ABBREVATIONS LIST

Transcript of ABBREVATIONS LIST

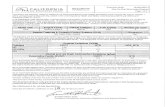

INDEX OF DRAWINGS

E1.G.01

SYMBOLS, INDEX AND ABBREVIATIONS LIST

ES1.1

OVERALL SITE LIGHTING PLAN

E1.G.11

6-BAY GARAGE BUILDING WITH STORAGE

ELECTRICAL CODE SUMMARY

ELECTRICAL SYSTEMS - EACH BUILDING WILL BE SERVED BY A MULT-METER CENTER. EACH

UNIT WITHIN THE BUILDING WILL HAVE ITS OWN ELECTRIC METER. THERE WILL ALSO BE A

"HOUSE", OR GENERAL, METER FOR OTHER LOADS. WIRE AND CONDUIT SIZE TO EACH METER

CENTER IS SHOWN ON DRAWINGS. TYPICALLY, EACH UNIT WILL BE SERVED WITH A 125A

PANEL. EACH UNIT PANEL SCHEDULE, WHICH IS INCLUDED IN DRAWING SET, INDICATES ALL

BRANCH CIRCUITS WITHIN THE UNIT AND HAS ITS LOAD CALCULATED IN ACCORDANCE WITH

NEC ARTICLE 220. THE "HOUSE", OR GENERAL, METER AND PANELBOARD SCHEDULES ARE

ALSO INDICATED.

EACH APARTMENT BUILDING WILL BE PROTECTED BY NFPA 13R SPRINKLER SYSTEM. THIS

SUPPRESSION SYSTEM WILL BE MONITORED BY AN ADDRESSABLE FIRE ALARM SYSTEM. IN

ADDITION, EACH TENANT UNIT WILL BE EQUIPPED BY AN NFPA 72 COMPLIANT RESIDENTIAL

UNIT SMOKE DETECTOR/SOUNDER BASE IN AND ADJACENT TO EACH SLEEPING UNIT. ADA

COMPLIANT ACCESSIBLE UNITS WILL BE PROVIDED WITH AUDIBLE AND VISUAL ANNUNCIATION

IN ACCORDANCE WITH NFPA 72 AND ANSI A117.1 GUIDELINES. EACH BUILDING FIRE ALARM

SYSTEM WILL REPORT TO A CENTRALIZED FIRE ALARM PANEL PROVIDED WITH OFF-SITE

MONITORING AND EQUIPPED WITH AN NFPA 72 DIALER UNIT.

NEAR CIRCULATOR (REFER TO HVAC &

PROJECT ELECTRICAL CONTRACTOR

PHOTOCELL, # INDICATES PHOTOCELL

TEMPERATURE CONTROL CONTRACTOR

MAIN SWITCHBOARD

MANUAL SWITCH WITH PILOT LIGHT

DRWGS FOR EXACT LOCATION.)

PLUMBING CONTRACTOR

PUSH BUTTON STATION

PRE-WIRED CONTROL PANEL

PUSH BUTTON WITH PILOT LIGHT

PART WINGING STARTER

SOLENOID AIR VALVE

REDUCED VOLTAGE STARTER

REVERSE ACTING THERMOSTAT

POWER ROOF VENTILATOR

PNEUMATIC ELECTRIC SWITCH

SUPERVISORY SWITCH

START-STOP WITH PILOT LIGHT

UNDERGROUND DUCT

UNDERFLOOR DUCT

LIGHT DESIGNATION

TRACKLIGHT, # INDICATES TRACK

TEMPERATURE CONTROL PANEL

STERILIZER CONTROLS

VENDOR SUPPLYING EQUIPMENT

UNLESS OTHERWISE INDICATED

DRWGS FOR EXACT LOCATION.)

SELECTOR SWITCHSPS

EWH ELECTRIC WALL HEATER

MULTI-RECEPTACLE DESIGNATION

MULTI-RECEPTACLE, # INDICATES

LINE VOLTAGE THERMOSTAT (120V)

LOAD (KW OR HP)

KILOVOLT-AMPERES

MOTOR GENERATOR

MOTORIZED DAMPER

MAIN CIRCUIT BREAKER

PROJECT GENERAL CONTRACTOR

GROUND FAULT INTERRUPTER TYPE

HAND-OFF-AUTO SELECTOR SWITCH

HEATING/VENTILATING CONTRACTOR

MAGNETIC STARTER

IN STARTER COVER

KVA

KW

MCB

MG

MFR

MD

LD

LVT

MR#

MLO

KILOWATT

MANUFACTURER

MAIN LUGS ONLY

G, GFI

GC

FZS

FS

EX

GND, GRND

H, HV

HP

HOA

GV

GS

KS

IS

IL

IU

I

F

GATE VALVE

IN UNIT

KEY SWITCH

INTERLOCK

INSTALLED BY

HORSEPOWER

GROUND

FREEZESTAT

EXISTING

FURNISHED BY

FLOW SWITCH

UO

V

W/

WP

USS

XFMR

WT

UOI

W

UNIQUE OUTLET

WITH

WIRED BY

UNIT SUBSTATION

WIRING TROUGH

WEATHERPROOF

TRANSFORMER

SS

SVS

SWGR

SWBD

TC

STAT

SSP

TL#

TS

TO

TCP

TCC

UG

UGD

UH

UFD

TV

UNIT HEATER

TELEVISION

UNDERGROUND

TYPICAL OUTLET

TAMPER SWITCH

THERMOSTAT

TIME CLOCK

SWITCHGEAR

SWITCHBOARD

SPEED SWITCH

MSBACT ABOVE COUNTER TOP

ABOVE FINISHED GRADE

ABOVE FINISHED FLOOR

BY ELECTRICAL CONTRACTOR

EXPLOSION PROOF

ELECTRIC DUCT HEATER

ELECTRIC UNIT HEATER

COMBINATION CIRCUIT BREAKER

CONTROL POWER TRANSFORMER

FULL VOLTAGE STARTER

VOLTAGE STARTER

CEILING EXHAUST FAN

DISCONNECT SWITCH

DOOR MANUFACTURER

CABINET UNIT HEATER

COMBINATION STARTER

COMBINATION FUSIBLE FULL

DUCT DESIGNATION

BUILT-IN OVERLOAD

BELOW FINISHED GRADE

BUS DUCT, # INDICATES BUS

CIRCUIT BRACKER(S)

