Acrome Delta Robot Courseware - Robot Kits | Robot Toys

Transcript of Acrome Delta Robot Courseware - Robot Kits | Robot Toys

©2015 Acrome Ltd., All rights reserved.

Acrome Ltd. ITU ARI4 Science Park Maslak, Istanbul Turkey [email protected] Phone: +90 532 132 17 22 Fax: +90 212 285 25 94

Printed in Maslak, Istanbul

For more information on the solutions Acrome Ltd. Offers, please visit the web site at:

http://www.acrome.net

This document and the software described in it are provided subject to a license agreement.

Neither the software nor this document may be used or copied except as specified under the

terms of that license agreement. All rights are reserved and no part may be reproduced, stored

in a retrieval system or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of Acrome Ltd.

ACKNOWLEDGEMENTS

Special thanks to Acrome myControl Team for their supports in embedded control and preparation of

the courseware.

2

Contents

1 Components of Delta Robot ............................................................................................................. 3

1.1 Round Electromagnet .............................................................................................................. 3

1.2 Smart Servo Motors ................................................................................................................. 4

1.2.1 Overview .......................................................................................................................... 4

1.3 ACROME Power Distribution Box ............................................................................................. 4

1.4 NI myRIO .................................................................................................................................. 5

1.5 Digital Camera.......................................................................................................................... 5

2 Kinematics of Delta Robot ................................................................................................................ 6

2.1 Forward Kinematics of Delta Robot ......................................................................................... 7

3 Trajectory Generation ...................................................................................................................... 8

3.1 Introduction ............................................................................................................................. 8

3.2 Cartesian Space Schemes ........................................................................................................ 8

3.3 Joint-Space Schemes ................................................................................................................ 8

3.3.1 Cubic Polynomials ............................................................................................................ 9

3.3.2 Higher Order Polynomials .............................................................................................. 10

4 Vision Guidelines for Delta Robot ................................................................................................... 11

4.1 Introduction to Vision Systems .............................................................................................. 11

4.2 NI Vision Acquisition Software ............................................................................................... 11

4.2.1 Vision Express Sub palette ............................................................................................. 11

4.3 Pick and Place Application of Delta Robot ............................................................................. 14

4.3.1 In-Lab Exercise: Pick and Place Application .................................................................... 15

References ............................................................................................................................................. 16

3

1 Components of Delta Robot

All the main parts of “ACROME Delta Robot” can be seen below.

Figure 1.1: Components: 1. Round Electromagnet 2. Smart Servo Motors 3. ACROME Smart Power

Distribution Box 4. myRIO 5. Camera

1.1 Round Electromagnet

Round electromagnet is used for ability to attract and hold ferromagnetic materials with

varying degrees of force, through the application of controlled DC electrical current.

Electromagnets also have the ability to release the item as required. Electromagnets are

commonly used in robotics and automated applications.

Figure 1.2: Round Electromagnet

4

1.2 Smart Servo Motors

1.2.1 Overview

HerkuleX DRS 0101 is composed of motor, gear reducer, control circuitry and

communications capability in one single package. These servos can be assembled easily with an

added advantage of simple wiring. If required, each servo allows serial or parallel connections.

Figure 1.3: HerkuleX Smart Servo Motor

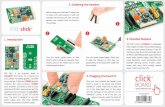

1.3 ACROME Power Distribution Box

Three servo motors, round electromagnet and myRIO connections are located on

ACROME power distribution box which is shown in Figure 1.5. It also has RGB led and switch

mode regulators.

Figure 1.4: ACROME Power Distribution Box

5

1.4 NI myRIO

myRIO is portable embedded device that students and hobbyist can design control,

robotic and mechatronic systems.

Figure 1.5: NI myRIO

1.5 Digital Camera

Microsoft LifeCam HD-3000 captures images on the purpose of determining the position

of the desired object. Communication between computer and digital camera is provided with

USB 2.0 port. Digital camera is compatible with Microsoft Windows 7, Windows 8 and Windows

10.

