About Kprene

-

Upload

visiondesign -

Category

Documents

-

view

111 -

download

1

description

Transcript of About Kprene

technical info

5

80

0-3

45

-05

83

ww

w.acrotechinc.com

Fax: 65

1-3

45

-37

59D

uro

mete

r D

Rockw

ell R

Duro

mete

r A

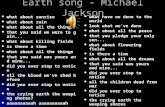

Hardness Scale150

140

130

120

110

100

90

70

50

85

75

65

55

459590

80

70

60

50

40

30

20

10

Plastics

K•Prene®Urethane

Rubber

Phenolics

Acrylics

Nylons

Polystyrenes

Bowling Ball

Shoe Heel

Tire Cord

Rubber

K•Prene® Urethane CharacteristicsTDI and MDI chemical structures, both are available in polyether and polyester formulas.

We manufacture over 25 formulations on a daily basis.

Hundreds of other formulations are available to meet your most demanding application.

Broad hardnesses ranging from 10 Shore A to 85 Shore D Durometer.

6 standard colors, CuSTOM COlORS ARe AVAIlABle.

Selecting K•Prene® for limitless applicationsUrethane provides a unique combination of properties. These include: high load-bearing capacity; toughness; hardness; abrasion resistance; and oil and ozone resistance.

Stocked Durometers/Hardnesses

K-400A K-600A K-800A K-900A K-950A K-750D

K-400A Yellow 40A Durometer: A low durometer material with a high coefficient of friction that will satisfy countless industrial needs such as rollers, bumpers, etc.

K-600A Black 60A Durometer: High coefficient of friction and excellent tensile strength makes this material a good choice for feed rolls and many other industrial applications.

K-800A Orange 80A Durometer: Good tear strength, abrasion resistance and excellent flex life. Good low temperature properties. Requires lower tonnage. Withstands greater deflection. Should not be used for material heavier than 20 gauge mild steel, except in special applications. Maximum recommended deflection 35%.

K-900A Blue 90A Durometer: Withstands consistent flexing. Good cut resistance. Good load-bearing capacity. Recommended for most applications where large radius bends or difficult bends require large deflection or flow of K•Prene®. Maximum recommended deflection 25%.

K-950A Red 95A Durometer: High tensile strength for higher blank-holding pressure. High load-bearing capacity. Best tear strength. Best cut resistance. Best abrasion/wear resistance. Recommended for most applications. Maximum recommended deflection 15%.

K-750D Brown 75D Durometer: Great load- bearing capacity. Excellent machinability and abrasion resistance. Offers great rigidity, yet will deflect. Maximum recommended deflection 5%.