Adsorption of carbon dioxide on organically functionalized SBA-16

-

Upload

jianwen-wei -

Category

Documents

-

view

215 -

download

1

Transcript of Adsorption of carbon dioxide on organically functionalized SBA-16

Microporous and Mesoporous Materials 116 (2008) 394–399

Contents lists available at ScienceDirect

Microporous and Mesoporous Materials

journal homepage: www.elsevier .com/locate /micromeso

Adsorption of carbon dioxide on organically functionalized SBA-16

Jianwen Wei, Jingjin Shi, Hua Pan, Wei Zhao, Qing Ye, Yao Shi *

College of Environmental and Resource Science, Zhejiang University (Xixi Campus), Hangzhou 310028, PR China

a r t i c l e i n f o

Article history:Received 4 January 2008Received in revised form 27 February 2008Accepted 23 April 2008Available online 6 May 2008

Keywords:SBA-16Particle sizeHydrolysisCarbon dioxideAdsorption

1387-1811/$ - see front matter � 2008 Elsevier Inc. Adoi:10.1016/j.micromeso.2008.04.028

* Corresponding author. Tel.: +86 571 88273591; faE-mail address: [email protected] (Y. Shi).

a b s t r a c t

The adsorption of CO2 on SBA-16 functionalized with N-(2-aminoethyl)-3-aminopropyltrimethoxysilane(AEAPS) was investigated by DSC–TGA at 333 K. Hydrolysis of the calcined SBA-16 improved the adsorp-tion performance. The functionalized samples prepared with hydrolyzed supports showed superioradsorption capacity and rate to those prepared with calcined supports. The adsorption capacity and rateincreased with decrease in the particle size of samples. The samples with fine particle size exhibited goodaccessibility and high surface area for the grafting agent. The maximum adsorption capacity of CO2 at333 K was 0.727 mmol g�1 for the functionalized SBA-16 (hydrolyzed SBA-16 as support) with the parti-cle size range of 0.124–0.15 mm. The relationship between adsorption capacity and amine content isY = 0.3855X�0.4397 where Y is adsorption capacity (mmol g�1) and X is amine content (mmol-N g�1).

� 2008 Elsevier Inc. All rights reserved.

1. Introduction

Considerable attention has been attracted in reducing green-house gases emissions, especially for CO2 capture and storage [1]resulted from fossil fuel combustion. Up to date, the chemicaland physical methods were widely used for separation of CO2 fromgas mixtures. Adsorption is one of the promising methods thatcould be applicable to separate CO2. Recently, adsorption and sep-aration of CO2 over a range of porous solid adsorbents have beenwidely investigated [2–9].

Microporous materials such as zeolites with high surface areasand specific sites of adsorption are most common physical adsor-bents [2]. However, gas diffusion in these small pore systems is dif-ficult, therefore adsorption rate may be inhibited [10]. On the otherhand, zeolites are difficult to regenerate entailing low productivityand high costs. Therefore adsorbents prepared with ordered meso-porous silicas such as MCM-41, MCM-48, SBA-15 and SBA-16 havebeen of interest [2,11–15].

Ordered mesoporous silicas are ideal solid supports because oftheir uniform and large pores, tunable pore sizes, high surfaceareas as well as a large number of highly dispersed active sites(the hydroxyl groups) on the pore walls and surface [13]. The hy-droxyl groups are essential for surface modification because onlythe silanol can anchor the organic molecules to the silica surfaceto form the functional groups. However, the calcining step in pre-paring mesoporous silica dehydrates the silica surface and removesmost of the silanols, which results in poor surface modification[16].

ll rights reserved.

x: +86 571 88273693.

In the case of functionalized ordered mesoporous silicas for CO2

adsorption, Harlick and Sayari [17] reported that the adsorptionperformance was directly related to the amine content and gavethe optimal quantity of aminosilane added to modify the mesopor-ous silica. Hiyoshi et al. [18] found surface density of amine onSBA-15 is an important factor for the reaction of CO2 with amineimmobilized on the mesoporous support SBA-15. However, the ef-fect of the particle sizes of the adsorbents on the functionalisationof the mesoporous silica and on the adsorption performance hasnot yet been reported. In fact, the particle sizes of the adsorbentsare equally important because of the adsorption dynamics. Onthe other hand, there are few reports about the effects of hydroly-sis on the functionalisation and adsorption performance of SBA-16.