Figure 1.6: Digital Camera

6

2 Kinematics of Delta Robot

The general mechanical structure of ACROME Delta Root is shown in Figure 2.1.

Figure 2.1: The General Mechanical Structure: 1. Smart Servo Motor 2. The base Plate

3. The Travelling End-effector Plate 4. The Upper Arm 5. The Lower Arm

In this chapter, we analyze the kinematics of Delta Robot including analytical solutions in

two section: Forward and Inverse kinematics. Delta Robot mechanism’s kinematics analysis is

simply the study of mapping between the Cartesian space and joint space. Mapping from the

joint space to Cartesian space is called forward kinematics, while the mapping which is from

Cartesian space to joint space is called inverse kinematics.

Forward Kinematics

Inverse Kinematics Joint Variables End-effector Variables

𝐽𝑜𝑖𝑛𝑡 𝑆𝑝𝑎𝑐𝑒

(𝜃1, 𝜃2 ,... 𝜃𝑛) 𝐶𝑎𝑟𝑡𝑒𝑠𝑖𝑎𝑛 𝑆𝑝𝑎𝑐𝑒

(𝑥, 𝑦, 𝑧, 𝛼, 𝛽,ϒ)

7

2.1 Forward Kinematics of Delta Robot

As the forward kinematics is described before, the three joint angles (𝜃1, 𝜃2, 𝜃3) are

inputs and the Cartesian coordinates (𝑥, 𝑦, 𝑧) are the outputs of the forward kinematics. Joint

angles is applied to servo motor and the corresponding Cartesian coordinates are calculated

via forward kinematics equations.

Figure 2.2: Mapping from Joint Space to Cartesian Space

In general, the forward kinematics of parallel robots are difficult to compute but 3-DOF

Delta Robot moves translation only. Therefore, a unique analytical solution could be chosen in

correct solution set for forward kinematics.

To construct the forward kinematics of the Delta Robot, let’s firstly designate the physical

parameters of robot below.

Figure 2.3: Delta Robot Schematics

Physical Dimensions of Delta Robot (mm)

𝒇 Side of the base plate triangle 230.59

𝒆 Side of the travelling plate triangle 112.96

𝒓𝒇 The length of upper arm 64.2

𝒓𝒆 The length of lower arm 192.6

Forward Kinematics

8

3 Trajectory Generation

3.1 Introduction

In general, a trajectory or path describes the desired motion of a manipulator in

multidimensional space. In robotics, trajectory defines as a time history of position, velocity,

and acceleration for each degree of freedom. Here, the basic problem is trajectory generation

which refers to how to design the trajectory in joint space from initial point to final point. In

order to solve this problem, we assume that we can compute the desired joint angle for final

point of the end effector. In other words, each point is converted into a set of desired joint

angles, 𝜃(𝑡). This conservation is called inverse kinematics.

Trajectory generation occurs at run time; in the most general case, position, velocity,

and acceleration are computed. These trajectories are computed on computers in discrete time

so the trajectory points are computed at a certain rate, called the path-update rate. In typical

manipulator systems, this rate lies between 60 and 2000 Hz.

3.2 Cartesian Space Schemes

In cartesian space, path generation is described in terms of functions of x, y and z

coordinates. The joint angles are repeatedly calculated through inverse kinematics equations

of Delta Robot. As mentioned before, the cartesian reference frame of the Delta Robot is the

center of the base plate triangle. Therefore, cartesian space trajectories moves relative to this

reference frame.

3.3 Joint-Space Schemes

In this section, methods of path generation are described in terms of functions of joint

angles. Each path point is actually frame usually expressed in terms of a desired position and

orientation of the tool frame {𝑇}, relative to the station frame {𝑆}. Each of these via points is

converted into a set of desired joint angles by application of the inverse kinematics.

Specifying the same duration for each joint, desired joint angle function for a particular

joint does not depend on the functions for the other joints. As a result, joint-space schemes

achieve the desired position and orientation at via points. Joint space schemes are the easiest

9

to compute compared with cartesian space. There is also no problem with singularities of the

mechanism.

