Adjustable Bookshelf(ABS) 10/04/2012 Design Review.

-

Upload

griffin-nethercott -

Category

Documents

-

view

214 -

download

0

Transcript of Adjustable Bookshelf(ABS) 10/04/2012 Design Review.

Team Members

Adhiraj Sharma – Project Leader, Mech. Engr.(Sophomore)Jianran Wang – Webmaster, Mech. Engr.( Sophomore)Ian Crombie – CFO, (Freshman)Seth Lerner – (Freshman)Karan Sharma- (Freshman)

ORIGIN OF THE PROJECT

• Origins of project– Started in spring 2006– Student was restricted to a wheelchair. He was

thus forced to throw books onto the stationary shelf and also had difficulty in accessing them from the shelf.

PROJECT REQUIREMENTS

The ABS project is being designed to accommodate and fulfill a number of specific criteria. Major requirements of the project include the following:• Functional Performance• Reliability• Production Cost• Coherence to Standards• Ease of Use• Service and Maintenance

PROJECT HISTORY

• Prior to Fall 2012– Working prototype• Actuators were located at the base(front) of the shelf,

reducing desk space • Lack of safety equipment• Shelf was unstable when moving up and down

– Current prototype will be modified to meet the required standards for the final prototype

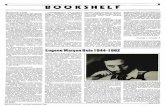

Previous Prototype (Spring 2012)

• Shelf was attached to two movable actuators moving up/in and down/out in a parabolic path

Current Design – Actuator location

• Relocating of the actuators from the front base of the desk to the rear bottom corners.

• This allows for more usable space on the desk surface

DETAILS OF THE ACTUATORS

The actuators used in are Firgelli Automations FA-400-L-12-12 with the following specifications

-12VDC Operation- 400lbs load capacity- ~0.5in/s movement speed (~24sec to fully retract or extend)- Retracted length: 18.88”- Extended length: 30.88”- 10A current draw at max load

• Installing safety sensors to the movable unit of the shelf such that motion is stopped the moment it touches an object.

• This ensures safety of the user and his belongings.

Current Design – Safety sensors

Current Design – Stability of the shelf

• Using ballpoint pen-like ball bearings to stabilize the shelf.

• Ensures safety of the user along with his belongings

BUDGET

Safety Equipment - $75Miscellaneous - $75

Steel Swing Arms + Hardware - $116.152 X 400 lbs actuators - $278.80

Brackets + Additional Mountings - $51.51New 12V Power Supply - $30Circuitry Components - $30

TOTAL = $656.46