A BURDEN OR AN OPPORTUNITY - A BURDEN OR AN...¢ °±°¾°´°»°¾°³°¾, ±â€³©°»³©°²°»³©°»±â€,

aération.pdf

Transcript of aération.pdf

JU

RI

ED

AR

TI

CL

ES

mallF

lo ws

Magazine,

Spr ing/S

umm

er2007, V

olume

8,N

umber

1

27

Prior to the upgrade detailed inthis case study, the wastewatertreatment plant (WWTP) serving thecity of Corcoran, California, em-ployed a conventional aerated/facul-tative (A/F) lagoon to treat primaryeffluent. The conventional lagoonwas ineffective and the effluent oftenexceeded the discharge limits of 40mg/L for five-day biochemical oxy-gen demand (BOD5) and 45 mg/Lfor total suspended solids (TSS). In2001, the plant exceeded the aver-age monthly discharge limits fourtimes for BOD5 and nine times forTSS. Most of the violations occurredduring the summer months.

In spite of effluent reclamation onland, the California Regional WaterQuality Control Board (CRWQCB)insisted that the plant adhere to thedischarge standards. Frequent no-tices of violation (NOV) were sent bythe CRWQCB to the city of Corco-ran regarding the ineffective plant. Inresponse, the city chose to upgradethe existing A/F lagoon using a dual-power, multicellular aerated (DPMC)lagoon system to bring the plant intocompliance. The use of a DPMC la-goon as a secondary treatmentprocess is innovative. This paper de-scribes and analyzes the project andits results.

Methods and MaterialsFor this analysis, we have used

mostly the available plant data, ex-cept a small amount of additionaldata obtained by taking several grabsamples for chlorophyll a and influ-

ent BOD5 and TSS to the A/F la-goon. Data available for raw waste-water consisted of average monthlyflows, total BOD5 and TSS basedon samples taken at the headworksonce per week (composite 24-hoursamples). The plant permit does notrequire testing the influent to thesecondary process for BOD or TSS.Thus, historical data was not avail-able on the characteristics of the in-fluent to the A/F lagoon.

After construction of the DPMCaerated lagoon, the data collectionmethod did not change. As a result,data was available for raw influentand final effluent characteristics.The sampling location for carbona-ceous BOD5 and TSS in the final ef-fluent is located at the aerated la-goon effluent weir. The plant opera-tor also has the option of taking thesamples at the effluent from the pol-ishing lagoon. However, during op-eration of the A/F lagoon, the pol-ishing pond effluent samples oftenshowed BOD and TSS results high-er than from the A/F lagoon weir.

A commercial laboratory ana-lyzed the BOD samples. The plantlaboratory was used to analyze theTSS samples. All effluent sampleswere grab samples.

Original A/F LagoonProcess

The Corcoran WWTP has twoseparate treatment plants: primaryand secondary. The primary plantincludes headworks with a Parshallflume, comminutor, auger screen,

Performance of a Dual-Power,Multicellular, Aerated LagoonSystem in Corcoran, CaliforniaAUTHORS

Alex Drohobyczer, Ph.D., P.E., Terry W. Schroepfer, P.E., and Jenelle H. Armstrong, P.E.

ABSTRACT:

A dual-power, multicellular, aerat-ed (DPMC) lagoon system wasdesigned and constructed for thecity of Corcoran, California. Thenew process brought the plantinto a full compliance with Cali-fornia Regional Water QualityControl Board (CRWQCB) efflu-ent limits while saving approxi-mately $110,000 per year in en-ergy costs. The project was amodification of an existing aerat-ed/facultative (A/F) lagoon thatwas plagued by algal growth forseveral years. The results afterthe first 19 months of DPMC op-eration indicated that the monthlyaverage effluent five-day bio-chemical oxygen demand (BOD5)and total suspended solids (TSS)concentrations were typically lessthan half of what they were prior.The DPMC aerated lagoon is ap-plicable to many small plants asa process upgrade to underper-forming lagoons or as a newprocess.

Sm

allF

low

sM

agaz

ine,

Spr

ing/

Sum

mer

2007

,Vol

ume

8,N

umbe

r1

28

JU

RI

ED

AR

TI

CL

E

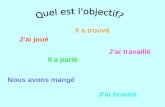

Figure 1 Original Corcoran, California, WWTP Aerated/Facultative Lagoon

Photo 1 Aerial View of the Primary and Secondary WastewaterTreatment Facilities, Corcoran, California

and two primary settling tanks. In ad-dition, an anaerobic digester stabi-lizes the primary sludge. The digest-ed sludge is then dewatered onsludge drying beds and disposed offin a landfill. The primary effluent ispumped approximately two miles tothe secondary plant.

