A W J J A W · b risk category ii 1 ... d drc shall be solely responsible for all job site safety...

Transcript of A W J J A W · b risk category ii 1 ... d drc shall be solely responsible for all job site safety...

1 GENERAL NOTES

1.1 CODES AND DESIGN CRITERIA

a BUILDING CODE: 2014 INDIANA BUILDING CODE (IBC 2012)

b RISK CATEGORY II

1.2 DESIGN LOADS

a ROOF LOAD

DEAD LOAD 20 PSF

LIVE LOAD 30 PSF + DRIFT

b ROOF WOOD TRUSS

DEAD LOAD

TOP CHORD 10 PSF TYP

BOTT.CHORD 10 PSF

LIVE LOAD

TOP CHORD 30 PSF + DRIFT

BEND CHECK BOTTOM CHORD LOAD 300 lbs (ANY LOCATION)

c MECHANICAL EQUIPMENT

COORDINATE WITH MECHANICAL ENGINEER

d FLOOR LOAD (SLAB ON GRADE)

DEAD LOAD 50 PSF

LIVE LOAD 125 PSF @ STORAGE CLOSETS

100 PSF @ CORRIDORS & PUBLIC ROOMS

40 PSF @ RESIDENTIAL

e SNOW LOAD

GROUND SNOW LOAD Pg 20 PSF

IMPORTANCE FACTOR Is 1.1

SNOW EXPOSURE FACTOR Ce 1.0

SNOW THERMAL FACTOR Ct 1.1

FLAT ROOF SNOW LOAD Pf 17.0 PSF

f WIND LOADS (ASCE7-10)

MWFRS

BASIC WIND SPEED 120 mph (3 SEC GUST)

RISK CATEGORY III

WIND EXPOSURE C

INTERNAL PRESSURE COEFFICIENT +/- .18

COMPONENTS & CLADDING (ASD)

TRIBUTARY AREA>20 SQUARE FEET

ROOF ZONE 1 +10/-19 PSF

ROOF ZONE 2 +10/-28 PSF

ROOF ZONE 3 +10/-44 PSF

WALLS (TRIBUTARY AREA > 20 SQUARE FEET)

WALL ZONE 4 +20/-21 PSF

WALL ZONE 5 +20/-25 PSF

NET WIND UPLIFT (ASCE7-10)

NET UPLIFT 28 PSF (WITHIN 10 FT OF ROOF EDGE)

NET UPLIFT 19 PSF (TYP UN)

g SEISMIC LOADS

RISK CATEGORY III

SEISMIC IMPORTANCE FACTOR 1.0

Ss 0.150 Sds 0.160

S1 0.075 Sd1 0.120

SITE CLASS - D

SEISMIC DESIGN CATEGORY - B

BASIC SEISMIC FORCE RESISTING SYSTEM: LIGHT FRAMED WOOD SHEAR WALLS

RESPONSE MODIFICATION FACTOR R = 6.5

SEISMIC RESPONSE COEFFICIENT Cs = 0.031

DESIGN BASE SHEAR (ASD) 18.9k

ANALYSIS PROCEDURE: EQUIVALENT LATERAL FORCE

1.3 GENERAL REQUIREMENTS

a DEFINITIONS

PRIMARY STRUCTURAL SYSTEM IS THE COMPLETED COMBINATION OF ELEMENTS WHICH SERVE TO

SUPPORT THE BUILDING'S SELF-WEIGHT, THE APPLICABLE LIVE LOAD, AND THE ENVIRONMENTAL

LOADS SUCH AS WIND, SEISMIC.

PRE-ENGINEERED STRUCTURAL ELEMENTS ARE STRUCTURAL ELEMENTS WHICH ARE SPECIFIED BY

THE SER AS DESIGN DELEGATED ITEMS TO BE THE DESIGN RESPONSIBILITY OF A SPECIALTY

STRUCTURAL ENGINEER (SSE)

SPECIAL INSPECTION IS INSPECTION PERFORMED BY A QUALIFIED PERSON, APPROVED BY THE

BUILDING OFFICIAL, FOR THE TYPES OF WORK REQUIRING INSPECTION PER THE GOVERNING CODES

AND CONTRACT DOCUMENTS.

