Advanced CAD/CAM technology for your perfect smile! ICORE KATALOG 2013.pdf · if you use our...

Transcript of Advanced CAD/CAM technology for your perfect smile! ICORE KATALOG 2013.pdf · if you use our...

1

Advanced CAD/CAM technology for your perfect smile!

2

Solutions for your highest expectations

intraScan3D & SpectroShade 4

i3Dscan & exocad CAD-Software 6

3Shape scanner & DentalDesigner™ 8

iCAM V4.6 10

iCAM V5 12

CORiTEC 140i 14

CORiTEC 240i 16

CORiTEC 250i 18

CORiTEC 340i 20

CORiTEC 440i 22

CORiTEC 450i 24

CORiTEC 550i 26

CORiTEC 750i 28

Suction units & Sintering furnaces 30

Materials 32

Milling & Grinding tools 34

Functions & Features 36

Upgrades 38

Reliable customer service! 39

3

Welcome to the future of dental technology!

Our currently eight different dental CAD/CAM systems of-

fer the optimal modular approach to the future demands

of every dental laboratory or milling center.

Our CORiTEC system provides highest precision and accu-

racy of fit and the entire freedom for development in all

fields of today’s dental prosthetics.

With our products we offer a network of safety and

productivity for the daily needs of our customers. While

doing this, we forward this inspiring precision and quali-

ty to our customers. Our high demand is supported by our

convincing program of scanners, furnaces, suction units

and high quality consumable materials. Whether

if you use our zirconia material, our waxes, resin materi-

als, titanium or cobalt chrome.

imes-icore is certified in:

EN ISO 13485:2003 + AC 2009

ISO 9001:2008

Let our products and service inspire you!

imes-icore. Makes your smile perfect!

The company imes-icore stands for traditional corporate

values like innovation and quality “Made in Germany“.

The aim is the development of individual CAD/CAM solu-

tions that fit the need of the individual practice and den-

tal laboratory. As a company of the isel-group known for

their quality milling machines and CAD/CAM components

for the global markets, imes-icore joins a long history

in technology combined with experience in the global

dental markets.

Our ambitious team of experienced CNC-, CAD/CAM and

dental technicians and our innovative high-tech deve-

lopment group along with our local dealerships will pro-

vide a new dimension in dental CAD/CAM solutions.

The faster and faster developing market for dental tech-

nology requires highly flexible CNC and dental production

systems with increasing efficiency. In addition, we expe-

rience increasing demand in the quality of software and

innovative materials.

We have a very clear mission for the dental future: As a

full-service company, we will develop and utilize global

alliances to realize your needs and our goals. We will

continuously increase the quality of our innovative tech-

nologies and update our software tools and improve our

materials and customized service.

4

intraScan3D:

intraScan3D that is the solution of imes-icore for creating digital

impressions allows dentists acquiring directly and completely the int-

raoral situation and processing it further as high-precision digital 3D

model in the CAD software exocad.

The digital acquisition of the oral situation happens in real time.

In contrast to most of the other scanners, the generated model data

are saved in the open STL format and can be used with any further CAD

application.

SpectroShade:

With the dental spectrophotometer SpectroShade the colors of the

teeth are defined fast and precisely. Hence, it indicates the closest

available chromatic standard for reconstruction considering aesthetic

peculiarities according to the customer‘s requirements.

It supports the following ceramic manufacturers:

The database is steadily extended and the data of new ceramic material can

be downloaded conveniently and for free.

The device is characterized by its simple handling and is CE-certified.

intraScan3D & SpectroShade

» AVANTI Shade Guide

» Candulor TCR

» Ceramco 3

» Ceramco II & II Silver

» Dentsply Esthet-X

» Dentsply Genios

» Ivoclar Chromoscop-Complete

» Ivoclar Vivodent PE

» Kiss V-Shades

» Kiss extreme

» Nobel Rondo Alumina

» Nobel Rondo Zirconia

» Noritake Tooth Guide

» Noritake Shade Guide

» Shofu Vintage Halo 7041

» Shofu Vintage Halo 7043

» Shofu Vintage Halo

» Shofu Vintg. Halo High Value

» Shofu Vintg. incl. High Value

» Trubyte Bioform Plastic

» Trubyte Bioform Porcelain

» Trubyte New Hue

» Trubyte Portrait

» Vita 3D Master-Complete

» Vita Classical

» Vita Lumin

» Dentsply CeramX

» 3M Filtek Supreme XT

SpectroShade

scanning of oral situation

intraScan3D

varieties of colour display milled models of intraoral scans

5

SpectroShade

SpectroShade is a technological achievement in the

range of colorimetric analysis and the global communi-

cation. The patented SpectroShade system consists of a

digital camera and is connected to a LED spectrophoto-

meter, a device for identifying colors which has proved to

be more effective than the human eye.

SpectroShade recognizes the color shades of the teeth

or dental prosthesis with high precision. Hence, the color

shades can be adjusted perfectly according to the shades

of the teeth themselves or the color scale in order to

reconstruct the teeth with the necessary materials.

This advanced communication device has been develo-

ped in order to avoid arising incongruities of color sha-

des while conveying photos between dentists and dental

technicians.

This new system does not only analyze the pictures but

also allows the detailed exchange of information refer-

ring to aesthetic issues between dental practice and la-

boratory.

Furthermore, there are a lot of opportunities for data

evaluation. The situation before and after the operati-

on is displayed simultaneously with different pictures on

the screen. Additionally, the degree of tooth bleaching

is traced, the size of every single tooth is measured and

X-ray pictures can be completely conveyed via email, CD-

ROM or Memory Card.

intraScan3D

The entire camera technology is integrated in the hand-

piece that weighs only 720 grams.

The intraScan3D is connected simply by USB cable plug

and play to PC / laptop.

The digital acquisition of the oral situation happens in

real time and is displayed digitally in exoScan software

as 3D model.

In contrast to most of the other scanners, the generated

model data are saved in the open STL format and can be

used with any further CAD application.

The scanning process can be interrupted at any time and

can be continued after drainage.

You do not need to hold the scanner in a certain distance

to the tooth.

Technical details:

» open STL interface

» no license fees

» plug and play installation

» all possible indications are included

» determination of preparation line is possible

» confocal technology

» powder-free scanning

» scanning field (x,y,z) 9,6 x 10,4 x 18 mm

» pixel on sensor (x,y) : 144 x 90

» pixel size: 50x86µm

» single frame acquisition time is lower than 0,1 second

Completely open solutions that already begin at treatment chair!

defining the preparation line

6

i3Dscan dental scanner

The new model of imes-icore i3Dscan convinces with impressive speed

and precision. The digitization of the complete jawbone happens in

only 90 seconds. The scan of 12 single dies with the new multiCase mo-

dule takes 80 seconds and hence sets new benchmarks in the segment

of stripe-light scanners.

By its very large measurement field and in combination with the exocad

dental CAD software, imes-icore offers a complete solution for highest

productivity which suits perfectly and precisely for implant-supported

restorations.

A trouble-free workflow will be ensured both for newcomers and expe-

rienced users due to simple and fast handling and the reliability of the

system even in case of very complex structures.