3.3.1 Cubic Polynomials

In order to moving the manipulator its original position to a goal position in a certain

rate, we have to know some equations for defining the path. Set of joint angles is easily

calculated with the help of inverse kinematic dynamics of manipulator so we have initial and

goal angles of the manipulator. We try to find the function whose value is the initial joint angles

at 𝑡0 and whose value is the goal joint angles at 𝑡𝑓. This process is for joint space schemes.

Similarly, in cartesian space scheme, we know the initial angles of the motors and the

end-effector initial position is easily calculated with the help of forward kinematics. The goal

position is the desired position to move. We try to find the function whose value is the initial

position at 𝑡0 and whose value is the goal positions at 𝑡𝑓.

There are many smooth functions which change between two points is drawn in Figure

3.2. To obtain cubic polynomial, four constraints are needed. Initial and goal position of the

manipulator is two constraints:

𝜃(0) = 𝜃0 , 𝜃(𝑡𝑓) = 𝜃𝑓 3.1

Figure 3.1: Possible Path Shapes for a Single Joint

10

In-Lab Exercise: Cubic polynomials for Joint Space

1. Make necessary connections for Delta Robot. Then, open “Cubic Polynomial for Joint

Space.vi”.

Figure 3.2. Front Panel of “Cubic Polynomial for Joint Space.vi”

2. Follow the instructions.

3.3.2 Higher Order Polynomials

In the previous section, we’ve seen how to build cubic polynomials with via points but

the problem is at each via point acceleration suddenly changes and this causes jerks in the

system. To prevent these disturbances, we can use higher order polynomials where we can

specify the acceleration along with position and velocity.

3.3.2.1 In-Lab Exercise: Higher order polynomials for cartesian space

1. Make necessary connections for Delta Robot. Then, open “Higher Order Polynomial for

Cartesian Space.vi”.

Figure 3.3. Front Panel of “Higher Order Polynomial for Cartesian Space.vi”

2. Enter the desired final positions and final time. Run the VI. Observe the graphs.

11

4 Vision Guidelines for Delta Robot

4.1 Introduction to Vision Systems

NI Vision Software is consisted of three packets which are listed below:

NI Vision Acquisition Software

NI Vision Development Module

NI Vision Builder for Automated Inspections

4.2 NI Vision Acquisition Software

NI Vision Acquisition Software is used for basic vision applications depending on user’s

needs. Displaying, saving and monitoring applications is realized with the help of NI Vision

Acquisition Software. This software also includes NI-IMAQ and NI-IMAQdx drivers to acquire

images from various devices. There are many sub palettes “Vision and Motion” palette of

LabVIEW: NI-IMAQ, NI-IMAQdx, Vision Express, Image Processing etc. Vision express allows you

to set up vision applications quickly. This sub palette will be explained in the next chapter.

4.2.1 Vision Express Sub palette

Vision Express sub palette has two different types of function: Vision Acquisition and

Vision Assistant. Vision Acquisition can acquire the images from a camera using two drivers of

NI Vision Acquisition Software or load existing image or video from file. Besides, Vision Assistant

can improve acquired image with lookup tables, filters, grayscale morphology and Fast Fourier

Transforms.

4.2.1.1 Vision Acquisition Express

In this section, we will explain how Vision Acquisition Express VI is used. The following steps

are listed below to acquire image from a USB camera.

Figure 4.1: Selection of Vision Acquisition Express VI

12

4.2.1.2 Vision Assistant Express

Vision assistant offers us to test the image and it is a kind of toolbox that records every

processed custom algorithm. After the processed chain, the image can be tested. Therefore,

Vision Assistant Express always works with the image.

The following functions are used for Pick and Place Application of Delta Robot.

4.2.1.2.1 Color Plane Extraction

This function extracts the HSL (Luminance Plane) from acquired image. In other words,

it converts a color image into a grayscale image which is required for the next step process

(threshold).

