Airex Composite Structures (ACS) a member of 3A · PDF filePLEASE CONSIDER: ALL INFORMATION...

Transcript of Airex Composite Structures (ACS) a member of 3A · PDF filePLEASE CONSIDER: ALL INFORMATION...

PLEASE CONSIDER: ALL INFORMATION SHARED IN THIS PRESENTATION IS INTELLECTUAL PROPERTY OF AIREX COMPOSITE STRUCTURES

Modular light weight structures - Potential off composite structures in

commercial vehicles and their production.

Bart Radema Key account manager bus Europe

A leading supplier of lightweight

systems for road and rail

Airex Composite Structures (ACS) a member of 3A Composites

3A Composites History –

More than 50 Years of Experience

© 3A Composites Holding AG

10.10.2014 2

One Group – Two Leading Divisions

3 © 3A Composites Holding AG

10.10.2014

Revenues: 100 MCHF Employees: 230

SSM Textile Machinery

3A Composites Revenues: 600-800 MCHF / Employees: 2'200 (of which 700 in Ecuador)

3A Composites - Global Footprint

5 © 3A Composites Holding AG

10.10.2014

Assets in North America

• 4 sites

• 338 Employees

High Point, NC Glasgow & Benton, KY Statesville, NC

Assets in South America

• 3 sites

• Headquarters in Guayaquil

• Sales office

• 111 plantations; 8’651 ha in Ecuador (thereof 5532 ha Balsa plantations)

• 696 Employees

Manta Guayaquil

Quevedo

Assets in Asia

• 5 Sites

• Headquarters in Singapore

• Sales office

• 358 Employees

Changzhou Shanghai

Singapore

Xiamen

Assets In Europe

• Headquarters in Cham, CH

• 6 Sites

• 806 Employees

Osnabrück, GER Singen, GER

Sins, Altenrhein, Neuhausen, CH

Loch Gowna, IE

Sao Paulo

Cuiabá

Dubai

Mumbai/Khopoli

Airex Composite Structures (ACS)

ACS is located at Altenrhein, CH

Competence Center for Engineering,

Tooling, Processes & Sales

Production co-operations in Eastern

Europe and China

© 3A Composites Holding AG

10.10.2014 6

04/19/2012

ACS – Key Technologies Airex Vacuum Bonding

Technology (AVT)

Vacuum Assisted Resin

Infusion (VAC)

Resin Transfer Molding

(RTM)

Application Area

Bus

Rail

Raw Materials

Aluminium, Steel, GFR skins

PVC, PS, PMI, and PEI foam cores as well

as Balsa cores

Integrated aluminium extrusions

Advantages

Low weight sandwich structures with high

stiffness, ready for pre-assembling

High potential for the integration of functions

High dimensional accuracy

Low tooling investment required

Application Area

Primarily Rail

Protected Mobility/ Defence

Raw Materials

Glass fiber mats

Filled UP resins

PVC, and PMI foam cores as well as Balsa

cores

Advantages

High dimensional accuracy

Consistent product quality

Function integration

Closed process, low emission (EHS)

Application Area

Automotive

Low noise fan blades

Raw Materials

Glass-, Carbon-fibers

EP, VE, UP-resins

PUR, PVC, and PMI-foam cores as well as

Balsa cores

Advantages

ACS is technology leader

Consistent product quality

Class A surface quality

Short-time from design to first part

Best for complex shapes w/ hollow parts

© 3A Composites Holding AG

10.10.2014 7

INNOCAB®

9 © 3A Composites Holding AG

10.10.2014

Free formed surfaces

Structural

Large size components

Impact resistant up to 600 km/h

Mechanical interfaces integrated

Painted and fully equipped on demand

Proven “cold” repair concepts

System competency

CAD - Design

& Engineering

Manufacturing

Assembly & Painting From design to

finished systems

Tooling FEA / Real Tests Together with external partners

© 3A Composites Holding AG

10.10.2014 10

COMFLOOR®

80% assembly time reduction

750 kg weight reduction per rail car

300 mm more internal width

30 years product lifetime

Integrated heating system

Maintenance free

© 3A Composites Holding AG

10.10.2014 11

ACS – Heated structural floor concept

conventional Heated floors

Limited leg space

Local hot / and cold area

T

1 T

2

Practically zero heat differences

Low weight + space requirements

High customer comfort

© 3A Composites Holding AG

10.10.2014 12

XBODY®

© 3A Composites Holding AG

10.10.2014 13

Structural, lightweight, stiff systems

Mechanical interfaces integrated

Maximum size 18m x 2.8m

Modular construction kit

Painted and fully equipped on demand

Supports excellent crash behavior

Proven “cold” repair concepts

ACS – current bus development projects

14 © 3A Composites Holding AG

10.10.2014

Components

Structural 2D Parts

Structural 3D Parts

Sandwich

interdeck with

seat fixations

Composite bus parts OEM’s ACS develops

Systems

Subassemblies

Mechanical integration

Electrical integration

Painting

etc.

