ABB Rectiformer Substation EPC Package for Qatalum · ations were required to adapt the design for...

Transcript of ABB Rectiformer Substation EPC Package for Qatalum · ations were required to adapt the design for...

Qatalum will be the firstaluminium smelter to go intooperating in Qatar and will

also be the first smelter worldwide tooperate with 1'750VDC. As ABB isalso supplying the power plantsubstation, Qatalum will be world’sfirst smelter with ABB’s integratedblackout protection

The rectiformer substation forQatalum’s pot line 1 and 2 was awardedon an EPC (Engineering, Procurementand Construction) basis to ABB Switzer-land in June 2007. As engineering and

ABB Rectiformer Substation EPCPackage for QatalumABB Switzerland

management resources have becomeincreasingly scarce in recent times, thetraditionally piece-meal project approachhas been replaced by larger packagedEPC solutions.

Power requirements in new smeltershave reached over 500MW per pot line,so an optimised overall power systemconcept is essential. An overall co-ordinated system approach eliminatescost overruns and guarantees on-timedelivery as well as best technical solution.

When phase one of Qatalum becomesoperational, over 1’000MW will need to be

controlled and converted to DC power forefficient smelter operation. At Qatalum,the power plant and the rectiformerstation are two separate EPC packageswith the 220kV GIS (Gas InsulatedSwitchgear) in the scope of power plantpackage and the 1’500m 220kV cables inthe rectiformer substation package.

As the power plant EPC contractor hasawarded the 220kV GIS with its latestcontrol and protection system based onIEC61850 to ABB Switzerland, the substa-tion integration and interface co-ordina-tion are simplified and an overall systemapproach is guaranteed.

Scope of the rectiformer EPCpackage

The rectiformer substation packageconsists of the following turnkeyelements:• Overall system design, studies and

performance calculations• 220kV cable runs and termination to the

GIS and the transformers• 1'750VDC/85kA rectiformers• DC collector busbar design, supply

and installation• 70Mvar harmonic current filters

operated off the regulation transformertertiary winding. Each filter can beenergised via a synchronised 33kVbreaker

• SCADA system• 33/0.4kV distribution for the substation• Fire detection and deluge system for

the entire substation• Detailed civil works design and

supervision• Interface to the 220kV GIS supplied by

ABB Switzerland to the power plantEPC package

• Substation controls and protection withthe new IEC61850 protocol.

The package also includes overallsystem integration and interface co-ordination with other EPC packagesuppliers.

Figure 2: GIS building cable entry

Figure 1: 220kV cable-road crossing

QATALUM SMELTER FEATURE

ations were required to adapt the designfor this HV DC application. The Qatalumrectifier frame is designed for 2'000VDCwith semiconductors and fuses suitablefor 1'750VDC.

Rectiformer bay and substationlayout

Traditionally rectiformer units arearranged in line with the front of the potroom allowing the most efficient pot roomconnection to the substation. The largerfootprint of the 200MVA capacity unitsrequired a new arrangement with themfacing each other. This required an in-depth study of the forces applied by theDC collector busbar as well as the effect

rectiformers. The interfacing of the GIScontrols and protection is often a verydemanding task for EPCM engineers,usually turns out to be a time-consumingand difficult exercise. At Qatalum the GIScontrols and protection, as well as therectifier control system, will be suppliedby ABB Switzerland permitting aseamless operation.

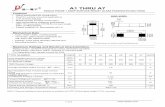

2’000VDC rectifier design

Having reached 1'650VDC at SoharAluminium, Qatalum specified 1'750VDCas the maximal smelter operation voltage.Following detailed rectifier design studiesand type testing on ABB’s standardproven rectifier design, only minimal alter-

220kV cable routing

Cable routing to the two pot lines hashad to be interfaced with many differentEPC package suppliers and to beintegrated into the overall road concept.Cable road-crossing points had to be inplace and cables laid in the ground wellbefore many other activities could start.With 10 feeders and an average cablelength of 1,500m, the excavation of thecable trench involves approximately35,000m3.

220kV GIS with IEC61850 EnhancedControls

The power plant is located close thesmelter, so it is possible to have a singleGIS serving both. On one side the GISdirectly connects to the generator step-uptransformers and, on the other, to the

QATALUM SMELTER FEATURE

Figure 4: Protection and controls with IEC 61850

Figure 5: 2’000VDC rectifier design Figure 6: Rectiformer bay

Figure 3: ABB’s ELK-14, 300KVGIS

and power quality equipment are aperfect fit. A team of experts in trans-former, rectifier and harmonic currentsfiltering technologies simulated the powergrid at different operation points as wellas the pot line operational behaviour andthen selected suitable parameters for thepower quality system.

Summary

Qatar’s first smelter will have, in manyrespects, the most advanced rectiformersubstation in the world and it willseamlessly interface with ABB’s electricpower plant and the EPC substationpackage. Environmental and powerquality levels will also set a new bench-marks for aluminium smelters. ■

For more information, contact:

ABB Switzerland 5401 Baden-Daettwil Phone +41 58 586 8508 Fax +41 58 586 7322 www.abb.com/aluminium

Max WiestnerIndustry Manager Primary AluminiumABB SwitzerlandEmail:[email protected]

Christian WinterChief System Engineer RectiformersABB SwitzerlandEmail: [email protected]

via a fibre optic cable to link the powerplant and smelter substation together forload control. This interconnection isrequired as the power plant will not beconnected to the Qatari utility grid.Qatalum will possess the most moderncontrol room visualisation system withlarge screen mimics based on the ABBextended working station 800xA

Power quality control

With each pot line requiring over500MW, power quality is critical. Manydifferent operational scenarios need to beaccommodated to allow the smelter tooperate without power quality restrictions.Power factor control and minimalharmonic current distortion are two of themany parameters to be addressed.

At Qatalum power quality targets havebeen set at the very highest levels of anyindustry worldwide. These power qualitylevels can only be met by an overallsystem approach. For example, ensuringa suitable transformer design and speci-fying tolerances so that the rectiformer

of having different length of busbarsbetween the rectiformer and the potroom.

Rectiformer control system

The rectiformer station consists of fiveunits with the possibility of adding a sixthunit at a later stage. The rectiformer unitscan be controlled from the central controlroom via the SCADA (System Control andData Acquisition) system or from themaster controller. From the mastercontroller as well as the SCADA system itis possible to connect to the power plant

QATALUM SMELTER FEATURE

Figure 8: Typical 33kV harmoniccurrent filter

Figure 7: Rectiformer control system architecture

Many different operational scenariosneed to be accommodated toallow the smelter tooperate without powerquality restrictions