The original secondary plant con-sisted of an A/F lagoon and a polish-ing pond. Final effluent from the pol-ishing pond is flows to three evapo-ration/ percolation ponds and is usedfor irrigation. The total area of evapo-ration ponds and treatment lagoonsis 37 acres and the irrigation dispos-al fields cover another 160 acres.

A/F Lagoon DescriptionThe original A/F lagoon, shown

on Figure 1 and in Photo 1, was 8 ftdeep with a total volume of 16.0 mil-lion gallons (MG). The lagoon hadan effluent weir located at the south-western corner and an emergencyeffluent structure located at thesoutheastern corner.

Twelve mechanical surface aera-tors, each rated at 20 horsepower(HP), provided aeration. These aera-tors operated 24 hours per day,equating to a mixing intensity of 15HP/MG, which classified the lagoonas partially mixed. At an averagedaily flow rate of 1.2 million gallonsper day (MG/D) the hydraulic reten-tion time (HRT) in the aerated la-goon was just over 13 days. ThisHRT was long enough for algae togrow in the lagoon.

Performance ProblemsThe poor performance of the la-

goon was analyzed with an objectiveof improving the effluent quality byoperational means and avoiding theexpense of constructing a newprocess.

The installed aeration power wasmore than sufficient to provide oxy-gen for a relatively weak influentwith a total BOD5 of just below 100mg/L. The poor effluent quality wasclearly a result of long detentiontime in the lagoon that enhancedalgal growth. Based on the greenishcolor of the A/F lagoon effluent, itwas evident that algae were con-tributing to the elevated BOD5 andTSS. Average BOD5 and TSS con-centrations during 17 months priorto the process modification were 37

EFFLUENT WEIR

EMERGENCYEFFLUENTSTRUCTURE

INFLUENT PIPEIRRIGATIONPUMP STATION

POLISHING POND POND NO. 3

POND NO. 4

= AERATORS

POND NO. 5

A/F LAGOON

Figure 1 – Original Aerated Facultative Lagoon – Corcoran WWTP, CA

Figure 2 Raw Wastewater Flows

Figure 3 Raw Wastewater BOD and TSS

SmallFlows

Quarterly,Spring

2006,Volume

7,Number

2

5

JU

RI

ED

AR

TI

CL

E

mg/L and 50 mg/L, respectively, in-cluding four BOD5 and nine TSSpermit violations.

Operational ChangesBefore designing a new system,

the plant staff experimented with thefollowing operational changes to re-duce the growth of algae:• moving the compliance point from

the effluent of the A/F lagoon tothe effluent from the first storagelagoon and using that lagoon as apolishing pond;

• iIntermittent release of A/F lagooneffluent at night only to prevent re-lease of floating algae;

• avoiding aeration during hourswith high light intensity (aroundnoon);

• application of copper sulfate tocontrol algae;

• installation of a baffle around theeffluent weir to reduce dischargeof solids; and

• using different aeration patternswith some aerators on and someoff.

The above operational adjust-ments proved unsuccessful andforced the city to search for an inex-pensive process modification to con-trol algal growth and increaseprocess flexibility and reliability.

Wastewater Characteristics

Several years of flow monitoringdata indicated that the averagemonthly flows to the plant were rela-tively stable at approximately 1.2MG/D (see Figure 2).

Raw wastewater total BOD5 andTSS concentrations averaged 166mg/L (see Figure 3) on a monthlybasis. The expected BOD5 and TSSvalues in the primary effluent wereapproximately 95 mg/L and 50 mg/L,correspondingly. These values werecalculated by assuming the rawBOD5 and TSS removal in the pri-mary clarifiers at typical rates of 30and 70 percent, respectively.