SBA-16 is an ideal mesoporous silica support for potential appli-cations, due to its hydrothermally stable cubic cage structure withmultidirectional and large pore systems allowing good accessibil-ity for functionalization and adsorption [19,20]. In this work, thefunctionalized SBA-16 ordered mesoporous silicas were synthe-sized. Some of the calcined silicas were hydrolyzed before thefunctionalisation step since calcination reduced the amount ofthe silanol groups. Functionalisation was used to graft AEAPS.The effects of hydrolysis and adsorbents particle size on theadsorption performance were investigated at 333 K as the temper-ature of flue gas after desulphurization is mostly below 333 K.

2. Experimental

2.1. Preparation of SBA-16 support

SBA-16 support was synthesized using tetramethoxysilane(TMOS, Aldrich) as silica source and polyethyleneglycol–block-

J. Wei et al. / Microporous and Mesoporous Materials 116 (2008) 394–399 395

polypropyleneglycol–block-polyethyleneglycol (PEO106PPO70PEO106 =F127, Aldrich) with an average molecular weight of 12600 as struc-ture directing agent [10,21]. TMOS was mixed through stirringwith n-butanol (Sinopharm Chem. Reagent Co.) before the surfac-tant F127 was added. The mixture was heated to dissolve F127(T = 313 K), then hydrochloric acid was added, finally vigorousstirring was carried out magnetically at room temperature. Hydro-chloric acid with a pH value of 2 was prepared by adding a certainamount of HCl (36 wt%, Hangzhou Chem. Reagent Co.) to distilledwater. All the chemicals were used as received without furtherpurification. The mass ratio of the mixture: F127:n-butanol:HCl/H2O:TMOS were 1:0.428:1.58:2.29. The typical synthesis proce-dure used 4.36 g F127, 1.87 g n-butanol, 6.89 g HCl/H2O and9.98 g TMOS. Stirring was continued until gelification started. Theformed clear gel was aged three days at room temperature, thencalcined in air at 823 K for 6 h with a heating rate of 2 K/min toremove the structure directing agent. Some of the calcined samplewas boiled in distilled water at 370 K for 2 h, and then dried in398 K for 12 h in air.

2.2. Functionalisation with AEAPS

The functionalisation was carried out at 383 K. 8.5 cm3 of theAEAPS (Aldrich) was added into 50 cm3 dry toluene (HangzhouChem. Reagent Co.). The mixture was stirred for 5 min before 1 gof dried silica (sieved to 120–100, 100–80 and 80–60 meshes)was added. The ranges of the particle size were simplified as themiddle values: 0.137 (0.124–0.15), 0.164 (0.15–0.178) and 0.214(0.178–0.25) mm, respectively. The system was held for 24 h withvapor reflux under N2 atmosphere with a flow rate of120 cm3 min�1. The functionalized silica was washed with toluene(total 200 cm3) three times, dried in a natural convection oven for12 h at 398 K and subsequently stored in capped vial until use. Thegrafted samples were denoted as Calcined-N for the calcined sup-port and Hydrolyzed-N for the hydrolyzed silica support.

The same quantity of AEAPS was added to each support andfunctionalization was carried out under the same conditions, suchas temperature and time.

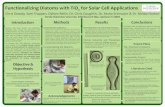

Fig. 1. Low angle X-ray diffraction pattern of the SBA-16 support.

2.3. Characterization of the samples

X-ray diffraction (XRD) measurements were performed on aRigaku powder diffractometer (Rigaku, Japan) with Cu Ka radia-tion. The tube voltage was 45 kV, and the current was 40 mA.The XRD diffraction patterns were taken in the 2h range of 0.5–10� at a scan speed of 2� min�1.

Thermal gravimetric analysis and differential thermal gravimet-ric analysis (TGA/DTG) was carried out with a DSC–TGA (SDT Q600,TA Instruments) under dynamic N2 atmosphere.