Technical details:

» extremely fast and fully automatic scanner

» stripe-light and projector technology

» newly developed large measurement field

» use of full-value articulated models including articulator

» perfectly for large-span and directly screwed implant restorations

» very short scanning and calculation times

» high-precision results by automated 3D calibration

» removable object holder

» precision up to 10 microns

» output as completely open STL file

exocad CAD software:

The i3Dscan is fully supported by the exocad software without restric-

tion.

Next to the standard applications such as crowns, bridges and tele-

scopes, extended functions are available, e. g. virtual articulator, di-

rectly screwed implant bridges / bars, one-piece individual abutments,

bite splints etc.

One further advantage of this combination

is the complete candor because there are

no license fees neither for the scanner nor

for the exocad software.

i3Dscan

multiCase adapter

ScanFixator

i3Dscan

bar restoration on six screw-retained implants including gingiva scan

imes-icore`s removable partials software

7

The CAD dream team “Made in Germany“ !

Furthermore, i3Dscan is able to digitize the cranium

related jawbone of the most articulators in the correct

position due to the patented scan fixators.

In combination with the CAD software exocad, a precise

production with cranium based data and module “virtual

articulator“ is possible.

Models that have been previously aligned in an articu-

lator (using a face bow) can be positioned within the

scanner using the corresponding magnetic spacer plates.

The scan software brings the measurements together au-

tomatically and positions them into the exact correlation

with the patient-specific centric relation.

exocad CAD-Software

exocad as dental CAD software is the ideal complement to

the dental scanner i3Dscan simplifying the technology

of digital dentistry for beginners by way of a coordina-

ted, step-by-step workflow and intuitive user interface.

exocad has been developed in close collaboration with

experienced dental technicians and software specialists

and enjoys a high level of acceptance among beginners

and digital experts.

From the simple design of a coping for a large-span,

anatomically-reduced bridge fabrication to implant-sup-

ported, fully anatomic restoration, exocad is your time-

saving guide to a perfect result.

Through the scanning of a bite record, situation model

or wax-up, optimal ceramic support is ensured. The po-

sition of articulated models is precisely transferred from

the physical articulator to the virtual articulator with the

scan fixator.

After using a face bow, the patented procedure precisely

transfers the patient‘s precise condylar position to the

CAD software.

Indications and functions:

» anatomical copings, crowns, bridges, telescopes,

inlays/onlays/veneers, abutments

» prefabricated customized crowns (pritidenta®)

» one-piece individual abutments, directly screwed

implant bridges / bars

» comprehensive, cost-free implant system library (also

for prefabricated abutments)

» use of full-value articulated models including

articulator

» bite splints; can be perfectly designed by full-value

and virtual articulator

» use of situation models and wax-up constructions

» reflection of existing teeth in the ongoing construction

» photo-realistic illustration of the construction in real

time

» no license fees; hence no running costs

i3Dscan

The new i3Dscan of imes-icore combines innovation and

knowhow of the optic scanner technology and is charac-

terized by its solid and compact design. The use of high

quality components and the “Made in Germany“ produc-

tion ensure reliability and durability of the devices. With

exceptional 10 micron precision , our scanner provides

fully open STL scans which result in the best fit and fine

detail for all kinds of dental CAD restorations.

Hence, the new i3Dscan has been developed in collabo-

ration with dental laboratories and clinics for everyday

use in practice. Many years of gained experience have

influenced the development.

The current software is the basis for precisely fitting con-

structions of all ranges.

The new fully-automated 3D calibration feature allows

the production of large-span and directly screwed im-

plant restorations.

Reduced wax-up bridge on implantsinlay bridge in TruSmile display

8

3Shape 3D dental scanner

3Shape scanner & DentalDesigner™

A scanner solution for every laboratory:

3Shape offers the market flexible solutions of technology-leading den-

tal scanners for 3D scanning of both impressions and gypsum models.

Whether you are looking for a secure entry into digital dentistry, or

expanding your business model with the full range of dental indications

and utmost accuracy - 3Shape has a high-precision scanner solution

for you.

Developed for productivity:

3Shape’s Dental Scanners series D500, D700, D800 and D900 ensure

laboratories increased productivity plus customer satisfaction through

faster delivery and superior clinical results. 3Shape’s dental scanners

are very easy to handle that extra training is barely required. Object

fixation is fast and a single click in the user-friendly software starts the

scanning process.

Two cameras with reduced angles enable the effective scanning of im-

pressions, deep inlays and full undercuts. The 3 axes motion system

tilts, rotates and translates the object facilitating scanning from any

perspective.

The DentalSystem™ of 3Shape allows a high-performance 3D scanning,

CAD modeling, job management and interfaces to all manufacturing

units and materials.

textures of removable partialsMultiLayer design

coping design in 40 seconds

function overview

3Shape scanner serie

9

The intuitive all-in-one solution3Shape D500:

3Shape’s D500 series scanner is designed for small to

medium-sized labs looking for an easy entry into CAD/

CAM digital dentistry. This compact scanner is built on

3Shape’s leading scanning technologies with a reduced

range of dental indications to provide a cost-efficient

CAD/CAM solution for any laboratory size and budget.

3Shape D700/D710 series scanners:

3Shape’s D700 series scanners are for medium-sized to

large labs where productivity and flexibility are key cri-

teria. The D700 scanner is applied by thousands of users

all over the world. The D700 is a designed for maximum

productivity, enabling high throughput for both standard

and advanced indications. Additionally, the D710 sup-

ports Multi-Die scanning for ultimate efficiency.

3Shape D800/D810/D910 series scanners:

3Shape’s D800 series scanners are designed for medi-

um-sized to large labs that demand the utmost accuracy

and detail levels for even the most advanced indications.

With its new and unique Texture Scanning capabilities

plus 5.0 MP cameras, 3Shape’s D800 series scanners

wield the market’s most advanced 3D scanning techno-

logies.This is a no limitations device, providing highest

productivity, extreme accuracy and the complete scope of

dental indications for full-service labs that accept only

the best results.

Brand-new in the DentalSystem™

» order form can be modified during the construction

» MultiLayer design for completely digital bridges

» implant bridges with gingiva share

» digital prosthesis construction

» fully anatomical modeling in DentalDesigner™

optimized productivity, durability and aesthetic with a

few clicks

» simultaneous modeling of upper and lower jaw

» dynamic virtual articulation outstanding occlusal

adaption and function

» inlays, onlays and veneers

» press ceramic for a fully digital restoration

» AbutmentDesigner™ individual abutments, parallel

abutments, outside-in design

» sophisticated implant bars and bridges highest

accuracy and flexibility

» removable prosthesis:

Removable partials can be designed in less than

10 minutes.

10

CORiTEC iCAM V4.6 is a renowned and extended 5 axes professional

CAM system based on Windows 7/8 that has come to maturity due to

gained experience for years. iCAM V4.6 is unique because of its easy,

safe and fast handling. It is the perfect user software for the automated

fabrication of high-end dental restorations. It calculates the milling

data in a very short time referring to optimized and safe milling strate-

gies developed in 10 years of dental CAD /CAM experience for all kind

of dental constructions and materials. Menu guided user interface and

ease to operate surfaces as well as many fully automated functions are

resulting in a reliable and simple handling.

iCAM V4.6 guides the beginner and expert automatically and safely to

the entire milling program. In the background of the dental front-end

a German fully industrial CAD/CAM system with over 25 years of expe-

rience is working. The open CAD/CAM software is used for professional

constructions and manufacturing in the industrial and medical field.

iCAM V4.6

moving bars

abutment hexagon

main menu

implant restoration with sintering bar

gravur

11

Highlights

The new CAM system iCAM V4.6 convinces with its simple,

fast and process reliable handling. The complete workflow

has been perfectly optimized.

