AC500 to EMAX Modbus RTU ABB LVP&S Training

Transcript of AC500 to EMAX Modbus RTU ABB LVP&S Training

©AB

B Au

tom

atio

n Te

chno

logi

es

AC500 to EMAX Modbus RTU

ABB LVP&S Training

Revision Date: Feb 16,2009

www.infoPLC.net

©AB

B G

roup

200

8 -

2

AC500 - PLC

CONTROLPRODUCTS Objective

Using AC500 to communicate to Emax Breaker with Modbus RTU.

This intermediate level course demonstrates how to connect an AC500 PLC to an Emax breaker. The student will wire an Emaxbreaker to a AC500 PLC with provided wiring diagrams. The student will also control and monitor Emax breaker with provided AC500 program (AC500_MODBUS_RTU_EMAX.pro).

www.infoPLC.net

©AB

B G

roup

200

8 -

3

AC500 - PLC

CONTROLPRODUCTS Required Items

Required Items Emax Breaker with Trip Unit PR122/3 or PR332/3

Communication Module PR120/D-M

AC500 PLC Program AC500_MODBUS_RTU_EMAX.pro

AC500 PM5xx

Instructional Manual – Trip Unit Modbus System Interface (1SDC200005D0201.pdf)

www.infoPLC.net

©AB

B G

roup

200

8 -

4

AC500 - PLC

CONTROLPRODUCTS Overview

Hardware ConnectionsCommunication ParametersMemory mappingPLC programEvaluationSummary

www.infoPLC.net

©AB

B G

roup

200

8 -

5

AC500 - PLC

CONTROLPRODUCTS Hardware Connections

Hardware ConnectionsCommunication Module Inside Trip Unit

Communication Module

Pin 1

Pin 10

W1 & W2 is your Modbus RTU twisted pair

W1 is Rx/Tx Data Positive connected to Pin 6

Rx/Tx +

W2 is Rx/Tx Data Negative Connected to Pin 5

Rx/Tx -

www.infoPLC.net

©AB

B G

roup

200

8 -

6

AC500 - PLC

CONTROLPRODUCTS Hardware Connections

Emax Internal Hardware Connections

Terminal K1= +24V

Terminal K2 = 0V

External 24V Power Supply Provide 24V Power to Trip Unit

W1 (Rx/Tx + )

W2 (Rx/Tx - )

Com Module to Terminal Strip

Emax Breaker

www.infoPLC.net

©AB

B G

roup

200

8 -

7

AC500 - PLC

CONTROLPRODUCTS Hardware Connections

Emax Breaker internal circuit diagrams

Optional Charging Motor, YC closing coil and YO opening coil

Refer to Emax Technical Catalog (1SDC200005D0201)

Wiring for Spring Charging motor if equipped YC wiring

through com module relay

YC wiring external circuit

YO wiring through com module relay

YO wiring external circuit

OROR

Communication Module

PR120/D-M

www.infoPLC.net

©AB

B G

roup

200

8 -

8

AC500 - PLC

CONTROLPRODUCTS Hardware Connections

AC500 External Communication Connections

Emax Breaker

AC500 COM1

W2 (Rx/Tx - )

OR

W1 (Rx/Tx + )

www.infoPLC.net

©AB

B G

roup

200

8 -

9

AC500 - PLC

CONTROLPRODUCTS Emax Communication Parameters

Setting the Com Module address, baud rate, and com mode.

In the Trip Unit display select <ESC> key.Go to Settings and select “Com Module”Select the Local option

Default password is “0001”Once module is in Local hit <ESC> key to go back until you are prompted to save and

confirm changesGo back to com module settings and select Address

Set address to “70”Select Baud Rate

Set baud rate to 19200kb/sSelect Protocol Type

Even, 8 data bits, 1 stop bit = “E,8,1”Select Addressing Type

Select Modbus StandardPlace Com Module back in Remote and confirm changes

www.infoPLC.net

©AB

B G

roup

200

8 -

10

AC500 - PLC

CONTROLPRODUCTS PLC Communication Parameters

PLC Com 1 port settingsBaud Rate, Parity, Stop Bits must match Emax communication module settings

Operation Mode must be set to Master

www.infoPLC.net

©AB

B G

roup

200

8 -

11

AC500 - PLC

CONTROLPRODUCTS Memory Mapping

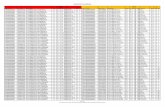

Emax Memory Mapping Index table

www.infoPLC.net

©AB

B G

roup

200

8 -

12

AC500 - PLC

CONTROLPRODUCTS Memory Mapping

Memory Mapping Read Only Registers (Status)Example:Reading Parameter 101 (Word Address 101)

If the Value = 16 then CB is closed means Bit 4 is ON (Addr 101 = 0000 0000 0001 0000 = 16 decimal)

www.infoPLC.net

©AB

B G

roup

200

8 -

13

AC500 - PLC

CONTROLPRODUCTS Memory Mapping

Memory mapping Read Only registers (Status)

Example:Reading Parameter 1028 (Word Address 1028)

If the Value = 70 then the Slave address is 70

www.infoPLC.net

©AB

B G

roup

200

8 -

14

AC500 - PLC

CONTROLPRODUCTS Memory Mapping

Memory Mapping Write Only registers

Example:

Command Value:

Binary Decimal0000 0000 0000 1000 = Open 8 = Open0000 0000 0000 1001 = Close 9 = Close0000 0000 0000 0001 = Reset Trip 1 = Reset

Note:

When writing a command you must write both Command Type and Command Parameter. This means you must sent a double word (32bits) at one time.

www.infoPLC.net

©AB

B G

roup

200

8 -

15

AC500 - PLC

CONTROLPRODUCTS PLC Program

Operating circuit breaker remotelyWhen you Go online with the program AC500_MODBUS_RTU_EMAX.pro the

correct breaker address should show on the top left corner of the HMI. Verify Address matches the breaker you want to operate remotely.

* Breaker Com Module must be in remote to accept commands*

Status Indicators

Commands

www.infoPLC.net

©AB

B G

roup

200

8 -

16

AC500 - PLC

CONTROLPRODUCTS

Operating circuit breaker remotelyTest operation of breaker by opening and closing

PLC Program www.infoPLC.net

©AB

B G

roup

200

8 -

17

AC500 - PLC

CONTROLPRODUCTS Evaluation

Was hardware connection content defined?

Was memory mapping instructions defined?

Did the PLC program communicate with the Emax?

www.infoPLC.net

©AB

B G

roup

200

8 -

18

AC500 - PLC

CONTROLPRODUCTS Summary

The Course provided a quick-start guide to interfacing an AC500 PLC to an Emax Breaker.

Modbus RTU communication protocal was used to communicate between the AC500 and Emax breaker.

The Emax Memory Mapping table linked PLC memory addresses to breaker commands and parameters.

The PLC program provided a user interface to execute commands and retrieve breaker parameters.

www.infoPLC.net

©AB

B G

roup

200

8 -

19

AC500 - PLC

CONTROLPRODUCTS Questions www.infoPLC.net