Alberta Construction Magazine Summer 2012

-

Upload

junewarren-nickles-energy-group -

Category

Documents

-

view

232 -

download

5

description

Transcript of Alberta Construction Magazine Summer 2012

QUALIFIEDBUILDREDUCTION

ENGI

NEER

ING

benc

hmar

k

CONT

RACT

HEALTHgrowth

EQUALITY

COM

MUN

ICAT

ION

safet

yPL

AN

TRAININGSTRUCTUREHIRINGSKILLS

ENGI

NEER

ING

PROGRAMS

ACHI

EVEM

ENT

DEVELOPMENT

PRODUCTIVITY

SAFETY

REPORTSSKILLS

hiring

REPO

RTS

benc

hmar

kDE

VELO

PMEN

T

PROGRAMS training

ENGINEERING

building

CONT

RACT

PLANNING

HIRING

EQUALITY

benchmark

performance

DEVELOPMENT

STRUCTURE

SKILLS

REDUCTION

safety

PRODUCTIVITY

committee

healthSKILLS

BUILDING

training

BUILD

RESPECT

INVESTIGATION

SAFETYRESPECT

PROGRAMS

STRUCTUREQUALIFIED

success

ACHIEVEMENTperformance

EQUALITY

implementationIMPROVEMENTACHIEVEMENT

STAN

DARD

S

safety

PEOPLE

development

commercialREPORTSperformance

CAREER

design

STRUCTUREco

mm

ittee

implementation

PROGRAMS

CONTRACTOR

INVE

STIG

ATIO

N

APPRENTICE

RESPECTBUILDERS

GROWTH

success

SKILLSequality

ENGINEERING

SKILLSEQUALITY

PROD

UCTI

VITY

DEVELOPMENT

SAFETY

committee

REDUCTION

GROWTH

perfo

rman

ceEN

GINE

ERING

safety

build

ing

building

SKILLSRESPECT

SAFETY

buildAC

HIEV

EMEN

TACHIEVEMENT

CONTRACT

PLAN

safet

y

ENGINEERING

CONSTRUCTION

BENCHMARK

CONSTRUCTION

PLANNING

health

EQUALITY

INDUSTRIALprojects

WORKFORCEcommittee

COMMUNICATION

PERF

ORM

ANCE

promotion

LEADERSHIP

IMPR

OVEM

ENT

qualifications

STRUCTURE

APPRENTICE

REPO

RTS

hiringENGINEERING

DEVELOPMENT

growth

investigation

ENGINEERING

REPORTScontractor

achievement

REPORTS

RESPECTREPORTSPRODUCTIVITY

SAFETY

SKILLS

hiring

PRODUCTIVITY

REPORTS

GROWTHbenchmark

INVESTIGATION

ARCHITECTURE

ARCH

ITEC

TURE

infra

struc

ture

INITIATIVE

SUPE

RVIS

OR

success

performance

GROWTH

SAFETY

HEALTHEQUALITYTRAINING

COMMUNICATION

WORKFORCE IMPROVEMENT

CONSTRUCTION

mentoring

QUALIFICATIONS

PLANNING

committee

leadershipPLANNING

promotionstandards

SKILLS

LEADERSHIPCONSTRUCTION

PROD

UCTI

VITY

REPO

RTS

SAFE

TYGR

OWTH

HIRING

IMPROVEMENTsuccess

BUILDING

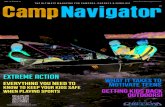

BEST PRACTICES THAT SET COMPANIES APARTBEST PRACTICES THAT SET COMPANIES APART

Summer 2012 | $8.00

Can

adia

n Pu

blic

atio

n M

ail P

rod

uct

Ag

reem

ent

#400

6924

0

HEART OF THE CITYTHE FIRST AND JASPER REVITILIZATION PROJECTP A G E 2 5

LEARNING LEGACYSAIT’S ROLE FOR INDUSTRYP A G E 2 9

PRESERVING HISTORYBIM’S ROLE IN RENOVATIONP A G E 4 1

PLUS | Commercial flooring options abound PAGE 93

Advice you can count onOur Global Infrastructure Advisory practice is one of the largest and fastest growing of its kind in Canada due to our in-depth knowledge and skills, and unrelenting commitment to client service excellence.

From strategy development through to operations and performance, our cross-functional teams provide advice to infrastructure contractors, operators, investors, and government organizations at every stage of capital projects and programs.

For more information and to request a copy of Insight, KPMG’s Global Infrastructure magazine, please contact:

Tim RogersDirector, Global Infrastructure, Alberta 403 691 8412linkedin.com/in/timjrogerskpmg

Randy KraftBuilding, Construction & Real Estate Leader, Calgary 403 691 8039linkedin.com/in/randykraftkpmg

Craig SneddonBuilding, Construction & Real Estate Leader, Edmonton 780 429 7397linkedin.com/in/craigsneddon

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

kpmg.ca/infrastructure

This portal consolidates plan room data from most of Canada’s local construction associations. That means that bidders will be able to access data on more than 20,000 projects, and buyers can display their projects in front of more than 12,000 firms!

Buyers and bidders be aware: construction-procurement opportunities just got a little easier to manage. Link2Build is an online portal that consolidates construction bidding opportunities from the electronic plan rooms of local construction associations across the country.

For bidders, the website’s introduction simplifies the job of searching for bid opportunities. It is a single window through which contractors gain access to private- and public-sector bid opportunities in British Columbia, Alberta (through the Edmonton Construction Association), Saskatchewan, Manitoba, Ontario, Quebec and the Atlantic provinces.

For buyers, the site offers a targeted, qualified audience of more than 12,000 firms from across the country.

“The great thing about Link2Build is that it is owned by construction associations across the country,” says Edmonton Construction Association Executive Vice-President Darlene La Trace. “These are the local organizations that represent all firms in the industry: general and trade contractors, road builders, heavy-construction firms, and manufacturers and suppliers. Exposure to such a large base of construction professionals is impossible to find on any other procurement site.”

Because buyers’ projects are exposed to so many more firms when they are posted on Link2Build, more firms compete for their projects and prices go down. Moreover, the team that stands behind Link2Build is composed of the specialists who run the plan rooms at most of the country’s local construction associations. These men and women understand the challenges associated with receiving, posting and distributing tender documents and they can communicate far more effectively with buyers and bidders than the people who run other, general bid-opportunity websites.

Get consistent, informed procurement adviceGreat service isn’t the only benefit buyers take away from posting on Link2Build. The staff that maintains Link2Build can also offer advice on the industry-standard bid-calling and contract-award practices that have been developed and maintained by the Canadian Construction Association and the Canadian Construction Documents Committee. Moreover, the staff can furnish owners with copies of some of these model contract documents and guides.

How it worksLink2Build is supported by a national aggregator that gathers real-time feeds from participating plan room service providers to build a single, national database. The database populates a website that manages the user registration and includes easy-to-navigate features including a search function. Each plan room provides a predetermined group of data on each project—basic information only, no plans or specifications—for the aggregator.

It’s easy to use!Using Link2Build is simple. Public users register, then receive a password that enables them to access the site. Users can review basic information on projects hosted across the country. If they wish to obtain the complete project file, they will be redirected to the host plan room. Host plan rooms may restrict access to projects, requiring users to either join their associations, or pay a fee to access only that project’s data.“I think the flexibility in this model, whereby plan rooms can determine the ways in which their project information is shared, and how much they charge for single-use access has been a big factor in the widespread acceptance of the national system,” says La Trace.

Check it outIf you haven’t already checked out Link2Build, visit www.link2build.ca now! View the FAQ for answers to basic questions and take a tour to see the site in action.

Canada’s national plan room service

advertisement

Chaz Osburn editor’s note

Coming next issue: The Energy Issue

As far as economic recoveries go, this is a strange one. Though the experts tell us the recovery has been underway for three years now, cautiousness and uncertainty are still prevalent.

Even economic powerhouse Alberta is not immune.We are all aware of the looming labour shortage. ATB Financial senior economist Todd Hirsch

recently pointed out that labour shortages are already starting to choke Alberta’s economy.The Harper government is responding by making it easier to employ foreign temporary

workers and changing rules on how much Canadian companies must pay these workers—up to 15 per cent less.

Of course, for every action there is an equal and opposite reaction. Critics argue that reducing wait times for foreign workers would also reduce the amount of time a domestic worker has to find a job within Canada. Oh, and paying workers up to 15 per cent less is likely to put downward pressure on average wages throughout the economy—even for domestic workers.