The following opportunities are offered by the new

iCAM V4.6

» complete open CAM system without commitment to a

material supplier

» no annual fees at an unlimited runtime

» very easy handling with a short training period

» suitable for 4 and 5 axes CORiTEC machine systems

» additional grinding of glass ceramics and lithium

disilicate blocks

» also available for existing machines through upgrade of

software (isy CAM 3.0/3.2 and iCAM V4)

» automatic data import

» automatic height optimisation according to demand

» everything at a glance, job view and all blanks.

» speed up of milling times 20%-40%

» hybrid milling technology

» automatic setting of bars

» milling strategies for nearly all implant systems

» improved job alignment with new calculation of

preparation line

» release of hexagon and octagon in implant systems

» intuitive milling strategies: By simple marking of an

area, this area is processed automatically with the next

smaller tool

» angle preselection for automatic “undercut milling“ of 4

axes machine systems

Unlimited possibilities with precision!

» extended and simplified functions for creating and

panning bars

» parameters for bars, drops, bridge connectors, job

marking are adjustable by material related preselec-

tions

» all jobs that are placed in the blank can be modified

arbitrarily

» milling strategies can be adapted more conveniently.

» automatic undercut acquisition

» 64 bit MultiCore support

New integrated modules

» automatic milling of tooth models

» production of prefabricated abutments of nt-trading®

» production of prefabricated ceramic crowns of

pritidenta®

» automated milling of splints, removable partials and

implant-supported screw-retained indications possible

Simulation of model millingundercut-detection milling of occlusal surfaces

12

iCAM V5 is the high-end CAM solution of imes-icore.

iCAM V5 allows a high-precision calculation of 5 axes simultaneous

milling data for best surface finish and accuracy of fit. Especially with

hard materials like glass ceramics, CoCr and titanium high resolution

milling data are important for best fittings and a high tool durability.

The extremely high resolution of milling data causes an absolutely

quiet and precise run of your milling machine and hence an increased

tool life.

The iCAM V5 offers you a valuable CAM solution that rises the produc-

tivity of the CAD/CAM system and maximizes the customer satisfaction

due to predefined milling strategies for all materials and applications

developed by imes-icore.

Exactly these possibilities will be used to control the high-end-milling

machines of imes-icore.

Furthermore, iCAM V5 contains essential features like the fully auto-

mated cutting of bars, automated creation of sinter bars for zirconium

oxide as well as the total flexibility while embedding further milling

tools or own milling strategies.

iCAM V5

blank with different indications

optimized strategies for implant restorations

height optimisation

automatic screw hole detection

automatic detection of edges

13

Highlights

» completely open CAM system without commitment to

a material supplier

» very easy handling with a short training period

» suitable for all 4 and 5 axes machines of imes-icore

» 5 axes simultaneous or 3+2 processing

» creating / copying / changing existing and own

milling strategies and templates

» grinding of glass ceramics and lithium disilicate blocks

» calculation of milling files for all originally produced

milling machines by imes-icore,

e.g. 2100, 4030,3020, 4820...

» milling of works with more insert directions/undercuts

on all 4 axes machines (3+1)

» automatic detection of preparation line and borehole

» fine-finishing strategies down to a tool diameter of

0,3 mm

» automatic height optimisation to save material

» optimal milling strategies that are faster compared to

other CAM solutions. Additionally, a higher surface

quality will be reached

» milling of teeth models, removable partials and bite

splints

» automatic detection and indication of undercuts

» complete or partial cutting of free definable bars

» optimisation of the milling direction on in- and

outside

» use of up to 8 CPU cores to speed up the calculation

of milling data

» simulation of the milling process including collision

control in real time

» dynamic preview with the possibility of measuring

» re-use of partial used blanks

» possibility to connect bars

» simply editable predefined tools and milling strategies

» possibility to create sinter pins and sinter plates

» automatic management of specific abutment shapes

like hexagon

» visually automatic collision control for tools, spindle

and machine components

» predefined, cost-free post processors for all imes-icore

milling machines

High-End CAM-Software with complete flexibility!

automatic angle detection

14

CORiTEC 140i

The new CORiTEC 140i of imes-icore is space-saving and compact due

to its minimal size.

The CORiTEC 140i is particularly suitable for the production of custo-

mized fully ceramic restorations directly in your practice laboratory.

The machine system has been developed explicitly for fast and high

quality processing of CAD/CAM blocks (25 x 25 x 60mm) in wet and

dry milling, e. g. zirconium oxide, wax, aluminium oxide, PMMA, glass

ceramics, lithium disilicate and feldspar ceramics.

Applications

Excellent processing precision of all essential dental materials in the

range of wet and dry milling in 4 axes processing!

» zirconium oxide

» aluminium oxide

» wax

» resins e.g. PMMA / composite

» lithium disilicate

» glass ceramics

» feldspar ceramics

CORiTEC140i

fixed CAD/CAM block

grinding of glass ceramics

6-times tool changer

15

Highlights

» very economical due to efficient cost-benefit ratio and

hence a shortened payback period

» stable, compact chassis construction available in steel

and aluminium version

» high quality machine components

» specially designed swinging hood for ergonomic opening

and closing

» automatic 6-times tool changer

» tool lifetime control / tool breakage control

» simplest tool management

» simplest handling: With one click to an excellent

result!

» highest precision by high-frequency spindle with up to

60.000 rpm

» 4 axes processing of material blocks (with undercut

acquisition)

» applicable in practice laboratories or as additional

laboratory system

» flexible adapter system facilitates the use of different

CAD/CAM block systems

» including control PC based on Windows

» available with optional machine table

Technology

» stable, compact chassis construction as table version

available in steel and aluminium

» swinging hood for ergonomic equipping

» 4 axes processing (NC-controlled)

» dry and wet processing with integrated cooling liquid

cycle

» machine integrated cooling liquid basin, filter station

and pump

» simplest connection to CAM software

» high-definition micro step controller and motors in all

axes

» one processing station with 360° axis with precision

gearing for vibration-free stability

» high-frequency spindle “Jäger“ with up to 60.000 rpm

» integrated purging device and three cooling nozzles for

wet processing in spindle holder

» suction unit for perfect exhausting of arising dust

» automatic 6-times tool changer

» tool holder with 3 mm shaft

» integrated precision length measuring switch

» including control software Remote DENTAL 2.0 with

tool breakage and tool lifetime control

» 115 V / 230 V versions

» consumption of compressed air approx. 50 l/min

(min. 6.0 bar)

» weight: 55 kg

» dimensions: 430 x 365 x 528 mm (w x h x d)

The chairside deluxe solution with perfection for practice laboratories!

grinding process

16

The CORiTEC 240i of imes-icore allows the productive entry in the

dental CAD/CAM automation. Space-saving and very compact the

CORiTEC 240i inspires by easy installation and handling. Thanks to an

automatic 10-times tool changer and 4 axes processing, up to 45 units

can be produced without changing the blank.

The CORiTEC 240i is designed to dry mill all essential materials like zir-

conium oxide, aluminum oxide, resins and waxes. The unit is especially

designed for small and medium-sized labs to enter the dental CAD/CAM

production.

