1077d1279567478 Tcs New Pattern Tcs Question Paper Format Changed Tcs Paper

A90 TCS 514 Training Material

Transcript of A90 TCS 514 Training Material

-

7/30/2019 A90 TCS 514 Training Material

1/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 1 -

GVP Flowmeter teamInternal use only

- 1 -

ROTAMASSAdvance Diagnostic for Increased Process Visibility

-

7/30/2019 A90 TCS 514 Training Material

2/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 2 -

GVP Flowmeter teamInternal use only

Slug detection

A coriolis meter is basicallya single phase flowmeter. Apresent of bubbles in liquid/ solid in liquid will causesome trouble.

Bubbles in liquid will causemuch trouble compare withsolids in liquid as densitydifferent between air with

liquid is so much different: Water density: 1,000 kg/m3

Air density: 1.29 kg/m3

SS density: 5,000+ kg/m3

Advance Diagnostic for Increased Process Visibility

A

ALiquid

only

-

7/30/2019 A90 TCS 514 Training Material

3/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 3 -

GVP Flowmeter teamInternal use only

When this bubbles enterthe meter, it will create tube

movement dampening. The tube will become heavy,

thus it needs more power toexcite. You can see this byincreasing of drive gain.

Option /HP is very useful as itallow amplifier to supply morepower to excite the tubes.

The higher bubbles thecoriolis meter may workcontinuously under dual

phase condition, the better itis. Please note that thisdoesnt mean the coriolis maymeasure accurately.

Reading will fluctuates.

Advance Diagnostic for Increased Process Visibility

B

B

-

7/30/2019 A90 TCS 514 Training Material

4/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 4 -

GVP Flowmeter teamInternal use only

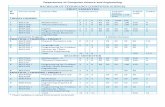

RCCS30LR ~ 33: No Limitation+RCCS/T34: No Limitation

RCCS/T36: 50 %

RCCS/T38: 30 %RCCS/T39: 7 %

RCCS/T39/IR: 3 %

RCCS/T39/XR

*

:

2 %

Advance Diagnostic for Increased Process Visibility

YokogawaROTAMASSBubbles Handling Capability is Published in GS

+ CS33 Ex type: 35%* with /HP

-

7/30/2019 A90 TCS 514 Training Material

5/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 5 -

GVP Flowmeter teamInternal use only

It is difficult to guaranteemeasurement accuracy during

present of bubbles, because: It depends on the size of the

bubbles

It depends on how the bubbles isdistributed among two tubes

EtcGenerally speaking, it is ok tosay that accuracy of density isrelatively good for indication,however not for mass flow

rate. In water measurement, density

reading of 900 kg/m3 show a10% present of bubbles.

Advance Diagnostic for Increased Process Visibility

C

C

-

7/30/2019 A90 TCS 514 Training Material

6/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 6 -

GVP Flowmeter teamInternal use only

When reading

fluctuates due to bubbles,customer may activatethe slug flow detection.Reading can be:

Measured value, meanscontinue, thus mayfluctuate

Hold, showing the last

reading before slug flowoccurrence

Advance Diagnostic for Increased Process Visibility

D

D

-

7/30/2019 A90 TCS 514 Training Material

7/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 7 -

GVP Flowmeter teamInternal use only

Slug detection only valid for liquid measurement.Criteria to be set: Drive gain Duration

After slug detection: Measurement continue or hold Alarm Yes / No

Advance Diagnostic for Increased Process Visibility

-

7/30/2019 A90 TCS 514 Training Material

8/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 8 -

GVP Flowmeter teamInternal use only

Advance Diagnostic for Increased Process Visibility

Measurement After Slug Detection

D

-

7/30/2019 A90 TCS 514 Training Material

9/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 9 -

GVP Flowmeter teamInternal use only

Generally, densitymeasurement can be lower thanactual due to bubbles. However,when the density measurementbecomes higher than actual, thismay be due to corrosion /erosion.By monitoring (and trend of)

density measurement, customermay see if the tube may havebeen corroded or eroded overthe time.Temperature measurement isalso mandatory as density may

go higher when the temperaturechange.Option /K6 will be very useful togive accurate densitymeasurement.