Hirsch, in a column written for Troy Media, says Albertans’ wages are 19 per cent higher than the Canadian average. If that’s not remarkable enough, he also notes that in the oil and gas sec-tor, the average weekly wage is $2,434—more than two-and-a-half times as high as the average Canadian weekly wage.

“Wages here could stand to be brought down a bit closer to earth,” Hirsch writes.I can’t see that happening. Alberta companies need all the help they can get on the labour

front, whether qualified workers come from Thailand or Timmons, Ont. And while companies may not like paying top dollar for anything—whether it’s for salaries or steel—that’s the reality of doing business in a hot economy.

As unlikely as this may sound, the one advantage companies may have on their sides—those not in need of additional workers, that is—is that the lingering economic uncertainty may actually be helping bolster employee retention.

Seriously. “Employees may be wearing slightly longer faces these days because of uncertainty about

the economy, but that uncertainty is unlikely to translate into wholesale job-hopping,” reports BusinessNews Daily. It was referring to a new survey by staffing firm Randstad US that finds that fewer than 50 per cent of respondents were likely to look for a new position in the next year.

While this was a U.S. survey done for the U.S. market, it may be somewhat applicable to Alberta—at least in the short term.

Perhaps the upside to the cautiousness and uncertainty is that it will buy companies time. Time to develop strategies to lure and retain workers. Time to look at processes and procedures to improve productivity. Time to jettison the things that aren’t working.

Because the clock is ticking.

Alberta Construction Magazine | 5

featuresCommErCIAL

25 Heart of the cityThe First and Jasper project promises to revitalize a crucial corner in Edmonton’s downtown core

By Joseph Caouette

IndUSTrIAL

45 Powerful projectImperial’s Nabiye expansion includes development of a new steam generation plant and bitumen processing plant

By Jim Bentein

InSTITUTIonAL

29 Learning LegacySAIT’s School of Construction plays critical role in industry’s future success

By Tricia Radison

InfrASTrUCTUrE

41 Preserving history through technologyBIM plays an important role in Legislature dome renovation

By Godfrey Budd

35 Become streetwiseHere are eight products and road-building techniques that are making driving surfaces perform better

By Tricia Radison

roofInG

96 Staying on topFive trends to watch in Alberta’s commercial roofing sector

By Joseph Caouette

EroSIon ConTroL

90 Sowing the seeds of successEnergy sector provides opportunities for Edmonton firm

By Jim Bentein

editorialEditOr

Chaz osburn • [email protected] EditOr

Joseph Caouette • [email protected] writErS

Jim Bentein, Godfrey Budd, Joseph Caouette, nordahl flakstad, Ken Gibson, mychal martin, Tim mavco, Tricia radison

EditOriAl ASSiStAnCE MAnAgEr

Samantha Sterling • [email protected] ASSiStAnCE

Kate Austin, Tracey Comeau, Alison dotinga, Brandi Haugen, marisa Kurlovich

CreativePrint, PrEPrESS &

PrOduCtiOn MAnAgEr michael Gaffney • [email protected]

CrEAtiVE SErViCES MAnAgEr Tamara Polloway-Webb • [email protected]

CrEAtiVE lEAd Cathlene ozubko

grAPhiC dESignEr Christina Borowiecki

CrEAtiVE SErViCES Angie Castaldi

COntributing PhOtOgrAPhErS Aaron Parker, Joey Podlubny

SaleSSales Manager—Advertising maurya Sokolon • [email protected]

Senior Account Executive della Gray • [email protected]

for advertising inquiries please contact [email protected]

Ad trAFFiC COOrdinAtOr—MAgAzinES denise macKay • [email protected]

direCtorSPrESidEnt & CEO Bill Whitelaw • [email protected]

ViCE-PrESidEnt & dirECtOr OF SAlES rob Pentney • [email protected]

dirECtOr OF EVEntS & COnFErEnCES Ian macGillivray • [email protected]

dirECtOr OF thE dAily Oil bullEtin Stephen marsters • [email protected]

dirECtOr OF digitAl StrAtEgiES Gord Lindenberg • [email protected]

dirECtOr OF COntEnt Chaz osburn • [email protected]

dirECtOr OF PrOduCtiOn Audrey Sprinkle • [email protected]

dirECtOr OF MArkEting Kim Walker • [email protected]

dirECtOr OF FinAnCE Ken Zacharias, CmA • [email protected]

oFFiCeSCAlgAry

2nd floor, 816 – 55 Avenue n.E. | Calgary, Alberta T2E 6Y4 Tel: 403.209.3500 | fax: 403.245.8666 | Toll-free: 1.800.387.2446

EdMOntOn

6111 – 91 Street n.W. | Edmonton, Alberta T6E 6V6 Tel: 780.944.9333 | fax: 780.944.9500 | Toll-free: 1.800.563.2946

SUBSCriPtioNSSubSCriPtiOn rAtES:

In Canada, 1-year $24 plus GST (4 issues), 2-year $39 plus GST (8 issues). In US, 1-year C$34 (4 issues), 2-year C$59 (8 issues).

International subscriptions, 1-year $40 (4 issues), 2-year $71 (8 issues). Single copies $8 plus GST.

SubSCriPtiOn inquiriES:

Tel: 1.866.543.7888Email: [email protected] Construction Magazine is owned by

JuneWarren-nickle’s Energy Group and is published bimonthly.©2012 JuneWarren-nickle’s Energy Group

All rights reserved. The contents of this publication may not be reproduced by any means, in whole or in part, without the prior written consent of the publisher. The

opinions expressed by contributors to Alberta Construction Magazine may not represent the official views of the magazine. While every effort is made to ensure accuracy, the

publisher does not assume any responsibility or liability for errors or omissions. Printed by PrintWest

Postage Paid in Edmonton, Alberta, CanadaIf undeliverable return to: Circulation department,

