Ad 750551

Transcript of Ad 750551

-

7/30/2019 Ad 750551

1/43

AD-750 5551HTPB POLYMER IMPROVEMENTW. D. Allan, et alLockheed Propulsion Company

Prepared for:Air Force Rocket Propulsion LaboratorySeptember 1972

DISTRIBUTED BY:

National Technical Information ServiceU.S. DEPARTMENT OF COMMERCE5285 Port Royal Road, Springfield Va. 22151

-

7/30/2019 Ad 750551

2/43

APRPI.,TR -72- go LPC DOCUMENT NO. 625-1- 2

HTPB POLYMER IMPROVEMENT

LOCKHEED PROPULSION COMPANYREDLANDS, CALIFORNIA

APPROVED FORPUBLiC RELEASE;DISTRIBUTION UNLIMITED

TECHNICAL REPORT AFRPL-TR-72-.89

SEPTEMBER 1972N,,*r";t,al I['t2,,A

AIR FORCE ROCKET PROPULSION LABORATORNRESEARCH AND TECHNOLOGY DIVISIONAIR FORCE SYSTEMS COMMANDUNITED STATES AIR FORCEEDWARDS, CALIFORNIA

-

7/30/2019 Ad 750551

3/43

Alt - wbite 31 :I

Div. 7-AVAILCOf~W-OILF'

Then U.S. Government drawings, specifications, or other data are used for any purpose other,than 'a definitely related Government , .ocurement operation, the Government thereby incursno responsibility nor any obligation whatsoever, and the fact that the Government may haveformulated, furnishled, or in any way supplied the said drawings, specifications, or other'datais not'to be regarded by implication or , otherwise, or in any rmanner licensins the, holder or any.person o*corporation, or conveying any rights or permission, to manufacture, use, or sell anypatented invention that'may in any way be related thereto. "

-

7/30/2019 Ad 750551

4/43

UNCLASSIFIEDSecurity Classification

DOCUMENT CONTROL DATA -R & D(Security classificationof title, body of abstraCtlid inde tinggnn totitonniu.. be entered "hen the -railreport Is classIfted)

ORIGINA TING AC TIVI 'Y (Corporate author) l20. REPORT i.CCURITY CLASSIFICATIONLockheed Propulsion Company UnclassifiedP.O. Box 111 b, GROW"Redlands, California 92373

3. REPORT TITLE

HTPB POLYMER IMPROVEMENT4. DESCRIPTIVE NOTES (Type of report and Inclusive dates)Technical Report,S, AU THOR450 (First name, middle Initial, last name)

W.D. Allan, W.E. Baumgartner and G.E. Myers, 1 May , '72 through 31 August 19720. REPORT DATE 7a. TOTAL NO. OF P .ES 7b. NO . OF REFS

September 1972 36] IBa.CONTRACT OR GRANT NO . 90. ORIGINATOk '1 ... RT NUMOERIS)

F04611-72-C-0038 625-1-2b. PROJECT NO.

C. 9b. OTHER REPO. t ?.O(S) (Any other numbors that may be asSIgnedthir report)

AFRPL 7 11-72-8910 DISTRIBUTION STATEMENT

Approved for Public Release; Distribution UnlimitedIt, SUPPLEMENTARY NOTES 1i2. SPONSORNG MILITARY ACTIVITY

Air Force Rocket Propulsion LaboratoryEdwards Air Force Base, California

13. ABSTRACT

From among the laboratory preparations of modified R-45M HTPBprepolymer that were previously examined, four were produced in a pilot plantfor evaluation in 90-percent solids propellant. The pilot plant samples covereda molecular weight range from 2700 to 4100 and possessed weight average func-tionalities between 2.0 and 2,1. Propellant processability in each case wasinferior to that of standard R-45M. On tht; basis of tensile properties and crackpropagation tests, no distinctive differences in propellant mechanical behaviorwere apparent. Detailed comparison of thermal cycling behavior will be madein the final program phase.

FORMDD I NOV 1473 UNCLASSIFIEDSccur.tlrl CI.ISSIIii .ItI'.f

-

7/30/2019 Ad 750551

5/43

UNCLASSIFIEDSecurity Classification

14 LINK A LINK B LINK CKEY WOROS ,,-ROL E WT R O L E WT ROLE, WT

HTPB prepolymer improvementFunctionalityMolecular weightProcessabilityMechanical properties

