

class*

Construction, No./Wirediameter

Approx.diameter

Standard weight

Calculatedbreakingstrength

ConstructionDC

resistanceat 20˚ C

cmil mm2 No./mm mm kg/km kN ohm/km

AkronAltonAmesAzusaAnaheim

AmherstAllianceButteCantonCairo

DarienElginFlintGreely

30.548.677.4123.3155.4

195.7246.9312.8394.5465.4

559.5652.4740.8927.2

15.5224.7139.1962.4478.55

99.30125.10158.60199.90236.40

283.70331.00374.50469.60

AAAA,AAA,AAA,A

AA,AAA,AAAA,AAA

AAAAAAAA

7/1.687/2.127/2.677/3.377/3.78

7/4.257/4.77

19/3.2619/3.6619/3.98

19/4.3619/4.7137/3.5937/4.02

5.046.368.0110.1111.34

12.7514.3116.3018.3019.90

21.8023.5525.1328.14

42.5867.80107.5171.3215.5

272.5343.3435.2548.5648.6

778.4908.210281288

4.927.8312.418.923.8

30.037.846.558.669.3

83.197.0107135

2.1581.356

0.85480.53650.4265

0.33730.26780.21120.16760.1417

0.11810.1012

0.089450.07133

* NOTE : AA - For bare conductors usually used in overhead lines A - For conductors to be covered with weather - resistant, slow - burning materials and for bare conductors where greater flexibility than is afforded by Class AA is required

13

BArE ALuMINIuM CONduCTOr STEEL rEINFOrCEd (ACSr)ACSR is a composite, concentrically stranded conductor in which the light weight and good conductivity of aluminium are

combined with the high tensile strength of steel. It is composed of one or more layers of EC grade hard-drawn aluminium wires

helically stranded around an inner core of high strength zinc-coated steel wires. The inner steel core may be a single zinc-

coated steel wire, or concentrically stranded of one or more layer of zinc-coated steel wires.

ACSR has long been widely used as overhead high tension transmission lines and has an established reputation for

economy and dependability. The illustration below shows typical standard sizes and stranding patterns.

ACSR Zebra ACSR SkunkACSR Batang

14

6+1 6+7(1+6) 12+7(1+6) 14+7(1+6) 14+19(1+6+12)

24(9+15)+7(1+6) 24(10+16)+7(1+6) 30(12+18)+7(1+6)18(6+12)+1

30(12+18)+19(1+6+12)54(12+18+24)+7(1+6)48(10+16+22)+7(1+6)45(9+15+21)+7(1+6)

54(12+18+24)+19(1+6+12) 72(9+15+21+27)+7(1+6+12) 84(12+18+24+30)+19(1+6+12)

15

ALuMINIuM CONduCTOr STEEL rEINFOrCEd (ACSr) (BS 215:Part 2)

CodeName

Nominalaluminium

area

Construction, No./Wire diameer Cross-sectional area Approx.

overalldiameter

Approx.weight

Calculatedbreaking

load

CalculatedDC

resistance at 20˚ CAluminium Steel Aluminium Total

mm2 No./mm No./mm mm2 mm2 mm kg/km kN ohm/ km

GopherWeaselFerretRabbitSkunk

HorseDogWolfDingoLynx

CaracalPantherJaguarBatang*Zebra

2530405060

70100150150175

175200200300400

6/2.366/2.596/3.006/3.35

12/2.59

12/2.796/4.72

30/2.5918/3.3530/2.79

18/3.6130/3.0018/3.8618/4.7854/3.18

1/2.361/2.591/3.001/3.357/2.59

7/2.797/1.577/2.591/3.357/2.79

1/3.617/3.001/3.867/1.687/3.18

26.2531.6142.4152.8863.22

73.37105.0158.1158.7183.4

184.3212.1210.6323.0428.9

30.6236.8849.4861.70100.1

116.2118.6194.9167.5226.2

194.5261.5222.3338.5484.5

7.087.779.00

10.0512.95

13.9514.1518.1316.7519.53

18.0521.0019.3024.1628.62

106128172214464

538394726506842

587974671

1,0101,621

9.6111.4515.2018.3552.94

61.2032.7069.2035.7079.80

41.1092.2546.5569.67131.9

1.0930.90770.67760.54260.4566

0.39360.27330.18280.18150.1576

0.15630.13630.1367

0.089140.06740

*Not in BS 215 : Part 2

ALuMINIuM CONduCTOr STEEL rEINFOrCEd (ACSr) (AS3607)