N2 adsorption/desorption was measured by BELSORP measuringinstruments (BELSORP-mini II, Inc., Japan). Each sample was de-gassed at 413 K under nitrogen flow for 4 h prior to measurement.The nitrogen adsorption/desorption data were recorded at the li-quid nitrogen temperature (77 K). The surface areas were calcu-lated using the Brunauer–Emmett–Teller (BET) equation. Thepore size distributions were determined by Barrett–Joyner–Halen-da (BJH) method. The total pore volume was calculated from theamount of adsorbed N2 at P/P0 = 0.99.

Elemental analysis was carried out with Flash EA1112 (ThermoFinnigan Inc. Italy) for amine content of the functionalized SBA-16.The amine content was defined as the number of nitrogen atomsper gram of the functionalized SBA-16.

The samples were pressed into thin wafers with KBr to obtainthe FTIR spectra of SBA-16 and AEAPS-modified SBA-16 withNexus-670 (Nicolet Co., USA).

2.4. Adsorption of carbon dioxide

Carbon dioxide adsorption was characterized by DSC–TGA (SDTQ600, TA Instruments). The typical samples weights loaded into a0.05 cm3 platinum sample pan used for both adsorption and regen-eration were about 10 mg. Using the balance, the response ofweight and heatflow of the functionalized SBA-16 to the elapseof time in the mixture was recorded. Each sample was first regen-erated (heated at 423 K) in the flow of N2 (120 cm3 min�1) beforeadsorption, then cooled to 333 K prior to exposure to the CO2/N2

mixture (15V%) for about 50 min. The adsorption capacities andenthalpies were calculated based on the DSC–TGA weight gainand the dry mass of the material versus time.

3. Results and discussion

3.1. SBA-16 support

The X-ray diffraction pattern of the SBA-16 support is displayedin Fig. 1. The XRD reflection peaks are well resolved and in goodagreement with the reported patterns of SBA-16 materials [20,22].

3.2. Characterization of the modified SBA-16

The results of the TGA/DTG mass loss profile of the functional-ized SBA-16 and the SBA-16 support are shown in Fig. 2. Significantmass loss occurred when the functionalized SBA-16 was heatedfrom 25 to 700 �C. The sample of the functionalized SBA-16 dis-played a mass loss of about 10% from room temperature to130 �C whereas the SBA-16 support did about 5%. This can beattributed to the loss of physically adsorbed water. From 130 to700 �C the SBA-16 support displayed no obvious mass loss. Thefunctionalized SBA-16 showed minor mass loss up to 200 �C. Abovethis temperature, the mass loss of about 15% may be associatedwith the decomposition of the amine group on the functionalizedSBA-16. Therefore, the thermal stability temperature of the func-tionalized SBA-16 in N2 can be determined as about 200 �C. Be-sides, the amount of amine groups loaded on the SBA-16 can beestimated to be about 15% of the functionalized SBA-16(2.79 mmol-N g�1), which is in agreement with the elementalanalysis.

The N2 adsorption/desorption isotherms of the SBA-16 supportand functionalized SBA-16 are presented in Fig. 3. For both of theSBA-16 support and the functionalized SBA-16, the isotherms weretypical of type IV characteristic of mesoporous silica. However, theisotherms demonstrate a significant reduction in total pore volumeand mesopore volume in the functionalized SBA-16.

Fig. 2. TGA/DTG mass loss profile of (A) the SBA-16 support and (B) thefunctionalized SBA-16.

Table 1Characterization details for the SBA-16 support and functionalized SBA-16 (Hydro-lyzed-N)

Sample Surface area(m2 g�1)

Pore volume(cm3 g�1)

Particle size(mm)

Amine content(mmol-N g�1)

1 296 0.26 0.214 2.222 193 0.24 0.164 2.793 123 0.18 0.137 3.067 479 0.48 0.214 –

Note. Sample 7 is the SBA-16 support boiled for 2 h and not functionalized.