UNC LASSIFIEDSecurity Classification

-

7/30/2019 Ad 750551

6/43

AFRPL-TR-72- 89 ITPC OCUMENI' NO. 625-1-2

HTPB POLYMER IMPROVEMENT

-S, ,TUMBIR 1972

-

7/30/2019 Ad 750551

7/43

AFRPL-TR-72-89

FOREWORD

This is the second Technical Summary Report issued under ContractF04611-72-C-0038, "HTPB Polymer Improvement", a program being con-ducted by Lockheed Propulsion Company, Redlands, California, and moni-tored by the Air Force Rocket Propulsion Laboratory (Robert L. Limoges,Second Lieutenant, MKPA, Program Monitor). The program is being con-ducted in cooperation with the manufacturer of the R-45 HTPB prepolymer:the Atlantic Richfield Corporation (ARCO), Philadelphia, Pennsylvania; andwith the Government Research Laboratory, Esso Research and Enginleering,Linden, New Jersey. Participating technical personnel are Dr. W. E.Baumgartner (Program Manager), Dr. G.E. Myev8 (Project Engineer),W. D. Allan and W. E. Heikkila at Lockheed Propulsion Company; Dr. P. W.Ryan and K. C. Ramey at ARCO; and A.E. Muenker at Esso.

Publication of this report does not constitute Air Force apnrovalof the report's findings and conclusions, it is published only for theexchange and stmnulation of ideas.

Robert L. LimogesSecond LieutenantMKPA

-ii

-

7/30/2019 Ad 750551

8/43

AFRPL-TR-72-89

ABSTRACT

From among the laboratory prep'-ratiens of modified R-45MHTPB prepolyrner that were previously exarnined, four were produced in apilot plant for evaluation in 90-percent solids propellant. The pilot plantsamples covered a molecular weight range from 2700 to 4100 and possessedweight average functionalities between 2.0 and 2.1. Propellant process-ability in each case was inferior to that of standard R-45M. On the basis oftensile properties and crack propagation tests, no distinctive differences inpropellant mechanical behavior were apparent. Detailed comparison ofthermal cycling behavior will be made in the final program phase.

-iii

-

7/30/2019 Ad 750551

9/43

AFRPL-TR-72-89

TABLE OF CONTENTSSection Page

I INTRODUCTION III SUMMARY 3III RESULTS 5

I. PREPOLYMER PREPARATION ANDCHARACTERIZATION 5a. Analytical Results 5b. Parameter Correlation 9

2. EVALUATION IN PROPELLANT 9a. Propellant Processability 9b. Propellant Tensile Behavior 16c. Propellant Fracture Mechanics 16d. Strain/Temperature Cycling ofJANNAF Specimens 30

3. CONCLUSIONS 30IV FUTURE WORK 33

AppendixA LABORATORY SAMPLE CHARACTERIZATIONSUMMARY 35

-iv-

-

7/30/2019 Ad 750551

10/43

AFRPL-TR-72-89

LIST OF ILLUSTRATIONSFigure Page

I Prepolymer Viscosity versus Mn 112 Prepolymer Tw versus Rn 123 Relative End-of-Mix Viscosity versus Mn 144 Tensile Behavior of Control Sample (90-percentSolids); NCO/OH = 0.80; 0.54 in./in./min 195 Tensile Behavior of Control Sample (90-percentSolids); I\TCO/OH = 0.80; No MT-4; 0.54 in./in./min 206 Tensile Behavior of Sample F-2 (90-percent Solids);NCO/OH = 0.95; 0.54 in./in./min 217 Tensile Behavior of Sample F-2 (90-percent Solids);

NCO/OH = 1.0; No MT-4; 0.54 in./in./min 228 Tensile Behavior of Sample G-2 (90-percent Solids);NCO/OH = .85; 0.54 in./in./min 23"9 Tensile Behavior of Sample G-2 (90-percent Solids);NCO/OH = 0.85; No MT-4; 0.54 in./in./min 24

10 Tensile Behavior of Sample R-2 (90-percent Solids);NCO/OH = 0.95; 0.54 irn./in./min 25II Ten~sile Behavior of Sample R-2 (90-percent Solids);NCO/OH = 0.95; No MT-4; 0.54 in./in./min 2612 Tensile Behavior of Sample S-2 (90-percent Solids);

NCO/OH = 1.05; 0.54 in, /in./min 27

4[~

-

7/30/2019 Ad 750551

11/43

AFRPL-TR-72-89

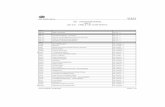

LIST OF TABLESTable Page

I ANALYTICAL CHARACTERIZATION OF PILOTPLANT SAMPLES 6II COMPARISON OF ANALYTICAL PARAMETERS:LABORATORY VERSUS PILOT PLANT SAMPLES 7

III SOLVENT PRECIPITATION FRACTIONATION OFPILOT PLANT SAMPLES 8IV COMPARISON OF MEASURED AND CALCULATEDP \RAMETERS FOR SOLVENT PRECIPITATEDFRACTIONATION 10V PROPELLANT P;'_OCESSABILITY (90% SOLIDS);VISCOSITY (KP AFTER HOURS) 13