80 Valleybrook dr., north York, on m3B 2S9made In Canada

GST registration number 826256554rTPrinted in Canada ISSn 1499-6308

Publication mail Agreement number 40069240

6 | Summer 2012

ENGI

NEER

ING

benc

hmar

k

CONT

RACT

HEALTHgrowth

EQUALITY

COM

MUN

ICAT

ION

safe

tyPL

ANTRAININGSTRUCTUREHIRINGSKILLS

ENGI

NEER

ING

PROGRAMS

ACHI

EVEM

ENT

DEVELOPMENT

PRODUCTIVITY

SAFETY

REPORTSSKILLS

hiring

REPO

RTS

benc

hmar

kDE

VELO

PMEN

T

PROGRAMS

DEVE

LOPM

ENT

PROGRAMS

HIRING

STAN

DARD

S

safety

PEOPLE

development

commercialREPORTSperformance

CAREER

design

STRUCTURE

com

mitt

ee

implementation

PROGRAMS

CONTRACTOR

INVE

STIG

ATIO

N

APPRENTICE

RESPECTBUILDERS

GROWTH

success

SKILLSequality

ENGINEERING

SKILLSEQUALITY

PROD

UCTI

VITY

DEVELOPMENT

SAFETY

committee

REDUCTION

GROWTH

perfo

rman

ceEN

GINE

ERING

safety

build

ing

building

SKILLSRESPECT

SAFETY

build

ACHI

EVEM

ENT

ACHIEVEMENT

CONTRACT

PLAN

safe

ty

ENGINEERING

CONSTRUCTION

STANDARDS

PRODUCTIVITYENGINEERING

REDUCTION

safetysuccess

RESPECT

BENCHMARK

CONSTRUCTION

PLANNING

health

EQUALITY

INDUSTRIALprojects

WORKFORCEcommittee

COMMUNICATION

PERF

ORM

ANCE

promotion

LEADERSHIPIM

PROV

EMEN

T

qualifications

STRUCTURE

APPRENTICE

REPO

RTS

hiringENGINEERING

DEVELOPMENT

growth

investigation

ENGINEERING

REPORTScontractor

achievement

REPORTS

RESPECTREPORTSPRODUCTIVITY

SAFETY

SKILLS

hiring

PRODUCTIVITY

REPORTS

GROWTHbenchmark

INVESTIGATION

ARCHITECTURE

developmentimplementation

APPRENTICE

GROWTHENGINEERING

trainingINVESTIGATION

PROGRAMS

ARCH

ITEC

TURE

infra

struc

ture

INITIATIVE

SUPE

RVIS

OR

success

performance

GROWTH

SAFETY

HEALTHEQUALITYTRAINING

COMMUNICATION

WORKFORCE IMPROVEMENT

CONSTRUCTION

mentoring

QUALIFICATIONS

PLANNING

committee

leadership

PLANNING

promotionstandards

SKILLS

LEADERSHIPCONSTRUCTION

PROD

UCTI

VITY

REPO

RTS

SAFE

TYGR

OWTH

HIRING

IMPROVEMENTsuccess

BUILDINGLEADERSHIPperformanceSAFETYPLANNING

PRODUCTIVITYsuccess

REPORTSGROWTH

SKILLSPLANNINGpromotion

standards

committeeIMPROVEMENTBUILDING

GROWTH

training

ENGINEERING

building

CONT

RACT

PLANNING

HIRING

EQUALITY

benchmark

performance

DEVELOPMENT

STRUCTURE

SKILLSQUALIFIED

REDUCTION

safety

PRODUCTIVITY

committee

healthSKILLS

BUILDING

training

BUILD

RESPECT

INVESTIGATION

SAFETYRESPECT

PROGRAMS

STRUCTUREQUALIFIED

success

ACHIEVEMENTperformance

EQUALITY

implementationIMPROVEMENTACHIEVEMENT

succ

ess

IMPROVEMENTperformance

STRUCTUREACHIEVEMENT

safetybenchmark

healthBUILD

SKILLSRESPECT

QUALIFIEDEQUALITY

train

ing

REDUCTION

BUILD

Volume 32, Number 2Published Summer 2012contents

8 � � � � � � � � � � � � � � � � � � � � � Project update 11 � � � � � � � � � � � � � � � � � � � � � � � � � nuts & bolts 23 � � � � � � � � � � � � � � � � � � � � Around Canada

59 � � � � People, Products & Projects 67 � � � � � � � � � � � � � � � � � � � � � � � � � � ECA report 71 � � � � � � � � � � � � � � � � � � � � � � � � � CCA report 79 � � � � � � � � � � � � � � � � � � � � � � � � � ACA report 83 � � � � � � � � � � � � � � � � � � � � � � � � � � � � trade talk 88 � � � � � � � � � � � � � � business of building 93 � � � � � � � � � � � � � � � � � Finishing touches 99 � � � � � � � � � � � � � � � � � � � � � � � � � � legal Edge 100 � � � � � � � � � � � � � � � � � � � � � � � � time Capsule

49 tooLS for SuCCeSSbest practices that set companies apart

By Jim Bentein

25

InSIdE

29

45

Cover STorY

Alberta Construction Magazine | 7

corporate and international training

Education for thE rEal World

Registration opens June 1.nait.ca/pes | 780.378.1230

an institutE of tEchnology committEd to studEnt succEss

start your pmp designationThe role of project managers is to initiate, plan, execute, monitor, control and complete projects on time and within budget. If you’re interested in obtaining a PMP designation and want to get ahead in your career, check out NAIT’s PMI-accredited Project Management Certificate — now available part-time and online.

This certificate includes 12, two-day modules and can be completed in 10 months, offering you the flexibility to fit your classes around your personal and professional commitments.

One of the biggest infrastructure projects in Alberta is the West LRT expansion project in Calgary, an eight-kilometre line running to 69 Street SW. And one of the more eye-catching parts of the project is the Sunalta Station.

Sunalta Station—the first elevated sta-tion on the CTrain network, according to the city—features the same elliptic canopy design theme as the other five stations on the West LRT line.

Design elements include a steel frame, copper roof, aluminum cladding, lamin-ated Douglas fir-larch beams and glass panels, much of it completed in March. The city says copper was chosen because of its durability and lower life-cycle costs as a roofing material. Due to Calgary’s dry climate, the copper will lose its sheen and become muted in colour. Longer term, the roof will turn green.

The half-billion dollar West LRT project traces its roots back to the 1980s. A final plan and funding for the West LRT was approved in 2007. Construction of the line should be completed by the end of the year with the new line open to the public in the first quarter of 2013.

SunaLta Lrt Station

8 | Summer 2012

projectupdate

PHo

To: A

Aro

n P

ArK

Er; I

nSE

T: C

ITY

of

CA

LGA

rY

C o n s t r u c t i o n O p p o r t u n i t i e s O n - L i n e N e t w o r k

construction opportunities

Always at your fingertip

A N o r t h A m e r i c A N L e A d e r i N e N v i r o N m e N t A L A N d e N e r g y s e r v i c e s

Tervita brings you a simpler, single-source solution that can save you time, money and headaches.

For over 30 years we’ve been a leader in providing customized environmental management to natural

resource and industrial companies that share our concern for, and commitment to, the future.

We have the expertise, specialized equipment and breadth of services to deliver integrated solutions

and manage them effectively and efficiently. All while meeting or exceeding regulatory requirements.

Whether it’s pond construction, dredging, de-watering, abandonment, demolition, decommissioning,

remediation or reclamation, we create value by delivering a solution tailored to your needs.

Our commitment is to minimize your environmental impact and maximize your returns through

a project management approach that offers you a simpler process, greater efficiencies and

decreased project risk. And there’s nothing frustrating about that. Visit tervita.com or

call 1-855-TERVITA today.

Copyright Tervita Corporation 2012. EARTH MATTERS and the TERVITA logo are the trademarks of Tervita Corporation. All rights reserved.

f the half-million tonnes of garbage handled each year by the Edmonton waste Management Centre, some-

where between 100,000 and 120,000 tonnes will be from construction and demolition projects.

that’s a lot of rusty nails and old rebar for one city.

to help tackle all of that waste, the City of Edmonton has built a $4.3-million construc-tion and demolition waste-recycling facility. the facility began operations in January, with an official opening in March.

while the city has been recycling segre-gated construction and demolition waste for years, this new facility has the ability to

sort and recycle mixed waste. no longer will area contractors be forced to sort their con-crete from their cardboard if they want to recycle—it can all be sent together to the facility, which uses a conveyor system as well as manual labour to separate the different types of waste.

the amount of material that can be sal-vaged from this waste is huge, according to bud latta, director of processing and disposal for the City of Edmonton’s waste manage-ment services.

“the program will divert probably some-thing close to 100,000 tonnes of material from landfills this year,” he says.

latta expects the facility to process an estimated 65,000 tonnes of waste in its first year, with somewhere between 50–75 per cent of that weight being recycled. Another 40,000–50,000 tonnes of segregated con-struction waste—all of which is recycled—will be processed as well.

the facility also has a unique advan-tage in the form of a waste-to-biofuels

facility currently being constructed on the Edmonton waste Management Centre site. when complete in early 2013, the plant will produce 36 million litres of ethanol per year from solid waste—meaning whatever can’t be recycled or composted can be put to good use producing fuel.

“the biofuels facility is another big enabler for us,” latta says. “knowing that we had that option helped us make the decision to go ahead with the construction demolition facility.”

And local builders looking for lEEd (leadership in Energy and Environmental design) certification will likely find the facil-ity a valuable resource, latta believes.

“Any lEEd construction project prob-ably wants to get those points for waste diversion, and people have been doing it by source segregating [waste] when they had room on their site,” he explains, noting that not every project has the ability—or the space—to sort material on site. “this is an option for them.”

Edmonton waste centre offers a welcome diversion

PHo

To: C

ITY

of

Edm

on

Ton

O

Edmonton’s new construction and demolition waste recycling facility officially opened in march of this year.

Alberta Construction Magazine | 11

nEwS briEFS FOr thE buSy COnStruCtiOn PrOFESSiOnAl

nuts & bolts

www.volvorents .com

5223 4th Ave. | Edson, Alberta T7E 1L4 | (780) 723-641010721 214 St. | Edmonton, Alberta T5S 2A3 | (780) 488-122411402-89 Ave. | Fort Saskatchewan, Alberta T8L 4L1 | (780) 997-6464

Volvo Rents CARRIES only THE BEST brands in equipment.

Always listen to mother

it looks like your mother was right—breakfast really is the most important meal of the day. So important, in fact, that it can even help prevent construction site accidents.

the Associated Press reports that the Olympic delivery Authority—the organiza-tion responsible for building london Olympic venues—found that many of its workers were skipping breakfast.

Concerned that lower blood-sugar levels were resulting in less attentive, more accident-prone workers, the Olympic organiz-ation offered workers discounted porridge, in order to fight the late-morning hunger crash.

the authority says that there has been a noticeable decline in the number of late-morning accidents on the site since the program began.