Table 2Characterization details for the SBA-16 support and functionalized SBA-16 (Calcined-N)

Sample Surface area(m2 g�1)

Pore volume(cm3 g�1)

Particle size(mm)

Amine content(mmol-N g�1)

4 282 0.26 0.214 2.105 190 0.25 0.164 2.296 144 0.17 0.137 2.597 479 0.48 0.214 –

Note. Sample 7 is the SBA-16 support boiled for 2 h and not functionalized.

396 J. Wei et al. / Microporous and Mesoporous Materials 116 (2008) 394–399

The surface area and pore volume are summarized in Tables 1and 2. It can be seen that the BET surface area of the SBA-16 sup-port is as large as 479 m2 g�1 and the pore volume is about0.48 cm3 g�1. After modification, the BET surface area and pore vol-ume decreased significantly. This was obviously caused by theamine grafted in the channels and surface. The conclusions con-sisted with the results of TGA/DTG.

Fig. 4 reveals the pore size distributions of the SBA-16 supportand the functionalized SBA-16. The pore size distributions wererelatively narrow, similar to the SBA-16 support itself, whichsuggested that the uniform pore size distributions were retained

Fig. 3. Typical N2 adsorption/desorption isotherms of (h) the SBA-16 support and(s) the functionalized SBA-16.

after the SBA-16 support was modified. The pore size distributionsof the functionalized samples with the different particle sizes werealmost identical, which was similar to the results of Hiyoshi et al.when the concentrations of modifying agents were the same[18]. The mean pore diameters of the functionalized SBA-16 were

Fig. 4. Pore size distributions of SBA-16 support and functionalized SBA-16. (A)Sample 1–3 are Hydrolyzed-N (B) sample 4–6 are Calcined-N; sample 7 is the SBA-16 support.

Fig. 5. The relationship between amine content and particle size of (h) Hydrolyzed-N and (d) Calcined-N. The particle sizes are the middle values of the ranges.

J. Wei et al. / Microporous and Mesoporous Materials 116 (2008) 394–399 397

smaller than that of the SBA-16 support (4.5 nm), indicating thatAEAPS was anchored on the pore walls of the SBA-16 support.

Elemental analysis was carried out to determine the amine con-tents of the functionalized samples. Amine contents of the sampleHydrolyzed-N are summarized in Table 1 as well as those of Cal-cined-N are summarized in Table 2. From Fig. 5 it was clearer thatAEAPS were more densely anchored on the surface of the sampleHydrolyzed-N than that of Calcined-N. The surface of the calcinedsample mainly consists of siloxane, and the surface siloxane can beeasily hydrolyzed to silanol by adsorption of water [23]. After boil-ing in water, more silanol groups were generated on the hydro-lyzed sample by hydrolysis for anchoring aminosilanes.

Fig. 5 shows the relationship between the amine contents of thesample Calcined-N and Hydrolyzed-N and the particle sizes. Theamine contents decreased with increase in the particle sizes of Cal-cined-N. In the case of Hydrolyzed-N, the similar results were ob-tained. The possible reason could be (1) AEAPS diffusion distance inthe pore tunnel with fine particle size was shorter than that ofcoarse size. (2) Fine particle sizes provide higher surface area thancoarse particle sizes and silanols generally. However, it can be seenin Tables 1 and 2 that that surface areas of the samples with fineparticle size are lower unusually than those with coarse particlesize. The reason is that the pore walls and surface of the samplesof fine particle size are grafted with more aminosilane than thoseof coarse particle size which has been proved by the elementalanalysis.

The FTIR spectra of the SBA-16 support and the functionalizedSBA-16 are displayed in Fig. 6. It reveals that the peaks are almost

Fig. 6. FTIR spectra of the SBA-16 supports and the functionalized SBA-16. (A)Calcined SBA-16 (B) Hydrolyzed SBA-16 (C) Functionalized SBA-16.

identical for the calcined sample and the hydrolyzed sample. Thearea of the peaks from 3740 to 3000 cm�1 due to the hydrogen-bonded silanol groups (broad band) increased after the calcinedsample was hydrolyzed. The weak peak at 3740 cm�1 is attributedto the single silanol groups [2]. After functionalisation, the singlesilanol group is absent and the broad band can be still observedas some silanol groups may be inaccessible for the surface func-tionalization with aminosilane. The intensity of the broad band de-creased sharply as most of the silanol groups consumed and thestretch intensity of NH anchored is lower than the silanol groups.The absorption band at 1635 cm�1 can be assigned to the NH2 scis-sor. The bands at 2933 and 2883 cm�1 are attributed to the asym-metric and symmetric stretch of CH2, respectively. The resultsprovided clear evidence that after hydrolysis the concentration ofsilanol groups increased and that AEAPS was grafted on the SBA-16 support.