Code Name

Construction, No./Wire diameer

Calculatedequivalentaluminium

area

Cross-sectional

area

Approx.overall

diameter

Aprrox.weight

Calculated minimumbreaking

load

ConstructionDC

resistanceat 20˚ CAluminium Steel

No./mm No./mm mm2 mm2 mm kg/km kN ohm/km

AlmondAppleBanana

CherryGrapeLemon

LimeMangoOrange

OlivePawpawPeach

6/2.506/3.006/3.75

6/4.7530/2.5030/3.00

30/3.5054/3.0054/3.25

54/3.5054/3.7554/4.75

1/2.501/3.001/3.75

7/1.607/2.507/3.00

7/3.507/3.007/3.25

7/3.5019/2.2519/2.85

29.041.865.3

105144207

282373438

508583936

34.3649.4877.31

120.4181.6261.5

356.0431.2506.0

586.9672.0

1078.1

7.509.0011.3

14.317.521.0

24.527.029.3

31.533.842.8

119171268

402676973

132414421692

196222413595

10.514.922.7

33.463.590.4

122119137

159178276

0.9750.6760.433

0.2700.1960.136

0.1000.07570.0645

0.05560.04850.0302

Standard High - Strength Conductors

QuinceRaisinSultanaWalnut

3/1.753/2.504/3.004/3.75

4/1.754/2.503/3.003/3.75

8.7717.931.649.4

16.8434.3649.4877.31

5.257.509.0011.3

95194244381

12.724.428.343.9

3.251.580.8970.574

16

ALuMINIuM CONduCTOr STEEL rEINFOrCEd (ACSr) (dIN 48204)

Nominalsectional

area

Aluminium Steel Totalsectional

aea

Overalldiameter

Approx.weightload

Calculatedbreaking

loadConstruction Area Construction Area

mm2 No./mm2 mm2 No./mm2 mm2 mm2 mm kg/km kN

16/2.525/435/644/3250/8

50/3070/1295/1595/55105/75

120/20120/70125/30150/25170/40

185/30210/35210/50230/30240/40

265/35300/50305/40340/30380/50

385/35435/55450/40490/65550/70

560/50680/85

6/1.806/2.256/2.7014/2.006/3.20

12/2.3326/1.8526/2.1512/3.2014/3.10

26/2.4412/3.6030/2.3326/2.7030/2.70

26/3.0026/3.2030/3.0024/3.5026/3.45

24/3.7426/3.8654/2.6848/3.0054/3.00

48/3.2054/3.2048/3.4554/3.4054/3.60

48/3.8654/4.00

15.2723.8634.3543.9848.25

51.1769.8994.3996.51105.7

121.6122.2128.0148.9171.8

183.8209.1212.1230.9243.1

263.7304.3304.6339.3381.7

386.0434.3448.7490.3549.7

561.7678.6

1/1.801/2.251/2.707/2.401/3.20

7/2.337/1.447/1.677/3.20

19/2.25

7/1.907/3.607/2.337/2.107/2.70

7/2.337/2.497/3.007/2.337/2.68

7/2.497/3.007/2.687/2.337/3.00

7/2.497/3.207/2.687/3.407/3.60

7/3.0019/2.40

2.543.985.7331.78.04

29.911.415.356.375.6

19.971.329.924.340.1

29.934.149.529.939.5

34.149.539.529.949.5

34.156.339.563.671.3

49.586.0

17.8127.8440.0875.6856.29

81.0781.29109.7152.8181.3

141.5193.5157.9173.2211.9

213.7243.2261.6260.8282.6

297.8353.8344.1369.2431.2

420.1490.6488.2553.9621.0

611.2764.6

5.46.88.111.29.6

11.711.713.616.017.5

15.518.016.117.118.9

19.020.321.021.021.9

22.424.524.125.027.0

26.728.828.730.632.4

32.236.0

6297

140373196

378284383714899

494904590604794

744848979874985

9981233115511741448

13361647155318602085

19432564

5.819.0212.745.517.2

44.326.335.280.2107

44.998.257.954.477.0

66.374.992.373.186.5

82.910599.392.6121

104136120153167

146210

17

ALuMINIuM CONduCTOr STEEL rEINFOrCEd (ACSr) (ASTM B 232)