Give us your tilers, your plumbers yearning to breathe free

by 2021, the Alberta government forecasts there will be 114,000 jobs in the province without people to fill them. So where will all of these workers come from?

the Canadian government is looking to answer that question with some major revisions to the Federal Skilled worker Program. Federal Minister of Citizenship and immigration Jason kenney unveiled the upcoming changes at the Calgary Chamber of Commerce in April, according to a report in the Daily Oil Bulletin, a sister publication of Alberta Construction Magazine.

the biggest change? Employers will have a much stronger say when it comes to bringing in workers from outside the country. PH

oTo

: Lo

nd

on

201

2

“we’ll let them do the recruitment overseas and assess the relevance of someone’s practical skills to the Canadian economy,” kenney says.

“One of the reasons we haven’t had a skilled-trades stream in the past is [that] it’s kind of hard to assess whether a welder from Poland meets the red Seal–certification standard in Alberta…but we think the employers are well-suited to look at someone’s background, their experience, their training and make that assessment,” he adds. “we see ourselves more as facilitators in the future.”

under the revised system, there will be a streamlined program dedicated to skilled tradespeople, including construction, transpor-tation and manufacturing positions. greater weight will be given to practical training and work experience over formal education, although minimal language requirements will not change.

the current system for assessing foreign skilled workers includes criteria such as years of education, which tends to favour profession-als and managers over skilled trades. At present, skilled tradespeople make up three per cent of foreign skilled workers.

the Olympic Stadium in london.the Olympic Stadium in london.

nuts&bolts

12 | Summer 2012

Years of Excellence

Sylvan LakeGrande Prairie

Phone: (780) 464-5551

Toll Free: 1-800-667-4847 www.albertatruss.com

• Residential• Farm

• Commercial• Open Web Floors

• LVL beams• I-Joists

NAIT shines a light on solar power

builders interested in adding some rooftop solar power to their next project may want to head back to school first.

the northern Alberta institute of technology (nAit) will be test-ing out a new solar photovoltaic (PV) array installed in April on the roof of its main campus in northern Edmonton.

the $50,400 project—jointly funded by the college and the City of Edmonton—is not a major power generator by any means. with just six pairs of solar panels, the array will offer only a modest contri-bution to the building’s electricity needs.PH

oTo

: nA

IT

but one thing it can offer in abundance is raw data. Each panel pairing will be placed at a different angle, allowing nAit to test dif-ferent construction setups. At the same time, the left-hand side will be brushed clear of snow, while the right will remain untouched in order to measure how snow sticks to the panel.

testing how solar PV works in the capital region’s extreme climate is crucial if the technology is to gain widespread adoption, accord-ing to James Sandercock, chair of nAit’s alternative energy technol-ogy program.

“this array is going to help us answer a lot of the unknowns people might have,” he says. “it’s going to allow people around the capital region to make informed investment decisions for a green energy future.”

The new rooftop solar array at nAIT’s main campus will test out different angles as it gathers information about solar power in the Edmonton area.

nuts&bolts

Alberta Construction Magazine | 13

Another sign of the boomyou don’t need to fly to Fort McMurray to see the effects of the oilsands boom. Visit nisku, Alta., and witness how busy every-one is. Or count the number of pickups trying to get to work in the morning.

As the artist rendering above indicates, the PCl family of com-panies is spending $10 million to construct a 35,000-square-foot

building at one of its two module fabrication yards in that com-munity, replacing more than 30 work trailers.

PCl employs more than 850 people at its yards and fabrication facilities, with the number expected to increase to well over 1,000 people this summer.

PCl’s original module yard was developed in 1997 as an eight-hectare site. that year PCl built 34 modules for dow Chemical.

how things have changed. PCl is now working on three large mod-ule projects that will produce, in total, 424 modules by the fall of 2013. Im

AG

ES: P

CL

Artist renderings of PCL’s $10-million office building at its fabrication yard in nisku, Alta.

nuts&bolts

14 | Summer 2012

▶ Aerial platform▶ Backhoe▶ Counter balance forklift▶ Excavators▶ Narrow aisle forklift

▶ Picker truck▶ Pavers▶ Rough terrain forklift

(zoom boom)

▶ Skid steer

▶ Wheel loader▶ Grader▶ Dozer▶ Compaction rollers▶ Scrapers

Chase Operator Training offers training on: Safety Training for YOUR

Power Mobile Equipment

Train the Trainer Available

1.800.317.3612 | [email protected] | chaseot.com

Edmonton invites public to speak on new arena design

is it cool and curvy? Or just plain weird and wonky?

there’s no shortage of opinions on the pre-liminary design work for Edmonton’s new arena, recently released to the public by the city. why not add your own to the mix?

Starting in late May, the city will kick off a public consultation process on the proposed arena design. People will be invited to offer their

opinion over the phone, in person or online.More information on the project—including

more detailed drawings—will be released prior to the public consultation. After the public has had its say, the designs will be revised and put before Edmonton city council for final approval.

the current budget for the building sits at $450 million, with $30 million of that total dedi-cated to design work.

ImA

GES

: CIT

Y o

f Ed

mo

nTo

n

The public is being invited to comment on the initial drawings of the proposed new Edmonton arena.

nuts&bolts

Alberta Construction Magazine | 15

INSURANCE BONDING

RISK MANAGEMENT Garth Lane: 780.930.3812 Don C. Barr: 780.930.3836

Mark McKinley: 780.930.3828 We Listen. We Think. We Deliver.

www.lloydsadd.com

The largest construction equipment manufacturers in 2011

Concrete progress on the gender front

Forget about breaking the glass ceiling. how about building the concrete flooring?

women building Futures (wbF) has long been dedicated to bringing women into the construction industry. the latest addition to its roster of programs is a new course for ready-mix drivers sponsored by lafarge Canada inc.

“lafarge was challenged to find and retain experienced driv-ers with a strong safety mindset and customer orientation,” says larry diduck, the company’s Edmonton general manager. “in a brainstorming session, wbF was put on the table as an alternate training and recruiting source.”

the five-week, 120-hour program will provide training in air brakes, load securement and ergonomics, as well as offer 30 hours of in-truck driver training. typical of wbF programs offered, the course will also tutor students on construction workplace culture, covering everything from attitude and attire to career development options.

the program is offered with the approval of the Alberta government.

ComPaNy2010

raNkiNg

1 Caterpillar 1

2 komatsu 2

3 volvoConstructionequipment 4

4 HitachiConstructionmachinery 3

5 liebherr 5

6 Sany 7

7 Zoomlion 8

8 terex 10

9 doosaninfracore 6

10 Johndeere 12

global construction equipment sales were uS$182 billion in 2011, according to khl group’s annual survey of the industry. the record figure surpassed the previous high of uS$168 bil-lion, set back in 2008.

Source: KHL Group ImA

GE:

STo

CK.

xCH

nG

nuts&bolts

16 | Summer 2012

3738 97 Street Edmonton, Alberta T6E 5S8Ph. 780.463.3555 Fax: 780.462.1482

For all your electrical needs, trust western.

STARS, industry team up to build some magic

the Edmonton-area construction industry and the Shock trauma Air rescue Society (StArS) are partnering once again to help save lives with an annual fundraising gala called building Magic in the Air.

the gala is being held on november 24 at the Crowne Plaza Chateau lacombe in Edmonton. the semi-formal event will begin

at 5:30 p.m. with cocktails, followed by a buffet dinner, silent and live auctions, raffles and live entertainment.

tickets can be purchased individually at a cost of $150 or by the table, with a limit of 350 people for the entire event. Organizers expect tickets to sell out quickly.

Visit the building Magic in the Air gala website to regis-ter and become a sponsor, make a donation, purchase tick-ets and get all the details on the event: foundation.stars.ca/buildingmagicintheairgala.PH

oTo

: mA

rK m

Enn

IE/S

TArS

The Edmonton-area construction industry will be taking part in a fall fundraiser to help support STArS air ambulance.

nuts&bolts

Alberta Construction Magazine | 17

• Jobsite-ready packaging & sizing •• Zero global warming potential •

• Lowest transport impacts •

• Permanent RSI-value •

• Most economical •

TERRAFOAM PLATINUM 3000Polystyrene thermal InsulatIon

1 888 453 5961 | www.beaverplastics.com (an Alberta company)

Superior ‘type 4’ inSulation from Graphite technoloGy

HELPING TO MEET THE GOALS OF SUSTAINABLE DESIGN

Survey saysConstruction executives may still be concerned about the shaky global economy, but there’s one sector of the economy that has them feeling pretty good—the energy industry.

those are just some of the conclusions to be drawn from the latest global construction survey from kPMg. the company talked to senior executives at 161 different engineering and construction firms around the world as part of the survey.

here are some highlights from the results:• 80 per cent of respondents believe governments aren’t showing enough leadership when it comes to infrastructure development

• 71 per cent are most concerned about economic uncertainty• 59 per cent of companies from the Americas say the energy sector offers the greatest opportunity for future growth

• 54 per cent admit that they failed to identify problems at the bidding stage for underperforming projects, suggesting a lack of rigorous upfront-risk assessments

• 49 per cent say their project backlogs are expected to increase from five to 15 per cent• 78 per cent of companies from the Americas say organizational culture is the biggest barrier to cost cutting

$208.8 billionworth of major construction projects recently completed, currently under-way or planned to start in the next two years in Alberta. Of that total, $157.7 bil-lion is in the Edmonton region or the north of the province.