3.3. Adsorption of carbon dioxide

The DSC–TGA weight profiles of sample Hydrolyzed-N and Cal-cined-N are given in Fig. 7. The DSC–TGA records were obtained forsample Calcined-N and Hydrolyzed-N when exposed to a CO2/N2

mixture. The adsorption performance was calculated from theweight gain profile. Each material was found to rapidly adsorbCO2 over the first 5 min, some further adsorption then continuedat a relatively slow rate until equilibrium was apparently estab-lished. Both the adsorption capacity and the adsorption rate ofthe sample Hydrolyzed-N outperformed the sample Calcined-Nafter the calcined samples were hydrolyzed. The adsorptioncapacities of the sample Hydrolyzed-N were higher about 28% on

Fig. 7. DSC–TGA weight gain profile of the sample of (A) Hydrolyzed-N and (B)Calcined-N.

Fig. 8. The relationship between adsorption capacities and particle sizes of thesample (h) Hydrolyzed-N and (d) Calcined-N. The particle sizes are the middlevalues of the ranges.

Table 3Adsorption characteristics of the functionalized SBA-16 and the SBA-16 support at333 K

Sample Adsorption capacity (mmol g�1) Hads (kJ mol�1)

1 0.425 672 0.626 703 0.727 734 0.34 625 0.454 656 0.591 717 0.04 20

398 J. Wei et al. / Microporous and Mesoporous Materials 116 (2008) 394–399

average than those of the sample Calcined-N. This may be due tothat the calcination step in preparing SBA-16 support dehydratedthe silica surface and removed most of the silanols, which resultedin poor functionalisation. After boiling treatment, the surface Si–O–Si bonds of the calcined samples were hydrolyzed, and moreSi–OH generated for grafting aminosilane [24].

The equilibrium adsorption capacities with different particlesize are shown in Fig. 8. It can be seen that for both the sampleof Hydrolyzed-N and Calcined-N, the adsorption capacities of thefunctionalized SBA-16 prepared from fine particle size were supe-rior to those of coarse particle size. This difference may be due tothat fine particle size allowed good accessibility for the graftingagent, and made good functionalisation. Interestingly, it wasshown in Fig. 9 that the adsorption capacities of sample Hydro-lyzed-N and Calcined-N were basically linear to the contents ofthe amine. More importantly, they were almost in the same line:

Y ¼ 0:3855X� 0:4397

where Y is adsorption capacity (mmol g�1); X is amine content(mmol-N g�1).

The reason would be that the adsorption of CO2 on the function-alized SBA-16 was carried out mostly on the amine groups an-chored on SBA-16.

Table 3 showed that all the functionalized SBA-16 exhibitedhigher adsorption capacities than that of the support. The CO2

adsorption capacity of the supports was indeed enhanced by theaddition of functional groups. The maximum CO2 adsorption

Fig. 9. The relationship between adsorption capacity and amine content.

capacity was observed for sample 3 to be 0.727 mmol g�1 at333 K. The adsorption capacity of carbon dioxide was comparedto other adsorbents. A direct comparison to other amine function-alized silica materials was given in Table 4. The results obtained inthis work were comparable to those reported by other researchgroups though the experiments conditions were different.