Code name Nominal size

Hard-drawncopper

equivalentarea

Construction,No./Wire diameter Calculated area Approx.

overalldiameter

Standardweight

Calculatedbreaking

load

CalculatedDC

resistanceat 20˚ CAluminium Steel Aluminium Steel

AWG/MCM AWG/MCM No./mm No./mm mm2 mm2 mm kg/km kgN ohm/km

Turkey*Swan*

Swanate*Sparrow*Sparate*

RobinRaven*Quail*

Pigeon*Penguin*

Waxwing*Partridge*

OstrichMerlin*Linnet*

Oriole*Chickadee*

Brant*Ibis*Lark

Pelican*Flicker*Hawk*Hen*

Osprey*

Parakeet*Dove*Eagle

PeacockSquab

TealKingbird*

Rook*Grosbeak*

Egret

64422

11/02/03/04/0

266.8266.8300.0336.4336.4

336.4397.5397.5397.5397.5

477.0477.0477.0477.0556.5

556.5556.5556.5605.0605.0

605.0636.0636.0636.0636.0

86644

321

1/02/0

3/03/0

188 7004/04/0

4/0250 000250 000250 000250 000

300 000300 000300 000300 000350 000

350 000350 000350 000380 500380 500

380 500400 000400 000400 000400 000

6/1.686/2.127/1.966/2.677/2.47

6/3.006/3.376/3.786/4.256/4.77

18/3.0926/2.5726/2.7318/3.4726/2.89

30/2.6918/3.7724/3.2726/3.1430/2.92

18/4.1424/3.5826/3.4430/3.2018/4.47

24/3.8726/3.7230/3.4624/4.0326/3.87

30/3.6118/4.7824/4.1426/3.9730/3.70

1/1.681/2.121/2.611/2.671/3.30

1/3.001/3.371/3.781/4.251/4.77

1/3.097/2.007/2.121/3.477/2.25

7/2.691/3.777/2.187/2.447/2.92

1/4.147/2.397/2.677/3.201/4.47

7/2.587/2.897/3.467/2.697/3.01

19/2.161/4.787/2.767/3.09

19/2.22

13.3021.1821.1233.5933.54

42.4153.5267.3385.12107.2

135.0134.9152.2170.2170.6

170.5200.9201.6201.3200.9

242.3241.6241.6241.3282.5

282.3282.6282.1306.1305.8

307.1323.0323.1321.9322.6

2.2173.5305.3505.5998.553

7.0698.92011.2214.1917.87

7.49921.9924.719.45727.83

39.7811.1626.1332.7346.88

13.4631.4039.1956.2915.69

36.6045.9265.8139.7849.81

69.6217.9541.8852.4973.55

5.036.356.538.038.26

9.0210.111.412.814.3

15.516.417.317.418.3

18.818.919.619.920.5

20.721.521.822.422.3

23.223.524.224.224.2

25.223.924.825.125.9

53.7785.6199.61135.8158.6

171.5216.3272.2344.1433.4

430.8543.9612.9543.3688.0

781.1641.3760.2811.2920.5

773.3911.8972.91105901.5

10651138129211551233

13921031121912981466

5.288.3010.512.716.1

15.819.423.329.437.1

30.350.256.638.262.8

77.443.464.772.190.3

52.376.886.410561.0

88.310112395.9108

133.469.7101112141

2.161.351.350.8540.854

0.6760.5360.4260.3370.268

0.2140.2150.1900.1690.170

0.1700.1440.1440.1440.145

0.1190.1200.1200.1200.102

0.1030.1030.1030.09460.0947

0.09470.08930.08970.09000.0900

*Indicate those “preferred” sizes most commonly used.