BOILER CONTROL PANEL

CEF

CF

CPT

CU

CS

CUH

CKT

DRWGS

DN

EDH

DM

D, DS

E, EC, X

ET

EUH

EM

EP

EF

DOWN

DRAWINGS

EMERGENCY

ELAPSED TIMER

EXHAUST FAN

COPPER

CIRCUIT

AFF

AQ

AU

B,JB

AS

ALT

AFG

BOL

BFG

BD#

CCB

CDT

CB, C/B

BCP

C CONTACTOR

CONDUIT

AQUASTAT

AS SHOWN

AT UNIT

ALTERNATE

JUNCTION BOX

PC

PCP

PRV

PEC

PW

R

PL

SC

SAV

RVS

RAT

RAI

RAF

PE

SPR

SPC

SP

SF

SSTERILIZER

SUPPLY FAN

SPACE

SPARE

SHOCK-PROOF

PILOT LIGHT

RECEPTACLE

REMAIN AS IS

RETURN AIR FAN

MSP

NC

NIC

NP

MTD

MT

OOS

NU

OU

NTS

PBL

PBS

P#

NOT TO SCALE

ON UNIT

ON-OFF SWITCH

DESIGNATION

MOUNTED

EMPTY

NOT IN CONTRACT

ABBREVATIONS LIST

A AMP MS MANUAL STARTER

CONDUIT, CAPPED

SD

FIRE ALARM - SMOKE DUCT DETECTOR

(#/#)

CIM

FIRE ALARM - CONTROL INTERFACE MODULE

FIRE ALARM - MONITOR INTERFACE MODULE

MIM

DH

TS

FS

T

S

TELEVISION OUTLET, (COAX)

TELEPHONE/DATA OUTLET, (TWO CAT 5)

SD

CEILING AS SHOWN (COMBO SMOKE/CO DETECTOR WHERE NOTE)

SMOKE DETECTOR - SELF CONTAINED, SURFACE MOUNTED ON WALL OR

FIRE ALARM - VISUAL ONLY SIGNAL

FIRE ALARM - AUDIO/VISUAL SIGNAL

FIRE ALARM - AUDIO ONLY SIGNAL

FIRE ALARM - SMOKE DETECTOR

FIRE ALARM - THERMAL DETECTOR

FIRE ALARM - WATER FLOW SWITCH

FIRE ALARM - VALVE TAMPER SWITCH

FIRE ALARM - DOOR HOLDER

SUBSCRIPTS:

FIRE ALARM - MANUAL PULL STATION

FA

ANN

FA

CP

FIRE ALARM CONTROL PANEL - SURFACE OR RECESSED AS SHOWN

#

MDP

AS SHOWN, # INDICATES ALPHA-NUMERIC PANEL DESIGNATION

PP

#

POWER PANEL - MOUNTED ON/IN WALL, SURFACE OR RECESSED

AS SHOWN, # INDICATES ALPHA-NUMERIC PANEL DESIGNATION

# INDICATES PANELBOARD DESIGNATION

PANELBOARD, SURFACE OR RECESSED MOUNTED, AS SHOWN.

PROTECTIVE DEVICE - DISCONNECT SWITCH

MOTOR

(PP) TELE-POWER POLE IN CEILING

(C) COMMUNICATIONS, (AL) AISLE LIGHT,

(S) SURFACE MOUNTED, (F) FLUSH MOUNTED,SUBSCRIPTS:

JUNCTION BOX, TWO-GANG

SPECIAL PURPOSE OUTLET - SEE SCHEDULE

CONVIENCE OUTLET - DUPLEX RECEPTACLE, MOUNTED 6" ABOVE

SUBSCRIPTS:

GROUND, (TSS) TRANSIENT SURGE SUPPRESSOR

FURNISHED BY OTHERS, (H) MOUNTED HORIZONTALLY,

TOE SPACE, (EP) EXPLOSION PROOF, (IG) ISOLATED

CONVIENCE OUTLET - DUPLEX RECEPTACLE, WALL MOUNTED 15" AFF

SWITCHED CIRCUIT

UNSWITCHED CIRCUIT

P PHOTOCELL

C CONTACTOR

TCTIME CLOCK

OCCUPANCY SENSOR - MOUNTED IN CEILING

SUBSCRIPTS:

LOCAL SWITCH, SINGLE POLE

(WP) WEATHERPROOF, (K) KEY OPERATED,

(3) THREE-WAY, (4) FOUR-WAY, (PL) PILOT LIGHT,

(I) INNER LAMP(S) SWITCHED, (OS) OCCUPANCY SENSOR

(MS) DUAL TECH OCC SENSOR, WATTSTOPPER #DW100

LT

#

EMERGENCY BATTERY UNIT

LIGHT FIXTURE - BRACKET-ARM, MOUNTED ON POLE

LIGHT FIXTURE - POST-TOP, MOUNTED ON POLE

ARROWS AS SHOWN

EXIT SIGN -

WALL MOUNTED, SINGLE FACED WITH DIRECTIONAL

ARROWS AS SHOWN

EXIT SIGN -

WALL MOUNTED, DOUBLE FACED WITH DIRECTIONAL

ARROWS AS SHOWN

EXIT SIGN -

CEILING MOUNTED, SINGLE FACED WITH DIRECTIONAL

ARROWS AS SHOWN

EXIT SIGN -

CEILING MOUNTED, DOUBLE FACED WITH DIRECTIONAL

SHADED FIXTURES INDICATE EMERGENCY OR 24 HOUR LIGHTING

LIGHT FIXTURE - WALL WASHER - RECESSED IN CEILING

LIGHT FIXTURE - RECESSED IN CEILING

LIGHT FIXTURE - RECESSED IN WALL

LIGHT FIXTURE - SURFACE MOUNTED ON WALL

LIGHT FIXTURE - SURFACE MOUNTED ON CEILING

LIGHT FIXTURE - FLUORESCENT, MOUNTED UNDER CABINET

LIGHT FIXTURE - FLUORESCENT, SURFACE MOUNTED ON WALL

RECESSED AS SPECIFIED IN LIGHTING FIXTURE SCHEDULE

LIGHT FIXTURE - FLUORESCENT, MOUNTED ON/IN CEILING, SURFACE OR

SYMBOLS LIST

COUNTER

GARAGE DOOR SENSOR - WIRE TO OPENER

GARAGE DOOR SENSOR - WIRE TO OPENER

CEILING MOUNTED PADDLE FAN

FLUSH MOUNTED FLOOR BOX WITH POWER, DATA AND COAX

FLUSH MOUNTED FLOOR BOX WITH POWER AND DATA

SUBSCRIPTS:*

CEILING SPEAKER - ROUGH IN

SWITCH DESIGNATION

SUBSCRIPTS: SPEAKER DESIGNATIONV,*

SPEAKER VOLUME CONTROL - ROUGH IN

ELECTRIC STRIKE - ROUGH IN

ES

DOOR CONTACT - ROUGH IN

DC

KEYPAD - ROUGH IN

KP

SECURITY CAMERA - ROUGH IN TV

SECURITY MOTION SENSOR - ROUGH IN

REMOTE EMERGENCY HEAD

BATTERY PACK FOR REMOTE EM. HEAD

OR EQUIVALENT

CO

ON WALL OR CEILING AS SHOWN

CARBON MONOXIDE DETECTOR - SELF CONTAINED, SURFACE MOUNTED

DAYLIGHT SENSOR - MOUNTED IN CEILING

CONTINENTAL 422 FUND LLCW134 N8675 EXECUTIVE PARKWAYMENOMONEE FALLS, WI 53051

262.502.5500 * FAX 262.502.5522

LPA #8374

Consulting Electrical Engineers/Planners

Ph. (262) 860-1544, Fax (262) 860-1566

Elm Grove, Wisconsin 53122

12970 W. Bluemound Road - Suite 101

E1.G.02

ELECTRICAL SPECIFICATIONS

Reviewed for CodeCompliance

PRBD20180209312

ReviewedCCEPR-dae.

16.00 ELECTRICAL SPECIFICATION INDEX:

16.10 Basic Requirements16.12 Wires and Cables16.13 Raceways16.14 Wiring Devices16.30 Electrical Service and Distribution16.46 Grounding16.47 Panelboards16.48 Motors and Special Outlets16.51 Interior Lighting16.52 Site Lighting16.70 Fire Alarm System16.76 Telephone System16.79 Television Cable and/or Satellite System16.80 Security System

16.10 BASIC REQUIREMENTS:A. General:

1. Design and build the electrical facilities for the Continental Properties, Springsat Hammock Cove apartment campus, Naples, Florida as outlined in thesespecifications and associated electrical design parameter schedules.

2. The electrical material counts specified in the electrical design parameterschedule establishes the minimum acceptable design. Increases in this designmay be necessary based on conditions that develop in the design phases.The electrical contractor is responsible for all costs involved in changesrequired from this specification.

3. Provide all materials, equipment, apparatus, electrical systems and incidentalsas necessary and/or herein specified for a complete installation.

4. The electrical work shall also include installation of equipment furnished byothers and equipment furnished and installed by others which shall be wiredand connected by the Electrical Contractor.

B. Work Included:1. Visit site and verify conditions.2. Temporary power service to be used for heating, lighting and power during

construction.3. Electric service from local Electrical Utility Company.4. Panelboards, and metering equipment as shown on drawings.5. Grounding system and bonding. Service metering board(s) shall be separately

grounded to cold water main and to supplementary grounding electrodes. Sizeground conductors as required by NEC 250.

6. Distribution systems for tenant loads.7. Equipment disconnect switches fused and non-fused in strict compliance with

code.8. Power wiring and controls for electrical heating equipment.9. Power and control wiring for kitchen equipment and electric controls for water

heaters.10. Power wiring for appliances, laundry equipment and vending machines.11. Outlets, receptacles, special power outlets and power wiring.12. Power wiring for ventilation, duct heaters, VAV boxes, boilers, air conditioning,

plumbing and fire protection equipment.13. Power wiring and interlocking with the fire alarm system for electrically operated

dampers where required.14. Indoor lighting, lamps, mounting accessories and controls.15. Outdoor lighting, lamps, mounting accessories, pole bases and controls.16. Exit and emergency lighting system, complete with associated conduit and

wiring.17. Provide battery unit with lamps where shown.18. Addressable fire alarm system in conformance with the applicable Codes.19. Residential smoke detectors.20. Telephone/data system.21. T.V. and cable system.22. Gate Access and Door security system.23. All permits, testing and inspection fees.24. One year guarantee on labor and materials.

C. Specified Elsewhere:1. The following will be provided under other Sections of the Specifications:

a. Motors for mechanical equipment.b. Controllers that are part of mechanical equipment.c. Temperature control wiring for the HVAC systems.d. Telephone/data instruments and terminals (not in Contract).e. Kitchen equipment.f. Appliances.

D. References:1. The electrical work shall be in accordance with the 2017 Florida Building

Codes, based upon 2015 IBC, 2015 IRC, 2015 IFC, 2015 IECC Energy Code,2014 NEC, with all applicable local, state and federal codes, and localinspection authority, Americans with Disabilities Act (ADA) and rules andregulations of the local power utility.

