Aiche 2011 Flow Reactor

description

Transcript of Aiche 2011 Flow Reactor

Bubbling Reactor Technology for Rapid Synthesis of Uniform, Small MFI-Type Zeolite Crystals

1

Wei Liu*, Yuxiang(Tony) Rao, Haiyin Wan, Abhi Karkamkar, Jun Liu, Liquan Wang

Pacific Northwest National Laboratory

Richland, Washington, USA

Presentation at AIChE 2011 Meeting

Minneapolis, MN, USAOct 19th, 2011

Outline

Motivation

New Bubbling Reactor Concept Wide range and controllable Si/Al ratio and crystal size with high throughput Uniform ZSM-5 crystal particle size distribution Short reaction time

MFI- Type Zeolite Preparation and Characterization Synthesis condition (growth solution, reaction temperature, pressure) SEM/EDS, XRD, TEM, N2 adsorption/desorption, NMR

Applications CO2 capture adsorbents HMF adsorption from ionic liquid mixtures

Concluding Remarks

2

Motivation and BackgroundMFI-type zeolite (such as ZSM-5, silicalite-1, catalysts and adsorbents for refining and petrochemical industries)

3

ZSM-5 , Framework type (MFI)Particles, 40~80meshPore size:5.4~5.6 angstroms• Shape-selective catalyst/support

material • Adsorbent (H2O and CO2)• Ion Exchanger

Pros•Porous solids with large adsorption capacity •Chemical and structural stability over a large

number of adsorption–desorption cycles.•High stability at harsh conditions (high

temperature, pH)•Shape-selective attribute•Low cost

Cons•Hard to make Nano and uniform zeolite crystals

(agglomerate of ZSM-5 crystals with a wide

range of particle sizes)•Expensive to make (Template, such as porous

carbons, Combustion)•Hard to get high Si/Al ratio zeolite•Long reaction time ( a few days)

Objective

4

Developing new reactor concept for producing MFI-type nano-zeolite crystals with the following properties: Wide range and controllable Si/Al ratio and crystal size with high throughput Uniform ZSM-5 crystal particle size distributionShort reaction time ( a few hours)

Proposed zeolite crystals growth process: Homogenous parent growth solutionUniform mass and heat transfer during the zeolite growth (temperature and precursor concentration)

Mass transport model during zeolite crystal growth

3/2,, CmTC

nSiCSi

Si mCCkdt

dm

3/2, ClAlCAl

Al mCkdt

dm

msi: mass growth rate of Si mAl: mass growth rate of AlCc, Si: concentration of the Si precursor Cc, T: concentration of template molecularmc: mass of a growing crystal

Proposed Zeolite Synthesis Routes

5

Homogenous parent solution

Formation of uniform nucleus

Growth of individual nuclei

Stable suspension of small crystals

Homogenous parent solution

Formation of uniform nucleus

Coalescence & growth

Agglomerates of different crystal sizes

(a) Desired zeolite growth pathway

(b) Un-desired zeolite growth pathway

Scheme 1 Proposed zeolite synthesis routes (a) desired and b) undesired zeolite growth pathway

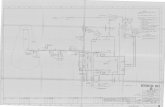

Novel Bubbling Reactor Technology

6

Hot plate with stirring and

temperature control functions

G/L separator

Condenser

SS beaker

Back pressure regulator

N2 Gas MFC

P

Liquid knock-

out drum

Pressure relief valve

Check valveMass flow controller

P

SS reactor

Cooling gas

Liquid pump

Silicone oil

Growth soln

Gas bubble

Zeolite crystal

Scheme 2. Laboratory multiphase reactor system used for zeolite growth

Uniform heat and mass transfer

Controllable flow rate

Intense nuclei collision

Homogenous growth solutionexample: molar ratioSi/Al/TPAOH/NaOH/H2O=1/0.1/0.36/0.008/23.2

Growth conditions:Temperature: 120ºC, 140ºC,160ºCPressure: 130psiTime: 1hr, 2hrs, 4hrs

Ind. Eng. Chem. Res. 2011, 50, 7241–7250

Experimental Matrix

7

Impact of growth conditions on Si/Al ratio in ZSM-5 product

a. Reactor pressure was maintained at 130psi.b. Si/H2O molar ration was kept constant.c. SEM/EDS analysis

a. Group I, the Si/Al ratio in the final product always lower than in starting solution. (due to incomplete Al incorporation replacement)

b. Group I & II, longer reaction time will slightly improve the Al replacement

c. Group III, increasing the temperature will also help but will increase the crystal size. (SEM Photo)

d. Group IV, increasing the N2 flow rate significantly prevented the Al atoms from incorporating into Si matrix.