VI RELATIVE PROPELLANT VISCOSITY AFTER3 HOURS AT 40 0C 15

VII PROPELLANT MECHANICAL PROPERTIES AT9, PERCENT SOLIDS (From Instron Load/Time"-.-ace) 17VilI COMPARATIVE TENSILE PROPERTIES 18

IX TENSILE PARAMETERS FROM TRUE STRESS/STRAIN CURVES FOR 90 PERCENT SOLIDSPROPELLANT 28X PROPELLANT CRACK PROPAGATION ?9XI TEMPERATURE/STRAIN CYCLING RESULTS 31

-vi-

-

7/30/2019 Ad 750551

12/43

AFRPL-TR-72-89

GLOSSARY

ARCO Atlantic Richfield CorporationB, C, E, F,G,K, L, M,N, N', O,P, Q Laboratory preparations of prepolymerEOM End of mixEsso Government Research Laboratory, Esso Research and

Engineeringfn Number average functionality"w Weight action furnct.ionalityGPC Gel permeation chromatographyHTPB Hydroxy-terminatvd polybutadieneIPDI Isophorane diisocyanateKP KilopoiseLPC Lockheed Propulsion Compan)Mn Number average molecular weightMw Weight average molecular weightMT-4 Bonding agentNCO/OH Isocyanate to hydroxyl equivalents ratiop poiseRR Round Robin R-45M. Lot 110225R-45M ARCO HTPB. Free radical polymerizedTSI Toluene sulfonyl isocyanateVPO Vapor phase osmometer7, Prepolymer viscosity in poise0-nE Stress and strain at maximum load (stress)in, rm0'b/Eb Stress and strain at rupture

(The reverse is blank)

-vii-

-

7/30/2019 Ad 750551

13/43

AFRPL-TR-72-89

SECTION IINTRODUCTION

The commercially available ARCO R-45M HTPB prepolymer isbeing extensively studied for applications in highly loaded solid propellantsand possesses some advantage over CTPB prepolymers in those systems.It does have some deficiencies, however, in potlife control and in balancing* mechanical properties at low and high niperatures, which presumnably arecaused by the material's low molecuh,' weight (Mn - 3000), high functionality(fw 2.3), and high reactivity of its functional groups.

This program was established to determine whether the availablevariations in ARCkAs free radical polymerization process could produce amodified R-45M possessing superior characteristics for use in solid propel-lants. in the program ARCO was to prepare 11 prepolymer samples underlaboratory conditions/scal-, each sample representing specific variationsin their polymerization process. Those samples were to be characterizedby both ARCO and Esso and evaluated in propellant on a small scale by LPC.Subsequently, three of those prepolymer lots were to be scaled up to thepilot plant level, characterized, and evaluated for propellant performance.

The first report under the program described the results of thecharacterization and evalu;.tion of the laborator7 samples (Ref 1) . Thosesamples possessed z vide range of average molecular weight and averagefunctionality. Their propellhnts also exhibited a wide range of proceso-ability, controlled primarily by molecular weight. However, propellanttensile properties generally showed relatively minor variations among thesamples, i. e. , molecular weight and functionality had little effect upontensile behavior.

From the available data three prepolymers were selected forscaleup, covering the molecular weight range from about 2500 to 4000 andpossessing functionalities very close to 2.0. This report describes thecharacterization and evaluation of the pilot plant samples.

(Ref 1). Baumgartner, W. E. and Myers, G.E., HTPB Polymer Improve-ment, AFRPL-TR-72-50, LPC Report No. 625-1-1, June 197Z(The reverse is blank)

-- I

-

7/30/2019 Ad 750551

14/43

AFRPTL-TR-72-89

SECTION HISUMMARY

From the polymerization process conditions previously employedin producing 14 laboratory samples of R-45M type prepolymers, ARCO hasused four conditions on the pilot plant scale to produce four prepolymers atthe 25- to 50-pound level. These were characterized analytically by ARCOand Esso, and evaluated by LPC in 90-percent solids propellant (Oronite-6plasticizer, IPDI curative, with and without MT-4).