Several tests prior to final designof the DPMC lagoon confirmedthese estimates. However, due to alack of long-term records, we haveapplied a safety factor of 1.5 on in-

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

Jul-98 Dec-99 Apr-01 Sep-02 Jan-04 May-05

Date

)d

gm(

wol

FFigure 2 – Raw Wastewater Flows

0

100

200

300

400

500

600

700

800

99-naJ

99-luJ

00-naJ

00-luJ

10-naJ

10-luJ

20-naJ

20-luJ

30-naJ

30-luJ

40-naJ

40-luJ

Date

L/g

m,n

oitartnec

no

C

BOD

TSS

Figure 3 – Raw Wastewater BOD and TSS

fluent BOD5 for design purposes.This safety factor also provides theflexibility for the modified lagoon totreat raw influent, if necessary.

New DPMC Aerated Lagoon

Early in 2002, the city of Corco-ran accepted the idea of convertingthe existing A/F lagoon to a DPMCaerated lagoon. The DPMC aeratedlagoon is an innovative process thatprevents algal growth by limiting de-

tention time in the lagoon and com-partmentalizing the settling processinto a series of cells. DPMC aeratedlagoon is a relatively new process. Atthe time when DPMC aerated lagoonwas put in operation in CorcoranWWTP, it was one of the first suchprocesses installed in California. Thisproject was both an incredible oppor-tunity and great risk for the city andengineer.

Sm

allF

low

sM

agaz

ine,

Spr

ing/

Sum

mer

2007

,Vol

ume

8,N

umbe

r1

30

JU

RI

ED

AR

TI

CL

E

Figure 4 Single-Basin DPMC Aerated Lagoon

Photo 2 DPMC Aerated Lagoon Cells. The Motor Control Center With a New Sun Shed and Cell 1 Are Shown at the Topof the Photo. Floating Baffles Separate the Cells.

General Process Description

Dr. Linvil G. Rich (1999) who haddeveloped the rationale for theprocess design pioneered theDPMC process. The DPMC aeratedlagoon (see Figure 4 and Photo 2below) uses multiple cells to treat ei-ther presettled or raw wastewater.

Aerators in the reactor cell vigor-ously mix and aerate to preventbiosolids from settling and to removesoluble organics. The role of the nextthree cells is to provide quiescentflow conditions for settling ofbiosolids and minimal aeration, atmuch lower power intensity than inthe first cell, to prevent the odors.The first half of the process name,“dual-power,” is derived from the twodifferent power intensities used.

The total HRT in the system istypically five days at the design flowrate. However, HRT is determinedfor each case by using a processdesign procedure and accounting forspecific wastewater characteristicsand other input parameters.

The DPMC aerated lagoon has acapacity to suppress algal growthdue to its multicellular configuration.Rich (1996) proposed an equation toquantify algal growth in a series of ncells. The equation predicts a sharpdecrease of algae numbers in the

ments: mixing and oxygen demand.Since the reactor basin must be acomplete-mix reactor, the mixingpower requirements depend onsolids concentration in the basin.Rich (1999) provides information oncalculating the required power inputusing low-speed mechanical surfaceaerators to maintain solids in sus-pension and a general procedure forprocess design based on a biokinet-ic approach.

Settling CellsSettling cells (Cells 2 through 4)

in the DPMC aerated lagoon systemprevent algal growth by using serialmulticellular configuration and by

effluent with the increased numberof lagoon cells for a given total re-tention time.

Reactor CellThe minimum HRT for the reac-

tor cell (Cell 1) is 1.5 days, which isnecessary for flocculation ofbiosolids and effective settling in thedownstream settling cells. Rich(1999) provides kinetic model andparameters for rational calculation ofthe retention time, biosolids produc-tion, oxygen, and power require-ments for the reactor cell. Mechani-cal surface aerators provide aerationin the reactor cell. Aerators satisfythe higher of the two critical require-

Figure 4 - Single Basin DPMC Aerated Lagoon

Sm

allFlo w

sM

agazine,S

pr ing/Sum

mer

2007, Volum

e8,

Num

ber1

31

JU

RI

ED

AR

TI

CL

E

Photo 3 New Effluent Structure with Baffled, Adjustable Weir (Water-LevelControl Planks Are Removed)

invaluable for reducing solids in theeffluent during the first summer afterthe new system construction. Figure5 shows the plan view of the Corco-ran DPMC aerated lagoon.