Source: Avison Young

“Of the more than 250,000 immigrants coming into the country every year, less than 700 a year would actually have construction skills.”

— Stephen Kushner, president,

merit Contractors Association

Source: Edmonton Journal

ImA

GE:

PH

oTo

S.Co

m

That’s 0.0028 per cent, in case you’re wondering

nuts&bolts

18 | Summer 2012

ROXUL® RHT INSULATION

Introducing our expanded lineupWhen you need high- temperature thermal performance or personnel protection, Roxul® has you covered with a wide range of boards, blankets or rolls to meet all your requirements.

Learn more about Roxul RHT products at www.roxul.com or call 1.800.265.6878.

Bring on the Heat.

www.roxul.com

RO

XI-2

102-

0112

In the Middleof Nowhere,Or in the Middle of Everything.

Only Astec has the patented Double Barrel Green® System.

Astec can configure a plant to fit your site, whether that site is in the middle of nowhere or in the middle of a major metropolitan area.

And every Astec plant, no matter where it is located, is also backed by the Astec Service and Parts departments available 24/7 anywhere.

Astec is the right choice.

In the Middleof Nowhere,Or in the Middle of Everything.

Only Astec has the patented Double Barrel Green® System.

Astec can configure a plant to fit your site, whether that site is in the middle of nowhere or in the middle of a major metropolitan area.

And every Astec plant, no matter where it is located, is also backed by the Astec Service and Parts departments available 24/7 anywhere.

Astec is the right choice.

Experience lasting change

www.pwc.com/ca/doingbusinessinalberta

At PwC, we can help you tackle the complex change that comes with growth.

We work with private companies to manage major capital programs, mergers, acquisitions and divestitures.

Let us help you engage your people, develop processes and implement technologies — creating change that sticks and value that lasts.

© 2012 PricewaterhouseCoopers LLP. All rights reserved. “PwC” refers to PricewaterhouseCoopers LLP, an Ontario limited liability partnership, which is a member fi rm of PricewaterhouseCoopers International Limited, each member fi rm of which is a separate legal entity. 2175-21 0512

David [email protected]+1 780 441 6700

AECon “ new project awards are strong, demand continues

to build in our core transportation, resources and power sectors, and our focus on project execution and risk management is generating improved earnings. i believe these factors will result in consistent, sustainable earnings growth for aecon through 2012 and 2013.”

— John M. beck, chairman and chief executive officer, Aecon group inc., in announcing his company’s

2011 performance while looking ahead.

ian a. Bourne, former president and director of transAlta Power lP, gets to occupy the big chair at SnC-lavalin group inc. while the global engineering firm searches for a new chief executive officer to replace Pierre duhaime.

duhaime reportedly received a $4.9-million golden handshake after the company relievied him of duties for Ok’ing the payment of millions of dollars to undisclosed agents.

bourne is chairman of the board of ballard Power Systems inc.

HandSHake

revenue generated in the fiscal year ended nov. 30, 2011, by quebec-based Cegertec inc., an engineering consulting engineering firm specializing in energy, industry, transport, infrastructure and building construction. in April, Cegertec and worleyParsons ltd. formed a joint venture company called Cegertec worleyParsons.

SoUrCE: WorLEYPArSonS LTd.

miLLion,000eStimated BarreL-Per-day capacity of planned expansion of kinder Morgan Energy Partners’ trans Mountain pipeline system, which runs between Alberta and the west coast of british Columbia. the expansion is projected to cost $5 billion

SoUrCE: KIndEr morGAn InC.

new BrunSwiCk’S construction industry should be able to draw on its own workforce to meet labour requirements for most of the next decade, a new report predicts.

Mining and other resource-related projects will be the main source of new jobs, but there will also be moderate increases in employment in the industrial, commercial and institutional sectors, says the Construction Sector Council’s Construction looking Forward forecast.

“with stronger construction markets in other parts of the country, the challenge lies in keeping the skilled work-ers here when they are needed to replace retiring workers,” says tim Flood, president of John Flood and Sons (1961) ltd.

when it comes to housing, overall losses in employment reach almost 20 per cent over the 2012-20 forecast period. the downward trend occurs mostly in new housing, while renovation and maintenance follow a gradual and steady increase in employment.

the industry’s labour force is estimated to decline by almost 2,700 workers from 2012 to 2020 as construction investment weakens. this decline will be offset by the expected retirement of 4,200 workers. industry will still need to recruit more than 1,500 workers to replace retirees and sustain a skilled workforce.

AS SHE GoES John m. Beck, chairman and chief executive officer, Aecon Group Inc.

PHo

To: A

ECo

n G

roU

P In

C.

Alberta Construction Magazine | 23

| AroUnd Canada

DESIGNEDFOR THE WAYYOU WORK

The All New NV SERIES

BRASSO NISSANCalgary, ABErnie Long

www.brassonissan.com

SHERWOOD NISSANEdmonton, AB

Jamie Bates780-449-5775

GORD SCOTT NISSANServing Central Alberta

Red Deer, ABMike Samson403-347-2258

GRANDE PRAIRIE NISSANServing Northern Alberta

Grande Prairie, ABCorey Sawchuk780-532-8040

AUTHORIZED ALBERTA DEALERS:

DESIGNEDFOR THE WAYYOU WORK

For years, the intersection of 101 Street and Jasper Avenue has been a perfect symbol of the problems aff licting

Edmonton’s downtown core: plenty of prime real estate, little imagination, no fun. On a beautiful Saturday afternoon in sum-mer, you might find a few people out there waiting for a bus to take them to West Edmonton Mall.A

LL Im

AG

ES: A

VISo

n Y

oU

nG

of the citytHe firSt and JaSPer ProJeCt promises to revitalize a crucial corner

in Edmonton’s downtown coreBy Joseph Caouette

Expect big changes, and soon. In May, the City of Edmonton began its two-year plan to renovate Jasper Avenue between 100 Street and 102 Street, widening sidewalks and ripping out the obtrusive, unpopular medians that run down the street. A new pedestrian-friendly space is envisioned, filled with shops and restaurants intended to jolt awake the city’s sleepy centre.

The first and Jasper project will be the guinea pig for the City of Edmonton’s revitalization of Jasper Avenue.

Alberta Construction Magazine | 25

commercial

CommerCial, industrial, meChaniCal ContraCtor

PRIORITYMECHANICALLTD. P.M.

Priority Mechanical Ltd.9259-35 Avenue, Edmonton, Alberta T6E 5Y1Phone: 780-435-3636 | Fax: 780-450-3550

www.prioritymechanical.com

Congratulations to Ledcor Construction Limited.

Proud to be the mechanical contractor for: First & Jasper

GE Capital Real Estate’s First and Jasper project will offer a preview of the new downtown to come. Designed by DIALOG and constructed by Ledcor Group of Companies, this massive renovation of the old Epcor Tower kicked off in January. If this corner is the heart of the city, expect it to beat a little quicker come March 2013, when the building is finished.

Originally built in the mid-1970s, the building has best been known as the home of Epcor Utilities Inc. since 1990, back when the company was still called Edmonton Power. Indeed, that’s likely all that anyone knows about the building, unless they happen to be Epcor employees. The place represented an older vision of downtown—sealed off, isolated and unvisited. It was a place you went to work, and then left at five o’clock without looking back.

The new vision for the site represents a radical break from that past, and nowhere is that more apparent than on the first two floors. Last year, the neighbouring Bank of Montreal building and Odeon Theatre were demolished to make way for a two-storey podium section connected to the main tower. Surrounded by glass and joined to the main building by a skylight, the new section will be a bright, open retail space. The old building, by compari-son, contained only a meagre coffee shop and convenience store.