Sample# N2, sccm Temp, oC Time, h Starting solution b Final product c

1 25 140 2 50 722 25 140 2 25 303 25 140 2 13 9*

4 25 140 6 25 285 25 140 6 13 12

8 25 120 2 25 482 25 140 2 25 309 25 160 2 25 23

2 25 140 2 25 306 50 140 2 25 327 100 140 2 25 86

Zeolites Characterization(SEM/EDS)

8

Figure 1 Morphology of zeolite crystals prepared in this work (*growth conditions same as sample #2 &3 but without Al precursor in the growth solution)

(a)Sample#2 (Si/Al=30) (b)Sample#6 (Si/Al=32) (c)Sample#7 (Si/Al=86)

(d)Sample#8 (Si/Al=48) (e)Sample#3 (Si/Al=9) (f) Silicalite* (Si/Al=infinity)

Zeolites Characterization(TEM)

9(b) ZSM-5 growth solution(Si/Al=13) after heated at 140oC for 1.0 h

(a) ZSM-5 growth solution(Si/Al=13) after heated at 140oC for 0.5 h

Figure 2 TEM analysis of particle evolution with growth time (Run condition #3)

Zeolite crystal growth rate: ~100nm/hour

Literature report*:1.8~3.8nm/hour

* Schoeman, B. J.; Sterte, J.; Otterstedt, J. E. “Analysis of the Crystal-Growth Mechanism of TPA-Silicalite-1”. Zeolites 1994, 14, 568.

Zeolites Characterization(TEM)

10

Figure 3 Small ZSM-5 crystals of different Si/Al ratio synthesized at 140oC for 2 h.

(a) ZSM-5 crystals of Si/Al=72 (sample#1) (b) ZSM-5 crystals of Si/Al=30 (sample#2)

(c) ZSM-5 crystals of Si/Al=9 (sample#3)

Zeolites Characterization(BET)

11

Table 2. Surface area of small-crystal ZSM-5 powder prepared with different growth times (Si/Al ratio of 13 in the parent growth solution, 140oC,

25sccm N2 flow)

Growth time, h

Langmuir surface area m2/g

Multipoint BET surface area m2/g

Micro-pore surface areaa m2/g

(T-method)

Meso-pore surface areaa m2/g

Estimated particle size nm (Dp)

1 495 352 194 158 202 NM 433 266 168 194 519 391 251 141 22

a. Surface area calculated with t method from N2 desorption isotherm.

Observation: a. zeolite pores (micro-pore)b. Void space inside zeolite crystal (meso-pore)c. meso-pore disappeared with increasing reaction time

ZPp SAd

6SAP = external surface area of a particle

z = density of ZSM-5 framework, 1.93 g/cc.

Dp = particle size for a sphere, cube or tablet

Cause of meso-porosity: a. TPAOH or gas bubble trapped inside the crystalb. Si precursors (TEOS) incorporated into particles

Figure 4 Pore size distribution of small crystal ZSM-5 powder prepared with different growth

times.

Zeolites Characterization(XRD)

12

Figure 5 XRD pattern of in-house zeolite (Si/Al=72) fitted with standard HZSM-5

High purity zeolite crystal was obtained!!!

Zeolites Characterization(NMR, 27Al)

13

Figure 6 27Al solid state MAS NMR spectra of nano ZSM-5 prepared in this work in comparison to two commercial ZSM-5 samples (Peaks with * is from the spinning side bands).