Advance Diagnostic for Increased Process Visibility

E

ELiquid

only

-

7/30/2019 A90 TCS 514 Training Material

10/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 10 -

GVP Flowmeter teamInternal use only

In a batch process, manytimes, the pipe (and the coriolismeter) is empty during the

beginning and end of the batchdue to flushing.This condition will cause error inmeasurement, due to dual phaseliquid.

As explained in page 5, thedensity reading will be lowerthan expected in the dual phasecondition.Customer may set a condition onwhich mass flow measurement

will start if only density conditionachieved. For instant, in a dripsliquid filling batch, themeasurement start (or stop)when density reading is higher(or lower) than 700 kg/m3.

Advance Diagnostic for Increased Process Visibility

F

FLiquid

only

-

7/30/2019 A90 TCS 514 Training Material

11/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 11 -

GVP Flowmeter teamInternal use only

Customer should takecare of the setting when

using this function. A seriesof on site test of the rightvalue of empty pipecondition with damping timeand low flow cut off may

allow optimizedperformance of theROTAMASS. Guideline: To set damping as low as

possible, thus ROTAMASSrespond immediately.

To adjust low flow cut off aslow as possible, however itshould remove the zeroinstability.

Advance Diagnostic for Increased Process Visibility

F

FLiquid

only

-

7/30/2019 A90 TCS 514 Training Material

12/24

A90-TCS-514Copyright Yokogawa Electric Corporation

April, 2013- 12 -

GVP Flowmeter teamInternal use only

Customer needs to do zeroadjustment after install theROTAMASS for the first time.This is required in order to obtainthe output signal that areaccurately proportional to theflow.Procedure for zero adjustment:

Flush the meter with fluid underprocess condition. Stop flow by closing upstream and

downstream valve. Wait for 2 minutes to allow density

and temperature to be stabilized.In liquid measurement, check thatdensity reading is not lower thanexpected.

Perform autozero. Store autozero value in the history.

Advance Diagnostic for Increased Process Visibility

G

G

-

7/30/2019 A90 TCS 514 Training Material

13/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 13 -GVP Flowmeter teamInternal use only

Zero-ing is required when zero verification procedure fails.

Verifying the zero helps you determine if the stored zero value isappropriate to your installation, or if a field zero can improvemeasurement accuracy.The zero verification procedure analyzes the Live Zero value underconditions of zero flow and compares it to the Zero Stability range forthe sensor.

If the average Live Zero value is within a reasonable range, the zerovalue stored in the transmitter is valid. Performing a field calibrationwill not improve measurement accuracy.Preparation procedure: Allow the flowmeter to warm up for at least 20 minutes after applying power. Run the process fluid through the sensor until the sensor temperature reaches

the normal process operating temperature. Stop flow through the sensor by shutting the downstream valve, and then the

upstream valve if available. Verify that the sensor is blocked in, that flow has stopped, and that the sensor

is completely full of process fluid.

Advance Diagnostic for Increased Process Visibility

Competitor claim zero adjustment in not necessary for their Coriolis

-

7/30/2019 A90 TCS 514 Training Material

14/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 14 -GVP Flowmeter teamInternal use only

After autozero, checkwhether zero value and zerofluctuation is higher thanexpected. If so, checkwhether ROTAMASShasbeen installed properly

ROTAMASS can stores 5values of zero value in thehistory. This is to:

check whether auto zero hasbeen done properly

check whether zero value driftover the time

Advance Diagnostic for Increased Process Visibility

G

G

-

7/30/2019 A90 TCS 514 Training Material

15/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 15 -GVP Flowmeter teamInternal use only

Advance Diagnostic for Increased Process Visibility

ROTAMASS Zero Fluctuation and Autozero Range

-

7/30/2019 A90 TCS 514 Training Material

16/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 16 -GVP Flowmeter teamInternal use only

When alarm occurs,

display will show thealarm type as well as howto overcome the problem.It is very easy to use. In

many cases, customerdoesnt even have to referto Instruction Manual tosolve a problem.