“Bringing the energy from the new retail and introducing it to the pedestrian traffic is going to be great for that location,” says Cory Wosnack, principal at Avison Young, the project’s leasing

agent. “First and Jasper has been an underutilized opportunity for retail for a very long time.”

“It’s going bring a little more life to this corner of Jasper that hasn’t been here in the last 10 or 15 years,” agrees Scott Kapty, project manager with Ledcor.

Communicating with the city, the project tweaked its design to ensure it would fit into the new Jasper Avenue and take full advantage of the city’s vision for the street. “We’ll be the first build-ing on Jasper…to be renovated and have [the avenue’s new look] incorporated off the bat,” Kapty says. “We were the guinea pigs.”

In a sense, First and Jasper will also be an environmental guinea pig, representing a rare example of a LEED-EB (existing building) gold project in the city. Details on the final certification are still not quite known—the building can’t be certified until it’s up and running—but there’s a lengthy checklist of qualifications to be met. These include minimum standards for water fixture and energy efficiency, as well as indoor air quality benchmarks. Every five years, the building must reapply for certification.

At the same time, Ledcor will be greening its own building practices as it works on the project. “We’re looking at cutting down dust, cutting down VOCs [volatile organic compounds] and con-taminants in the air by using something as simple as a low-VOC spray balm for an electrician laying out stuff,” Kapty says. “Even if it isn’t a LEED job, we found they’re easy practices to adopt.”

A skylight will connect the main tower to a two-storey addition.

26 | Summer 2012

commercial

14518-115A AvenueEdmonton, AlbertaP: (780) 732-5316F: (780) 732-1139

❖ Load Bearing Studs❖ Interior Steel Studs ❖ Insulation❖ Gypsum Board❖ Wall/Ceiling Texture❖ T-bar Ceiling Tile❖ Acoustic Panels❖ Cement Stucco❖ Acrylic Finish ❖ EIFS Stucco

❖ Terwillegar Recreation Centre

❖ Alberta Heart Institute

❖ Kingsway Garden Mall

❖ London at Heritage Station

Pleased to be part of the First and Jasper project

standard, unitized aluminumcurtain wall systems

aluminum storefrontand entrances

innovative glazing solutions

2007-91 Ave., Edmonton, Alberta T6P 1L1Ph: (780) 449-6014 • Fax: (780) 449-6016

Email: [email protected]

Tenant interest has been strong so far, with three major clients already lined up. Williams Engineering Canada Inc. has taken the entire 33,000-square-foot second floor—“boutique office space,” as Wosnack describes it—with high ceilings, huge windows and an open-concept layout. The Association of Professional Engineers and Geoscientists of Alberta has staked out three floors in the tower, while the federal government has four floors to itself.

Close to half of the 220,000-square-foot project has already been leased out, and Wosnack expects interest to remain high,

even with projects like the new Epcor Tower adding more premium office space downtown. Consider it a welcome side effect of Alberta’s growing economy.

“Vacancy has been declining and rent rates have been climbing upwards of 20 per cent,” he says, suggesting companies will scoop up properties now rather than let prices climb higher.

“Real estate deals that will be done six months from now are going to look quite a bit different from the real estate deals that are available today,” Wosnack says.

Using wider sidewalks, lots of windows and more green

space, the first and Jasper project hopes to lure more

pedestrian traffic to its corner of the city.

Using wider sidewalks, lots of windows and more green

space, the first and Jasper project hopes to lure more

pedestrian traffic to its corner of the city.

Alberta Construction Magazine | 27

commercial

Keep it in

For over 75 years, Brandt has built its legacy by providing exceptional service and top quality equipment – like the John Deere D-Series Skid Steers. They provide the same reliable versatility that you’ve come to expect from all your heavy-duty John Deere equipment. D-Series Skid Steers provide the perfect balance of power, versatility and

maneuverability. They also feature premium cab space, extra glass ensuring best-in-class visibility, increased serviceability and improved structure – making the D-Series Skid Steer a welcome addition to your John

Deere family of equipment at your worksite. Add Brandt’s uncompromising commitment to after-sales support in 21 locations across Western Canada, and what you’ll have is a machine as dependable

as the company that sold it to you. That’s Powerful Value. Delivered.

the family.

Call 1-888-2BRANDT for a demo or visit www.brandttractor.com for more information on our products and financing options.

Brandt is celebrating $1billion in annual revenue and we’re thanking our customers by offering special rebates throughout 2012. Visit thanksabillion.ca for details.Rebates!

As baby boomers retire, Alberta is expected to experience a 77,000 -

person shortfall in workers over the next decade. At the same time, companies will continue to find themselves needing to do more with less—less labour, less money, less time—to stay competitive. Although it might be a surprise for an educational institution, SAIT Polytechnic is stepping up to help the construction industry proactively manage these challenges.

Learning

Sait’S SCHooL of ConStruCtion playscriticalrolein

industry’sfuturesuccess

legacy

PhO

tO: J

OEy

PO

dlu

bn

y

By Tricia Radison

larry rosia is dean of the School of Construction at SAit Polytechnic.

Alberta Construction Magazine | 29

institutional

First, and most obviously, SAIT is helping to ensure that labour is available. SAIT’s School of Construction offers 5,000 apprenticeship seats across 16 trades, as well as another 800 seats through the two-year technology diploma programs in areas such as civil engineering technol-ogy, architectural technology, and engin-eering design and drafting.

The new four-year bachelor of science in construction project management degree program will graduate another 72 or so people a year when the first class finishes in 2015, and the new Trades and Technology Building, scheduled to open this fall, will allow for 8,100 more full- and part-time learners. Online learning options are also increasingly available, attracting people who might not have been able or willing to leave jobs for apprentice-ship training.

“Over 10 years, we feel we will deliver about 20,000 additional skilled trades-people, technicians and technologists to

the industry,” says Larry Rosia, dean of the School of Construction.

the right stuffBut SAIT isn’t interested in just pumping out graduates. They have to be the right graduates, trained in the right areas, with the knowledge and skills that are going to meet industry’s needs. That requires work-ing closely with government and industry to identify areas where graduates are required.

“We watch the Construction Sector Council’s employment projects very closely to see where the skill-set shortages are going to be,” Rosia notes. This year, that led to the creation of a new insulator appren-ticeship program, the first in Calgary. SAIT designed the curriculum and built new labs to make room for the program.

“SAIT has always been an institu-tion that actually listens to industry,” says Kees Cusveller, vice-president, busi-ness development, Graham Group Ltd. from his Calgary office. “They ask us, as

employers, if the programs are offering what we need them to offer. Are the apprentices doing what we need them to do? Are the technology programs provid-ing what industry needs?”

Moving the construction management certificate online is one example. In dis-cussions with industry, Rosia and his team heard that some people interested in tak-ing the certificate program were working on-site, or are just too busy to miss work time for class. The online delivery model solves the problem, meeting the needs of the employee who wants to train and advance, and of the employer who will need people with management skills.

Industry is welcome to bring issues to SAIT. The construction project man-agement degree program is the perfect example. The Calgary Construction Association brought the idea to the edu-cational institution about six years ago when people like Cusveller realized that trouble lay ahead.

30 | Summer 2012

institutional

IT’S OUR ANNIVERSARY!We’d give you a slice of cake if we had one, but at our age we have to watch what we eat! Yes, we’re celebrating 35-years and the competition can’t hold a candle to us. Many have come and gone, but we’re still going strong – thanks to you.

CALGARY EDMONTON RED DEER FORT MCMURRAY EVERYTHINGCONCRETE.CA

“The traditional way to become a superintendent or a project manager was to start as a labourer and come up through the ranks,” Cusveller says. “We don’t have time to do that anymore.” He adds that the job has also become more complicated, with complex projects and more technology.

The degree program is the first of its kind in Canada and transfers knowledge and skills much more quickly than work-ing your way up the ladder. Just as import-antly, it’s relevant because its been built by industry. For example, third-year students take a business skills and processes course that covers the major aspects of the con-struction business. That wasn’t something the School of Construction included when the program was first designed, but it was a must for advisory board members so that students were prepared for the real world of work upon graduation.

To get people into the workforce faster, SAIT is also offering a third-year

advanced standing option for the construction project man-agement degree. Graduates of SAIT’s civil engineering tech-nology diploma program, or an equivalent, can apply to take a summer bridging pro-gram and enter the four-year program in its third year, in order to graduate in just two years.

