MORURI IMMACULATE EDEL A90/0142/2008 SUPERVISOR PROF J.K IMUNGI

A90 TCS 510 Training Material

Transcript of A90 TCS 510 Training Material

-

7/30/2019 A90 TCS 510 Training Material

1/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 1 -

Internal use only

ROTAMASSReal Insulation By Design

-

7/30/2019 A90 TCS 510 Training Material

2/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 2 -

Internal use only

Why Insulation

Choose insulation when

The temperature of media is high

Avoid accidental contact

To prevent the loss of heat fromthe measured product

To prevent the heat gain from

measured product

NOTE: If the piping around the flow meter isinsulated, most of the time the flow meter

has to be insulated also.

-

7/30/2019 A90 TCS 510 Training Material

3/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 3 -

Internal use only

Why Heat Tracing

Choose tracing when

Maintain fluid temperature

Prevent temperature loss to ambient

Prevent temperature gain from ambientin food industry

Handling high viscous fluids

Maintain Viscosity

Prevent Solidification/crystallization

Prevent Condensation (Gases)

So prevent phase change of fluid

NOTE:

Above statements are valid if temperature ofheating media is well controlled which isunder customer responsibility

If the piping around the flow meter is heattraced, most of the time the flow meter hasto be heat traced also.

-

7/30/2019 A90 TCS 510 Training Material

4/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 4 -

Internal use only

Where to look out for Heat Tracing

Handling high viscous fluid Molten Sulphur

Pitch

Asphalt

Bitumen

Coal tar

Crude Palm Oil (CPO)

Heavy Fuel Oil

Hot melt adhesive

DMT

Phthalic anhydride Molasses

Syrup

Hot chocolate

Oligomer

Small change in temperature results in alarge change in viscosity and in a change

in fluid state (e.g. from liquid to solid likemolten sulfur, asphalt, )

Food industry applications

Bread Yeast

-

7/30/2019 A90 TCS 510 Training Material

5/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 5 -

Internal use only

Viscosity for fluids

-

7/30/2019 A90 TCS 510 Training Material

6/41

Copyright Yokogawa Electric Corporation

- 6 -

Internal use only

Heat Loss

Fundamentals

-

7/30/2019 A90 TCS 510 Training Material

7/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 7 -

Internal use only

Heat Transfer

Temperature is a measure of the internal energy of an object.

The hotter an object is, the more its molecules will vibrate andthe higher its temperature will be.

If two combined objects (thermal conductivity & thermalradiation) are at different temperatures, the hotter object willtransfer thermal energy to the cooler object until they reach thesame temperature.

This exchange of thermal energy is known as heat transfer, and atemperature difference is the driving force for heat transfer.

-

7/30/2019 A90 TCS 510 Training Material

8/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 8 -

Internal use only

Heat Loss

Bare Pipe - High Heat Loss

Insulated Pipe - Lower Heat Loss

Insulated & Traced PipeLess or noHeat Loss

-

7/30/2019 A90 TCS 510 Training Material

9/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 9 -

Internal use only

Heat Loss

Fluid Ambient

Temp.

Thermal

Insulation

Heat Tracing

Secondarycontainment

-

7/30/2019 A90 TCS 510 Training Material

10/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 10 -

Internal use only

Heat Transfer Rate

The rate at which heat is transferred between two objects atdifferent temperatures can be determined from the following

simple equation:Q = U x A x T Where,

Q is the amount of heat transferred (in W/m)

U is specific heat transfer coefficient (in W/m2.oC) of heat transfer area

A is the effective heat transfer area (in m2) T is the temperature difference between the two objects (in Deg.C)

A system which transfers heat easily (low thermal resistance)would have a high U. A system which impedes heat transfer

(such as insulation) would have a low U. The U value must bedetermined for the entire system using industry standard,empirically based heat transfer formulas.

-

7/30/2019 A90 TCS 510 Training Material

11/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 11 -

Internal use only

T Heat Loss (From mass flow meter percepective)

T = Tflowtube Tambient

T Heat Loss

Higher the flow tube temperature,higher is heat loss

Lower the ambient temperature,higher is heat loss

Note : Heating system is not directly on themeasuring tube but on the secondarycontainment.

-

7/30/2019 A90 TCS 510 Training Material

12/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 12 -

Internal use only

Heat Transfer through pipe

If the temperature of the pipe is greater than theambient temperature, heat will transfer from the pipeto the ambient, thus reducing the fluid temperature.

The rate of heat transfer will depend on heat transfercoefficient, pipe surface area and the temperaturedifference between the process and ambient.

In order to maintain fluid temperature, the amount ofheat that is lost to ambient must be replaced by aheating system.

The ability and efficiency of a heating system to

maintain the fluid temperature can be assessed byconsidering the heat transfer equation

-

7/30/2019 A90 TCS 510 Training Material

13/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 13 -

Internal use only

Heat Transfer through pipe

T - The temperature difference is defined by the heating medium (steam,hot oil, etc.) temperature and the desired fluid maintenance temperature. Byusing a hotter heating medium, heat transfer rate will increase.