Advance Diagnostic for Increased Process Visibility

H

H

-

7/30/2019 A90 TCS 514 Training Material

17/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 17 -GVP Flowmeter teamInternal use only

Competitors DiagnosticMicro Motion

-

7/30/2019 A90 TCS 514 Training Material

18/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 18 -GVP Flowmeter teamInternal use only

RFT9739E/R

-

7/30/2019 A90 TCS 514 Training Material

19/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 19 -GVP Flowmeter teamInternal use only

Overrange and sensor error messages "Sensor Error "Drive Overrng "Input Overrange "Temp Overrange "Dens Overrng"

Transmitter failure messages "Xmtr Failed "(E)eprom Error "RAM Error "RTI Error"

Slug flow and output saturated messages Conditions such as slug flow (gas slugs in a liquid flow stream), adversely affect

sensor performance by causing erratic vibration of the flow tubes, which in turncauses the transmitter to produce inaccurate flow signals.

The message display reads "SLUG FLOW". The frequency/pulse output goes to 0 Hz. The mA outputs indicating the flow rate go to the level that represents zero flow.

Informational messages Zero too noisy. It is due to mechanical noise. Zero too high / too low. It is due to flow during auto zero.

Available Diagnostic in RFT9739E/R

-

7/30/2019 A90 TCS 514 Training Material

20/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013

- 20 -GVP Flowmeter teamInternal use only

Verifying the zero helps you determine if the stored zero value is

appropriate to your installation, or if a field zero can improvemeasurement accuracy.The zero verification procedure analyzes the Live Zero value underconditions of zero flow, and compares it to the Zero Stability range forthe sensor. If the average Live Zero value is within a reasonable range,the zero value stored in the transmitter is valid. Performing afield

calibration will not improve measurement accuracy.Live zero: The real-time bidirectional mass flow rate with no flowdamping or mass flow cutoff applied. An adaptive damping value isapplied only when the mass flow rate changes dramatically over a veryshort interval. Unit = configured mass flow measurement unit.Field Verification Zero: A 3-minute running average of the Live Zero

value, calculated by the transmitter. Unit = configured mass flowmeasurement unit.Zero Verification: A procedure used to evaluate the stored zero anddetermine whether or not a field zero can improve measurementaccuracy.

1700

Verify the Zero

-

7/30/2019 A90 TCS 514 Training Material

21/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013 - 21 -

GVP Flowmeter teamInternal use only

Smart Meter Verification evaluates the structural integrity ofthe sensor tubes by comparing current tube stiffness to thestiffness measured at the factory. Stiffness is defined as theload per unit deflection, or force divided by displacement.Because a change in structural integrity changes thesensors response to mass and density, this value can be

used as an indicator of measurement performance.Meter validation compares flowmeter measurementsreported by the transmitter to an external measurementstandard. Meter validation requires one data point.Calibration establishes the relationship between a process

variable and the signal produced at the sensor. You cancalibrate the flowmeter for zero, density, and temperature.Density and temperature calibration require two data points(low and high) and an external measurement for each.

1700

Options for Measurement Support

-

7/30/2019 A90 TCS 514 Training Material

22/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013 - 22 -

GVP Flowmeter teamInternal use only

The transmitter must be paired with an enhanced coreprocessor, and the Smart Meter Verification optionmust be ordered for the transmitter.

Although it is not necessary to match factoryconditions or change the transmitter's configuration

during a Smart Meter Verification test, the test will runmore smoothly when conditions are stable.

Maintain a constant fluid pressure and temperature.

Avoid changes to fluid composition, e.g., two-phase flow orsettling.

Maintain a constant flow rate.

The Smart Meter Verification test runs best when flow isstopped through the sensor.

Smart Meter Verification

-

7/30/2019 A90 TCS 514 Training Material

23/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013 - 23 -

GVP Flowmeter teamInternal use only

Smart Meter Verification Abort Code

-

7/30/2019 A90 TCS 514 Training Material

24/24

A90-TCS-514

Copyright Yokogawa Electric CorporationApril, 2013 - 24 -

GVP Flowmeter teamI t l l

Thank you for your attention