Adam Pettis Resume v9

-

Upload

adam-pettis -

Category

Documents

-

view

43 -

download

6

Transcript of Adam Pettis Resume v9

SKILLS

CADDFMAGD&TCreativity3D ModelingLean Six SigmaProcess Management

Problem-SolvingCommunicationPublic SpeakingStress AnalysisData AnalysisMachiningTeamwork

SOFTWARE

PTC Creo 3.0/Pro EMicrosoft OfficeMathematicaMATLABMinitab

Adobe After EffectsAdobe PhotoshopAdobe PremiereAdobe AuditionAdobe InDesign

INTERESTS

Manual DraftingBuilding restoration/constructionCinematographyPractical Film EffectsMotorcycle RestorationMachining/WoodworkingMusic CompositionAudio Recording/Mastering

ADDITIONAL EXPERIENCE

• Extensive history in live entertainment including stage crew, sound, lighting, pit orchestra, and acting.

• Architectural studies including historic building restoration and designing, draft-ing, and constructing custom outbuildings.

EXPERIENCE

Wax Area Engineer: 8/2015–4/2016 with Alcoa Howmet Whitehall Casting

• Established an entirely new and experimental engineering position.• Responsible for troubleshooting and improving wax molding processes.• Experience with injection presses and tooling.• Rapidly implemented innovative and organized methods that effectively reduced

department scrap, optimized efficiency, and facilitated better communication be-tween shifts and other departments.

• Worked extensively with floor operators to understand the department’s needs and improvement opportunities.

• Developed standard work instructions and quality documentation in accordance with ISO 9001.

• Utilized Lean and Six Sigma techniques in boosting wax department efficiencies.

Volunteer FIRST Robotics Coach: 9/2011–1/2016 with Nelly B. Chisholm Middle School

• Lead 7th and 8th graders in the design process to define their objectives/constraints, research proven techniques, brainstorm new concepts, and construct/redesign all elements of a competition robot.

• Placed 1st in qualifiers and 10th in the MI State Championship 2015 season.

Media Technician: 5/2012–5/2015 with Grove City College Media Services

• Provided audio/video services (e.g., equipment setup, live video streaming, live audio mixing) to faculty and student events.

• Ensured equipment layouts met or exceeded the clients’ needs.

EDUCATION

BS in Mechanical Engineering: 8/2011–5/2015 at Grove City College ABET Accredited Program

Senior Design Project• Designed key mechanical systems that achieved the sponsor’s objectives while re-

maining within constraints.• Managed all 3D part and assembly files and instituted a consistent naming and

filing convention.• Produced detailed drawings for new parts.• Manufactured parts and assembled their respective subsystems.• Documented and organized system instructions and diagrams.

717.701.9231 | [email protected] 100 Pond Vista Lane APT B, Manheim, PA

Adam Pettis adampettis.com

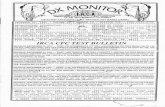

MECHANICAL ENGINEERING SENIOR DESIGN PROJECT

Abstract: Wendell August Forge, est. 1923, is one of America’s oldest and finest metalcrafters. One of their most beloved

products is their hand-designed annual Christmas ornament. With the popularity of this product, Wendell August

desired to produce a higher volume of these ornaments and charged senior Grove City College mechanical engi-

neers with designing an automated hammering prototype to be used as the basis for a future production machine.

Building off of the single-ornament hammering unit created by the previous year, the second-year team solved addi-

tional automation challenges by developing four key systems: the feeding, punching, clamping, and linkage sys-

tems.

Cameron Daugherty Adam Hopkins Cory Kirchhofer Adam Pettis Ben Satre

Erin Fulton Andy Herbener Maxine Fereshetian Rob Streiff Dr. Blair Allison

Clamping The clamping system holds the sheet firmly to the die as

each ornament is hammered. It is actuated by a pneumatic cyl-

inder that engages the clamp after the feeding system releases

the sheet. This permits the alignment table to move the material

to the correct locations for hammering and stamping.

Feeding Aluminum stock (thickness: 0.090”) is roll-fed into the

machine via a nip roller system. The bottom roller is made of

precision-ground steel and driven by an Aerotech servomo-

tor. A pneumatic cylinder moves the upper, urethane roller

vertically to engage or disengage the system depending on

the state of the other operations. When engaged, the system

precisely feeds stock into the machine.

Linkage Wendell August Forge desired for the project to operate

without exceeding excessive noise levels - i.e. run in an office-

like environment. The crank and toggle system was

developed to provide the necessary forces while remaining

quiet and efficient. The hammer block was designed to

include an offset stamp for impressing the Wendell August

Forge logo into the back of each ornament after hammering.

Punching Indexing each hammered ornament is crucial to locating

the ornament in subsequent operations. A 4 1/2” pneumatic

cylinder actuates a punch that creates a 1/4” index hole for

each ornament as the stock feeds through. These index holes

align with pins on the die and will also be used for blanking

operations in the future.

AA

D

C

AA

B

C

D

4 2 13

3 2 14

3rd Angle Proj

dwg name

material

dateSCALE SI

TOL

2 decimal lin: 0.013 decimal lin: 0.0014 decimal lin: 0.00011 decimal ang: 0.5

B

0.600

sheet

.750

.5002x

R.010

7.20

4.00

2.27

6.02

1.00

4.50

.99

1.00

.020

R.102xR.25

2x

1.000.50

6.02

5.00

4.13

.25

.25

2.00

4.00

.25 .25

4.00

.50

.25.25 2.27

3.55

hammer_mount_v3

Steel 1018

Jan-28-15 1 of 1

EMAIL CONTACT NAME BOX #[email protected] Adam Pettis 918

drawn by modeled by

Adam P Adam P

1/4-20 UNC - 2B TAP 1.250 #7 DRILL ( 0.201 ) THRU -( 2 ) HOLE

THRU -( 2 ) HOLEP DRILL ( 0.323 ) 5/16-18 UNC - 2B CLEAR

SECTION A-A

5/16-18 UNC - 2B TAP 0.620 F DRILL ( 0.257 ) 0.770 -( 2 ) HOLE

SCALE 0.300

5/16-18 UNC - 2B TAP 0.750 F DRILL ( 0.257 ) 1.000 -( 4 ) HOLE