The analytical results are summarized as follows:* Reproducibility between pilot plant and laboratorypreparations is excellent.F Kin varied from 2700 to 4100 with fw values between

2.0 to 2.1.* Solvent precipitation fractionation took place on the basisof molecular weight and/or equivalent weight, with someindication that w increases with Mn"Evaluation in propellant showed the following:* Processability of the pilot plant samples was inferior tothat of standard R-45M. However, this may be at leastpartially the consequence of higher impurity levelsoccasioned by incomplete pilot plant cleanup.0 No clear superiority over standard R-45M was observedfrom tensile properties or from crack propagation tests.(Some indication of improved thermal cycling capabilitywas obtained from feasibility tests of a simultaneous

strain/temperature cycling procedure, but these resultsmust still be regarded with caution.)However, this somewhat unexpected failure of material havinghigher no,,lecular %eight and functionaiities close to two, to produce improvedpropellant mechanical behavior could b the consequence of relying largelyupon uniaxial tensile tests for the mecL-w. A.t.properties evaluation. Thelast phase of the program will evaluate ki- :eater detail the thermal cycling

capability of propellants prepared from tlhrec of the pilot plant prepolymers.

(The reverse is blank)

-3-

-

7/30/2019 Ad 750551

15/43

~AFRPL-TR-72-89

SECTION IIIRESULTS

1. PREPOLYMER PREPARATION AND CHARACTERIZATIONFour prepolymers were prepared in the ARCO pilot plant at approxi-mately the 50-pound level; three of them were prepared under conditionsduplicating those used for the laboratory samples F, G, and R.,, while thefourth (S-2) involved a further process modification. Initial preparationscontained unacceptably high iron levels due to reactor startup problems.The repeat preparations tended toward higher iron levels than possessed bythe laboratory samples but were regarded as satisfactory for the program.After preparation, all samples were stored under nitrogen in air-tight con-tainers. Pilot plant samples have been designated F-2, G-2, R-2, and S-2to distinguish them from the laboratory samples F, G, etc.a. Analytical. Results

The samples were characterized by number average molecularweight, analytical GPC, equivalent weight, number average and weightaverage functionality, viscosity, and impurities using methods described inthe previous report (Ref 1). 'In addition, preparative scale fractionationswere conducted by solvent precipitation at ARCO and the fractions also werecharacterized.Table I summarizes the analysis results for the pilot plantsamples, and Table II compares several parameters for pilot plant versus

laboratory preparations. The following points are noted: Kn varies from about 2700 to 4100 and polydispersitiesare nearly equal. fn values are all 2.0 within experimental error

whereas values of fw are between 2.0 and 2.1.. S-2 appears to be equivalent to R-2.* Reproducibility between laboratory and pilot plant isexcellent.ARCO separated each of the pilot plant samples into threefractions by addition of methanol to a 10-percent cyclohexane/acetone solu-tion at 25 0C. Table III summarizes the analytical values for the fractionsand Table IV compares the corresponding parameters for each of the originalprepolymers with those calculated from the fractionation data, The frac-tionation obviously took .lace on the basis of both Mn and equivalent weight.

Table III indicates that 1w increases with molecular weight, but some doubtis cast upon that conclusion by the comparison of measured and observed fw': A tabulation of analytical results obtained for the laboratory samples is

included as Appendix A for reference purposes.-5-

-

7/30/2019 Ad 750551

16/43

AFRPL-TR-72-789

0- X0: 0k

00.- 0 ~0 0IA0

4-14

0" cc0

W4H

0 0 03 0 oo0o o0 0 0Dv v M4InA

.0> N N NN

-1 0Z 0000 -0 0 0 0 0 0u.. to uNN N N N N N to

0 v.

0 * u

H -6-

-

7/30/2019 Ad 750551

17/43

AFRPL-TR-72-89

TAB LE IICOMPARISON OF ANALYTICAL PARAMETERS:LABORATORY VERSUS PILOT PLANT SAMPLES

Parameter(a)Sample n(b ) Eq Wt (c) (d)

F 4100/4080 2270/2060 1.81/1.99 2.03/2.03( 1%)(e) (-9%) (+10%) (0)G 3100/3010 1770/1490 1.75/2.03 2.04/2.08

(-3%) (-15%) (+16%) (+Z%)R 2530/2760 12Z0/1420 2.08/1.94 Z.10/2.03

(+9%) (+16%) (-7%) (-3%)(a) Laboratory/pilot plant(b) VpO(c) TSI(d) Laboratory samples without catalyst. Pilot plant samples with catalyst.(e) Percent change from laboratory to pilot plant.