The energetic nature of the adsorbents was obtained duringadsorption of CO2 using calorimetric heatflow measurements,which was very important to characterize the adsorption. Theenthalpies of adsorption on the different functionalized SBA-16were calculated from the DSC heatflow profile. A typical DSC heat-flow profile was shown in Fig. 10. The enthalpies of adsorptionintegrated from the DSC heatflow profile were shown in Table 3.The values obtained with the calcined samples and the hydrolyzedsamples were about 20 kJ mol�1, which were in the range of theenthalpies of physical-sorption (below 40 kJ mol�1). The enthalpiesof adsorption for the calcined and hydrolyzed sample correlatedwell with previously reported data [10,17,25]. In the case of thegrafted samples, high adsorption enthalpies about 70 kJ mol�1

were obtained, which were slightly higher than those of Knowleset al. [25] with an aminopropyl-functionalized silica gel. These dif-ferences between the results of us and Knowes would be due to thenature of the amine. The high enthalpies indicated that the interac-tion between carbon dioxide molecule and amine groups is strong,that is, chemo-sorption.

Dreyfuss et al. [26,27], Leal et al. [28] and Hiyoshi et al. [18] re-ported that each molecule of carbon dioxide uses two surface ami-no groups to form an ammonium carbamate species (-NHCOO�)and the absorption band due to NH stretch of carbamate was ob-served. At the stage of our research we can not clearly elucidatehow carbon dioxide is absorbed on the amine modified SBA-16and additional research on the state of CO2 adsorption on the func-tionalized SBA-16 is required. However, whether in our research or

Table 4Adsorption data for amine functionalized silica

Functionalized silica Conditiona Method Capacity(mmol g�1)

Refs.

Aminopropyl-SBA-15 333 K/15 kPa

Flow method 0.66 [18]

Propylethylenediamine-SBA-15

333 K/15 kPa

Flow method 1.36 [18]

Propylethylenetriamine-MCM-41

298 K/5.1 kPa

TGA 0.97 [17]

Propylethylenediamine-SBA-16

300 K/100 kPa

Microcalorimetry 0.8 [10]

Aminopropyl-MCM-48 298 K/5 kPa

TGA 1.13 [13]

Aminopropyl-HMS 293 K/90 kPa

DTA/TGA 1.6 [25]

Propylethylenediamine-SBA-16

333 K/15 kPa

DSC–TGA 0.727 b

a Pressure was the CO2 partial pressure.b This study.

Fig. 10. DSC heatflow profile of the functionalized SBA-16.

J. Wei et al. / Microporous and Mesoporous Materials 116 (2008) 394–399 399

in other literature, it was obvious that the adsorption performancedepended on at least one important factor, that was, the content ofthe amine groups. In our study, adsorption capacities of both thesample Calcined-N and Hydrolyzed-N were almost linear to theamine content and close to the same line. However, the amine con-tent and the adsorption capacities increased when the particle sizedecreased. Therefore, it was clear that the fine particle sizes of thesamples improved the functionalisation and adsorptionperformance.

4. Conclusion

The effects of hydrolysis and particle size on functionalisation ofthe SBA-16 support were investigated. The sample Hydrolyzed-Nexhibited superior equilibrium adsorption capacity as well asadsorption rate to those of the sample Calcined-N, mainly due tothe increase of silanol group concentration on the surface of theadsorbents by hydrolysis. The samples with finer particle size out-performed the samples with coarse particle size in the equilibriumadsorption capacity. Fine particle size allowed good accessibilityfor the grafting agent. Hence more grafting agents were anchored.Measurement of the enthalpies of adsorption highlighted that theCO2 adsorption on the AEAPS functionalized SBA-16 was a stronginteraction, indicating that the interaction between the aminegroup and CO2 is a chemisorption. The maximum amount of

carbon dioxide adsorbed at 333 K was 0.727 mmol g�1 for theAEAPS functionalized SBA-16 (hydrolyzed SBA-16 as support) ofthe particle size range at 0.124–0.15 mm. It is suggested that therelationship between adsorption capacity and amine content isY = 0.3855X�0.4397 where Y is adsorption capacity (mmol g�1)and X is amine content (mmol-N g�1).