Summary of Modificationsto the Existing Process

Modifications to the original A/Flagoon that were necessary for itsconversion to the DPMC aerated la-goon consisted of the following:• increasing the total depth of the

existing lagoon from 10 to 12 ft(10 feet side water depth plus twofeet freeboard);

• using part of the excavated soil forconstruction of a dyke in the mid-dle of the existing lagoon to cre-ate two lagoons, each capable ofholding 10 MG. The east part ofthe A/F lagoon became the pres-ent DPMC aerated lagoon and thewest part of the A/F Lagoon be-

Table 1 – Basis of Design Summary

Parameter Unit Design ValueValue at the Time of

DesignAverage Flow MGD 2.0 1.2Influent CBOD5 mg/L 150 100 (total)Influent TSS mg/L 100 <100HRT Cell 1 Day 2 3.3HRT Cells 2, 3 and 4 Day 1 1.7Total HRT Day 5 8.4

Table 1 Basis of Design Summarylimiting the overall hydraulic reten-tion time. The HRT for the settlingcells is determined using processdesign approach proposed by Rich(1999). The purpose of minimal aer-ation in the settling cells is to satisfythe benthal oxygen demand for odorcontrol. The aeration energy is lowenough to prevent any excessiveturbulence. Biosolids settled at thebottom of the settling cells undergoaerobic and anaerobic decomposi-tion as a benthic deposit.

Impact of Algae on EffluentBOD and TSS

Algae are generally the maincomponent of BOD5 and TSS in thelagoon effluent, especially during thesummer months. Chlorophyll a is re-sponsible for biosynthesis found inalgal cells. Standard Methods (2003)includes an analytical procedure forits quantification. Chlorophyll a con-tent in algal cells varies fromspecies to species, but its measure-ment provides a good estimate ofalgae concentration. The algal TSSconcentration determines the frac-tion of carbonaceous BOD5 due tochlorophyll a Toms et al. (1975) pro-posed expressions relating algaeconcentration to TSS and particulatecarbonaceous fraction of CBOD.

Design CriteriaThe DPMC system for the city of

Corcoran was designed for 2.0 MGDaverage daily flow. System configu-ration included a total of four cells(one reactor cell and three settlingcells) in a single basin with a totalwater volume of 10 MG and total in-stalled aeration power of 150 HP.The cell dividers consisted of threebaffles made of synthetic membranematerial. Table 1 presents a summa-ry of the basis of design.

The volume of the cells providesa total of 5 days HRT at the designflow rate (2.0 MGD). The volumes ofthe reactor cell and each Settlingcell were 4 MG and 2 MG, respec-tively. The design included six exist-ing 20 HP aerators in the reactorcell and six new 5 HP aerators inthe settling cells. Under normal op-erating conditions, five 20 HP aera-tors are used in the reactor cell andone 5 HP aerator is used in eachsettling cells. The normal aeratorpower load is, therefore, 115 HP, or

48 percent of the original A/F lagoonoperating aeration power.

Hydraulic Retention TimeFlexibility

Changing HRT is one of themethods available to control theDPMC system performance. Thefinal effluent weir has two removableweir planks to vary the water surfaceelevation within the system (seePhoto 3). In addition, the existingemergency effluent structure pro-vides the fourth and the lowestwater level control option. There arefour effective water depths availablefor operation: 10.0, 9.5, 9.0, and 8.5ft. Each lower water depth reducesthe HRT by approximately 3.5 per-cent. Therefore, the plant has theflexibility for up to 14 percent volumereduction when needed during peri-ods of low flow. This flexibility in con-trolling water level in the lagoon was

Sm

allF

low

sM

agaz

ine,

Spr

ing/

Sum

mer

2007

,Vol

ume

8,N

umbe

r1

32

JU

RI

ED

AR

TI

CL

E

came the future DPMC aeratedlagoon;

• the DPMC lagoon consisted offour compartments constructedusing synthetic membrane baffleswith curtains/windows for passageof flow in a meandering patternfrom one cell to another;

• upgrading the motor control cen-ter (MCC) with new aerator motortimers (since overall power re-quirements were reduced, it waspossible to reuse all the existingmotor starters and posts withmotor disconnects—most of theexisting underground cables wereleft unexcavated to power the aer-ators that were simply relocated);

• Installating 14-inch ductile ironpipes (DIP) with butterfly valvesbetween the East and WestDPMC aerated lagoons provideflexibility for future rerouting of theflow.

• Stabilization of the lagoon em-bankments, initially with soil-ce-ment, later, after deterioration dueto aeration and wave action, withShot-Crete ® lining.