As an option the CORiTEC 240i is also available for wet processing of

glass ceramic blocks.

Applications

Processing of all essential dental materials by dry and wet milling with

4 axes processing

» zirconium oxide

» aluminum oxide

» resins like PMMA / composite (also as blocks)

» wax

» glass ceramics, feldspar, lithium disilicate (optional)

CORiTEC 240i

processing of nano-composite wet grinding of different materials

automatic 10-times tool changer

wet grinding in detail

CORiTEC 240i

17

The entry with precisionHighlights

» very economical due to low investment costs

and hence a shortened payback period

» fully automatic 10-times tool changer including

automatic tool length measurement

» tool lifetime control with display

» automatic tool breakage control

» simplest tool management and blank equipping

» simplest handling: With one click to an

excellent result!

» night mode: After successful completion the

software switches off automatically.

» highest precision due to a high frequency spindle with

up to 60.000 rpm

» undercut processing through active use of the rotary

axis

» as extension in larger labs and milling centres

» milling of approximately 45 units without changing a

blank

» available with adequate machine table

Technology

» stable, compact chassis construction as table version

available in steel and aluminium

» swinging hood with gas spring for ergonomic opening

and closing

» 4 axes processing (NC-controlled)

» simplest connection to iCAM V4.6 and iCAM V5 software

» high-definition micro step controller and motors in all

axes

» rotary axis with transmission for high stability

» one processing station with NC-controlled , automatic

360° axis and real 4 axes simultaneous processing

» high-frequency spindle “Jäger“ with up to 60.000 rpm

» cooling vent integrated into spindle holder

» suction unit with closed lid for perfect exhausting of

arising dust

» automatic 10-times tool changer

» tool holder with 3 mm shaft

» integrated precision length measuring switch up to

2 µm

» automatic air pressure control

» including control software Remote DENTAL 2.0

» 115 V / 230 V versions

» consumption of compressed air approx. 60 l/min

(min. 6.0 bar)

» weight: 106 kg

» dimensions: 506 x 670 x 738 mm (w x h x d)

18

The newly developed CORiTEC 250i is the compact 5 axes machine

system for wet and dry processing.

Experience the complete flexibility with imes-icore’s new and solid ma-

chine conception that stands out due to the use of professional machi-

ne components.

Applications

Processing of all essential dental materials in the range of wet and dry

milling in 5 axes processing

» zirconium oxide

» aluminium oxide

» resins e.g. PMMA / composite

» wax

» glass ceramics, feldspar ceramics, lithium disilicate

Highlights

» 5 axes processing with axis alignment up to 30°

» fully automatic 10-times tool changer including automatic tool

length measurement

» tool lifetime control / tool breakage control

» integrated precision length measuring switch

» integrated tank and cooling liquid cycle

» simplest tool management and blank equipping

» simplest handling: With one click to an excellent result!

» night mode function: After successful completion the software

switches off automatically.

» highest precision by high frequency spindle with up to 60.000 rpm

» applicable as flexible, affordable starter model as well as additional

laboratory system in larger laboratories and milling centres

» milling of approximately 45 units without changing a blank

» including control-PC based on Windows

» available with adequate machine table

CORiTEC 250i

CORiTEC 250i

processing station

rotary swiveling axis

19

Stable, high-precision, fast...The revolutionary 5 axes dental milling system CORiTEC 250i on granite basis!

Technology

» high quality and polished basic granite plate for

highest precision and stability

» 5 axes processing 3+2 or 5 axes simultaneous

processing

» simplest connection to CAM software

» high-definition and high-performance (up to 8 A)

micro step controller and motors in all axes

» processing station as rotating and pivoting axis with

“Harmonic Drive“ gearings for highest vibration-free

stability

» high-frequency spindle “Jäger“ with up to 60.000 rpm

» integrated purging device and three cooling nozzles for

wet processing in spindle holder

» suction unit for perfect exhausting of arising dust

» machine integrated cooling liquid basin, filter station

and pump

» automatic 10-times tool changer as direct tool

changer

» tool holder with 3 mm shaft

» integrated precision length measuring switch up to

2 µm

» automatic control of air pressure and cooling liquid

» including control software Remote DENTAL 2.0 with

tool breakage and tool lifetime control

» 115 V / 230 V versions

» consumption of compressed air approx. 60 l/min

(min. 6,5 bar)

» weight: 85 kg

» dimensions: 520 x 550 x 650 mm (w x h x d)

250i on granite basis

20

The CORiTEC 340i of imes-icore offers you optimized milling re-

sults with higher productivity. Space-saving and very compact the

CORiTEC 340i emphasizes with best quality of the milling results. The

used servo motor technology allows an accelerated processing at high

dynamic with consistent high precision and quality. The new user-sur-

face “Remote DENTAL 2.0“ inspires with easiest operation. Doing this ,

you will reach perfect milling results with one mouse click. Thanks to

the fully automatic 10-times tool changer and real 4 axes processing, it

is possible to produce up to 45 units of one material without changing

the blank. In the standard version the CORiTEC 340i is made for pro-

ducing all relevant dental materials with dry processing like zirconium

oxide, aluminium oxide, PMMA, wax .

Optionally, the CORiTEC 340i is also available for wet processing of

glass ceramic and lithium disilicate blocks. The machine is well suitable

for an entry into the dental CAD/CAM-production at particularly highest

flexibility and material diversity. Also the machine is usable for enlar-

ging your current CAD/CAM spectrum.

Applications

Processing of all relevant dental materials in wet and dry processing

with 4 axes up to 16 units

» zirconium oxide

» aluminium oxide

» resins like PMMA/composite (also in block shape)

» wax

» glass ceramics, feldspar, lithium disilicate (optional)

CORiTEC 340i

POWER + START = your success

optimized for wet processing

CORiTEC 340i

21

Compact, flexibel and productiveHighlights

» the integrated servo motor technology allows a faster

processing at consistent high quality

» the fully automatic 10-times tool changer including

automatic tool length control allows the complete

tool assembly for all usable materials

» tool lifetime controller with report

» automatic tool breakage control

» automatic tool change after wear-out

» night mode: After successful processing the software

will shut down automatically

» highest precision thanks to the high-frequency spindle

with up to 100.000 rpm

» undercut-processing with processing in different

insertion directions

» up to 45 units possible without changing the blank

» incl. control-PC based on Windows with preinstalled

control software “Remote DENTAL 2.0”

» automatic control of the suction unit

» tri-color LED interior lightning

» optional with suitable desk

Technology

» rigid, industrial, heavy duty

steel/aluminium table top

design

» swinging hood with integ-

rated gas spring for ergono-

mic opening and closing

» 4 axes processing (NC-cont-

rolled)

» servo controller and motors

in all axes for high precision

and dynamic

» rotation axis with 100:1

transmission for highest

stability

» high-frequency spindle with up to 100.000 rpm

» cooling system for wet processing (optional)

» cooling vent integrated into spindle holder

» suction with closed lid for optimized absorbing

» automatic 10-times direct tool changer

» tools with 3 mm shaft

» integrated high-precision tool length sensor

» automatic air pressure control

» established blank holder for blanks with a diameter of

98,5 mm

» 115 V/230 V versions

» compressed air consumption approx. 60 l/min

(min. 6 bar)

» weight: 120 kg

» dimensions: 650 x 670 x 738 mm (w x h x d)

22

The CORiTEC 440i of imes-icore is an established milling system spe-

cialized for dry milling for years. The compact desktop machine offers

you the flexibility to process different materials or different material

heights in one throughput with two blank holders. Up to 90 units wit-

hout a blank change are possible with one mouse click. The used high-

performance controller with powerful brushless 200W AC motors in all

linear axes allows an extremely fast machining with high dynamic on

optimized precision and quality.

