AEROFAST : THERMAL/ABLATION ANALYSIS OF THE FRONT HEAT SHIELD FOR A MARTIAN AEROCAPTURE MISSION

description

Transcript of AEROFAST : THERMAL/ABLATION ANALYSIS OF THE FRONT HEAT SHIELD FOR A MARTIAN AEROCAPTURE MISSION

AEROFAST: THERMAL/ABLATION ANALYSIS OF THE FRONT HEAT SHIELD FOR A MARTIAN AEROCAPTURE MISSION

A.J. van Eekelen, G. Pinaud, J.-M. Bouilly

Modelling approach Loads and boundary conditions

Thermal response calculation

Finite element model

Problem description

Results

1D calculation

3D calculation

RTE

Ni

i

Ncv

Nvii

iiii eA 111

PKP.

ggP hmTTcH .

tTDSqTtDSTnq wewRii ,,,,, 44

1cos2

1,,0,,,, qtTDSqtTDSq ww

tTDSqtTDSqq ww ,,180,,,0,

Tss

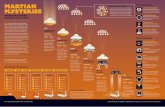

In the frame of the AEROFAST (AEROcapture for Future space tranSporTation) R&D project (FP7), we aim to increase the TRL level of a Martian Aerocapture mission.

The Aerocapture trajectory and maneuver results in significant aerodynamic heating, necessitating a Thermal Protection System (TPS). The selected shield has an Apollo like shape with a 3.6 m diameter.

The thermal and ablation behavior of a low density (phenolic impregnated) cork TPS is analyzed. The heat shield is subjected to a 3D convection and radiation load obtained for a CO2 Martian atmosphere.

Time (s)

He

at

flux(

Tw=

30

0K

):[k

W/m

2]

Alti

tud

e(k

m)

0 200 400 600 800 1000 1200 14000

50

100

150

200

250

300

350

0

20

40

60

80

100

120

Windward: S/D=0.475Leeward: S/D=0.0

Maximum cold wall heat loads historyon leeward and windward

Conclusions

S/D=0.482

S/D=0.561

Distance from outer surface: [m]

Den

sity

:[kg

/m3]

0 0.005 0.01 0.015 0.02150

200

250

300

350

400

450

S/D =0.00S/D =0.482S/D=0.561

TPS thickness: [mm]

Glu

ete

mp

era

ture

:[K

]

14 15 16 17 18 19 20400

420

440

460

480

500

Time: [s]Co

Gtr

an

svers

ald

isp

lace

men

t:[m

m]

Co

Gaxi

ald

isp

lace

men

t:[m

m]

0 200 400 600 800 1000 1200 14000

10

20

30

40

-3

-2.5

-2

-1.5

-1

-0.5

0HEAT SHIELD CoG DISPLACEMENT

Position S/D: [-]

Angula

rposi

tion

:[d

eg]

0 0.1 0.2 0.3 0.4 0.50

50

100

150

Recession: [mm]4.243.83.63.43.232.82.62.42.221.81.61.41.210.80.60.40.20

LEEWARD

WINDWARD

FR

ON

TS

HIE

LD

A 3D finite element model, including charring and ablation, has been implemented in SAMCEF. A preliminary TPS design of a phenolic impregnated cork material has been obtained, while complementary work on advanced (cork based) TPS material modeling is underway within the AEROFAST project.

CFRP

Aluminum honeycomb

CFRP

Silicon based glue

Cork based TPS

Through the thickness and 3D finite element distribution

Heat flux at t = 160. s [kw/m2]

Edge cross-section for = 180°

The elements have multiple degrees of freedom per node (T,P,,1,…,n), and the balance equations are implemented on a moving mesh (transport terms). The 3D half model consists of 58.894 elements with a total of 144.031 degrees of freedom.

Energy balance:Mass conservation: Arrhenius-type charring law:Boundary balance:Explicit ablation law:

3D transient temperature dependent (convection) heat flux, evaluated using an Euler-boundary layer computation and empirical correlation adapted to CO2 gas.

Parametric analysis to determine the TPS thickness (17 mm), for a maximum allowable structure temperature of 180 °C.