Agripower presentation: An overview - Townsville Industry ... · Towers, north Queensland in...

-

Upload

doankhuong -

Category

Documents

-

view

222 -

download

0

Transcript of Agripower presentation: An overview - Townsville Industry ... · Towers, north Queensland in...

Agripower Introduction

Agripower Australia Limited is an Australian Public Company

Agripower owns the world’s largest deposit of amorphous

silica, near the town of Greenvale in north Queensland

This led to establishing various testing and trials of the

amorphous silica applications and development of products

Agripower built a pilot processing plant site at Charters

Towers, north Queensland in 2015/2016

Agripower have established an international marketing

network for sales and distribution

Agripower is at the forefront of an expanding supply chain

and expanding its operations and with it, future development

opportunities in north Queensland

Agripower History

2011 - 2016

Trials and

registration of

products,securing

markets overseas

and in Australia

1999-2008

Research and

studies on

Amorphous Silica

2008

Incorporated as

Agripower

Australia Limited

2003/09

Secured a 2 billion

tonnes deposit of

amorphous silica

located in north

Queensland

2013 / 2016

Site establishment

and design of

Processing Facilities

at Charters Towers

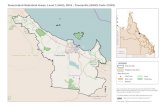

Mine site approximately 300kms

by road NE of Charters Towers

Mined product trucked to Charters

Towers processing plant

Mined product is stockpiled at

Charters Towers and processed to

produce a number of Silicon

based fertiliser products

Mine Site and Plant Site Locations

Cairns

Townsville

1

2

1. Mine Site

2. Charters Towers Processing Site

Agripower’s Amorphous Silica

Sydney

Cairns

Brisbane

Amorphous silica resource

▪ World’s largest holding of Amorphous Silica, with approximately 2

billion tonnes located in north Queensland Australia, which enables

production of a range of high quality “natural” silicon fertilisers.

▪ The deposit is located near surface to a depth of 30 metres.

▪ The mined product is solar dried then transported by road to the

plant site at Charters Towers.

▪ Mined product is stockpiled at Charters Towers and processed to produce

a number of Silicon based fertiliser products.

Townsville Greenvale

Resource Outline

Resource

Resource covers an area of approximately 9,000

hectares to an average depth of approximately 25m

and contains approximately 2B cubic metres of

amorphous silica

Wyandotte

Creek

Foresters

Creek

5kms

20kms

15kms

20kms

5kms 10kms 15kms

5kms

9

Various uses of amorphous silica

Of the various uses of amorphous silica, Agripower’s target market is agriculture

Medical grade silica for the health care market

Filtration products

Cosmetics

Chemical and oil spills absorbent products

Animal Health

Fertilisers

Animal sanitary

Pesticides/Insecticides – Animals / Plants

Grain Storage

Desiccants and absobents for dampness and home care

o 26% total silicon that is readily available

o Agrisilica is composed of amorphous silica, which uniquely provides a continuous and high level of monosilicic acid (plant available silicon)

o A natural product that has been approved for use in organic agriculture

There are few sources of

silicon fertilisers that are

used in agriculture, the

most common:

o 11% total silicon

o Slags are a byproduct of steel furnace production

o Slags were the first sources of silicon to be used on crops in India, Japan, China, USA, Brazil and South Africa but in many cases they had heavy metal contaminants and the use was stopped

o Slags are not an approved input into organic agriculture

Agrisilica has high Soluble Silicon

Agrisilica

Calcium Silicate Slags

Over the years:

Agripower has been researching, developing and

in some cases initialising trials of products such

as foliar sprays and liquid fertilisers. GrainSave

grain pest and storage products, DriSorb for

chemical spills and absorbents range and

Gallus10 chicken pesticide range.

Agripower has also established an internationally

recognised brand through its trials and

developments with the international parties,

patents and trademarks are in place in most

countries worldwide.

Agripower has designed and developed its

processing operations allowing for future

expansion of production of up to 1M tpa.