Sub-System Suppl.

Composite-Sidewalls

Flooring systems

Sandwich roofs

Middle-

chassis

Engine tower

10/10/2014

ACS – Selected references – Monorail

© 3A Composites Holding AG

10.10.2014 15

The Modular Sandwich Roof

© 3A Composites Holding AG

10.10.2014 19

20 © 3A Composites Holding AG

10.10.2014

Reference-dimensions:

Length: L = 9.8- 13.3 m

Width: B = 2,2 bis 2.4 m

t1 a1

a2

b

t2

Cross-beam: 25 mm x 50 mm x 1,2 mm (a1 x a2 x t2)

Solebar: 50 mm x 50 mm x 2,0 mm (a1 x a2 x t2)

Cover sheet: Steel (0,6 mm); GRP (2,0 mm) (t1)

Adhesive thickness: 3 - 5 mm (tough-elastic adhesive)

b

Foam core: 35 – 50 mm (a)

Cover sheet: Aluminium 0,6 - 0,8 mm (t1)

GRP 2,0 mm (t1)

Adhesive thickness : 0,2 mm (structural adhesive)

t1 a

Dimensions

Dimensions for a representative

City- and Coachbusroof L

B

Modular Sandwich Roof Traditional Bus Roof

Airex Composite Structures Sandwichtechnology for Bus solutions

A Proven Concept

21 © 3A Composites Holding AG

10.10.2014

Funktion

Komfort

Sonstiges

Anforderungen Sandwich

Anforderungen Busdach

Kosten

Werkstoff Konstruktion Produktion

Temsa Avenue

Nabi Metro 45C

• Dach und Boden

• Deckschicht: GFK

Quellen: VDL, Nabi, Alcan, Temsa, ATZ

VDL Citea

VDL AmbassadorVDL Bova Magiq

OPTARE/ EAST LANCS

VDL Phileas

Merceds-Benz Cito

• Dach und Boden

• Deckschicht: GFK

• Dach und Boden

• Deckschicht: Aluminium

• Dach und Boden

• Deckschicht: GFK

• Dach und Boden

• Deckschicht: Aluminium

• Dach

• Deckschicht: Aluminium

• Zwischenboden

• Deckschicht: Aluminium

• Dach und Boden

• Deckschicht: GFK

Requirements Roof

Functions

Comfort

Costs

Others

Material Construction Production

Requirements Sandwich

Roof

Aluminium cover sheets

Roof & Floor

Aluminium cover sheets

Roof & Floor

GRP cover sheets

Roof & Floor

GRP cover sheets

Roof & Floor

GRP cover sheets

Roof & Floor

GRP cover sheets

Interdeck

Aluminium cover sheets

Roof & Floor

Aluminium cover sheets

23 © 3A Composites Holding AG

10.10.2014

• Aluminium and GRP

Density

E-Modul

Long. strength

Thermoconductivity

Aluminium

2,6 - 2,8

70.000

300

80-220

GFK

1,6

17.600

267

0,1-0,2

g/cm³

MPa

MPa

W/mK

Mechanical properties

Cover sheets

Cantrails

• Execution of cantrail as extruded aluminium-

profile

• Cantrail could be connected to Steel- or

Aluminium structures of busses. It‘s possible

about a bolted or glued connection.