The design of the new processtook four months, including prepara-tion of drawings, specifications andbid documents. The client received

grant assistance from both Commu-nity Development Block Grants andPacific Gas and Electric’s SB 5X In-centive Fund grant based on peakload reduction. The Pacific Gas andElectric grant was sufficient to pur-chase six, 5-HP surface aerators forsettling cells.

Process ComparisonThe plant permit does not re-

quire testing for characteristics of in-fluent to the aerated lagoon. There-fore, data for BOD and TSS is notavailable for the old A/F lagoon orfor the new DPMC aerated lagoon.Therefore, the removal efficienciesof BOD5 or TSS across the second-ary treatment process have notbeen calculated. Instead, the per-formance of the new treatmentprocess was evaluated by compar-ing effluent data and number of per-mit violations. Table 2 presents theperformance data of the original A/Flagoon versus the new DPMC aerat-ed lagoon.

The results presented in Table 2demonstrate the superior perform-ance of the DPMC aerated lagoonversus the conventional A/F lagoon.The new process drastically reducedboth the BOD5 and TSS averagemonthly concentrations. More impor-tantly, the plant eliminated all viola-

tions caused by an under-performingtreatment process. The single TSSviolation on the record was due to abatch discharge of industrial waste-water containing concentrated oils.For the same reason, the effluentTSS concentrations were also ele-vated during three months in 2003(March, May, and June). Figure 6presents the DPMC aerated lagooneffluent characteristics for the period19 months after DPMC system con-struction.

After construction of the newDPMC aerated lagoon, there was noincrease in the difficulty of plant op-eration. The new process uses thesame type of aerators (six of oldones, included); the same motorcontrol center with improved timers;new, but low-technology equipment,such as synthetic membrane baffles,pipes, and butterfly valves intercon-necting the east (future) and thewest (new) DPMC lagoons; and thenew weir with adjustable planks forvarying the water level in the lagoon.The plant operators did not have anydifficulty operating the new lagoonand no additional training was re-quired. Once the new process start-ed to produce effluent in compliancewith the discharge requirements, theclient and the operators were greatlyrelieved.

The DPMC aerated lagoon offersthe following advantages as com-pared to a conventional A/F lagoon:• the DPMC aerated lagoon is less

costly to construct and operatethan an A/F lagoon;

• it can achieve better effluent quali-ty with a smaller footprint and lesspower input;

• it can be constructed in earthenbasins—thus, an existing lagoonsystem can be easily modified toa DPMC aerated lagoon;

• it does not require external me-chanical clarifiers;

• the only mechanical parts re-quired are the aerators;

• sludge can be accumulated in thelagoon for years without disposal(sludge in one existing DPMC aer-ated lagoons has not been re-moved in 16 years of operation);

• the DPMC aerated lagoon is freeof odor

EFFLUENT WEIR

EMERGENCYEFFLUENTSTRUCTURE

INFLUENT PIPEIRRIGATIONPUMP STATION

POLISHING PONDPOND NO. 3

POND NO. 4

= AERATORS

POND NO. 5

NEW EFFLUENTWEIR

CELL 4

CELL 3

CELL 2

CELL 1

FUTUREDPMC

LAGOON BAFFLES

NEWDPMCLAGOON

14" DIP

Figure 5 – DPMC Aerated Lagoon – Corcoran WWTP, CAFigure 5 DPMC Aerated Lagoon

Sm

allFlo w

sM

agazine,S

pr ing/Sum

mer

2007, Volum

e8,

Num

ber1

33

JU

RI

ED

AR

TI

CL

E

Table 2 Performance of A/F Lagoon Versus DPMC Aerated Lagoon

Rich, L. G. 1999. High performanceaerated lagoon systems. Annapolis,Maryland: American Academy ofEnvironmental Engineers.

————. 1996. Modification ofdesign approach to aeratedlagoons. ASCE: Journal ofEnvironmental Engineering Division.122. 149–153.

Toms, I. P., et al. 1975. Observationson the performance of polishinglagoons at large regional works.Water Pollution Control. 74.383–401.

BOD5 of just about 100 mg/L. Thereason for it might be the presentlyhigh HRT in the reactor cell, 3.3days and the process should bereevaluted when the flow reachesits design value of 2.0 MGD.

As a process, DPMC aerated la-goon is applicable to many smalltowns and rural wastewater agen-cies that currently operate under-performing lagoon systems. There-fore, DPMC aerated lagoon is a vi-able alternative for a new processor a process modification.