2. Applicable standards published by NEMA, IEEE, ANSI and NFPA shall befollowed.

3. Underwriters Laboratories (UL) label is required on equipment where suchstandards have been established.

4. Permits, Licenses and Inspection Fees: The PEC shall prepare and submitapplications and submittals required, obtain necessary permits and certificatesof compliance and approvals required, and shall deliver these to the A/Epaying all necessary fees.

5. All materials and equipment shall be new and in perfect condition wheninstalled and shall be of the best grade and of the same manufacturerthroughout for each class or group of equipment. Materials shall meet withapproval of the Division of Industrial Safety and all governing bodies havingjurisdiction. Materials shall be manufactured in accordance with applicablestandards established by ANSI, NEMA, and NBFU.

E. Performance Requirements:1. General:

a. Work shall be done by skilled persons qualified and competent to performthe best grade of workmanship.

b. The electrical contractor shall carefully check the heating and ventilating,plumbing and architectural drawings and the existing conditions todetermine exact location and manner of installing electrical outlets andconnections.

c. The electrical contractor shall cooperate with the other contractors inrunning of conduit and installation of boxes, etc.

d. Contractor shall perform all verification, observations, test, and examinationof work prior to the ordering of the electrical equipment and actualconstruction. Contractor shall issue a written notice of all findings to theContracting Officer listing all malfunctions, faulty equipment anddiscrepancies.

e. Patch, repair, and paint any area that has been damaged in the course ofthe electrical work.

f. Penetrations in fire rated walls shall be sealed in accordance with

applicable codes.

2. Equipment Identification:a. Materials and electrical equipment installed under this contract shall be

clearly and permanently identified.b. Engraved plastic nameplates shall be securely attached to all panelboards,

disconnect switches and motor starters.c. Identify each new conductor at each panel, pull box and at each outlet with

permanently attached adhesive markers.

3. Equipment Grounding:a. Metal boxes, cabinets, switch enclosures; motor frames and other metallic

enclosures shall be bonded with green color coded equipment groundwires.

b. The ground wires shall be run in the same raceway with the feeder orbranch circuit wires.

c. Provide separate equipment grounding conductor within all raceway sizedper NEC for all lighting and receptacle branch circuit conduits.

d. Terminate ground wires at the panelboard ground bus.

F. Assurance Submittals:1. Shop Drawings:

a. Submit shop drawings, product data and manufacturer's instructions for thefollowing:

1) Lighting Fixtures.2) Panelboards.3) Wiring Devices.4) Service Metering and Distribution Equipment.5) Fire Alarm System.

2. Load Calculations:a. Electrical load calculation including panel schedule, panel load, feeder

sizes, voltage drop and main distribution panel sizing shall be provided withfinal design review. Also, short circuit calculations and coordination ofcircuit protection devices shall be provided to meet NEC requirements.

G. Quality Assurance:1. After completion, all electrical systems shall be tested and demonstrated to

show satisfactory compliance with the specified performance criteria andinstallation requirements. A written record of the results of performance testsmade on special systems and equipment shall be furnished to the Owner.Special systems shall include fire alarm and smoke detection systems, all otheralarm systems and lighting systems.

2. Make such changes as directed to make installation comply with thespecifications.

3. Repair or replace all faulty work or equipment.4. Provide the Owner with a written certificate that all parts of the electrical

system have been inspected and final approval has been obtained from theappropriate authority.

5. Submit data and certificates of final inspection and approval as issued by localinspection authority or affidavit attesting to compliance with applicable codes.

6. Provide the Owner with reproducible set of “As-Built” Record Drawingsdepicting electrical construction at job completion. Drawings shall bedimensioned showing equipment locations, ratings and circuits.

7. Complete job shall be guaranteed for a period of one year after date of jobacceptance by Owner. Any work, material or equipment found to be faultyduring that period shall be corrected at once upon written notification, at theexpense of the contractor.

16.12 WIRES AND CABLES:

A. General: All building wires and cables and associated splices, connectors andterminations for the wiring system shall be rated for 600 volts.

B. Feeders:1. Type THWN copper or aluminum conductors with ground in raceway.2. Type SE or USE cable, copper or aluminum conductor, 75C insulation

minimum where allowed by local codes and Authority Having Jurisdiction (AHJ).

C. Branch Circuits:1. Type THHN/THWN, copper conductor in raceway.2. Type MC, AC or NM cable, copper conductor, 75C insulation minimum where

allowed by local codes and Authority Having Jurisdiction (AHJ).

16.13 RACEWAY:A. General: Raceways shall be installed as a complete system continuous from

service to outlet or equipment, mechanically and electrically connected, constitutinga continuous ground system.

B. Conduit Installation Schedule:1. Electric metallic tubing, dry interior locations only.2. Rigid Steel Conduit:

a. Exposed outdoor locations.b. Wet interior locations.c. Floor slab or foundation wall penetrations, within 5-feet from foundation

wall.

3. Schedule 40 PVC Conduit:a. Under concrete slab on grade.b. Underground more than 5-feet from foundation wall, wet locations.

C. Raceway shall generally be concealed whenever possible. Surface raceways shallbe employed in unfinished areas and where impossible to conceal and wheredirected by the A/E.

D. Flexible metal conduit as approved and required by Code. Employ liquidtightflexible metal or nonmetallic conduit with ground wire for final connections tomotors, vibrating equipment, etc. Employ “greenfield” flexible metal conduit for finalconnection to recessed lighting fixtures, etc.

E. All rigid steel conduit and IMC fittings shall be threaded type.

F. All connectors shall have insulated throats. Connectors for use with flexible metalconduit shall be threaded type.

G. Indentation type, set-screw type and push-on type fittings are not acceptable for

rigid steel, EMT or flexible metal conduits. Fittings with die-cast bodies, wholly orpartially, are not acceptable.