Figure 4.2: Front Panel of “Vision Acquisition and Grayscale Processing.vi”

4.2.1.2.2 Threshold

Threshold function converts a grayscale image to a binary image. In this way, it basically

performs isolation that keeps the interest of you for instance; applying threshold to an object

separates the objects and the base. With this operation, background pixels are set to 0 and the

object pixels to non-zero value.

Figure 4.3: Process of Conversion Color Image to Binary Image

13

4.2.1.2.3 FFT Filter

Filters can remove, smooth and transform noise from the image. In addition to this FFT

(Fast Fourier Transform) filter analyze the image in frequency domain.

4.2.1.2.4 Look-up Table

To improve the brightness and contrast of an image look-up tables which are defined

transformations previously are applied to image.

Figure 4.4: Front Panel of “Vision Acquisition with Threshold, FFT Filter and Lookup

Table.vi”

4.2.1.2.5 Pattern Matching

This algorithm measures the similarity between template and image, after this weight

the similarity in the range of 0-1000. Minimum score is chosen 600 and template image for coin

is shown in Figure 6.13.

Figure 4.5: Template Image for Pattern Matching

14

Figure 4.6: Front Panel of “Non-calibrated Pattern Matching”

4.2.1.2.6 Image Calibration

An image data is read in the form of pixels. Spatial calibration offers you to convert a

measurement from pixel units into physical units. If the camera is perpendicular to the image

plane, one pixel corresponds one inch. In general, the camera takes the images at a certain

angle and is not perpendicular. Therefore, distorted images are acquired. To compensate for

perspective errors and nonlinear lens distortion of the camera, the image calibration function

should be used.

Figure 4.7: Front Panel of “Calibrated Pattern Matching.vi”

4.3 Pick and Place Application of Delta Robot

Pick and Place applications requires two different vi’s. “Pick and Place Application (Host

Side).vi” runs on My Computer and it acquires to image and detects coin position. Position of

coin is send to myRIO. “Pick and Place Application (myRIO Side).vi” reads the position. A

trajectory generates between initial and final positions on myRIO side and three motor moves

15

the coin position. Then, coin is grabbed and three motor moves initial position with coin again.

If three motor are at initial positions, the coin ungrabs. Finally, myRIO sends “Trajectory Done”

function to stop vi’s.

4.3.1 In-Lab Exercise: Pick and Place Application

1. Open the “Pick and Place Application (Host Side).vi” under My Computer.

Figure 4.8: Front Panel of “Pick and Place Application (Host Side).vi”

2. Open the “Pick and Place Application (myRIO Side).vi” under myRIO.

Figure 4.9: Front Panel of “Pick and Place Application (myRIO Side).vi”

16

References

[1] John J. Craig. Introduction to Robotics: Mechanics and Control (3rd Edition). Prentice Hall, 3

edition, August 2004.

[2] Alashqar, A.H. (2007). Modeling and High Precision Motion Control of 3 DOF Parallel Delta

Robot Manipulator. Post Graduated Thesis, The Islamic University of Gaza,Palestine.

[3] Trossen Robotic Community (t.y.).,<http://forums.trossenrobotics.com/tutorials/introducti

on-129/delta-robot>, (ET: 10.06.2015)

[4] R.L. Williams II, “The Delta Parallel Robot: Kinematics Solutions”, Internet Publication,

www.ohio.edu/people/williar4/html/pdf/DeltaKin.pdf, April 2015.

[5] Olsson A., Modeling and control of a Delta-3 robot. Master Thesis, Lund University, February

2009.

[6] K.S. Hsu, M. Karkoub, M.C. Tsai and M.G. Her, “Modelling and index analysis of a Delta-type

mechanism”, 2004.

[7] S. Folea, “Practical Applications and Solutions Using LabVIEW Software”, <intechweb.org>

[8] R. Posada-Gómez, O.O. Sandoval-González, A. M. Sibaja etc., Instituto Tecnológico de

Orizaba, Departamento de Postgrado e Investigación, México