GALLUS 10

Some other Milestones

Agripower Certifications

Agripower Registered its products as inputs into organic agriculture in various regions worldwide

Accredited by FIFA

(Fertiliser Industry

Federation of Australia)

Accredited Product

of Australia

Inspected by

ECOCERT SA F - 32600

Product suitable for use

in Organic Agricultur e

conforming to (CE) r egulation

n° 834/2007 and 889/2008

Listed by OMRI

(Third party reviewer of

inputs for organic use

under the U.S. National

Organic Program)

One Cert India Appr oved

as an input into

Organic Agriculture

as per NPOP

(Australian Organic)

as an input into

Organic Agricultur e

(European Union)

Distribution Partnerships

TURKEY

MALAYSIA

INDONESIA

AUSTRALIA

INDIA

BRAZIL

MOROCCO

SPAIN

CHINA

o Key to Agripower’s commercialisation strategy is the use of partnerships.

o Agripower's commercialisation and market penetration strategy is to partner with major conglomerates and

market influencers to achieve product registrations and target market specific distribution solutions. These

parties are called “Market Partners”.

Distribution Partnerships

Agripower has conducted over 300 trials

(scientific and commercial -

independently monitored work).

Over 35 different crop types aimed at

proving the benefits of Agrisilica

fertilisers.

These trial results have consistently

shown yield increases and improved

quality parameters in a wide

range of crops.

Trials have focused on the addition of

Agrisilica fertilisers to existing fertiliser

practice.

Examples of some trial results

India Trials Agreement

In 2012 Agripower entered into an Agreement with 11 Agricultural Universities from 11 States in India in a 4 year trial agreement program.

These programs have now finalised with very positive results achieved.

In the past few weeks Agripower has now obtained Fertiliser Control Order for India, which means that Agripower will be the only Silicon Fertiliser provider throughout India.

India’s demand for Fertilisers in the order of 48M tonnes per annum.

Middle East and Europe

Agripower has executed a Distribution Agreement for product trials and sales in the Middle East and Gulf Region.

In Spain Agripower has executed an Agreement with the largest fertiliser producer in Spain and Portugal and a sales and marketing team is being developed.

Brazil

Agripower has ongoing trials in Brazil and is establishing a current distribution network throughout Brazil.

Agripower’s relationship is with the largest agricultural group in Brazil.

Current Plant

Agripower commissioned the pilot

plant for Granular, Chip and Powder

production with estimated granular

production at 30,000 tonnes per

annum and 50,000 tonnes per annum

of chip product.

As the demand is growing Agripower

has entered into Funding Agreements

to expand the processing plant.

Present Project Development Plans

1. Electrical, finalising plans to supply power for the

new processing plant and beyond.

2. Queensland Rail finalising rail siding for the new

processing plant. Agripower land adjoins the main

Townsville – Mt Isa rail line. Trains, once loaded, will

then travel directly into the Port of Townsville.

3. Port of Townsville reviewing Agripower plans for

immediate future and beyond in terms of rail,

warehousing, ship loading facilities.

Future Plans - Transportation

4. When Agripower expands production beyond 500,000

tpa, transportation methods of raw, mined product, from

the mine requires re-assessing.

5. If Agripower were only to increase production to 1M tpa

then existing transportation and processing land at

Charters Towers would be suitable.

Future Plans – Development

6. Agripower has spent the last 9 months finalising the

engineering design and plans for the plant expansion

both in the immediate future and long term and also

looking at long term power supply, rail, port and

transportation of mined product to processing facilities.

This has been quite an extensive engineering

assessment as a number of technical and commercial

decisions are required, now, prior to this next

processing plant being built.

7. Final engineering will be completed by early August

2017, already all major items of plant and equipment

have been ordered with deposits paid. It is expected

that the first stage of the new processing facility will be

completed late 2018.

Future Plans - Development

8. The Chinese market for silicon fertilisers is massive. Beijing have

a silicon fertiliser institute who have determined that the market

size for silicon fertilisers in China would be in excess of 5M tpa.

9. In Russia, Agripower have received strong interest from

distributors and supermarkets setting out opportunities for

Agrisilica into the Russian market and confirmation of the desire

to move things forward into a full business marketing plan.

10. All the above supports all of the studies Agripower have been

undertaking, as part of a master plan to look at transportation, rail,

port and ultimately far larger processing facilities.

11. The present plant expansion will take production up to 500,000

tpa at a capital cost of around US$45M and will add an additional

55 jobs directly.

12. Further expansions in production capacity will not only involve

increases to plant size but also capital expenditure in relation to

rail, port storage, ship loading and transportation from the mine to

the processing facilities. As a guide once production is in the

order of 1M tpa, the capital expenditure requirements covering the

aforementioned key areas will amount to $400M and result in an

additional 250 new jobs.