16.14 WIRING DEVICES:A. General:

1. Convenience receptacles shall be commercial grade 15- or 20-amperegrounding type similar to Hubbell Nos. BR15 or BR20. Switches used shall becommercial grade 15- and 20-ampere quiet type, rated for use on 120 voltsystems similar to Hubbell No. CSB120 (CSB15), CSB320 (CSB315) andCSB420 (CSB415). All devices shall be commercial specification grade.

2. GFCI receptacles shall be 15- or 20-ampere specification grade with lockoutcapability upon GFCI failure.

3. Exterior receptacles shall be marked “WEATHER RESISTANT” per NEC.4. Receptacles utilized in dwelling units, and elsewhere required by Code shall bemarked “TAMPER RESISTANT” per NEC.

5. Flush mount wiring devices under a smooth nylon device plate with a whitefinish.

B. Outlet Requirements:1. Provide minimum number of 15- and 20-ampere, 120 volt receptacle required

by NEC 210.2. Provide GFI type receptacles when located within 6'-0” of sinks and basins and

where required elsewhere by NEC.3. Provide convenience receptacles for housekeeping in corridors and other

common areas at a maximum of 50 feet on center.

16.30 ELECTRICAL SERVICE AND DISTRIBUTION:A. General:

1. Provide single phase, 120/240V electrical service with local utility approvedmetering gear at each separately metered building or structure as shown ondrawings.

2. Ratings of switchgear and switchboard assemblies shall ensure that maximumavailable short-circuit currents are safely interrupted.

B. Provide temporary electric power and lighting during the construction period asnecessary to meet OSHA requirements.

16.46 GROUNDING:A. Systems grounding conductors from neutral bus in main service equipment to water

service in accordance with Code requirements -- terminate grounding conductorson service side of water meter using O.Z./Gedney Type CG connector orequivalent. Extend copper grounding electrode conductor(s) from serviceequipment to supplemental driven electrodes and water service entrance as well asother grounding electrodes required by NEC 250.

B. In accordance with Code, provide supplementary service ground as follows:

1. Provide ground grid consisting of at least (3) 8'-0" by 5/8" copper-claddriven ground rods, 10'-0" on centers and minimum 6'-0" from building. Thedriven rods may form a triangular pattern.

2. Ground resistance shall be 25 ohms or less. Provide additional rods orelectrodes as required to obtain proper resistance to ground.

C. All grounding connections must be approved for the purpose, as manufactured byO.Z./Gedney or equivalent.

D. Metallic raceway system shall be grounded as required by Code, so that groundwill be electrically continuous from the service entrance conduit to all outlet boxes.

E. Motors shall be grounded with a separate green ground conductor routed viaflexible metal conduit.

16.47 PANELBOARDS:A. Distribution Equipment:

1. Panelboards and cabinets shall accommodate active and spare circuit breakersin voltage ratings as required. Cabinets shall be flush or surface mounted.Minimum 20" wide by 5-3/4" deep, common keyed, complete with directoryholder mounted on door interior. Panels served on a riser feeder shall includean auxiliary 6" wiring gutter. Circuit breakers shall be plug-in type in ratingsand interrupting capacity as scheduled. Square D “QO” or “NQOD”panelboards.

2. Panelboards shall include a main circuit breaker.3. Panelboards supplying lighting and receptacle and appliance-branch circuits

shall be located in each respective dwelling unit and as shown on drawings.4. Approved Manufacturers: Eaton, Square D (EXCLUDING Homeline series

equipment), G.E, Siemens.

16.48 MOTORS AND SPECIAL OUTLETS:A. Feeders to be extended from the service equipment panel to feed mechanical and

building service equipment and from remote panelboards to feed minor mechanicalequipment. Circuit breakers to be provided to feed all equipment shall be permanufacturer's recommendations. Disconnect switches to be provided at the unitsto comply with Code.

16.51 INTERIOR LIGHTING:A. All Areas:

1. Provide and install light fixtures per drawings and fixture schedule(s).2. All fluorescent ballasts shall be electronic type with total harmonic distortion

(THD) of less than 10%.

16.52 SITE LIGHTING:A. Provide lighting for the entry drive, parking lot and walkways. Refer to the site plan

for areas requiring lighting.B. Provide flagpole illumination as shown on drawings and fixture schedule.C. Provide electrical connection to monument sign and mail kiosk. See site plan.D. Fixtures shall be cut-off type luminaires with HID, LED lamps or other light sources

as shown on drawings and fixture schedule.E. Poles shall be as shown on drawings and fixture schedule.F. Fixtures are to be controlled by a photo-cell and/or time clock.G. Provide 2'-0” AFG bases for all poles and install in accordance with the

manufacturer's instructions.H. Provide a ground rod in each pole base.

I. Branch wiring to lighting poles shall be #10 THWN minimum copper wire in3/4-inch minimum PVC conduit. Wiring shall include #10 green equipmentgrounding conductor that shall be bonded to the metal pole, luminaire and thepanelboard ground bus.

16.70 FIRE ALARM SYSTEM:A. Provide a zoned fire alarm system in each Apartment building for Sprinkler System

supervision. Each Apartment building shall be monitored for Alarm, Supervisoryand Trouble conditions by an addressable fire alarm system in the Clubhouse. TheClubhouse fire alarm system shall protect the clubhouse, monitor the Apartmentbuildings and transmit status of the system to an approved supervising station. AllFire Alarm Systems shall comply with NFPA 72 (2013), International Fire Code(IFC), ADA (ANSI A117.1), Florida Building Code 2017 (FBC), Florida AccessibilityCode (2014), NEC (2014) and all State and Local Codes and the requirements ofthe local fire department.

B. Pull stations shall be provided at each exit door of public areas.

C. Combination strobe/horn units shall be provided to be effective throughout thefacility.

D. Strobe/horn unit shall comply with the ADA requirements.

E. Smoke detectors to be provided in the return air duct of each air handling unitwhere required.

F. Sleeping area smoke detectors shall include an 88dBA low frequency sounder baseproviding a minimum 70 dBA at the pillow.