-7-

-

7/30/2019 Ad 750551

18/43

AFRPL-TR-72-89

'0 N N

U) -4 NN N N NN'0~~ ~ NttAN

. 4 4J-*-1-4 r. r-0U) 41 -.-4 X'C N- 000'

H- 1 a ,NC0NCY "ot-a- -N-Co 4NN N- N1N N--

0 Il 0 0 0 00 0 0o0oM0'

'~ 0 U~jN -'U-o4 0 000 000 00(0 06001 0'CO 00N - n-C) o o t- 4-I -n .- %0

' 4j> 00 0-00 n 000 000c

V o tJo'ON%0NL0. 0ON'LooCoC-40 40 0\3O nN N MOp44HN

-

7/30/2019 Ad 750551

19/43

AFRPL-TR-72-89

in Table IV, which indicates that some modification of the fractions mayhave occurred during their preparation. Such modification, however, didnot significantly affect molecular and equivalent weights.b. Parameter Correlation

The first interim report presented crossplots for a number ofthe measured prepolymer parameters to determine what correlations mightexist. Figures 1 and 2 illustrate two such plots when data points for thepilot plant samples are included. Figure 1 demonstrates that both labora-tory and pilot plant sampler follow the same 1/Mn relationship, and Figure 2confirms that the ARCO polymerization process can vary molecular weightand functionality independently.Z. EVALUATION IN PROPELLANT

The four pilot plant prepolymer samples and a control (standardR-45M, Lot 008281) were evaluated at the 1-gallon mix scale in propellantcontaining 90-percent solids, 3-percent Oronite-6 plasticizer, and curedwith IPDI. The evaluation was made at a minimum of two NCO/OH ratioswith MT-4 bonding agent, and at one NCO/OH ratio without MT-4. Curewas at 160OF for 7 days.

a. Propellant ProcessabilityThe propellants were processed in a 1-gallon vertical Baker-Perkins mixer modified with a bottom discharge valve for casting directlyfrom the mixer. A 170-minute mix cycle was employed, including 90minutes after completing the addition of solids and 30 minutes final mixafter curative addition. The end-of-mix (EOM) and potlife viscosities weredetermined by means of a Brookfield viscometer and a T-F bar. Table V

summarizes the viscosity data.As expected, much higher propellant viscosities were observed

in the propellants containing MT-4 than in those that had no bonding agent.Where MT-4 was present, all of the pilot plant samples had EOM viscositieshigher than those of the control (except sample S-2 at an NCO/OH ratio of1.05). The relationship between prepolymer Mn and the relative EOM vis-cosity of the pilot plant samples is presented in Figure 3, along with theprevious data for the laboratory samples. Within the data scatter, EOMviscosity is controlled generally by prepolymer Mn, with deviationsprobably occasioned by reactivity differences.Table VI lists the relative mix viscosities 3 hours after EOM

for the formulations containing MT-4. These values were obtained bysmoothing the data from Table VI and are judged to be accurate to 0.05-0.J.Processability therefore is in the order of Control >F, R> G, S. It is possible,however, that the poorer processability of the pilot plant samples to someextent may be due to their relatively high iron content. As noted earlierthis is a temporary deficiency that should be obviated in further production.In the present study, no casting difficulties were encountered with any ofthe test formulatio'ns.

-9

-

7/30/2019 Ad 750551

20/43

,AFRPL-TR-72-89

.4 4 4C

$ A ao p t

Z P40

m 0000

UlU

(4N 0 '44 -4c -4

0 Cd N -4

-)' to~

z IV U -- -C) ~ , 4) . N N

lz U4 c a - N00

.4 0 '0 CC

N~ N N Nq

0~~U .- ' c-to-4

-

7/30/2019 Ad 750551

21/43

AFRPL-TR-72-89

70 0 SAMPLE-

6 R-45 (LAB),40 0 --- ,R-45,(PILOT PLANT)---- 6 -- 6 N, PO-CTPBbTELAGEN HT A N'

200 -s- . Q"" B0

0100 L,F-20

> 70 -A CG

SG-2 CONTROL,RR40 - _ _ M

202D KR,

1 2 3 4 5 6 710 - 3 n

Figure 1 Prepolyrner Viscosity versus Mn-!l-

- ii m

-

7/30/2019 Ad 750551

22/43

7 AFRPL-TR-72-89

zc

U,)

C=))C))

C4 1-4m0

-

7/30/2019 Ad 750551

23/43

*" -- -nvAFRPL-TR-72-89 'r.~~0

0 o 0 0 n40n 10 Z

0 00

N Nl Nd N N

oI-1300 N0 c

-

7/30/2019 Ad 750551

24/43

1 AFRPL-TR-72-89

7 . I SAMPLEC1 86% SOLIDS6 0 88% SOLIDS

A 90% SOLIDS 0p

5_ NC1 N4F20 p -- F, F

- LQCG3 .-- G-2 -- CONTROLS-2 R-2 KRE2 O M

0 1 2 3 4 5 6 7 8RELATIVE EOM VISCOSITY (sample/control)

Figure 3 Relative End-of-Mix Viscosity versus Kn

-14-

-

7/30/2019 Ad 750551

25/43

AFRPL-TR-7Z-89

TABLE VIRELATIVE PROPELLANT VISCOSITY AFTER 3 HOURS AT 4 0C(a)

Sample Relative ViscosityControl 1.0

F-2 1.3G-2 1.6R-2 1.4s-2 1.7

(a) MT-4 formulations

-15-

-

7/30/2019 Ad 750551

26/43

AFRPL-TR-72-89

b. Propellant Tensile BehaviorUniaxial tensile properties at -65, 70, and 140F were

measured at a strain rate of 0.54 in./in./min using the milnithirn tensilespecimens previonsly described (Ref 1).