18

ALuMINIuM CONduCTOr STEEL rEINFOrCEd (ACSr) (ASTM B 232) - continued

Code name Nominal size

Hard-drawncopper

equivalentarea

Construction,No./Wire diameter Calculated area Approx.

overalldiameter

Standardweight

Calculatedbreaking

load

CalculatedDC

resistanceat 20˚ CAluminium Steel Aluminium Steel

AWG/MCM AWG/MCM No./mm No./mm mm2 mm2 mm kg/km kgN ohm/km

FlamingoGannet

StiltStarlingRedwing

Cuckoo*Drake*Tern*

CondorMallard

RuddyCanaryRail*

Cardinal*Ortolan

CurlewBluejay*Finch*

BuntingGrackle

Bittern*Pheasant*

DipperMartin

Bobolink*

Plover*Nuthatch

ParrotLapwing*Falcon*

666.6666.6715.5715.5715.5

795.0795.0795.0795.0795.0

900.0900.0954.0954.01033.5

1033.51113.01113.01192.51192.5

1272.01272.01351.51351.51431.0

1431.01510.51510.51590.01590.0

419 000419 000450 000450 000 450 000

500 000500 000500 000500 000500 000

566 000566 000600 000600 000650 000

650 000700 000700 000750 000750 000

800 000800 000850 000850 000900 000

900 000950 000950 000

1 000 0001 000 000

24/4.2326/4.0724/4.3926/4.2130/3.92

24/4.6226/4.4445/3.3854/3.0830/4.14

45/3.5954/3.2845/3.7054/3.3845/3.85

54/3.5145/4.0054/3.6545/4.1454/3.77

45/4.2754/3.9045/4.4054/4.0245/4.53

54/4.1445/4.6554/4.2545/4.7854/4.36

7/2.827/3.167/2.927/3.28

19/2.35

7/3.087/3.457/2.257/3.08

19/2.48

7/2.407/3.287/2.477/3.387/2.57

7/3.517/2.66

19/2.197/2.76

19/2.27

7/2.8519/2.347/2.93

19/2.417/3.02

19/2.487/3.10

19/2.557/3.18

19/2.62

337.3338.3363.3361.9362.1

402.3402.5403.8402.4403.8

455.5456.3483.8484.5523.8

522.5565.5565.0605.8602.8

644.4645.1684.2685.4725.3

726.9764.2766.0807.5806.2

43.7254.9046.8859.1582.40

52.1665.4427.8352.1691.79

31.6759.1533.5462.8136.31

67.7338.9071.5741.8876.89

44.6681.7247.2086.6850.14

91.7952.8497.0355.59102.4

25.425.826.326.727.5

27.728.127.027.829.0

28.729.529.530.430.8

31.632.032.833.133.9

34.235.135.236.236.2

37.237.238.338.238.2

12721362136814611644

15171622134015281833

15131733160718411740

19851876213420112281

21402437227025882407

27442537289426793048

105117113126154

12414098.8124171

111141118150125

161135175144184

154194163206173

218180231190243

0.08590.08570.07970.08010.0802

0.07200.07200.07180.07200.0719

0.06360.06350.05990.05980.0553

0.05540.05120.05150.04700.0483

0.0450.04510.04230.04250.0399

0.04010.03790.03800.03590.0361

*Indicate those “preferred” sizes most commonly used.

19

PVC - COVErEd ALuMINIuM CONduCTOrSThe PVC - covered conductors have been developed primarily to give protection to telecommunication lines which arecrossed by power lines and to give protection to the public from low voltage lines in case of accidental contact for shortperiods.

The PVC - covered overhead power lines have also been found useful in corrosive atmospheres and for preventing faults due to birds and trees. For such purposes, thickness of covering other than those specified in this catalogue may be used. The conductors are sometimes referred to as “Weather - Resistant Line Wire” and may consist of a single solidwire, or all aluminium stranded conductors (AAC) over which a covering has been applied.

The insulation thickness of Type 8 is intended for use where the operating voltage does not exceed 650 V r.m.s. between any two conductors or 250 V r.m.s. between any conductor and earth.