“We’re hoping it will catch on as a [human resources] strat-egy for construction companies,” Rosia says. “They can fast-track those real high performers into a management program and into positions like project manager and supervisor.”

evolution and innovationPerhaps one of the most surprising ways in which SAIT helps industry is by con-ducting applied research that can give companies a competitive edge.

“If a company or an individual in the construction industry has an idea that he or she wants to commercialize and take to market, we will work with that idea and assist them in building the application for it,” Rosia says.

getting INVOLVeDthe School of Construction has advisory committees made up of industry members for all its programs. if you’d like to contribute to the curriculum and ensure that graduates are going to meet industry needs in the future, contact the main office at 403-284-8367 or [email protected].

Alberta Construction Magazine | 31

institutional

Leading With Energy TM

Bantrel offers a complete and fully integrated

Engineering, Procurementand Construction solution.

Through SAIT’s Applied Research and Innovation Services (ARIS), companies can work on ideas such as developing a new concrete pouring system, a piece of equipment to speed up a process, or even a new process to speed up the entire building process.

Some of the areas ARIS has worked on in the past include green building technology, GIS mapping, and energy-efficiency codes and code requirements.

“SAIT’s team, including master trades-people with industry experience, will ensure projects align with the needs of private sector partners, with the goal of transforming industry with economic, social and environmental benefits,” says David Silburn, research associate, Green Building Technologies, ARIS.

The research potential SAIT holds is exciting to Ken Gibson, executive director of the Alberta Construction Association.

“Construction by its very nature is [about] solving problems out in the field,” he says. “Today we have exacting customer require-ments, and ever more challenging safety and environmental regulatory require-ments, which are a reflection of societal pressure. We have all these forces of change impacting our industry that are requiring new solutions, and fortunately we now have this multidisciplinary problem-solving team at SAIT. What a great resource.”

The Green Building Technologies depart-ment has worked with a number of partners to have innovative products and processes, such as advanced walls, foundation and roof assemblies using advanced or renewable technologies, developed and proven.

There is a cost to the company. The amount depends on project scope, project management and principal investigator timelines, technical exper-tise from the college, lab and infra-structure requirements, and material or publication resources.

Provincial and federal grants and SAIT grant options may cover part of the cost, but companies are expected to cover at least 25 per cent of the costs of research. They don’t, however, have to worry about transferring intellectual property.

Says Silburn: “Despite SAIT adding value to the original work, industry part-ners will retain the intellectual property in exchange for a SAIT royalty fee, negoti-ated based on expected revenues.”

32 | Summer 2012

institutional

Leaders don’t flinch.

When the going gets tough, the tough stay put. Through the credit crunch, depressed commodity prices and global economic turmoil, we’ve done just that. We never left the side of the people who’ve made Alberta an economic powerhouse, and we continue to custom build solutions to help them do what they do best…lead. Because Alberta means the world to us.

atb.com/corporate

TM Trademarks of Alberta Treasury Branches.

10years

Living Leadership

“Duro-Last” and “The World’s Best Roof” are registered marks owned by Duro-Last Roofing, Inc.

Five reasons why one seam isbetter for your roof than ten.

1. Faster, higher quality installation. 2. Non-disruptive to building operations.3. Virtually maintenance-free durability.4. Proven long-term, watertight performance.5. Exceptional energy efficiency.

Each Duro-Last® roofing system is precision fabricated to perfectly fit thebuilding it’s designed for, right down to the stacks and flashings. While other systems require extensive seaming on the rooftop to install, every customizedDuro-Last roofing system is delivered to

the job site with up to 85 percent of themembrane seaming already completed inour factory. So your roof goes on faster anddelivers superior, watertight protection.Best of all, Duro-Last’s proven performancemeans your investment will continue topay off for years to come, with significantenergy savings, little to no maintenance,and the best warranties in the business.

The numbers all add up: Duro-Last is the best roofing system for your building.

To find out more, call us or visit www.duro-last.com/value and request our free brochure.

800-248-0280 • www.duro-last.com

WISESTREET

To the untrained eye, a road surface is just a layer of asphalt or concrete.

But there are an abundance of products, techniques and treatments that can do everything from preventing pavement from cracking to reducing traffic noise to helping us conserve water.

“There is a lot of great technology available. We are way ahead of where we were even 10 years ago, so obviously we have to take advantage of it,” says Ludomir Uzarowski, principal, pavement and materials engineering, Golder Associates Ltd.

Here are products and road-building techniques that are making driving surfaces perform better

By Tricia Radison

Alberta Construction Magazine | 35

infrastructureIL

LUST

rATI

on

S: A

nG

IE C

AST

ALd

I

www.sealitwaterproofing.ca

• Dampproofing • Waterproofing • Blindside Waterproofing • Methane Barrier • Tunnels and Underground Structures • Deck and Between Slab

A

WORLD

OF DIFFERENCE

FORREAL WORLD CON

DITIONS

Waterproof ing SystemsWATERPROOFING

• Dampproofing • Waterproofing • Blindside Waterproofing • Methane Barrier • Tunnels and Underground Structures • Deck and Between Slab

www.sealitwaterproofing.ca

Here are eight innovations in road-surface products and road-building techniques that are driving the future of road construction.

noise-reducing asphalt“There have been a few cost-benefit analyses done that show

that using asphalt to reduce noise lev-els makes more sense than constructing sound-wall barriers,” says Jim Bird, dir-ector of performance for the western Canada Asphalt, Paving & Construction

product line at Lafarge. Durawhisper is a Lafarge product designed to reduce traf-fic noise while meeting all the normal specifications for hot-mix asphalt. It’s ideal for use in residential areas.

eco-friendly manufacturingAs a result of the focus on green technologies that is permeating

the industry, asphalt mixes are being developed that have less of an impact on the environment.

Lafarge’s Duraclime is a warm mix that meets all the specifications of a hot mix. Because it is manufactured at a lower temperature, odour, smoke, fuel

consumption and emissions are reduced during manufacturing. According to the company’s website, using Duraclime can lower the carbon footprint of an asphalt-producing plant by up to 20 per cent.

Cost-wise, Duraclime is about the same as traditional hot-mix asphalt. Says Bird: “I’m not sure that anybody has a good reason not to use Duraclime. Regardless of whether it’s a Lafarge product or one belonging to our competitors, the technical data coming out of analyses concludes that warm mixes are equivalent to hot mixes in terms of performance standards.”

eco-friendly ingredientsAnother way manufacturers are making roads more sustainable

36 | Summer 2012

infrastructure

Mobile OfficesWorkforce

CampsStorage Products

ModularBuildings

800.782.1500www.willscot.com

Offices in Edmonton, Calgary, Fort McMurray

Lafarge has used porous asphalt in trial projects in Calgary, including a demonstration section in the parking lot of the new water building. What’s not known is how the asphalt will handle Alberta winters.

“With our winter sanding efforts, there is some trepidation as to how quickly the permeability deteriorates,” Bird says. “We just have to work out strategies for main-taining a porous parking lot.”

Perpetual pavementsPerpetual pavements are designed to last around 50 years, compared

to 20 years for conventional pavements. According to Uzarowski, the durability is due to the components of superior-performing asphalts and the ability to model and analyze road systems before construction.

“Fatigue cracking occurs when the tensile strength at the bottom of asphalt exceeds the limit. So the trick with per-petual pavement is to design it from the bottom up,” Uzarowski says.

Uzarowski and his team designed the first municipal perpetual pavement in

There is a lot of great technology available. We are way ahead of where we were even 10 years ago, so obviously we have to take advantage of it.

— Ludomir Uzarowski, principal, pavement and materials engineering, Golder Associates Ltd.

from an environmental perspective is by using recycled material in the mix. For instance, Canadian Road Builders Inc. offers a mix called Vegecol that is made entirely from renewable, plant-based material and can be used on major roads as well as for walking and biking paths.

Like Duraclime, Vegecol is manufac-tured at a cooler temperature, reducing its carbon footprint. As an added benefit, there are no petrochemical ingredients to contaminate runoff water.

Computer modelling“The advances in road building are coming in engineering

areas,” says Gene Syvenky, chief exec-utive officer, Alberta Roadbuilders & Heavy Construction Association. Computer modelling is being used much more for designing structures,

benefiting taxpayers and resulting in better-performing roadways.