References

[1] R. Idem, P. Tontiwachwuthikul, Ind. Eng. Chem. Res. 45 (2006) 2413.[2] S. Kim, J. Ida, V.V. Guliants, Y.S. Lin, J. Phys. Chem. B 109 (2005) 6287.[3] Y. Takamura, S. Nartia, J. Aoki, S. Hironaka, S. Uchida, Sep. Purif. Technol. 24

(2001) 519.[4] M. Ishibashi, H. Ota, N. Akutsu, S. Umeda, M. Tajika, J. Izumi, A. Yasutake, T.

Kabata, Y. Kageyama, Energ. Convers. Manage. 37 (1996) 929.[5] M. Katoh, T. Yoshikawa, K. Tomonama, T. Tomida, J. Colloid Interf. Sci. 226

(2000) 145.[6] F. Dreibach, R. Staudt, J.U. Keller, Adsorption 5 (1999) 215.[7] Z. Yong, V.G. Mata, A.E. Rodrigues, Adsorption 7 (2001) 41.[8] F. Dong, H.M. Lou, A. Kodama, M. Goto, T. Hirose, Sep. Purif. Technol. 16 (1999)

159.[9] H.P. Huang, Y. Shi, W. Li, S.G. Chang, Energ. Fuel. 15 (2001) 263.

[10] C. Knöfel, J. Descarpentries, A. Benzaouia, V. Zelenák, S. Mornet, P.L. Llewellyn,V. Hornebecq, Micropor. Mesopor. Mater. 99 (2007) 79.

[11] X. Liu, L. Zhou, X. Fu, Y. Sun, W. Su, Y. Zhou, Chem. Eng. Sci. 62 (2007)1101.

[12] A.C.C. Chang, S.S.C. Chuang, M. Gray, Y. Soong, Energ. Fuel. 17 (2003)468.

[13] H.Y. Huang, R.T. Yang, D. Chinn, C.L. Munson, Ind. Eng. Chem. Res. 42 (2003)2427.

[14] X. Xu, C. Song, J.M. Andresen, B.G. Miller, A.W. Scaroni, Micropor. Mesopor.Mater. 62 (2003) 29.

[15] X. Xu, C. Song, J.M. Andresen, B.G. Miller, A.W. Scaroni, Energ. Fuel. 16 (2002)1463.

[16] X. Feng, G.E. Fryxell, L.-Q. Wang, A.Y. Kim, J. Liu, K.M. Kemner, Science 276(1997) 923.

[17] P.J.E. Harlick, A. Sayari, Ind. Eng. Chem. Res. 45 (2006) 3248.[18] N. Hiyoshi, K. Yogo, T. Yashima, Micropor. Mesopor. Mater. 84 (2005) 357.[19] D. Zhao, Q. Huo, P. Feng, B.F. Chmelka, G.D. Stucky, J. Am. Chem. Soc. 120

(1998) 6024.[20] T.-W. Kim, R. Ryoo, M. Kruk, K.P. Gierszal, M. Jaroniec, S. Kamiya, O. Terasaki, J.

Phys. Chem. B 108 (2004) 11480.[21] P. Feng, X. Bu, G.D. Stucky, D.J. Pine, J. Am. Chem. Soc. 122 (2000) 994.[22] J.J.S. Wesley, M. Myrjam, M. Steven, T. Ivo, V.T. Gustaaf, C. Pegie, F.V. Etienne,

Micropor. Mesopor. Mater. 93 (2006) 119.[23] A. Matsumoto, T. Sasaki, N. Nishimiya, K. Tsutsumi, Langmuir 17 (2001) 47.[24] A. Matsumoto, T. Sasaki, N. Nishimiya, K. Tsutsumi, Colloid. Surface A 203

(2002) 185.[25] G.P. Knowles, J.V. Graham, S.W. Delaney, A.L. Chaffee, Fuel Process. Technol. 86

(2005) 1435.[26] K.P. Battjes, A.M. Barolo, P. Dreyfuss, J. Adhesion Sci. Technol. 5 (1991) 785.[27] Y. Eckstein, P. Dreyfuss, J. Adhesion 15 (1983) 163.[28] O. Leal, C. Bolívar, C. Ovalles, J.J. Garcaí, Y. Espídel, Inorg. Chim. Acta 240 (1995)

183.