PVC - COVErEd ALuMINIuM CONduCTOrS (BS 215, Part 1 and BS 6485)

Nominalaluminium

area

Construction,No./Wirediameter

Approx.overalldiameter of

bare conductor

CalculatedDC

resistanceat 20˚C

Approx.breaking load

Approx.overall

diameter ofcovered

conductor

Aprrox.mass ofcovered

conductor

Type 8 Type 16 Type 8 Type 16mm2 No./mm mm ohm/km kN mm mm kg/km mm2250100200

7/2.067/3.107/4.3919/3.78

6.189.30

13.1718.90

1.2770.54190.27020.1349

3.998.28

16.0032.40

8.211.716.021.7

10.413.517.223.1

100200360690

150270480830

* The insulation thickness of Type 8 is intended for use where the operating voltage does not exceed 650V r.m.s between any two conductors or 250V r.m.s between any conductor and earth.

* The insulation thickness of Type 16 is intended for use where the operating voltage exceeds 650 V r.m.s between any two conductors or 250V r.m.s between any conductor and earth, but does not normally exceed 11kV r.m.s between conductors or 6.6kV r.m.s between any conductor and earth.

20

LOW VOLTAGE AErIAL BuNdLE CABLE COMPLYING TO TENAGA NASIONAL BErHAd rEquIrEMENT

dESCrIPTIONLow voltage Aerial Bundle Cable with Polyethylene (PE) insulation is designed for overhead distribution lines.It consists of insulated neutral messenger wire made of All Aluminium Alloy Conductor (AAAC) which helically woundby the insulated aluminium phase conductors.

CONSTruCTION

Phase ConductorH68 aluminium wire to BS 2627, compacted circular stranded.

Neutral ConductorThe neutral of messenger conductors shall be of Aluminium Alloy and compacted circular stranded.

Street LightingH68 aluminium wire to BS 2627, compacted circular stranded.

InsulationBlack Polyethylene (PE) shall be extruded over phase conductor, neutral conductor, and street lighting.

AssemblyRight hand (Z) direction of lay.

TNB specification 0.6/1(1.2)kV

Size of cable 1C X 16mm2 + 25mm2 3C X 16mm² + 25mm2

Phase conductor

Nominal cross-sectional area mm2 16 16

Minimum number of wires 6 6

Nominal thickness of insulation mm 1.0 1.0

Approx. each core diameter mm 6.8 6.8

Max. d.c. resistance of conductor at 20°C Ohm/km 1.91 1.91

Messenger

Nominal cross-sectional area mm2 25 25

Nominal thickness of insulation mm 1.2 1.2

Approx. each core diameter mm 8.5 8.5

Max. d.c. resistance of conductor at 20°C Ohm/km 1.312 1.312

Minimum breaking load kN 6.4 6.4

Completed cable

Approx. overall diameter mm 15.3 19.2

Approx. cable weight kg/km 162 289

21

TNB specification 0.6/1(1.2)kV

Size of cable 3C X 95mm2 + 70mm2 + 16mm2 3C X 185mm2 + 120mm2 + 16mm2

Phase conductor

Nominal cross-sectional area mm2 95 185

Minimum number of wires 15 30

Nominal thickness of insulation mm 1.6 2.0

Approx. each core diameter mm 15.1 20.7

Max. d.c. resistance of conductor at 20°C Ohm/km 0.320 0.164

Messenger

Nominal cross-sectional area mm2 70 120

Nominal thickness of insulation mm 1.4 1.6

Approx. each core diameter mm 13.1 16.6

Max. d.c. resistance of conductor at 20°C Ohm/km 0.469 0.273

Minimum breaking load kN 18.0 30.8

Street lighting

Nominal cross-sectional area mm2 16 16

Minimum number of wires 6 6

Nominal thickness of insulation mm 1.0 1.0

Approx. each core diameter mm 6.8 6.8

Max. d.c. resistance of conductor at 20°C Ohm/km 1.91 1.91

Completed cable

Approx. overall diameter mm 40.5 54.8

Approx. cable weight kg/km 1325 2407

22

AErIAL BuNdLE CABLE COMPLYING TO AS/NZS 3560.1

CONSTruCTION

Phase ConductorCompacted circular stranded aluminium 1350

Neutral ConductorCompacted circular stranded aluminium 1350

InsulationCross-linked Polyethylene (XLPE) shall be extruded over phase and neutral conductor.

AssemblyLeft hand (S) direction of lay.

Core identification:Phase core shall be marked with numerals and letters “1 ONE”, “2 TWO” or “3 THREE” and identified by one rib, two ribs or three ribs.