(i) Summary of Conventional Tensile Parar,,etersTable VII summarizes, for all formulaticris tested, the

values of tensile parameters as conventionally reported. The,,e includeinitial modulus E0 , stress and strain at maximum load (O/E)n, ai!d stressand strain at rupture (o/O)b. Additionally, swell and gel measuirclnen-ts,which are indicative of binder crosslink density, are included for ach ofthe formulations tested. The effect of MT-4 is to "harden" the pr6dellantat higher temperatures and to increase strain at -65 0 F.

(2) Comparison at Constant 75F %mTo permit comparison of tensile properties under similarconditions, NCO/OH ratios were selected that produced values for am at75 0F between 140 and 160 psi. Resultant conventional tensile paramileters

are given in Table VIII. On this basis none of the prepolymer samples isclearly superior to the control lot.

(3) True Stress/Strain Curves and ParametersFigures 4 through 12 present true stress/strain curves ata single NCO/OH ratio for formulations both with and without MT-4; the

ratio chosen was that closest to the value employed above. The tensileparameters from these curves are presented in Table IX. As with thelaboratory samples, no clear superiority above the control lot over thefull temperature range can be observed.

c. Propellant Fracture MechanicsCrack propagation measurements were conducted at -65 and70F in an attempt to distinguish more clearly among the pilot plant samples.

Propellant strips measuring 3 by I by 0.1 inch were bonded to wooden tabsalong the 3- by 0.1-inch edges and, after a 0.5-inch edge cut was made,were pulled at a rate of 0.2 in./min. Stress and strain at ini"t"-'iion of cutgrowth were measured, as well as the subsequent rate of growth from 0.5-to 0.7-inch cut length.

Data scatter was such that the only significant differenceobserved (see Table X) was a larger critical stress and strain, and hencefracture energy, fo r F-2 propellant at 70 0 F. How meaningful a superioritythis may be--for motor thermal cycling, for example--is not clear, although

-16-

-

7/30/2019 Ad 750551

27/43

* ~ - - -89

U) -' -0 0 - 00 mN - I- n -D N -D D

Ii)N U'0 in 2' D ~ mV ac-) -ten ton Mc 0 N m Nc n3 mcc .

N ) N N N' m' m~ m" " " "~-i0 0 ' 0 0 0 C 10 0 0UY 10' DN r w co% N 4_ Nl N

00 0o 0O0 0 0 0 0 0 0 0 0 0 4 >v N ' r " 0 -3 'D N U') '3 m3~ ) 30r 0 0 0 0 0 0 0 0 n ~0 U

C4,)N*0 N,- N. N, N, N. v N, N, In in :

Ni 0 0 0 0 ' 0 0 0 0 0 0 '3 NN'- C 0U' 023 a'' 03 N- - ---- - - - - - -

3~~ en3 N03 c 2 C O U ) N m'") 9- IN. Nu 0 -A N N N N N NZ in ND in ND t 0U) 0 0 0 0 0 0 000 0 071 m

x i N0 10 o 10 0 0 - 0 0 0 M0 0 M 0 0 tUN tnn tnc tn3 C- t.' U) r N C)N~ w 0a 0 0 a , CiuC-; '3 cc 4" C; N; 3' 4'; C; 0* in

a cc 0 =-1 0 C)'2 ' " ''1') ~~ ~ ~ ~ ~ ~ L3 '2' Xl)t 3 U) ' 3 ' C) ' 3E U

-17-

-

7/30/2019 Ad 750551

28/43

AFRPL-TR-72-89

TABLE VIIICOMPARATIVE TENSILE PROPERTIES(a)

E o/am/i m(b)

Sample NCO/OH - 65F 750 F,, 140FControl 0.80 17,000/600/14 740/140/26 530/120/28(Lot 008281)F-2 0 .9 2 5 (c) 13,000/580/10 540/150/25 590/120/25G-2 0.85 14,000/600/10 760/150/28 590/120/30R-2 0.95 10,000/630/10 550/150/25 500/110/29S-2 1.05 15,000/660/9 830/160/25 515/110/27

(a) Comparison at NCO/OH ratio which has o at 75F between 140-160 psi.MTT-4 formulations

(b) , and ( at maximum stress from Instron curvesm m(c) Extrapolated from 0.90 and 0.95 NCO/OHI