cantrail sandwich

adhesive

Connection to the cantrail

connection profile

skeleton

Connection to the bus structure

adhesive

sandwich

cantrail

Airex Composite Structures Sandwichtechnology for Bus solutions

Sandwich properties

24 © 3A Composites Holding AG

10.10.2014

• XPS- and PU-foams

• Absorption of dynamic loads

• Low Thermoconductivity

• High temperature resistance

• Use of XPS-foams in case of higher

mechanical requirements, higher durability,

is a future trend

• Use of PU, higher temperature resistance,

lower mechanical properties, embrittling

possible

Mechanical properties

Foam density

E-Modul

Tensile strength

Modulus of shear

Thermoconductivity

Compressive strength

Shearing resistance

PU

50

10.000

430

4.000

0,024

400

240

XPS

45

25.000

1.000

14.000

0,025

700

500

kg/m³

kPa

kPa

kPa

W/mK

kPa

kPa

Core materials

Airex Composite Structures Sandwichtechnology for Bus solutions

Sandwich properties

25 © 3A Composites Holding AG

10.10.2014

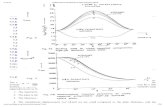

0%

50%

100%

150%

200%

250%

Stahl AL 08 - XPS 40 AL 08 - XPS 50 AL 06 - XPS 40 AL 06 - XPS 50 GF 2 - XPS 40 GF 2 - XPS 50

Steifigkeit Gewicht

-53%

+45%

+125%

-49%

+8%

-61%

+68%

-57%

-7%

-37%

+44%

-34%

Stiffness- and weight comparision

Airex Composite Structures Sandwichtechnology for Bus solutions

Steel

Stiffness Weight

Airex Composite Structures Sandwichtechnology for Bus solutions

26 © 3A Composites Holding AG

10.10.2014

Requirements/ Funcitions Connections Aluminium/ framing

Mechanical properties

Long. strength

Long.- shear strength

Ultimate elongation

Max. temperature

1K-PU

1

2

400

80

2K-PU

5 - 10

5 - 8

25 - 350

120

MPa

MPa

%

°C

1K-PU (SMP)

3,5

3

200

120

adhesive

glued Cone connection

Steel sidewall Skeleton with steel connection-profile

Aluminium cantrail for High loads

Aluminium

Sandwich roof

connection

ACS glued cone connection

Airex Composite Structures Sandwichtechnology for Bus solutions

27 © 3A Composites Holding AG

10.10.2014

FE Analysis with glued cone connection in the complete vehicle model

Tensions in

Sandwich cover sheets and

cantrail

Distensions

in cone connection

12 m complete citybus

model with high load gas

tanks an airconditioner

Improved Stiffness

Compared to the steel roof, the sandwich roof is stiffer under longitudinal,

vertical and torsional loading (5% to 22% smaller displacements),

28 © 3A Composites Holding AG

10.10.2014

Compared to the a welded joint bounded joint is 50 % stronger

Bending Test (push/pull testing) of sandwich roof element with

integrated cant-rail and welded steel side-wall underbody structure

joined by bonded V-notch joining

Sandwich

Airex Composite Structures Sandwichtechnology for Bus solutions

29 © 3A Composites Holding AG

10.10.2014

Doubledecker series development E400 for Alexander Dennis SOP 2014

FE calculation:

3 g vertical hit

incl. passanger loads and seats Tension distribution

Displacement

30 © 3A Composites Holding AG

10.10.2014

• ECE-R66 rollover requirements today will fulfilled

with the amount of potential of the sandwichstructure

• Survival space remains preserved

• Fulfillment of requirements will tested in

FE- Simulations and attempts

Survival-

space

Sources: Temsa

Verification of the structure – rollover test

Verification of the cantrail connection

• Bending charge of the

sandwichpanels against

connection profile

• Failure of component

at the steel connection

on the termation bar

(section window pillar)

• Sufficent strenghtness of

sandwich panels

Airex Composite Structures Sandwichtechnology for Bus solutions

Crash & Roll Over

31 © 3A Composites Holding AG

10.10.2014

Airex Composite Structures Sandwichtechnology for Bus solutions

32 © 3A Composites Holding AG

10.10.2014

33 © 3A Composites Holding AG

10.10.2014

Various advantages through the modular assemblage of the roof

• Ergonomical assemblage (no overhead assembling)

• Optimized work flow

• Reduced floor space in BiW

• Lower warehousing costs

• Simplier handling in the factory

• Pooling of all glue processes to one sector

(Front- and Side windows)

• Summarized and optimized quality inspection

• Reduction of the assembly time (concept 1)

in BiW and assembling (- 50 %)

Airex Composite Structures Sandwichtechnology for Bus solutions

0

500

1000

1500

2000

2500

3000

3500

Rohbaufertigung Montage Summe

Fert

igu

ngs

zeit

[min

]

- 73 %

- 39 %

- 50 %

34 © 3A Composites Holding AG

10.10.2014

0

100

200

300

400

500

600

700

800

Gewichtsanteile Gewichtsanteile

Sonstiges

Beplankung

Stahlgerippe

- 160 kg

0

100

200

300

400

500

600

700

800

Gewichtsanteile

Sonstiges

Anschlussprofile

Sandwichprofil

Roof module weighs ca. 700 - 750 kg* (6 % amount of total weight)

Weight reduction through sandwichroof ca. 160 kg (= 20%)

Weight saving variies and depending on the execution of the sandwich technology

For example omission of interior cladding (24 kg), optimization of the

aluminiumprofile (ca. 30 kg), design of cut-outs, integration of HLK-channels etc.