References

American Public Health Association(APHA), American Water WorksAssociation (AWWA), and WaterEnvironment Federation (WEF).2003. Standard methods forexamination of water and wastewater.20th ed.

0

10

20

30

40

50

60

30-naJ

30-rpA

30-luJ

30-tcO

40-naJ

40-rpA

40-luJ

40-tcO

Month - Year

L/g

m,n

oitartnec

no

C

BODTSS

Figure 6 – DPMC Aerated Lagoon Effluent BOD and TSSFigure 6 DPMC Aerated Lagoon Effluent BOD and TSS

Table 2 – Performance of A/F Lagoon vs. DPMC Aerated Lagoon

EffluentCharacteristic

OriginalA/F Lagoon 1

Effluent

NewDPMC Lagoon 2

EffluentPercent

ReductionBOD5, mg/L 37 14 62%TSS, mg/L 50 24 52%BOD Violations 4 0 100%TSS Violations 9 13 89%

• it produces effluent BOD5 andTSS concentrations typicallybelow 30/40. In addition, effluentBOD5 is frequently in single digits.

Conclusions The DPMC aerated lagoon sys-

tem brought the city of CorcoranWWTP into discharge compliancewhile saving $110,000/year on ener-gy expenses in the process. Totalconstruction cost was approximately$650,000, including the cost of roadimprovements around the lagoons.The next least expensive alternativeconsidered for this project was con-version of the aerated lagoon to asix-cell A/F lagoon estimated to costover $2 million. The new DPMC aer-ated lagoon is approximately halfthe area and 62 percent of the vol-ume of the original A/F lagoon andrequires less than half the horse-power.

The DPMC aerated lagoon pro-duces significantly better quality ef-fluent than the original A/F lagoon.Average BOD5 and TSS concentra-tions during 17 months prior to theprocess modification were 37 mg/Land 50 mg/L, respectively. AverageBOD5 and TSS concentrations dur-ing 19 months after modificationwere 14 mg/L and 24 mg/L, corre-spondingly, with nine months show-ing BOD5 of less than 5 mg/L.

The DPMC aerated lagoon inCorcoran, treating presettled waste-water is unique since, originally, theprocess was developed for treat-ment of raw wastewater. Eventhough Rich (1999) does not recom-mend application of the DPMC aer-ated lagoon when the influent solu-ble CBOD (carbonaceous biochemi-cal oxygen demand) is below 100mg/L, the system in Corcoran is per-forming well with total presettled

Sm

allF

low

sM

agaz

ine,

Spr

ing/

Sum

mer

2007

,Vol

ume

8,N

umbe

r1

34

JU

RI

ED

AR

TI

CL

E

mental engineering and biological sciencesfrom the University of California, Irvine, anda M.S. degree in sanitary engineering fromthe University of California, Berkeley. He isthe author/coauthor of over five technical pa-pers. He can be contacted by e-mail at [email protected].

Jenelle H. Armstrong, P.E.,is a senior engineer and proj-ect manager with Brown andCaldwell, El Paso, Texas. Sheearned a B.S. degree in civilengineering and an M.S. de-gree in environmental engi-neering from the University ofTexas at El Paso. She has ten

years’ experience in water and wastewatersystems modeling, preliminary engineering,and detailed design. She is currently manag-ing numerous wastewater improvementsprojects for the Fort Bliss Water ServicesCompany and the El Paso Water Utilities,which provide water and wastewater servic-es to Fort Bliss and the El Paso community.She can be contacted at [email protected].

34

Alex Drohobyczer, Ph.D., P.E.,is a principal engineer with Brownand Caldwell, El Paso, Texas. Hehas over 22 years of experiencein process design for municipaland industrial wastewater andwater treatment facilities, piloting,modeling, and troubleshooting oftreatment processes. He was re-

cently involved in pilot studies and the de-sign of six different arsenic treatment facili-ties and the design of ozonation, nitrificationand denitrification processes. However, hecounts this paper’s subject project as one ofhis most satisfying professional experi-ences. If you have questions about the proj-ect, please contact Drohobyczer at [email protected].

Terry W. Schroepfer, P.E.,is principal civil engineer and vicepresident of Quad Knopf, Inc.,Bakersfield, California. He is a li-censed civil engineer in Californiawith over 30 years’ experience inplanning, special studies, design,and construction management ofwater and wastewater facilities.

He earned B.S. degrees in civil and environ-

CONTRIBUTING AUTHORS