The new user interface “Remote DENTAL 2.0“ elates with easiest opera-

ting. With only one mouse click you reach perfect milling results. The

fully automated 8-times tool changer allows a complete placement with

all necessary tools for all materials. Thanks to the real 4 axes operation,

it is possible to process undercuts and different insert directions for

perfect precision and fitting.

The CORiTEC 440i is the specialist for the manufacturing of all es-

sential dental materials in dry milling like zirconium oxide, aluminium

oxide, PMMA, wax or CoCr. The equipment is especially adapted for the

entrance into the dental CAD/CAM production with a high level stan-

dard of your zirconium oxide or other materials.

Also it is suitable for the connection into your milling center to cover

the ever growing market on zirconium oxide constructions.

CORiTEC 440i

ergonomic swinging hood

CORiTEC 440i

double blank holder

23

MILL CoCr instead of sintering!

Applications

Processing of all relevant dental materials in dry proces-

sing with 4 axes up to 16 units

» zirconium oxide, aluminium oxide

» resins like PMMA/composite

» wax

» CoCr (optional)

Highlights

» due to the specialization of the CORiTEC 440i on dry

milling you expect perfect milling results with highest

precision and fitting

» the integrated high-performance controller guarantees

highest dynamic and speed on optimized precision

» the fully automatic 8-times tool changer including

automatic tool length control allows the complete

tool assembly for all usable materials

» tool lifetime controller with report

» automatic tool breakage control

» automatic tool change after wear-out

» night-mode: After successful processing the software

will shut down automatically

» undercut-processing with processing in different

insertion directions

» up to 90 units possible without changing the blank

» incl. control-PC based on Windows with preinstalled

control software “Remote DENTAL 2.0”

» automatic control of the suction unit

» tri-color LED interior lightning

» optional with suitable table

Technology

» rigid, industrial, heavy duty steel/aluminium table

top design

» swinging hood with integrated gas spring for ergono-

mic opening and closing

» real 4 axes processing (NC-contolled)

» high-performance servo controller in combination

with powerful 200W-AC motors

» rotation-axis with 100:1 transmission for highest

stability

» two blank holders

» high-frequency spindle with up to 60.000 rpm

» suction with closed lid for optimized absorbing

» automatic 8-times direct tool changer

» tools with 6 mm shaft

» integrated high-precision tool length sensor

» automatic air pressure control

» established blank holder for blanks with a diameter of

98,5 mm

» 115 V/230 V versions

» compressed air consumption approx. 60 l/min

(min. 6.0 bar)

» weight: 150 kg

» dimensions: 730 x 820 x 820 mm (w x h x d)

24

TThe CORiTEC 450i of imes-icore offers you complete flexibility in ma-

chining of all essential materials in 5 axes simultaneous processing.

Choose this way into a safe future with this high-end desktop machine

of imes-icore:

Shall it be the conventional processing of crown and bridge construc-

tions or complex geometry like abutments, removable partials or the

milling of tooth models, CORiTEC 450i leaves nothing to be desired!

These precise milling results are enabled through a high-performance

servo controller for 5 axes simultaneous processing with powerful

200W-AC motors in all linear axes as well as the compact rotation swin-

ging unit. With the extension to wet processing it is also possible to

process materials like glass ceramics/lithium disilicate or titanium.

With the CORiTEC 450i you acquire a system with accomplished flexibi-

lity on the highest level standards in precision and dynamic.

The new user interface “Remote DENTAL 2.0“ elates with easiest opera-

ting. With only one mouse click you reach perfect milling results. The

fully automated 12-times tool changer allows a complete placement

with all necessary tools for all materials.

Optionally, the CORiTEC 450i can be connected to a 6- to 20-times

blank magazine. Therefore, the CORiTEC 450i is adapted to enter the

digital dental technology as well for milling centers with additional

standards on high unit output.

Applications

Processing of all relevant dental materials with 5 axes simultaneous

processing on every kind of indication

» zirconium oxide, aluminium oxide, PMMA, composites, resins, wax

» CoCr (optional), glass ceramics, feldspar, lithium disilicate and

titanium (optional)

» teeth models, surgical guides, removable partials

CORiTEC 450i

CORiTEC 450i

milling of CoCr bar

milling of Zr

25

Processing center with automation

Highlights

» 5 axes simultaneous processing with three linear axes

and one rotation swinging unit offers full flexibility

wet and dry processing allow the machining of all

essential dental materials

» the integrated high-performance controller guaran-

tees highest dynamic and speed on optimized

precision

» the fully automatic 12-times tool changer including

automatic tool length control allows the complete

tool assembly for all usable materials

Technology

» rigid, industrial, heavy duty steel/aluminium table

top design

» swinging hood with integrated gas spring for ergono-

mic opening and closing

» 5 axes simultaneous processing

» high-performance servocontroller in combination

with powerful 200 W motors

» incl. a compact high-class control-PC in a modern

design based on Windows

» modern 19” TFT display

» high-frequency spindle with up to 60.000 rpm

» wet processing with cooling liquid circuit (optional)

» blank magazine for up to 20 blanks (optional)

» automatic 12-times direct tool changer

» integrated high-precision tool length sensor

» automatic air pressure control

» established blank holder for blanks with a diameter of

98,5 mm

» 115 V/230 V versions

» compressed air consumption approx. 60 l/min

(min. 6.0 bar)

» weight machine: 180 kg

» weight blank magazine: 70 kg

» 730 x 820 x 820 mm (w x h x d) without blank

magazine

» 2150 x 1770 x 920 mm (w x h x d) with blank magazine

and machine table

26

The CORiTEC 550i of imes-icore offers you highest productivity in wet

and dry milling with 5 axes simultaneous processing.

The CORiTEC 550i fascinates with its multifunctional production sys-

tem and is made for laboratories where the metal production plays an

important role. Laboratories which have requirements on high effici-

ency 5 axes processing will find the ideal production center with the

CORiTEC 550i.

The new axes system with high-precision massive granite construction

warrants highest stability and smoothness. Hence, you can expect best

milling results also on difficult millable materials like CoCr and tita-

nium. Thanks to the automatic 16-times tool changer and two blank

holders with NC-controlled automatic rotation unit, it is possible to

realize up to 90 units without changing a blank.

The powerful high-frequency spindle with 1,6 kW and 80.000 rpm as-

sures highest precision and longest tool lifetime. The CORiTEC 550i is

predestined for manufacturing of all essential dental materials in dry

and wet processing like zirconium oxide, aluminium oxide, PMMA, wax,

CoCr alloys, glass ceramics, feldspar, lithium disilicate titanium and

titanium alloys.