* Declaration for a full assembled and isolated roof

Weight balance

Airex Composite Structures Sandwichtechnology for Bus solutions

35 © 3A Composites Holding AG

10.10.2014

** labor costs are based on a westeurope production

Manufacturing costs

0

2000

4000

6000

8000

10000

12000

Materialkosten Arbeitskosten Gesamt

Fert

igu

ngs

kost

en [€

]

Stahl

Sandwich

+ 7 %

- 50 %

- 10 %

• Higher material costs of the roof framing (purchased part versus raw steel)

• Saving of material costs in the buildout throught component integration

• Significant reduction of manufacturing costs through lower personel expenses** (50 %)

• Savings of manufacturing costs (10 %)

0

2000

4000

6000

8000

10000

12000

Stahl Sandwich Stahl Sandwich Stahl Sandwich

Rohbau Montage Summe

Fert

igu

ngs

kost

en B

usd

ach

[€]

Arbeitskosten Materialkosten

- 10 %

- 21 %

+ 24 %

Manufacturing costs bus roof Manufacturing costs bus roof

Airex Composite Structures Sandwichtechnology for Bus solutions

Higher flexibility and reduction of variants

36 © 3A Composites Holding AG

10.10.2014

Escape hatch

Air conditioning

Left/ Right drivervariants

Art of propulsion technology

Variants induced through:

Vehicle length

Quantity of doors and bus specific

positions

Engineconcept/ doors

Airex Composite Structures Sandwichtechnology for Bus solutions

37 © 3A Composites Holding AG

10.10.2014

As example the brand new Alexander Dennis Enviro 400 MMC

400 kg weight saving in the new model design MMC

Due to the weight savings it was possible to win up to 7 seating capacities,

as result the bus could be authorized to 86 seats

only through the composite-components it was achieved arround 80 %

of the total weight savings

Due to excellent thermic isolation of the

Composite-roof it was possible to prevent condensation

The new production method, the modular construction, allows to improve

essentially the production time, quality and consistency in production

over the different plants

at the sametime the stiffness was significantly improved

Weightsaving potential – as example

Weight reduction:

Sandwich-roof primary:

160 – 250 kg

Sandwich-roof, floor and optimised chassis:

1.000-1.250 kg

Total including „down-sized“ engine:

2.000 kg

No structural reinforcements in the sandwich roof

are necessary, indipendent for the drive concepts.

40 % weight reduction in comparision to the

convetional solution

Lower overall weight results with significant fuel

savings up to 16%.

38 © 3A Composites Holding AG

10.10.2014

VDL Citea:

overall weight reduction of

2000 kg results in a only 12

tons weighty bus

Repair methods

Proved and authorized repair methods

ACS After-Sales provides on request a

qualified repair team

Repairing of small damages could be done

locally (provider or ACS)

Repairing of structural damages could be

executed from service centers or qualified

staffs (MAN or ACS)

© 3A Composites Holding AG

24.02.2013 39

Proved repair methods

Airex Composite Structures Sandwichtechnology for Bus solutions

Bus product development Airex Composite Structures

• Sandwichpanels fulfill all the requirements for a bus roof

• Stiffness, strength

• Durability

• Repair

• Comfort

• Advantages:

• Weightsavings in the roof section

• Reduced manufacturing costs

• Higher manufacturing flexibility, lower diversity of variants

• Lower vulnerability in operation

• Alternative provisions for lightweight construction are less effective and associated with

higher costs, but realisable without impact on the existing prodution.

Thank you for your attention

ACS Mission

We offer customers high value mobility and industrial composite solutions for a

sustainable future

41 © 3A Composites Holding AG

10.10.2014

Airex Composite Structures

Airex AG

Park Altenrhein

CH-9423 Altenrhein, Switzerland

Phone +41 71 858 48 48

Fax +41 71 858 48 58

www.airexcompositestructures.com

CHINA

www.airexcompositestructures.com