#1 (Si/Al=72)

#2 (Si/Al=25)

#3 (Si/Al=9)

CBV2314 (Si/Al=15)

CBV8014 (Si/Al=46)

* *

*

*

*

*

55ppmAl(OSi)4 unit, tetrahedral-coordinated framework Al with four Al-O-Si bonds

Zero ppmAl(OSi)6 unit, octahedral coordinated framework Al with six Al-O-Si bonds

Al atoms are fully incorporated into the zeolite lattice framework without any defectsHigh purity zeolite crystals were obtained!!!

Zeolites Characterization(NMR, 1H)

14

Figure 7 Solid State 1H NMR spectra taken at room temperature for samples as received

Line-widths for three in-house zeolites are much narrower than two commercial ones

The commercial samples have higher chemical shifts

Al atoms are fully incorporated into the zeolite lattice framework without any defects

In-house zeolite crystals have more uniform local chemical environments for proton species

Zeolites Characterization(NMR, 1H)

15

Figure 8 Solid State 1H MAS NMR of in-house ZSM-5 samples taken at different temperatures. (a) at 25oC as received, (b) at 250oC after heating up to 250oC for 10min, (c) at 25oC after cooling down from 250oC.

Zeolites Characterization(NMR, 1H)

16

Figure 9 Solid State 1H MAS NMR of two commercial ZSM-5 samples taken at different temperatures. (a) at 25oC as received, (b) at 250oC after heating up to 250oC for 10min, (c) at 25oC after cooling down from 250oC.

The chemical environment of protons in in-house zeolites are more prone to change (high proton mobility) when heated to moderate temperature (250C, slightly shifted toward lower ppm number ) than two commercial ones (no change)

This change is fully reversible

Applications #1(bubbling reactor)CO2 capture adsorbents

17Scheme 2. Experimental set-ups for CO2 gas adsorption

As-synthesized small crystal zeolites powder (~300nm, silicalite-1 or ZSM-5 with different Si/Al ratio)

Hydrophobic modification of zeolites(13X beads, ZSM-5 particles) through surface membrane coating technology

Applications #1(bubbling reactor)CO2 capture adsorbents

18Scheme 3 Silicalite crystal layer growth on the surface of 13X beads/ZSM-5 particles

Figure 11. SEM images of 13X beads after silicalite coating.(cross section view)

Figure 10. Adsorption curves for 13X beads under wet CO2 gas stream, a) unmodified, b) silicalite coated)

Applications #2 (bubbling reactor)HMF adsorption from ionic liquid mixtures

19

Preparation and Testing of Adsorbents for the Separation of Ionic Liquids From HMF

Wednesday, October 19, 2011: 1:45 PM208 D (Minneapolis Convention Center)Yuxiang Rao1, Alan Cooper2, Heather Brown2 and Wei Liu3, (1)Energy and Environment Directorate, Pacific Northwest National Laboratory, Richland, WA, (2)Pacific Northwest National Lab, Richland, WA, (3)Pacific Northwest National Laboratory, Richland, WA

HMF is an important chemical product since it has the potential to be used as a feedstock to replace petroleum-derived aromatics for production of a range of specialty chemicals and plastics. In this work, we will demonstrate an economically-viable, ionic liquid catalytic process for conversion of biomass-derived raw sugar to 5-hydroxymethylfurfural(HMF). The experimental work includes preparation of adsorbents materials by membrane coating, catalytic reactions in ionic liquid fluids and separation of reacted products by extraction and adsorption, which includes (i) catalytic reaction tests in both a batch and flow reactor system to develop systematic understandings to critical process operation parameters and establish material balances, and (ii) screening of adsorbents and identification of an effective adsorption process for separation of HMF product from reaction mixtures and for complete recovery of the catalyst and ionic liquid.The adsorbent materials tested for this project were characterized by XRD, SEM/EDS and Nitrogen adsorption/desorption technology.

Acknowledgment

PNNL-LDRD-Nano ZSM5 Program (Lab Directed Res & Dev.)

Environmental Molecular Science Laboratory, PNNL

Colleagues

Nathan Canfield

Xiaohong Shari Li

Jarrod Crum

20

Thank you!

21