Applications

Manufacturing of all relevant dental materials with 5 axes simultaneous

wet and dry processing

» zirconium oxide, aluminium oxide

» resins like PMMA/composite or wax

» CoCr alloys

» titanium and titanium alloys

» glass ceramics, feldspar, lithium disilicate

» teeth models, surgical guides, removable partials

» model milling

» processing of 98 mm blanks and CAD/CAM blocks

CORiTEC 550i

CORiTEC 550i

high-quality manufacture

ergonomical hood

27

Highlights

» 5 axes simultaneous processing with three linear

axes, one rotation and one swinging axis

» wet and dry processing allow to process all

essential dental materials and indications

» the massive granite construction of the whole axis

system warrants highest precision and running

smoothness

» complete tool management: 16-times fully automated

tool changer, tool change after wear-out, tool lifetime

control, tool measurement, breakage control

» integrated control-PC based on Windows

» up to 90 units of one material without changing a blank

or 45 units with two different materials without

changing a blank

Technology

» massive steel-granite construction for highest

precision

» swinging hood

» high-end servo controller for fastest processing tech-

nology

» 5 axes simultaneous processing

» powerful AC–servo motor drives in all axes

» two blank holder in an integrated cooling liquid basin

» powerful 1,6 kW high-frequency spindle with up to

80.000 rpm and 3-times hybrid ball bearings

» blow and water cooling system integrated in the spindle

nose

» integrated cooling system with pump in a stainless

steel basin and filter device

» suction device and cooling system

» tools with 6 mm shaft

» fully automatic 16-times direct tool changer

» integrated high-precision tool length sensor

» integrated control-PC based on Windows

» control system i8000

» 115 V/230 V versions

» air consumption appox. 180 l/min (min. 6.0 bar)

using air cooling for milling spindle

» air consumption approx. 60 l/min (min. 6.0 bar)

using a water cooling system for the milling spindle

» weight: 750 kg

» dimensions: 1180 x 1760 x 920 mm (w x h x d)

High-Precision! Massive! 550i!

28

The CORiTEC 750i of imes-icore is the ultimate high-performance ma-

chine for the dental processing in dry and wet milling with 5 axes

processing. The CORiTEC 750i amazes by its outstanding precision and

productivity. It is the high-end system for laboratories with premium

standards in quality, productivity and flexibility.

The massive natural stone construction and the backlash-free high pre-

cision linear motor drives with “Heidenhain“ length measuring system

assure you outstanding precision and dynamic on all materials. Fur-

thermore, the powerful 1,6 kW high-frequency spindle with 6 mm shaft

ensures extreme running smoothness of the tool.

Thanks to the fully automatic 16-times tool changer and four working

stations, up to 180 units of a material can be realized without changing

a blank. The assembly of different materials is possible, as well.

Therefore, the CORiTEC 750i is designed for the high productive manu-

facturing of all possible indications in a 24 hour operation cycle.

Applications

Processing of all relevant dental materials with 5 axes simultaneous wet

and dry manufacturing in highest precision and speed.

» zirconium oxide, aluminium oxide

» resins like PMMA/composite or wax

» CoCr alloys

» titanium and titanium alloys

» glass ceramics, feldspar, lithium disilicate

» teeth models, removable partials, surgical guides

CORiTEC 750i

milling of CoCr

CORiTEC 750i

four blank holders

29

» integrated cooling system with a pump in a stainless

teel basin and filter device

» suction device

» tools with 6 mm shaft

» fully automatic 16-times direct tool changer

» integrated high-precision tool length sensor

» integrated control-PC based on Windows

» control system i8000

» 3 phase/380V version

» air consumption approx. 180 l/min (min. 6.0 bar)

using air cooling for milling spindle

» air consumption approx. 60 l/min (min. 6.0 bar)

using water cooling for milling spindle

» weight: 1200 kg

» dimensions: 1400 x 1220 x 2000 mm (w x h x d)

Highlights

» 5 axes simultaneous processing with three linear

axes, one rotation and one swing axis

» wet and dry processing afford the production of all

essential dental materials for every type of indication

» the massive granite construction of the whole axis

system warrants highest precision and running

smoothness

» linear motor drives with “Heidenhain“ length measuring

system assure highest precision and dynamic

» complete tool management: 16-times fully automated

tool changer, tool change after wear-out, tool lifetime

control, tool measurement, breakage control

» integrated control-PC based on Windows

» up to 180 units of one material without changing a

blank

» preferred in larger laboratories and milling centers as

a dynamic high-performance production system for

5 axes processing

Technology

» high-strength and restraining granite construction

made of massive grinded natural stone in industrial

precision with steel base chassis

» high-end servo controller for fastest processing

technology

» closed swinging hood

» powerful digital linear motor drives in all linear axes

with integrated “Heidenhain“ length measurement

system

» 5 axes simultaneous processing

» four autonomous working stations

» powerful 1,6 kW high-frequency spindle with up to

80.000 rpm and 3-times hybrid ball bearings

» blow and water cooling system integrated into spindle

holder

Premium class for milling centre

30

On the one hand the CORiTEC iCompVAC offers a high-performance

suction with brushless turbine, on the other hand it consists of an oil

free compressor that allows the direct operation of the CORiTEC machi-

nes 140i, 240i, 250i, 440i and 450i.

The control is automatic when starting and ending the milling program

in order to ensure an autarkic milling overnight or during the weekend.

Additionally, the CORiTEC iCompVAC can be switched on manually so

that it can be used for cleaning the machine, as well. The large integra-

ted filter bag allows maximum filtering of fine dust and hence does not

need to be replaced often.

The CORiTEC iVAC eco+ is the “little sister“ of CORiTEC iCompVAC. The

only difference is that it does not consist of the integrated compressor.

This high-performance suction unit is very compact and quiet-running

due to the brushless turbine. Furthermore, the dust will be piped into

special developed filter bags which meets the required filtering rate for

e.g. zirconium oxide. A downstream HEPA filter avoids the loosing of

remaining fine dust. Hence, the CORiTEC iVAC eco+ can be directly used

in the working area of the laboratory.

The sintering furnaces CORiTEC iSINT HT-S and iSINT HT are designed

for everyday sintering processes due to its 4-6 MoSi2 heating elements.

By the steady temperature distribution in the combustion chamber, a

homogeneous shrinkage of zirconium oxide restorations is ensured and

hence best fitting results are reached especially for large-span bridges

and bars.

The microprocessor-controlled temperature regulation allows a sinte-

ring process taking less than four hours in the “Speed“ version. The

emergency cooling function secured by accumulator prevents device

damage due to blackout. Hence, 25-60 units can be sintered up to two

levels up to maximum 1650°C without any problem.

Suction units & Sintering furnaces

iCompVAC

iVAC eco+

iSINT HT-S/HT

integrated HEPA filter zirconium frameworks on sintering pearls

31

A further suction unit is the CORiTEC iVAC pro. Due to

its automatic self-cleaning function of the filter, the

iVAC pro is nearly maintenance-free. Hence, it is not

necessary to replace the filter bag regularly. Merely the

dust collecting tray needs to be evacuated within a few

minutes.

The suction units of imes-icore are absolute low-mainte-

nance and characterized by a long life. They have been

especially developed for the needs of the machines and

the dental materials.

All suction units are designed for a permanent and every-

day use upon highest requirements. They are controlled

automatically by the machine system.

The sintering furnaces that are available as “Speed“ ver-

sion allow heating and cooling rates up to 70°C/min.