G. The fire alarm control panel shall monitor flow switches and valve tamper switchesfor the flow of water and the positioning of sprinkler system valves.

16.76 TELEPHONE SYSTEM:A. The Telephone System shall be provided by the Owner under separate contract.

The Electrical Contractor shall coordinate with the Owner and/or his contractor toprovide a raceway and back box system as required.

B. The telephone service and main distribution frame shall be provided by the Ownerunder separate contract.

C. Telephone instruments, switching equipment and other accessories shall befurnished and installed by the Owner.

D. All wall type telephone/data outlet shall be 4-inch square boxes with single gangplaster frame.

E. Provide a conduit, raceway or cable from each telephone/data outlet to telephoneservice point.

F. UTP type Level 5 for data and Level 3 for voice wiring shall be provided. Wiringshall be grouped and neatly bundled, run at right angles, secured with nylon cableties of proper size and supported every four feet from either structural supports orby placing new wire hangers. All cables shall be identified at each end.

16.79 TELEVISION CABLE OR SATELLITE SYSTEM:A. The Television or Satellite System shall be provided by the Owner under a

separate contract. The Electrical Contractor shall coordinate with the Ownerand/or his contractor to provide a raceway and back box system as required.

16.80 SECURITY SYSTEM:A. General: This specification section in conjunction with the drawings shall serve as

the basis for the scope of the system.1. EC to coordinate with local vendor and owner's representative(s) to provide

and install complete and functional system to the satisfaction of the owner.2. Final design and layout (including, but not limited to, devices, cabling, DVR,

monitors, amplifiers, locations, head-end and peripheral equipment, etc.) shallbe specified by contractor's vendor, in coordination with owners localrepresentative.

02

CONTINENTAL 422 FUND LLCW134 N8675 EXECUTIVE PARKWAYMENOMONEE FALLS, WI 53051

262.502.5500 * FAX 262.502.5522

LPA #8374

Consulting Electrical Engineers/Planners

Ph. (262) 860-1544, Fax (262) 860-1566

Elm Grove, Wisconsin 53122

12970 W. Bluemound Road - Suite 101

01

02

Reviewed for CodeCompliance

PRBD20180209312

ReviewedCCEPR-dae.

1/4" = 1'-0"

1

TYPE 6G GARAGE BUILDING (TYPICAL)

COMMON/GARAGE - LIGHTING FIXTURE SCHEDULE

LAMP DATA

UTILITY GLOBEGG

DES.

1

DESCRIPTION

12010W LED A19

TYPE

VOLT

SURFACE RECESS

LIGHTING FIXTURE

MFR.

P3408-09

CAT. NO.

GF

1' x 4' FLUORESCENT

2 12032W T8 -

XEM4-232-DCA-EU

WET LABELED

UBV 3 120 -

GJ STANDARD STRIP 1 12032W T8 P7267-30EB

GH

7.25" LED FLUSH MOUNT FIXTURE

1 120

17W LED

-

PROGRESS

P8222-28-30K

WET LABELED, PROVIDE WITH

3000KLIGHTING

COLUMBIA

LIGHTING

PROGRESS

LIGHTING

-

-

OVER THE MIRROR 3 LT VANITY

BATHROOM

P2006-09

PROGRESS

LIGHTING

GEMH

EMERGENCY BATTERY UNIT-

2 6V -

WITH HEADS

LM-50-

12WDUAL-LITE

GEMO

EMERGENCY EGRESS

2 6V -

REMOTE HEADS, WP

OCR-D-W-0603L

3W LEDDUAL-LITE

SRHSW0612

*LIGHT FIXTURES SPECIFIED ARE THE STANDARD PRODUCT FOR ALL CONTINENTAL PROPERTIES INC. PROJECTS*

**FURNISH LIGHT FIXTURES AS SPECIFIED WITHOUT SUBSTITUTION**

***ALL LIGHT FIXTURE MUST BE APPROVED BY OWNER PRIOR TO PURCHASE***

PROGRESS

LIGHTING

20W LED

A19

GB

GARAGE BUILDING/MAITENANCE

WALL PACK, DARK BRNZ

- 120 -

26W LED

DSXW1 LED-10C-

700-40K-T3M-

4000K

LITHONIA

LIGHTING

120-DDBXD4000K LED

4" JBOX FOR INSTALLATION.

0' 6'2' 4'1'

CONTINENTAL 422 FUND LLCW134 N8675 EXECUTIVE PARKWAYMENOMONEE FALLS, WI 53051

262.502.5500 * FAX 262.502.5522

LPA #8374

Consulting Electrical Engineers/Planners

Ph. (262) 860-1544, Fax (262) 860-1566

Elm Grove, Wisconsin 53122

12970 W. Bluemound Road - Suite 101

01

NO SCALE

3

ELECTRICAL SERVICE RISER

02

02

Reviewed for CodeCompliance

PRBD20180209312

ReviewedCCEPR-dae.