The neutral cores shall be identified by a series of approximately evenly spaced ribs around the circumference.

23

AS/NZS 3560.1 specification 0.6/1(1.2)kV

Phase conductor 1 Core

Nominal cross-sectional area mm2 16 25 35 50 95

Minimum number of wires 6 6 6 6 15

Nominal thickness of XLPE insulation mm 1.3 1.3 1.3 1.5 1.7

Approx. each core diameter mm 7.3 8.5 9.6 11.4 15.1

Max. d.c. resistance of conductor at 20°C Ohm/km 1.91 1.20 0.868 0.641 0.320

Max. continuous current carrying capacity per phase

a. 40°C ambient air temperature " A 78 105 125 150 230

b. 30°C ambient air temperature A 87 118 140 168 258

Conditions:Solar radiation = 1000W/m²Windspeed = 1m/s"

Messenger

Nominal cross-sectional area mm2 16 25 35 50 95

Minimum number of wires 6 6 6 6 15

Nominal thickness of XLPE insulation mm 1.3 1.3 1.3 1.5 1.7

Approx. each core diameter mm 7.3 8.5 9.6 11.4 15.1

Minimum breaking load kN 4.4 7.0 9.8 14.0 26.6

Completed cable

Approx. overall diameter mm 14.7 17.1 19.2 22.8 30.1

Approx. cable weight kg/km 140 202 265 375 679

24

Phase conductor 2 Cores

Nominal cross-sectional area mm2 25 35 50

Minimum number of wires 6 6 6

Nominal thickness of XLPE insulation mm 1.3 1.3 1.5

Approx. each core diameter mm 8.5 9.6 11.4

Max. d.c. resistance of conductor at 20°C Ohm/km 1.20 0.868 0.641

Max. continuous current carrying capacity per phase

a. 40°C ambient air temperature A 97 120 140

b. 30°C ambient air temperature A 109 134 157

"Conditions:Solar radiation = 1000W/m²Windspeed = 1m/s"

Messenger

Nominal cross-sectional area mm2 25 35 50

Minimum number of wires 6 6 6

Nominal thickness of XLPE insulation mm 1.3 1.3 1.5

Approx. each core diameter mm 8.5 9.6 11.4

Minimum breaking load kN 10.5 14.7 21.0

Completed cable

Approx. overall diameter mm 18.4 20.6 24.6

Approx. cable weight kg/km 297 391 552

25

AS/NZS 3560.1 specification 0.6/1(1.2)kV

Phase conductor 3 Cores

Nominal cross-sectional area mm2 16 25 35 50 70 95 120 150

Minimum number of wires 6 6 6 6 12 15 15 15

Nominal thickness of XLPE insulation mm 1.3 1.3 1.3 1.5 1.5 1.7 1.7 1.7

Approx. each core diameter mm 7.3 8.5 9.6 11.4 12.9 15.1 16.5 17.9

Max. d.c. resistance of conductor at 20°C Ohm/km 1.91 1.20 0.868 0.641 0.443 0.320 0.253 0.206

Max. continuous current carrying capacity per phase

a. 40°C ambient air temperature " A 74 97 120 140 175 215 250 280

b. 30°C ambient air temperature A 83 109 134 157 196 241 280 314

Conditions:Solar radiation = 1000W/m²Windspeed = 1m/s"

Messenger

Nominal cross-sectional area mm² 16 25 35 50 70 95 120 150

Minimum number of wires 6 6 6 6 12 15 15 15

Nominal thickness of XLPE insulation mm 1.3 1.3 1.3 1.5 1.5 1.7 1.7 1.7

Approx. each core diameter mm 7.3 8.5 9.6 11.4 12.9 15.1 16.5 17.9

Completed cable

Minimum breaking load kN 8.8 14.0 19.6 28.0 39.2 53.2 67.2 84.0

Approx. overall diameter mm 17.7 20.6 23.1 27.5 31.2 36.4 39.9 43.2

Approx. cable weight kg/km 277 401 528 746 988 1353 1672 2003

26

AErIAL BuNdLE CABLE COMPLYING TO dES/LVC/ABC SPECIFICATIONCONSTruCTION

ConductorThe conductor of phase, neutral and street lighting conductor shall be H68 condition aluminium in accordance with BS 2627, compacted cicular stranded

InsulationCross-linked Polyethylene (XLPE) shall be extruded over phase, neutral, street lighting conductor.