These special speed heating elements consisting of

MoSi2 avoid the green coloring of the zirconium oxide

restorations already with the first sintering process.

The furnaces offer for pre-colored works an aired heating

which can be perfectly used for unsupervised air drying

programs.

Hence, the early malfunction of the heating elements due

to remaining humidity is avoided.

A further criteria for perfect fitting restorations is the

homogeneously tempered combustion chamber which is

suitable for sintering highly translucent material up to a

maximum temperature of 1650°C.

Convincing suction technologies Sintering at the highest stage!

32

It is our duty to provide exclusively highest quality materials and mil-

ling tools that are optimized for all imes-icore machines in order to

offer you maximum quality together with the CORiTEC machine system.

We offer you:

CORiTEC Zr Blanks + CORiTEC Zr transpa Blanks

» isostatic pressed zirconia blanks and transparents with the following

features

» fully ceramic material for highest aesthetic claims

» extremely high bending strength values

» perfect fitting of all restorations up to large-span bridges

» unlimited biocompatibility

» age-resistant

» aesthetics milled from solid blanks: fully anatomical and fully

ceramic

The increased light transmission and optimal microstructure for a spe-

cial infiltration behavior coloring-liquids provide exclusive and fully

anatomical results.

PMMA blanks in 16 teeth colors

» fixing for the interim solution or for the long time interim solution

» excellent mechanical properties

» excellent milling behavior

» aesthetic color effect

» high biocompatibility

» very good suitability for allergy sufferers

» simple and fast mechanical processing in the laboratory

» temporary solutions, e.g. for the implantology

Materials

prefabricated abutments and crowns

round blanks in 98,5 mm

CAD/CAM blocks

33

CORiSHADE solution is indicated for coloring non

sintered zirconium dioxide frames for dental restorations

» aesthetic color effects

» basic colors (A, B, C, D) can be adjusted by simply

diluting according to the individual needs

» covering the entire spectrum of natural teeth

» no white gingival borderline

» perfect coloring of all kinds of constructions made of

CORiTEC Zr frameworks

CORiTEC Wax Blanks

» excellent milling behavior also in combination with

modeling wax

» cauterisation without remains

» grey coloring for optimal contrast behavior

» very high economic efficiency

CORiTEC Training Blanks

» excellent milling behavior

» perfectly suitable for milling tests, calibration bodies

and for checking the accuracy of fit

CORiTEC CoCr Blanks

» excellent mechanical properties

» excellent thermal properties

» perfect precision of all restorations up to large-span

bridges

» high biocompatibility

» high corrosion resistance

» bridges up to 16 units

» full bridges and VMF technology

» crowns and telescoping technology

» primary/ secondary crowns

» implant restorations

» adhering bridges

CORiTEC Ti Blanks (grade 2 and grade 4)

» excellent mechanical properties

» high hardness and bending strength values

» perfect accuray of fit of all restorations up to large-

span bridges

» high corrosion resistance

» single crowns in anterior and lateral tooth area

» span up to three units in anterior tooth area

» span up to three units in lateral tooth area

» bridges up to 16 units

» perfectly suitable for large-span implant and bar

restorations

Integrated solutions for...

With the machines of imes-icore it is possible to mill

materials from our technology partners.

Especially through the developed high-precision strate-

gies the following materials can be milled on the ma-

chine.

Following materials are supported:

» VITABLOCS® Mark II, TriLuxe, TriLuxe forte

» VITA PMMA blocks: VITA CAD-Temp® monoColor,

VITA CAD-Temp® multiColor

» VITA ENAMIC®

» Cercon® ht

» pritidenta® priti®crown:

» preform blanks of nt-trading®

Precision with excellent materials!

grinding of glass ceramicsCoCr implant bars with special tool

34

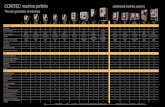

0,6 / 3,0 mmitem No.: 526009 0603

1,0 / 3,0 mmitem No.: 526009 1003

2,5 / 3,0 mmitem No.: 526009 2503

0,6 / 3,0 mmitem No.: 526016 0603

1,0 / 3,0 mmitem No.: 526018 1003

1,5 / 3,0 mmitem No.: 526000 1503

1,5 / 3,0 mmitem No.: 526001 1503

2,0 / 3,0 mmitem No.: 526018 2003

3,0 / 3,0 mmitem No.: 526018 3003

1,0 / 3,0 mmitem No.: 526016 1003

2,5 / 3,0 mmitem No.: 526016 2503

2,5 / 3,0 mmitem No.: 526013 2503

1,0 / 3,0 mmitem No.: 526013 1003

CORiTEC Zr / PMMA / NC / WaxThe specialized cut shapes ensure best sur-

faces even with very thin edges. They are de-

signed for milling in zirconium oxide, PMMA,

nano-composite and wax up to 25 mm blank

height and available in the diameters 2,5 mm

and 1,0 mm.

Additionally, a fissure tool is available with

a radius of 0,3 mm which ensures a detailed

milling result.

These tools are designed for 3,0 mm collets

and hence usable for the following machine

types:

CORiTEC 140i, 240i, 250i, 340i, 440i and 450i.

CORiTEC CoCr / Ti

The specialized coating as well as the parti-

cular cut shapes are designed for the heavy

duty milling in CoCr and titanium. They are

usable for a blank height up to 15 mm and

suitable for dry and wet milling . In additi-

on to the standard tools with the diameters

3,0 mm, 2,0 mm and 1,0 mm, two special mil-

ling tools are available, as well. These tools

have been especially developed for the mil-

ling of abutments and restorations in order

to ensure an ideal screw seating and precise

fitting in the implant range. They can be used

for zirconium oxide, PMMA, wax and nano-

composite.

The milling tools are designed for 3,0 mm col-

lets and hence usable for the following ma-

chine types:

CORiTEC 140i, 240i, 250i, 340i, 440i and 450i.

CORiTEC Zr / Al - diamond

The highly abrasion-resistant specialized

coating of diamond nano particles provides

an enormous lifetime of at least 250 zirco-

nium units! These high-performance tools

have been developed for zirconium oxide and

aluminium oxide up to 25 mm blank height

and hence universally usable. In addition to

the milling tools with the diameters 2,5 mm

and 1,0 mm, a fissure tool is available with

a radius of 0,3 mm which ensures a detailed

milling result. These tools are designed for

3,0 mm collets and hence usable for the

following machine types:

CORiTEC 140i, 240i, 250i,

340i, 440i and 450i.

CORiTEC glass ceramics

The special abrasion-resistant galvanic dia-

mond coating provides best surface quality

with long lifetime. Especially designed for

glass ceramics and feldspar ceramics up to 15

mm block height and available in the diame-

ters 2,5 mm, 1,0 mm and 0,6 mm.

These grinding tools are designed for 3,0 mm

collets and hence usable for the following ma-

chine types:

CORiTEC 140i, 240i, 250i, 340i, 440i and 450i.

Milling & Grinding tools

35

First-class precision by excellent milling tools!