SPECIALTY STRUCTURAL ENGINEER (SSE) IS A LICENSED PROFESSIONAL/STRUCTURAL ENGINEER,

NOT THE SER, WHO IS RESPONSIBLE FOR SEALING PLANS AND DESIGNS FOR PRE-ENGINEERED

STRUCTURAL ELEMENTS WHICH ARE NECESSARY FOR THE STRUCTURE TO BE COMPLETED AND THE

SER HAS DESIGNATED AS DESIGN DELEGATED ITEMS.

STRUCTURAL ENGINEER OF RECORD (SER) IS THE STRUCTURAL ENGINEER WHO IS LEGALLY

ELIGIBLE TO SEAL THE STRUCTURAL DOCUMENTS FOR A BUILDING PROJECT. THE SER IS

RESPONSIBLE FOR THE DESIGN OF THE PRIMARY STRUCTURAL SYSTEM.

DESIGNATED REPRESENTATIVE FOR CONSTRUCTION (DRC - I.E., CONSTRUCTION MANAGER OR

GENERAL CONTRACTOR) IS RESPONSIBLE FOR THE OVERALL CONSTRUCTION OF THE PROJECT

INCLUDING PROJECT SCHEDULING, JOB SITE SAFETY AND MEANS AND METHODS OF

CONSTRUCTION.

SPECIAL INSPECTOR: A QUALIFIED PERSON EMPLOYED OR RETAINED BY AN APPROVED AGENCY AND

APPROVED BY THE BUILDING OFFICIAL AS HAVING THE COMPETENCE NECESSARY TO INSPECT A

PARTICULAR TYPE OF CONSTRUCTION REQUIRING SPECIAL INSPECTION.

b THE STRUCTURAL DRAWINGS ARE TO BE USED IN CONJUNCTION WITH THE SPECIFICATIONS AND

THE GEOTECHNICAL REPORT.

c THE DRC SHALL COORDINATE WITH THE MECHANICAL AND ARCHITECTURAL DRAWINGS

AND WITH THE MECHANICAL CONTRACTOR, THE LOCATION OF ALL MECHANICAL EQUIPMENT.

d THE DRC SHALL NOTIFY THE ARCHITECT IF THE WEIGHTS OF MECHANICAL UNITS ETC. ARE

DIFFERENT FROM THE WEIGHTS POSTED ON THE DESIGN DRAWINGS. DISCREPANCIES

SHALL BE RESOLVED BEFORE PROCEEDING WITH CONSTRUCTION.

e THE DRC SHALL NOTIFY THE ARCHITECT/ENGINEER IMMEDIATELY OF ANY DISCREPANCIES TO AVOID

THE POSSIBILITY OF UNNECESSARY FUTURE PROBLEMS AND POSSIBLE FIELD ORDERS. FAILURE TO

DO SO WILL PUT THE FULL RESPONSIBILITY OF CORRECTION ON THE DRC.

f THE DRC SHALL COORDINATE THE WORK OF ALL TRADES AND MAKE NECESSARY

INVESTIGATIONS AND FIELD MEASUREMENTS.

g DO NOT SCALE DRAWINGS.

h THE SER HAS NO SUPERVISORY RESPONSIBILITY, HAS NO CONTROL OF OR

RESPONSIBILITY FOR THE MEANS, METHODS, TECHNIQUES, PROCEDURES OR SEQUENCE OF

CONSTRUCTION, HAS NO RESPONSIBILITY FOR THE FAILURE OF ANY CONTRACTOR TO

PERFORM THE WORK IN ACCORDANCE WITH THE DESIGN DOCUMENTS AND NO RESPONSIBILITY TO

DEVISE, IMPLEMENT OR ENFORCE ANY SAFETY PRECAUTIONS OR PROGRAMS FOR THE PROJECT

1.4 SLEEVES, ANCHORAGES, OPENINGS, ETC.

a IN GENERAL, STRUCTURAL DRAWINGS DO NOT SHOW EQUIPMENT PADS, DRAINS, HOLES,

ANCHORAGES, INSERTS AND SLEEVES FOR ITEMS PASSING THROUGH OR ATTACHED TO CONCRETE

OR FRAMING. REFER TO ARCHITECTURAL, MECHANICAL, AND ELECTRICAL

DRAWINGS AND PROJECT SPECIFICATIONS. ADJUST EQUIPMENT PADS AND SUB FRAMING TO FIT

EQUIPMENT FURNISHED.