AssemblyLeft hand (S) direction of lay.

Core identification:First phase conductor shall be identified by single rib, while the second and third conductors by two and three ribs respectively.

The neutral conductor shall be identified by ribs all-around the circumference.

Street lighting conductor shall be marked with words “S/L”

27

DES/LVC/ABC specification 0.6/1(1.2)kV

Size of cable 3C X 25mm² + 25mm² 3C X 35mm² + 35mm²

Phase conductor

Nominal cross-sectional area mm2 25 35

Nominal thickness of insulation mm 1.4 1.4

Approx. each core diameter mm 9.0 9.9

Max. d.c. resistance of conductor at 20°C Ohm/km 1.2 0.868

Messenger

Nominal cross-sectional area mm2 25 35

Nominal thickness of insulation mm 1.4 1.4

Approx. each core diameter mm 9.0 9.9

Minimum breaking load kN 3.1 4.3

Completed cable

Approx. overall diameter mm 21.7 23.9

Approx. cable weight kg/km 421 549

Approx. overall diameter mm 15.3 19.2

Approx. cable weight kg/km 162 289

28

DES/LVC/ABC specification 0.6/1(1.2)kV

Size of cable 3C X 120mm2 + 120mm2+ 25mm2 3C X 185mm2 + 185mm2 + 25mm2

Phase conductor

Nominal cross-sectional area mm2 120 185

Nominal thickness of insulation mm 1.7 2.2

Approx. each core diameter mm 16.5 20.8

Max. d.c. resistance of conductor at 20°C Ohm/km 0.253 0.164

Messenger

Nominal cross-sectional area mm2 120 185

Nominal thickness of insulation mm 1.7 2.2

Approx. each core diameter mm 16.5 20.8

Minimum breaking load kN 15.0 23.0

Street lighting

Nominal cross-sectional area mm2 25 25

Nominal thickness of insulation mm 1.4 1.4

Approx. each core diameter mm 8.8 8.8

Completed cable

Approx. overall diameter mm 40.0 51.0

Approx. cable weight kg/km 1783 2707

Max. d.c. resistance of conductor at 20°C Ohm/km 1.91 1.91

Completed cable

Approx. overall diameter mm 40.5 54.8

Approx. cable weight kg/km 1325 2407

29

OPGW CABLEALuMINIuM-COVErEd STAINLESS STEEL LOOSE TuBE TYPE

rEFErENCE SPECIFICATION - TNB

Optical Fiber (OP)

Aluminium-covered stainless steel loose tube (AC-SSLT)

Aluminium-clad Steel Wire (ACS)

Structure Layer Material Number Diameter Unit

Center AC-SSLT 1 5.2 mm

1st Layer 27ACS * 7 3.8 mm

* Conductivity : 27%

Mechanical Characteristic

OPGW Size 90

Construction 1/5.2mm – OP Unit + 7/3.8mm 27ACS

Max. Overall Diameter # 13.0 mm

Total cross-section area 92.58 mm2

Ultimate tensile strength ≥ 71 KN

Nominal Weight (approx.) 528.5 kg/km

D.C. Resistance at 20°C (Max.) 0.63 Ohm/km

Short-circuit current capacity ≥ 6 kA/1sec

Modulus of elasticity 105,000 N/mm2

Coefficient of linear expansion 14.1 1/°Cx10-6

Outer layer lay direction Ringht-Hand (Z)# The actual cable overall diameter to be advised after production.

30

AC-SSLTCharcteristic

Number of Fiber @ 24

Overall diameter of tube 5.2 mm

Surplus length of Fiber Max. 0.6 %

Ultimate Tensile Strength Min. 210 Mpa

Optical Fiber Characteristic

Fiber Material Silica/Silica doped, Single Mode

Max. Attenuation at 1310nm 0.40 dB/km

Max. Attenuation at 1550nm 0.25 dB/km

Mode Field Diameter at 1310nm 8.6 – 9.5 µm

Mode Field Diameter at 1550nm 9.3 – 11.5 µm

Cut off Wavelength (Fiber) 1130 – 1350 nm

Cut off Wavelength (Cable) ≤1260 nm

Zero dispersion wavelength 1310 ± 10 nm

Maximum Chromatic Dispersion at 1310nm 4 ps/nm.km

Maximum Chromatic Dispersion at 1550nm 20 ps/nm.km

Maximum Zero dispersion slope 0.092 ps/(nm².km)