- 18-

-

7/30/2019 Ad 750551

29/43

AFRPL-TR-72-89

0 10 2060040

, oo400

f-650F

400 300

ILlI- " 200- 200FC--

70oF -. N/0 010 / 100// 140F

S0 20 40STRAIN 40 0

Figure 4 Tensile Behavior of Control Sample (90-percentSolids); NCO/OH = 0.80; 0.54 in./in./min

-19-

-

7/30/2019 Ad 750551

30/43

AFRPL-TR-72-89

0 10 20600 400

-65OF

400 300

c/)u-iS200 200I-

0 10 070'F140' F

0 20 40STRAIN(%)

Figure 5 Tensile Behavior of Control Sample (90-percent Solids):NCO!O/Q- 0.80; No MT-4; 0.54 in./in./min

-20-

I 1M m m I i I k m m i

-

7/30/2019 Ad 750551

31/43

AFRPL-TR-72-89

0 10 20600 -650F 400

400 300

CIOS200 200U 70OF

/140F

0 10 0

0a 20 40STRAIN (,)

Figure 6 Tensile Behavior of Sample F-2 (90-percent Solids):NCO/OH ; 0.95; 0.54 in./in./min

S-21-

-

7/30/2019 Ad 750551

32/43

"AFRPL-TR-72-89

0 10 20600 400

400 300

7.i C,,

"LUw 200- 200-i

I-

0 10 0S70 0F

S01- 140OF00 20 40STRAIN (%)

Figure 7 Tensile Behavior of Sample F-2 (90-percent Solids);NCO/OH = 1.0: No MT'-4; 0.54 in./in./min

-22-

-

7/30/2019 Ad 750551

33/43

AFRPL-TR-72-89

0 10 20600 400

-650F400 r 300

CL

"200 200I-

700 F

0 100

00 20 40STRAIN (%)

Figure 8 Tensile Behavior of Sample G-Z (90-percentSolids); NCO/OH = 0,85; 0.54 in./in./min

-23-

-

7/30/2019 Ad 750551

34/43

AFRPL.-TR-72-89

0 10 20600 4001-651F

400 300

LU_200 200

0 10070OF

T-1400F020 40STRAIN (%)

Figure 9 Tensile Behavior of Sample G-2 (90-percent Solids);NCO/OlI = 0.85; No MT-4; 0.54 in./in./min

-24-

-

7/30/2019 Ad 750551

35/43

AFRPL-TR-72-89

0 10 20800' 500

600 , 400

400 - 300

-650w

200 200

S70F0 7 A 100

/I 140OF/0

0 20 40STRAIN (,4

Figure 10 Tensile Behavior of Sample R-2 (90-percentSolids); NCO/OH = 0.95; 0.54 in./in./min

-25-

-

7/30/2019 Ad 750551

36/43

AFRPL-TR-72-89

0 10 20600 400

I451F400 300

4.) uJo200 - -200LuI--

0- 10070OF I

140OF

0 20 40STRAIN (0/)

Figure 11 Tensile Behavior of Sample R-Z (90-percent Solids);NCO/OI-= 0.95; No MT-4; 0.54 in./in./min

-26-

-

7/30/2019 Ad 750551

37/43

AFRP1 TR-72-89

0 10 20800 500

600 400

-650F

400 300Coe)

I-l200 200

70OF$/0 __" 100

S/ 140FS//1/

00 20 40STRAIN (%)

Figure 12 Tensile Behavior of Sample S-2 (90-percentSolids); NCO/OH = 1.05; 0.54 in./in./min

-27 -

-

7/30/2019 Ad 750551

38/43

AFRPL-TR-72-89

00 t 03LA 0 S 0 0 0

>O 0 L

m m. LA r t- In N)1- N k" N 0 '1'N, fn t 'n N 'N 'N kA'N N

0A0 0- 0 0 In 0 0 0 0

Lo, 4 E ) LA NA 1 A- 0) 0) M) LAN N

tA 0 0 0 0%n 0 0 0

a'0 0 N 0 LA A"'N~ mN.. " InN I ' I 'CL

co 0 L S 0 I Lr- 0rA I~ ' I .

tn LA A n n A 0n 0 3 10 0o 0 0

eq ^I - N 4 -r m L In ' ' LA v%Nn wUu%%0~~~~~~~ u,0000000

Nr

Ho 0OHo>

-

7/30/2019 Ad 750551

39/43

F AFRPL-TR.-72-89'o LA LAI 'd A

0 - CO CO C' CO+,

+~L 01 0- 0 000

U -4 )

LA0 CO-4 i 40 -4.

'-44

0)0L, C>~04) 0 C)

I Y000700

-. ) Cl) .4

0 tn 0

0 %10U 0000

4'.