FLAG POLE

LTG

6

SIGN

8

KP

3

5

KP

3

ENTRY

GATES

TC

PANEL

AV4S-20

AV4S-20

AV4S-20

AV4S-20

AV3-20

AV3-20AV3-20

AV5-20

AV5-20

AV5-20

AV3-20

AV3-20

AV3-20

AV3-20

AV3-20

W

W

AV3-20

POOL GATE

HARDWARE

POOL GATE

HARDWARE

TYP. OF 7 GATES

AV3-20AV3-20

2

34

27

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

AV3-20

AV3-20

AV4S-20

BV3-20

BV3-20

CV2-8

CV2-8

15

1

777

7

7

7

7

7

7

33

16

13

17

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

METERS

1

1212 10

9

B20

PANEL

G24

PANEL

BUILDING #1

G28IIE

BUILDING #2

G24E

PET

PLAYGROUND

BUILDING #3

B20E

BUILDING #10

B20E

BUILDING #5

G28IIE

BUILDING #7

G28IIE

BUILDING #4

G24E

BUILDING #6

G24E

BUILDING #8

G24E

BUILDING #9

G24E

BUILDING #11

G24E

BUILDING #12

G24E

BUILDING #13

G24E

BUILDING #14

G24E

CLUBHOUSE

35

3535

3535

4

11

MG

PANEL

GARAGE 1

-6GS-

GARAGE 2

-8G-

GARAGE 3

-8G-

GARAGE 4

-8G-

PET

PLAYGROUND

MAINTENANCE

GARAGE

MAIL KIOSK

SHEET NOTES

1

2

3

4

5

6

7

MAINTAIN FOUR FEET (4'-0") CLEARANCE IN FRONT OF ELECTRICAL

METERS.

PROVIDE POOL DECK LIGHTING POWER FROM PANEL 'CH' LOCATED

WITHIN CLUBHOUSE - 3 #10 & #10G IN 3/4"C. PROVIDE PHOTOCELL

CONTROL.

PROVIDE ROUGH-IN FOR NEW CARD-READER COORDINATE WITH

CARD-READING SYSTEM

PROVIDE ENTRY GATE POWER FROM PANEL 'CH' LOCATED WITHIN

CLUBHOUSE - 3 #10 & #10G IN 3/4"C. PROVIDE ALL ROUGH-IN FOR

ENTRY GATE SYSTEM, INCLUDING EXIT VEHICLE DETECTION LOOP.

PROVIDE MAIL KIOSK POWER FROM PANEL 'B20' LOCATED

WITHIN BUILDING #3 - 2 #10 & #10G IN 3/4"C.

PROVIDE FLAG POLE LIGHTING POWER FROM PANEL 'CH' LOCATED

WITHIN CLUBHOUSE - 3 #10 & #10G IN 3/4"C. VERIFY EXACT LOCATION

WITH OWNER IN FIELD.

PROVIDE UNIT BUILDING MOUNTED LIGHTING FROM HOUSE PANEL

CIRCUIT. REFER TO ELECTRICAL SECOND FLOOR PLANS FOR

FIXTURE LOCATIONS & ARCHITECTURAL PLANS FOR ELEVATIONS.

SHEET NOTES

PROVIDE SIGN LIGHTING POWER [(2) 20A/1P CIRCUIT BREAKERS]

FROM PANEL 'CHA' LOCATED WITHIN CLUBHOUSE - 3 #10 & #10G IN

3/4" C. PROVIDE TIMECLOCK IN MEP2 TO CONTROL SIGN LIGHTING.

PROVIDE '6G' GARAGE PANEL 'GB6' POWER FROM PANEL 'G24'

LOCATED WITHIN BUILDING #4 - 3 #6 & #8G IN 1"C.

PROVIDE '8G' GARAGE PANEL 'GB8' POWER FROM PANEL 'G28'

LOCATED WITHIN BUILDING #5 - 3 #6 & #8G IN 1"C.

PROVIDE MAINTENANCE GARAGE PANEL 'MG' POWER FROM

ELECTRICAL METERS LOCATED ON BUILDING #3 - 3 #1 & #6G IN

1-1/2"C.

PROVIDE '8G' GARAGE PANEL 'GB8' POWER FROM PANEL 'G28'

LOCATED WITHIN BUILDING #7 - 3 #6 & #8G IN 1"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #12 - 3 #10 & #10G IN 3/4"C.

PROVIDE TRASH COMPACTOR POWER FROM METER CENTER

LOCATED ON BUILDING #2- 3 #1 & #6G IN 1-1/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'CH' LOCATED WITHIN

CLUBHOUSE - 3 #10 & #10G IN 3/4"C.

8

9

11

10

12

13

14

15

SHEET NOTES

PROVIDE SITE LIGHTING POWER FROM PANEL 'G28' LOCATED WITHIN

BUILDING #1 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #13 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'B20' LOCATED WITHIN

BUILDING #3 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #4 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G28' LOCATED WITHIN

BUILDING #5 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #6 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G28' LOCATED WITHIN

BUILDING #7 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #8 - 3 #10 & #10G IN 3/4"C.

16

17

18

19

22

23

20

21

SHEET NOTES

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #9 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'B20' LOCATED WITHIN

BUILDING #10 - 3 #10 & #10G IN 3/4"C.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #11 - 3 #10 & #10G IN 3/4"C.

PROVIDE POWER TO THE POOL GATE HARDWARE FROM THE

CLUBHOUSE.

PROVIDE 240V, 40A 1-PHASE CONNECTION TO FOUNTAIN FROM

BUILDING 5 HOUSE PANEL. INSTALL FUSED DISCONNECT PEDESTAL

WITHIN 15 FEET OF LAKE EDGE WITH CONDUIT THAT RUNS 3 FEET

INTO LAKE FOR FOUNTAIN CONTROL WIRING CONNECTION.

PROVIDE 240V, 40A 1-PHASE CONNECTION TO FOUNTAIN FROM

BUILDING 13 HOUSE PANEL. INSTALL FUSED DISCONNECT PEDESTAL

WITHIN 15 FEET OF LAKE EDGE WITH CONDUIT THAT RUNS 3 FEET

INTO LAKE FOR FOUNTAIN CONTROL WIRING CONNECTION.

24

25

26

27

28

29

SHEET NOTES

PROVIDE 240V, 40A 1-PHASE CONNECTION TO FOUNTAIN FROM

BUILDING 11 HOUSE PANEL. INSTALL FUSED DISCONNECT PEDESTAL

WITHIN 15 FEET OF LAKE EDGE WITH CONDUIT THAT RUNS 3 FEET

INTO LAKE FOR FOUNTAIN CONTROL WIRING CONNECTION.