Cladding diameter 125 ± 1 µm

Coating diameter 250 ± 15 µm

Mode Field concentricity error 0.6 µm

Cladding non-circularity 1.0 %

Colour coding of Optical Fibers: 24 Cores

Fiber Bundle Binder Colour Fiber No & Colour

1

Blue

1 2 3 4 5 6

Blue Orange Green Brown Slate White

7 8 9 10 11 12

Red Black Yellow Violet Pink Aqua

2 Yellow

13 14 15 16 17 18

Blue Orange Green Brown Slate White

19 20 21 22 23 24

Red Black Yellow Violet Pink Aqua

Note: number of fibers may vary upon customer request ranging from 12 to 36 fibers per cable.

31

OPGW CABLEALuMINIuM-COVErEd STAINLESS STEEL LOOSE TuBE TYPE

rEFErENCE SPECIFICATION - SESCO

Optical Fiber (OP)

Aluminium-covered stainless steel loose tube (AC-SSLT)

Aluminium-clad Steel Wire (ACS)

Structure Layer Material Number Diameter Unit

Center AC-SSLT 1 5.2 Mm

1st Layer 40ACS * 7 3.8 Mm

* Conductivity : 40%

Mechanical Characteristic

OPGW Size 90

Construction 1/5.2mm – OP Unit + 7/3.8mm 40ACS

Overall Diameter (Nominal) # 12.8 mm

Total cross-section area 92.58 Mm²

Ultimate tensile strength 49 kN

Nominal Weight (approx.) 429 kg/km

D.C. Resistance at 20°C (Max.) 0.4533 Ohm/km

Short-circuit current capacity 9 kA/1sec

Modulus of elasticity 11,100 kg/mm²

Coefficient of linear expansion 15.5 1/°Cx10-6

Outer layer lay direction Ringht-Hand (Z)# The actual cable overall diameter to be advised after production.

32

AC-SSLTCharcteristic

Number of Fiber @ 16

Overall diameter of tube 5.2 mm

Surplus length of Fiber Max. 0.6 %

Optical Fiber Characteristic

Fiber Material Silica/Silica doped, Single Mode

Max. Attenuation at 1310nm 0.36 dB/km

Max. Attenuation at 1550nm 0.21 dB/km

Mode Field Diameter at 1310nm 9.2 ± 0.4 µm

Mode Field Diameter at 1550nm 10.4 ± 1.0 µm

Cut off Wavelength (Cable) ≤1260 nm

Zero dispersion wavelength 1300 ~ 1324 nm

Chromatic Dispersion at 1310nm < 3.5 ps/nm.km

Chromatic Dispersion at 1550nm < 19 ps/nm.km

Maximum Zero dispersion slope 0.093 ps/(nm².km)

Cladding diameter 125 ± 1 µm

Coating diameter 245 ± 5 µm

Mode Field concentricity error 0.8 µm

Cladding non-circularity 1.0 %

Life Span > 30 Years

Core numerical aperture < 0.23

Colour coding of Optical Fibers: 16 Cores

Fiber Bundle Binder Colour Fiber No & Colour

1

Blue

1 2 3 4 5 6

Blue Orange Green Brown Slate White

7 8 9 10 11 12

Red Black Yellow Violet Pink Aqua

2 Yellow

13 14 15 16

Blue Orange Green Brown

Note: Number of Fibers may vary upon customer request ranging from 12 to 36 fibers per cable.

Leader Cable Industry Berhad (26936-P)

Lot 1385, Tikam Batu Industrial Estate 08600 Sungai Petani, Kedah, MalaysiaTel: 604-438 9988 Fax: 604-438 8497 www.leadercable.com.my

Selangor Sales OfficeUnit 8.2, Level 8, Building A, Peremba Square Saujana Resort, Seksyen U2 40150 Shah Alam, Selangor, Malaysia.Tel: 603-7845 7788/6699 Fax: 603-7845 2258/8323