0,6 / 6,0 mmitem No.: 526009 0606

1,0 / 6,0 mmitem No.: 526011 1006

2,0 / 6,0 mmitem No.: 526011 2006

3,0 / 6,0 mmitem No.: 526011 3006

1,0 / 6,0 mmitem No.: 526009 1006

2,5 / 6,0 mmitem No.: 526009 2506

0,6 / 6,0 mmitem No.: 526019 0606

1,0 / 6,0 mmitem No.: 526019 1006

2,5 / 6,0 mmitem No.: 526019 2506

1,0 / 6,0 mmitem No.: 526013 1006

2,5 / 6,0 mmitem No.: 526013 2506

CORiTEC CoCr / Ti

The specialized coating as well as the par-

ticular cut shapes are designed for the hea-

vy duty milling in CoCr and titanium. They

are usable for a blank height up to 20 mm,

suitable for dry and wet milling and availa-

ble in the diameters 3,0 mm, 2,0 mm and

1,0 mm.

The milling tools are designed for 6,0 mm

collets and hence usable for the following

machine types:

CORiTEC 440i, 450i, 550i and 750i.

CORiTEC Zr / PMMA / NC / Wax

The specialized cut shapes ensure best sur-

faces even with very thin edges. They are

designed for milling in zirconium oxide,

PMMA, nano-composite and wax up to 25

mm blank height and available in the dia-

meters 2,5 mm and 1,0 mm.

Additionally, a fissure tool is available with

a radius of 0,3 mm which ensures a detailed

milling result.

These tools are designed for 6,0 mm collets

and hence usable for the following machine

types:

CORiTEC 440i, 450i, 550i and 750i.

CORiTEC universal

These special tools have been developed

separately for the milling of abutments and

implant restorations in order to ensure an

ideal screw seating and precise fitting in the

implant range.

They can be used for zirconium oxide,

PMMA, wax and nano-composite and are

available as two/four-flute cutter.

CORiTEC glass ceramics

The special abrasion-resistant galvanic dia-

mond coating provides best surface quality

with long lifetime. Especially designed for

glass ceramics and feldspar ceramics up to

15 mm block height and available in the

diameters 2,5 mm and 1,0 mm.

Additionally, a fissure tool is available with

a radius of 0,3 mm which ensures a detailed

milling result.

These grinding tools are designed for

6,0 mm collets and hence usable for the fol-

lowing machine types:

CORiTEC 440i, 450i, 550i and 750i.

CORiTEC Zr / Al - diamond

The highly abrasion-resistant specialized

coating of diamond nano particles provi-

des an enormous lifetime of at least 250

zirconium units! These high-performance

tools have been developed for zirconium

oxide and aluminium oxide up to 25 mm

blank height and hence universally usable.

Additionally, a fissure tool is available

with a radius of 0,3 mm which ensures a

detailed milling result.

These tools are designed for 6,0 mm col-

lets and hence usable for the following

machine types:

CORiTEC 440i, 450i, 550i and 750i.

1,5 / 6,0 mmitem No.: 526002 1506

1,5 / 6,0 mmitem No.: 526000 1506

1,5 / 6,0 mmitem No.: 526001 1506

36

Precise milling of models

» pinned and sawn or as dies-ditched model

» patented model pin plates facilitates direct applica-

tion by magnet

» optimized model material with high edge stability and

attention to detail

» short milling times

Grinding and milling of block materials

» production of all materials in the range of wet

grinding (e. g. glass ceramics & lithium disilicate)

» additional adapter appropriate for nano-composite

blocks

» crowns, onlays, inlays, veneers, bridge frameworks

etc.

Production of bite splints

» modeling and milling of bite splints, sport splints and

nightguards

» short milling times, low material costs (available in

all 16 colors), high accuracy of fit, almost polished

surfaces

Removable partials

» modeled in a few minutes

» cauterizing in WAX/PMMA or directly usable by flexible

resins

» manufacturable on all imes-icore blank machines

Functions & Features

37

Innovative applications and features

pritidenta® priti®crown

» considerable cost and time saving as compared to

conventional methods

» suggestion, selection and customization of the perfect

crown chosen by the dental library of the CAD software

» individual completion by automatic adjustment in the

CAM software

Prefabricated abutments

» reduced milling time (20 – 30 min per abutment)

» constant precision and reproduction for all well-estab-

lished implant systems

» simultaneous milling of six abutments without

changing process

» no use of special tools

Implant-supported or screw-retained indications

» scan bodies and appropriate libraries of all well-esta-

blished systems are integrated

» highest accuracy of fit by newly developed scanner

technologies and milling strategies of the

CAM software

» tension-free fitting also with respect to larger spans

» cost-effective special tools

38

Upgrades

During the development of the new systems with new technologies, imes-icore also offers to upgrade your system

to the newest technology, if possible. Get in contact with us for technical clarification, if you will have a specific,

not listed ,request.

Remote DENTAL 2.0: For all existing machine types with the known

control software Remote. Machine types: 240i, 340i, 440i, 450i, 2100,

4030.

Advanced features, e. g. replacement tool function or auto shut down

make the control software simpler, safer and better! Please ask for our

information flyer!

iCAM V4.6: For all machine types of imes-icore! Expand your possibi-

lities of your existing milling system! Read more on page 10 and 11.

Quick-release-ring with nonius: For all machine types of imes-icore!

Save 60 seconds at each blank change! The nonius scale with its 1/360

degree marks allows advanced features with iCAM V4.6!

Adapter for CAD/CAM blocks: Expand the possibilities of your milling

machine with the processing of CAD/CAM block material. The adapter is

available for every machine type of imes-icore.

Decide on your own which CAD/CAM material meets your requirements

best.

Prefabricated abutments: Produce individual abutments with perfect

fit and precision! Do not compromise with implant-supported restora-

tions with the new adapter system of imes-icore.

39

Sales & technology advice

Michael Pachowski:

+49 (0) 6672 898-467

Sebastian Henkel:

+49 (0) 6672 898-263

Michael Frohnapfel:

+49 (0) 6672 898-464

Material advice

+49 (0) 6672 898-465

Technical support

+49 (0) 6672 898-469

Completely local

We offer the complete solution: Transportation, installa-

tion and training right at your location. This is the most

elegant solution. Our service technicians deliver on time,

your CAD/CAM system is installed properly and your staff

is trained accordingly.

In-House

Of course, we offer internal trainings that take place at

regular intervals. If we could arouse your interest we

would like to arrange an appointment with you.

Service & Support

Our highly qualified service team is using future-oriented

support opportunities like remote access via Internet.

Hence, common problems can be blanksussed together,

e.g. explanation of the user surface, controlling the para-

meters of the milling machine, diagnosing problems and

much more.

According to our experience, most questions and prob-

lems can be solved remotely by applying this method.

imes-icore offers convenient service agreements inclu-

ding the important machine and system maintenance!

A system maintenance directly from the first hand of the

manufacturer guarantees a long lifetime of your milling

system at constant high precision!

It is our purpose to assure a trouble-free, continuous

operation of your system.

Reliable customer service!

imes-icore sets new standards with its future-oriented technology. The optimal

product line of equipment, software and consumable materials combined with

ambitious service and support guarantee highest productivity and quality.

imes-icore. Makes your smile perfect!

imes-icore GmbHIm Leibolzgraben 16D-36132 Eiterfeld

Fon: +49 6672 898-228Fax: +49 6672 898-222

Hamburg

Bremen Berlin

Hannover

Kassel

A7

A10

A2

A9

A4

A5

A44

A7

LeipzigDortmund

Eiterfeld

KölnFulda

Frankfurt

Saarbrücken

Stuttgart

Nürnberg

München