“Using computer modelling for a structure like an overpass, for instance, is much more effective,” explains Syvenky. “Engineers can test ideas and you can instantly see the impacts, including the cost impacts, of changes.”

water-saving pavementBuilt using porous asphalt or pervious concrete, water-saving

paved surfaces allow stormwater to drain through the surface into a catchment area below. The products work well in park-ing lots, allowing owners to collect run-off and store it for uses such as on-site irrigation.

“It’s very expensive for municipal-ities to treat water, and irrigation may not be a very good use of clean water,” Bird says. “Porous asphalt also helps fil-ter sediment out of runoff water, which is another benefit for municipalities.”

Alberta Construction Magazine | 37

infrastructure

Where do I find a

PPPrrrooofffeeessssssiiiooonnnaaalll EEEllleeeccctttrrriiicccaaalll CCCooonnntttrrraaaccctttooorrr???

Since 1993 the ECAA received professional status under the Professional and Occupational Associations Registration Act as Professional Electrical Contractors (PEC), making them the first trade Association in North America to grant professional status to electrical contractors.

Professional Electrical Contractors, PECs are

Educated in all Aspects of Business • Project Management • Estimating • Accounting • Safety Principles • Legal Issues Affecting Contracting • Business & Public Relations

PECs are accountable for their work and

business practices and strive for excellence in the Electrical Industry.

For more information on PECs Call the

Electrical Contractors Association of Alberta

Ph. 780 451-2412 Toll Free 1-800-252-9375 Email: [email protected] Web: www.ecaa.ab.ca

Canada, the Red Hill Valley Parkway in Hamilton, Ont., constructed in 2007. The bottom layer is a rich bottom mix, a specially designed mix packed with asphalt cement that is basically inde-structible and therefore highly resist-ant to cracking.

The middle and top layers are made of high-quality Superpave asphalt mixes that resist rutting, cracking and wear.

“On the day the construction is com-pleted, the pavement will start to deteri-orate. That’s normal,” Uzarowski says. “But if it’s a perpetual pavement, noth-ing will happen at the bottom and the majority of the pavement remains sound. Deterioration will occur at the top, but it’s easy to fix.”

Repair work only has to be done every 20 years or so and, because it only involves milling and replacing the sur-face, it can be done overnight.

While they’re too expensive for low-traffic-volume roads, perpetual pavements are predicted to become increasingly popular for major roadways.

full-depth reclamationRepairing roads has tradition-ally involved removing the old

asphalt pavement and hauling it off-site for disposal. Full-depth reclamation is a repairing technique in which the old asphalt is mixed with the underlying gravel and the resulting asphalt/gravel combination is used to form a new road base.

Mixing the asphalt into the gravel has been proven to produce a better-quality base material, saves the cost and environ-mental implications of removing the old asphalt from the site, and reduces the amount of new aggregate used.

CollaborationIt’s not a product or a road- building technique, but it is

affecting the quality of roads.“Industry partners—the road builder

group, transportation people from all lev-els government, consulting engineers—are sharing information and best practices, and taking a much more col-laborative approach in creating a solu-tion,” Syvenky says. The result going forward is going to be better products and even more innovation.

38 | Summer 2012

infrastructure

QUALITY EQUIPMENT. READY FOR RENT.Hertz Equipment Rental has a complete line of equipment and services to help you at any job site. Our knowledgeable staff will assist in evaluating what the need is at hand and help you get the right equipment to get the job done. Whether it is a construction site or at an industrial plant, our network of 20 locations throughout the Alberta region are dedicated to help with the tools & equipment you need.

√ Short or Long-Term Rentals √ Customized Rental Programs √ Wide Selection of Equipment

√ National Network of Locations √ Equipment Delivery & Pick-up Available √ 24/7 Service

® U.S Pat Off. © 2011 Hertz System, Inc. All rights reserved. All other trademarks are the property of their respective owners.*Warranty is available at participating locations only. Limitations apply.

1-888-777-2700 | hertzequip.comREADY TO HELP. Rental. Sales. Service.

Vancouver: P: 604.214.9453 F: 604.214.9455TF: 1.877.252.0070

Calgary: P: 403.252.0070 F: 403.259.3992TF: 1.877.252.0070

Edmonton: P: 780.486.2111 F: 780.486.2155TF: 1.877.252.0070

Everything you need!www.spatialtechnologies.ca

We have a straight line to all your survey needs!

Our aim is to be your first choice supplier of quality measurement solutions and service

to the Geomatics community.

From the sales, service and repair of Leica surveying equipment, through training and

exemplary customer support.

From prisms to paint, and field books to flagging tape, we offer a one-stop shop for all your surveying needs.

Includes: complete GNSS base and rover, UHF radios, data collector,tripod, pole, post-processing software, Navcom Survey Cad software

and a 3 year warranty.$24,950 CDN

Introductory Price

Price good until September 30, 2012.

Offering all of the elements of a traditional UHFRTK-based solution with the added benefits of the

included lifetime StarFire™ license. Includes RTK Extend™, Ultra RTK (GPS + Glonass & Galileo ready)

and GSM 3G Network support.

Introducing the new NAVCOM LAND-PAK.

By Godfrey Budd

biM PlAyS An iMPOrtAnt rOlE in lEgiSlAturE dOME rEnOVAtiOn

A $6.1-million renovation project for the Alberta Legislature dome

is expected to take about one year and is slated for a late-2013 completion. Construction should start at the site this fall, shortly after celebrations marking the 100th anniversary of the official opening of the building in September 1912.

Elements of the dome are approach-ing the end of their shelf life, hence the renovations.

“The existing terracotta on both the major dome and the minor dome above the Legislature chamber has deteriorated,” says Lyle Butchart, an area manager for property at Alberta Infrastructure. “The project will include replacing the terra-cotta on the cupola as well as the terracotta on the main dome.”

The deterioration of the terracotta, however, is not yet severe, but the issue of potential water penetration was a major spur to do the work now, says Butchart, who notes that the terracotta has no water-proof membrane. There is only concrete book tile beneath it.

Restoring these elements of the 54-metre-high dome is going to rely heav-ily on some of the latest 3-D modelling software and methods from the Building Information Modelling (BIM) tool box. “We didn’t have an adequate set of draw-ings with enough detail, so BIM is going to have a role in filling in gaps for the design process,” Butchart says.

Planning and design began with con-sultation and determining what the dome required for restoration and improved waterproofing, with Edmonton-based Building Science Engineering Ltd. (BSE) contracted to run the project.

“BSE designs the anchorage and some other components and sets up the cri-teria for them,” notes Chris Makepeace, a principal at BSE.

HIP Architects, in turn, did much of the modelling and other design work on the project. The use of 3-D BIM not only saved both time and money in the design process, but also played a crucial role in analyzing the existing curved terracotta and tile sur-faces, and developing a design that would replicate these elements.

PRESERVING

TECHNOLOGY

Alberta Construction Magazine | 41

infrastructure | Bim

need for precisionAllan Partridge, a former principal with HIP who is now with Group2 Architecture Engineering Ltd., did much of the design work for the project. He says, “One of the hardest things is to do a 3-D model of curving surfaces. Having [the dome] scanned and developing a BIM was the best way to access how to represent work that needed to be done. This would take into account not only the surface in three dimensions, but also the deformations from age—and the original imperfections that may have been built in. So, with BIM, we can develop an exact profile of what’s there and therefore what needs to be done within plus or minus a quarter of an inch. And precision was essential to the dome project.”

The structural elements and build-ing components required detail analysis and modelling from outside to inside.

Some of the area on the inside of the dome was also scanned to pro-vide a series of control points.

“Once we had enough data to derive control points, we used those control points to measure the rest of the interior using a hand-held laser. This gives you a virtual replica of the interior structure,” Partridge says.

Advances in laser scanning technology help the process, as earlier laser-scanning technology was relatively limited, he says.

Without today’s laser technology and BIM, the process of developing a model and design based on the original may have had to resort to “stereo-photogrammetry,” a process of determining the geometric properties of objects from photographic images. In this case, Partridge says, “Someone with a special camera would have to be up there on a crane.”

Older systems of measurements and analysis could take weeks. Instead, BIM, assisted by modern laser scanning, enabled this measurement and analysis to be done in a matter of days.

Most restorations projects today can expect to include the application of some scanning technology. A pro-ject in Calgary recently used the same technologies, Partridge notes. He says the scanning, combined with BIM, pro-vided a very comprehensive record of both older and more recently installed building components.

The rendering above is derived from a process using scanning technology that provides precise

and detailed information about a section of the

dome structure. The two arching forms on the

left are images of the exterior and interior