01

-

7/30/2019 Ad 750551

40/43

AFRPL-TR-72-89

it seems possible that F-2 at a lower NCO/OH ratio might possess improvedcrack resistance while maintaining high-temperaturo capability.d. Strain/Temperature Cycling of JANNDVF Specimens

Since neither the tensile nor the crack propagation data gaveevidence of major differences among the propellants, the feasibility of alaboratory test 1zr evaluating relative capability to withstand motor thermalcycling was examined. Standard JANNAF specimens (four of each propellantin parallel) were slowly strained on an Instron tester from 0 to 15.5 percent,while the temperature was simultaneously decz eased from 140 to -65 0F o.,era 90-minute period. The cycle was then reversed to permit return within90 minutes to the- original crosshead displacement and to 140 0F. Total loadfor the four specimens was recorded continuously.Available data are summarized in Table XI in terms of the rateof load reduction (-650 F) and qualitatdive observations of sample damage.Although these results must be considered highly preliminary, they indicate

definite potential for laboratory characterization of thermal cycling capa-bility and the possibility of improved behavior for R-2 and S-2.3. CONCLUSIONS

(1) Good duplication is shown between ARCO's laboratory andpilot plant processing.(2) Propellant processability with the pilot plant samples ispoorer than with standard R-45M. This may be partially

a reflection of higher contents of residual catalyticimpurity (iron compounds) resulting from limited use ofthe pilot plant reactor.'3) On the basis of the tests employed in evaluating mechanicalbehavior, no clear superiority is apparent for pilot plantsamples relative to standard R-45M.

-30-

-

7/30/2019 Ad 750551

41/43

AFRPL-TR-72-89

TABLE XITEMPERATURE/STRAIN CYCLING RESULTS

LoadReductionSample NCO/OH Rate(a) Number Cycles and SpecimenoCondition(b)Control 0.80 9 23 full cycles; 3 specimens broken and Iwith no cracksF -2 0.95 7 36 full cycles plus 7 cycles without cool-ing (between 13th and 14th full cycles);

3 specimens with cracks and 1 uncrackedR-2 0.95 4 38 full cycles; 3 specimens cracked, Ifailed after 30 cyclesS-2 1.05 2 35 cycles; I specimen failed, 3 withcracks

(a) Pounds per cycle. Slope of straight line through maximum load (-65degrees)/cycle plot.

(b ) Three-hour cycle. Visual observation of condition.

(The reverse is blank)

-31-

-

7/30/2019 Ad 750551

42/43

AFRPL-TR-72-89

SECTION IVFUTURE WORK

The original program plan called for final evaluation of one pilotplant prepolymer at the 10-gallon mix level with emphasis upon analog motorthermal cycling tests. In view of the results obtained to date and with therealization that different temperature cycling behavior may not be apparentfrom uniaxial tensil,. data, the program has been redirected to permit amore detailed evaluation of three pilot plant samples (F-2, R-2, S-2) at the1- or 21/ 2-gallon mix level. For each of these prepolymers and control,thermal cycling capability will be compared using analog motors as well asthe laboratory strain/temperature cycling test.

(The reverse is blank)

-33-

-

7/30/2019 Ad 750551

43/43

AFRPL-TR-72-89

u 0No C '

enN N CO N..E'? N 0N

00 r0

co 0 -- J n n c ao in* )e. -n IV3 Nn N' in 0~~00M InC~ in 0n COD 0 ' 0 0 4inCO e. Non a~MN M V'I ~ ~~ 05 0' ~ 0

ZI 0jN 0 0 ~ 0 n ror- v o0 i 0n. . 0 m . en c, -: 3.n.N- I mVH4 E o, 0a e a In 0 Z-

COn N M' inIZ i v30- 0f 00 0U co N . I.0n i'n N in 'MrN' 0(31 0 0 .n,' 0in in N N'(D1 C) N N in E.CN .0!0 In n 0 I4 Nr- N N~N - -M IV 0 I

oj'0 n t'D en inNM N- N- i 0(I) o )oI O M0 CO 0 0 0CO 0 N Iq O l ~

00H4 in i 10 tO - n-en '3 n .j N en~ ~~ -e t'- mn 0in L. in ,N0' 0n LIZ) coCin ~ e N C ~ CN 0n in n inN3* ~ C0 ~~ NNNM en in N -C0-'3 0

a M 0- ? 0n 00 0 0 NO10 I - . V'~ C ~ ~ I coin C 'N ~ N .~ >r r - - NM Nn3 NN - 0~t,r )n in 10 ~- in' C' n n ' eN-N - - m N- '

u-1 4. C~) ~ U(i

enn. n - ! 0 .11

(The ro erso is blank)