PROVIDE 240V, 40A 1-PHASE CONNECTION TO FOUNTAIN FROM

BUILDING 6 HOUSE PANEL. INSTALL FUSED DISCONNECT PEDESTAL

WITHIN 15 FEET OF LAKE EDGE WITH CONDUIT THAT RUNS 3 FEET

INTO LAKE FOR FOUNTAIN CONTROL WIRING CONNECTION.

PROVIDE METER PEDESTAL FOR IRRIGATION SYSTEM, DESIGNED BY

A DESIGN-BUILD CONTRACTOR. FINAL LOCATION AND EXACT

REQUIREMENTS TO BE COORDINATED WITH OWNER AND

LANDSCAPE/IRRIGATION CONTRACTOR.

PROVIDE SITE LIGHTING POWER FROM PANEL 'G24' LOCATED WITHIN

BUILDING #14 - 3 #10 & #10G IN 3/4"C.

PROVIDE ELECTRICAL ROUGH-IN FOR POOL GATE HARDWARE.

CONFIRM EXACT REQUIREMENTS WITH POOL CONTRACTOR.

REFER TO ACCESSORY BUILDING SETS FOR WALL-MOUNT FIXTURE

MOUNTING DETAILS.

30

31

32

33

34

35

GENERAL NOTES

1. COLLIER COUNTY LOCAL LIGHTING ORDINANCES 6-143, 6-144, 6-145,

6-146, 6-147 ALL REFERENCE MAINTAINING A MAXIMUM LIGHT LEVEL

OF 1.0 FOOT CANDLES AT ADJOINING PROPERTY LINES.

2. POLE LOCATIONS ADJACENT TO PEDESTRIAN SIDEWALKS TO BE

INSTALLED WITHIN 1' OF SIDEWALK EDGE.

3. POLE FIXTURES MUST COMPLY WITH RISK CATEGORY 1 WIND

DESIGN LOAD OF 149 MPH WIND LOADS.

4. FINAL SITE LIGHTING POLE LOCATIONS AND LIGHTING

PHOTOMETRIC TO BE COORDINATED WITH FINAL LANDSCAPE

DESIGN.

2.

LIGHTING FIXTURE NOTES:

1.

PROVIDE PHOTOCELL ON FIXTURE.

PROVIDE ROUND DIRECT BURIAL POLE.

SITE LIGHTING FIXTURE SCHEDULE

LAMP DATA

DES. DESCRIPTION

TYPE

VOLT

SURFACE RECESS

LIGHTING FIXTURE

MFR. CAT. NO.

W 1 120 --

WALL-MOUNT LED FIXTURE

AV3-14 1 240 0.67

2,3,4

1,2,4

GB

WALL-MOUNT LED FIXTURE

1 120 --

DARK BRONZ, MAINTENANCE

4,5

AV3-20 1 240

55W LED

0.67

VPS-24NB-55-4K-

4000K

AREA LED FIXTURE, TYPE 3 DIST.

1,2,4

20'-0" ROUND POLE, DARK BRNZT3-UNV-PCR-TL-

BEACON

PRODUCTS

CV2-8 1 240 0.8

1,2,4

AV5-20

1 240 0.67 1,2,4

AV4S

1 240 0.67

1,2

-20

3. PROVIDE FIXTURE WITH HOUSE SIDE SHIELD.

4. ***NO SUBSTITUTIONS ACCEPTED.***

3,4

HOUSE-SIDE SHIELD, DARK BRNZ

UNIT BUILDING WALL PACK

BV3-20

1 240 0.67 1,2,4

AREA LED FIXTURE, TYPE 4 DIST.

20'-0" ROUND POLE, DARK BRNZ

AREA LED FIXTURE, TYPE 5 DIST.

AREA LED FIXTURE, TYPE 3 DIST.

HOUSE-SIDE SHIELD

55W LED

4000K

55W LED

4000K

72W LED

4000K

25W LED

4000K

26W LED

4000K

55W LED

4000K

26W LED

4000K

AREA LED FIXTURE, TYPE 3 DIST.

20'-0" ROUND POLE, DARK BRNZ

20'-0" ROUND POLE, DARK BRNZ

14'-0" ROUND POLE, DARK BRNZ

BEACON

PRODUCTS

BEACON

PRODUCTS

BEACON

PRODUCTS

BEACON

PRODUCTS

LITHONIA

LIGHTING

LITHONIA

LIGHTING

LITHONIA

LIGHTING

GARAGE / GARAGE BUILDINGS

AREA LED FIXTURE, TYPE 2 DIST.

8'-0" ROUND POLE, DARK BRNZ

RA-DBT

VPS-24NB-55-4K-

T4-UNV-PCR-TL-

BLC-RA-DBT

VPS-24NB-55-4K-

T5R-UNV-PCR-TL-

RA-DBT

VPS-30NB-70-4K-

T3-UNV-PCR-TL-

RA-DBT

VPS-24NB-55-4K-

T3-UNV-PCR-TL-

RA-DBT

DSXWPM-LED-10C-

700-40K-T2M-240-

DSXW2-LED-20C-

350-40K-T3M-120-

PE-HS-DDBXD

DSXW1-LED-10C-

700-40K-T3M-120-

DDBXD

5. CONTROLLED BY SEPARATE TIMECLOCK.

--

1.9

--

3.0

2.3

3.0

3.0

3.0

02

NORTH

0' 120'40' 80'20'

CONTINENTAL 422 FUND LLCW134 N8675 EXECUTIVE PARKWAYMENOMONEE FALLS, WI 53051

262.502.5500 * FAX 262.502.5522

LPA #8374

Consulting Electrical Engineers/Planners

Ph. (262) 860-1544, Fax (262) 860-1566

Elm Grove, Wisconsin 53122

12970 W. Bluemound Road - Suite 101

01

02

Reviewed for CodeCompliance

PRBD20180209312

ReviewedCCEPR-dae.