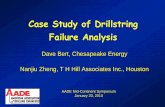

Aade Ntce0904 2009 Mud Stripper Presentation

description

Transcript of Aade Ntce0904 2009 Mud Stripper Presentation

-

Case Study Reducing Drilling hours by up to 54% in the Barnett Shale

Douglas Gust P.Eng., QMax Solutions Inc. Scott Marquess, QMax Solutions Inc. Lane Dunham, Savanna Drilling USA

March 31, 2009

-

*Barnett Shale Drilling Optimization ProjectIntroductionProject ScopeAchievementsConclusions

-

*Project OverviewGOAL Reduce well construction cost - $/ftScope of ProjectBuild on what others had done bits/directional etc.Optimization of Drilling FluidSolids Free Drilling Fluid SFDFSolids ControlWaste ManagementReduction of hole sizesNew Technology Drilling Rigs NTDRsTime Frame20 month project 3Q 2006 to 1Q 2008

-

*SFDFSolids Free 10.5 ppgLow rheology Low ECDViscosity = 28 to 31YP = 1 to 3100% reusable

-

*Solids Control MudStripperDesigned for SFDFRemove 99.5% drill solidsFootprint = 15 x 60Operates as Closed LoopSludge density range:14.5 to 17.5 ppg

Shaker CuttingsMudStripper Sludge

-

*Cuttings Handling

-

*Well ConstructionHole size ReductionSurface holeReduced from 12 to 8 Reduced Casing from 9 5/8 to 7Main HoleReduced from 7 7/8 8 to 6 1/8Reduced Casing from 7 to 4

BenefitsReduced cuttings volumeReduced cement volumeLower cost casingIncreased casing availability

ConcernsROPTool ReliabilityCement quality

-

*NTDRNTDR New Technology Drilling RigIntegrated top drive / pipe handling systemSome rigs drill with coil tubingSmall footprintFast moving (12 to 15 loads)

BenefitsSafety reduced risk for crewsImproved ROPDrill with CoilNo connectionsDrill with Range 3 pipeSmaller location sizesFast Rig up/Tear downShorter move times

-

*Accomplishments41% reduction in average Drilling Hours226 hours/well to 133 hours/well41% reduction in average Well Days20 days/well to 12.5 days/well83% reduction in average Fluid Volume10,000 bbls/well to 1,729 bbls/well100% reduction in Dilution VolumeDilution was eliminated75% reduction in surface area of drilling site400 ft x 400 ft to 200 ft x 200 ft

-

*Average Drilling HoursProject Start226 hours/wellConventional Rig 44 wells155 hours/wellNTDR 96 wells123 hours/wellBest 2 rigs 34 wells103 hours/well

One NTDR w/ & w/o SFDF31 wells w/SFDF 131 hours/well7 wells w/o SFDF153 hours/well

-

*Average Days / WellProject Start 20 days/well157 wells 12.5 days/wellSFDF149 wells 11.9 days/well97 wells NTDR10.5 days/well77% of wells < 15 days

-

*Average Drilling PerformanceAverage Performance based upon well days670 ft/day

SFDF700 ft/day

Best 2 Rigs848 ft/dayNOTE: Op #2 calculated from assumed 10,000 ft well depth and days from Spud to TD

-

*Drilling Performance by Bit Diameter

Bit Diameter (in)# wellsAverage Drilling Performance (ft/day)SFDF6 1/8 to 6 1256927197 7/8 to 8 32577613157670700

-

*Fluid Volume ReductionSFDF & MudStripper is a Closed Loop systemSFDF is 100% reusableReduced hole sizes reduces volumesSeepage lossFluid on cuttings

-

*Reduced Location SizeLocation reduced from 400 x 400 to 200 x 20075% reduction in surface areaNTDRSmall footprintMudStripperClosed Loop system with small footprint

-

*ConclusionKEY Success FactorsProject Integration & ExecutionSFDFNTDRHole Size ReductionSignificant reduction in $/ft achievedSome individual costs (product and services) increasedVariable cost time related decreasedSome costs (casing) decreased

-

*Conclusion Project Milestones

2.3% average suspended solids ( 1,000 ft/day157wells in the dataset700ft/day average with SFDF1,729bbls/well average fluid volume4,240ft most footage drilled in one 24 hour period

*****************