U - The U value considers each component of thermal resistance within thesystem, including the affluence with which the heating medium transfers heatto the pipe wall, conduction through the pipe wall, and convection from thepipe wall to the fluid. Heating technologies differ in how easily they transferheat from the heating medium to the pipe wall. The ability to achieve good

contact between the heating element and the piping is critical in establishingthe U value for heat tracing system. When a fluid is flowing rapidly through apipe, it has the ability to accept heat more rapidly. For processes where thereis no flow (such as startup or melt-out scenarios), the heat that can betransferred into the process is significantly limited. In these situations, theprocess rather than the heating system can become the limiting factor in

heat transfer. A - The heat transfer area is defined as the surface area in direct contact

between the heating system and the pipe. For tube tracing, the area isdefined by the size and shape of the elements.

-

7/30/2019 A90 TCS 510 Training Material

14/41

Copyright Yokogawa Electric Corporation

- 14 -

Internal use only

Thermal Insulation

-

7/30/2019 A90 TCS 510 Training Material

15/41

A90-TCS-510Copyright Yokogawa Electric CorporationApril, 2013

- 15 -

Internal use only

Thermal Insulation

What is thermal insulation?

Thermal insulation are thosematerials or combination ofmaterials which, when properlyapplied, retard the flow of heatenergy by conduction, convection,and radiation transfer modes.

-

7/30/2019 A90 TCS 510 Training Material

16/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 16 -

Internal use only

Thermal Conductivity

Thermal Conductivity (k) is the property of matter by

which it transmits heat by conduction Materials which transfer heat rapidly such as copper, silver and

iron are called good conductors, while those which transferheat slowly such as fiberglass, rubber or wood are called poorconductors(or isolators).

Units commonly used for expressing thermal conductivity(k value) are: In the SI system, k = W/mK

Mild steel has a thermal conductivity of 45 W/mK while an average k valuefor fiberglass insulation is 0.036 W/mK.

k values will vary somewhat with temperature depending on thematerial.

Insulation Thickness 1/ (Heat Loss)

Insulation Conductivity Heat Loss

-

7/30/2019 A90 TCS 510 Training Material

17/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 17 -

Internal use only

Thermal Insulation

The mineral wool is fibrous

construction with bestperformance with k-factor of0.4 W/mK.

The insulation thickness in

ROTAMASSdoes not vary

with meter size and is 80mm

-

7/30/2019 A90 TCS 510 Training Material

18/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 18 -

Internal use only

Thermal Insulation

-

7/30/2019 A90 TCS 510 Training Material

19/41

Copyright Yokogawa Electric Corporation

- 19 -

Internal use only

Heat Tracing

-

7/30/2019 A90 TCS 510 Training Material

20/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 20 -

Internal use only

Heat tracing design

The theory of maintaining temperaturein an insulated line evolves around a

very simple heat balance. If the process temperature is to remain

constant, the heat input into the linemust be equal to the heat loss (Wper meter) through the thermalinsulation.

Selecting the heat tracer type with aheat output that will most closely

match this heat loss is the key to

efficient heat tracing.

-

7/30/2019 A90 TCS 510 Training Material

21/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 21 -

Internal use only

Heat Tracing

In general we should be careful with theword heating because in fact we are

not heated the fluid we are justmaintaining a constant temperatureinside the detector housing.

For tube size upto RCCS38, only oneside is heat traced.

For RCCS39 & RCCS39IR, both sides areheat traced

Select option /T2 or T3 as per heatingmedia

-

7/30/2019 A90 TCS 510 Training Material

22/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 22 -

Internal use only

Insulation/Heat Tracing By Customer

User can use heat tracing

of their own and insulatewith any material whichthey normally use

Use option /S2

Note:

Don't trace theelectronics/feed-through.

Make sure you don'texceed the detectorsambient temperature limits

-

7/30/2019 A90 TCS 510 Training Material

23/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 23 -

Internal use only

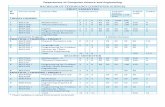

Hazardous Area Certification

ROTAMASS GSindicates the Max. process & ambienttemperature for different Temperature Class in Ex areas, whenselected with insulation & without insulation

Detail information on ATEX certificate

Be aware : The would be relation between Temp. Class,Max. process or ambient temperature

-

7/30/2019 A90 TCS 510 Training Material

24/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 24 -

Internal use only

Factory Fitted

Plug-n-Play Insulation &

Heat tracing solution Factory Fitted & Tested

Guaranteed Performance

Part of product catalogue

Stainless Steelenvironment protection

No de-gradation inperformance in on-linecondition

Cost Effective solutionEase of installation

-

7/30/2019 A90 TCS 510 Training Material

25/41

Copyright Yokogawa Electric Corporation

- 25 -Internal use only

Customized Design

Heat Tracing

-

7/30/2019 A90 TCS 510 Training Material

26/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 26 -

Internal use only

Customized Design Molten Sulphur

Thermal maintenance of moltensulphur is a difficult problem

Maintain a temperature window of138-154C is critical

Below 138C, hydrogen sulphide

can be emitted if vapour spaceexists, creating a potentiallyhazardous situation.

Above 320F (160C) the viscosityof molten sulphur risesexponentially.

-

7/30/2019 A90 TCS 510 Training Material

27/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 27 -

Internal use only

Customized Design Molten Sulphur

Special design includingheating flow divider

Complete instrument (includingflow-splitter) will be under aconstant temperature in orderto avoid corking / blockage

Not mandatory to have suchspecific design if customer is

doing proper insulation of thepiping including processconnections

-

7/30/2019 A90 TCS 510 Training Material

28/41

A90-TCS-510Copyright Yokogawa Electric Corporation

April, 2013- 28 -

Internal use only

Molten Sulphur flow measurement Application photographs

Fig 1: Tank where the sulfur was kept in 134C Fig 2: Oven where the Molten Sulfur will be burnt toproduce SO2

Fig 3: Location where the ROTAMASS is to be installed Fig 4: After ROTAMASSinstallation

-

7/30/2019 A90 TCS 510 Training Material

29/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013

- 29 -Internal use only

Molten Sulphur flow measurement

Where do I look for this application

Phosphate fertilizer company

Molten sulphur used for manufacturing sulphuric acid

Refinery

Sulphur Recovery Unit (SRU)

CS2 plant (carbon Di-sulphide)

Sulphur Melting Facility area

NOTE :

When installation has a shutdown customer has to ensure that heat tracingwill be stopped only when the pipe is totally empty.

Otherwise, if molten sulfur is still in the pipe and heat tracing is stopped;user will have some corking / blockage problem.

-

7/30/2019 A90 TCS 510 Training Material

30/41

Rota Yokogawa Flow Center of Excellence

Copyright Yokogawa Electric CorporationOctober 2011 PMK Department

- 30 -Internal use only

Competition offeringHeat Tracing Designs

-

7/30/2019 A90 TCS 510 Training Material

31/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013

- 31 -Internal use only

Due to its designMicroMotion EliteSeries has to usea soft envelop inorder to avoidvibration effects.

Vibrations effectwould generatean important loss

of accuracy, lossof zero stability.

Where are we compare to MicroMotion Elite

-

7/30/2019 A90 TCS 510 Training Material

32/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013

- 32 -Internal use only

Where are we compare to MicroMotion Elite

Only one side

is heated.

No direct heating for thispart of the meter.

Soft envelop with Velcro stripWhat about the resistance in case of:

- Humidity?

- Ultraviolet radiation (UV)?

- Aggressive environments?

What about heat transfer when theroom temperature is far away from thetemperature inside the envelop?

IS IT A PROPER INSULATION ?

Will this design avoid all

corking or blockage?

-

7/30/2019 A90 TCS 510 Training Material

33/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013

- 33 -Internal use only

Heat Loss

What Happens if Insulation Gets Wet?

The Heat lostthrough Wet insulation is 12-15 times morethan dry insulation.

Loss of thermal insulation value is a consequence of wet

insulationwater conducts energy. "If insulation is

wetted, it becomes a conductor of energy rather than aresistor"

Wet insulation

Metal Cladding in ROTAMASSdesign will protect better against wet insulationinstead of soft envelope

-

7/30/2019 A90 TCS 510 Training Material

34/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013

- 34 -Internal use only

Metal Cladding vs Soft envelope design

Metal

Cladding

Softcladding

Insulation Protected by metalcladding

Insulation Protected by softenvelope

Micromotion soft envelope design is more vulnerable to environmental affects oninsulation than ROTAMASS design

-

7/30/2019 A90 TCS 510 Training Material

35/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013

- 35 -Internal use only

Few Site Installation Photographs Picture Speaks

ControHeat Bolt-On Jackets for Micro Motion flow meters

-

7/30/2019 A90 TCS 510 Training Material

36/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013

- 36 -Internal use only

ControHeat Bolt-On Jackets for Micro Motion flow meters

Installation of heating medium jump-overs on jacketed Micro Motion

-

7/30/2019 A90 TCS 510 Training Material

37/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013 - 37 -

Internal use only

Installation of heating medium jump-overs on jacketed Micro Motionsensors

-

7/30/2019 A90 TCS 510 Training Material

38/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013 - 38 -

Internal use only

What competition does

i d d i

-

7/30/2019 A90 TCS 510 Training Material

39/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013 - 39 -

Internal use only

E+H imported design

Uptobendtubesectiononly

E H i d d i

-

7/30/2019 A90 TCS 510 Training Material

40/41

A90-TCS-510

Copyright Yokogawa Electric CorporationApril, 2013 - 40 -

Internal use only

E+H imported design

Upto bendtube sectiononly

-

7/30/2019 A90 TCS 510 Training Material

41/41

A90-TCS-510

C i h Y k El i C i 41

Thank you for your attention