b PROVIDE SUB FRAMING FOR EQUIPMENT SUPPORTED ON OR SUSPENDED FROM THE

STRUCTURE.

1.5 STRUCTURAL STABILITY AND CONSTRUCTION

a INDIVIDUAL STRUCTURAL COMPONENTS ARE DESIGNED TO SUPPORT LOADS IN THEIR

FINAL ERECTED POSITION AS PART OF THE TOTAL COMPLETED STRUCTURE.

b DRC TO PROVIDE TEMPORARY GUYING AND BRACING AS REQUIRED UNTIL ALL

CONSTRUCTION AFFECTING LATERAL STABILITY IS COMPLETED.

c DRC SHALL BE SOLELY RESPONSIBLE FOR STABILITY OF STRUCTURE, ITS PARTS BY USE OF

GUYING, BRACING, SHORING, BARRICADES, SAFETY RAILINGS AND DEVICES DURING THE

ENTIRE PERIOD OF CONSTRUCTION.

d DRC SHALL BE SOLELY RESPONSIBLE FOR ALL JOB SITE SAFETY AND MEANS AND METHOD OF

CONSTRUCTION.

1.6 SHOP DRAWINGS AND TEST REPORTS

a DRC SHALL CHECK ALL SHOP DRAWINGS BEFORE SUBMITTAL TO SER FOR REVIEW.

b DRC SHALL PREPARE A SHOP DRAWING SUBMITTAL SCHEDULE WITH A MINIMUM OF TWO

WEEKS INCLUDED FOR THE SER'S REVIEW OF EACH SUBMITTAL LISTED BELOW.

c REVIEW BY SER WILL BE FOR CONFORMANCE TO GENERAL LAYOUT AND DESIGN INTENT ONLY.

d CONTRACTOR SHALL BE SOLELY RESPONSIBLE FOR ACCURACY OF DIMENSIONS,

FABRICATION, FIT UP OF PARTS AND BILLS OF MATERIALS.

e CONTRACTOR SHALL COORDINATE WORK OF VARIOUS TRADES AND MAKE NECESSARY

FIELD MEASUREMENTS.

f THE CONTRACT SPECIFICATIONS PROVIDE A COMPLETE LISTING OF SUBMITTALS. THE

FOLLOWING IS A SUMMARY OF THE REQUIRED SUBMITTALS:

CONCRETE

CONCRETE MIX DESIGNS WITH ASSOCIATED HISTORICAL TEST DATA

REINFORCING STEEL PLACEMENT DRAWINGS PER ACI 315

CONCRETE MASONRY

PRODUCT DATA SHEETS

REINFORCING STEEL PLACEMENT DRAWINGS

STRUCTURAL STEEL

STRUCTURAL STEEL SHOP DRAWINGS

CONNECTION DESIGN SIGNED AND SEALED BY LICENSED SSE.

PRECAST CONCRETE

PRECAST SHOP DRAWINGS

PRECAST DESIGN SIGNED AND SEALED BY LICENSED SSE.

WOOD PRODUCTS (WOOD TRUSSES/ENGINEERED WOOD PRODUCTS)

SHOP DRAWINGS

DESIGN CALCULATIONS SIGNED AND SEALED BY LICENSED SSE.

MISCELLANEOUS METALS (STAIRS/HANDRAIL/GUARD RAIL/LADDERS ETC.)

STRUCTURAL STEEL SHOP DRAWINGS

DESIGN CALCULATIONS SIGNED AND SEALED BY LICENSED SSE.

1.7 DEFERRED SUBMITTALS - DESIGN DELEGATED COMPONENTS

a CERTAIN COMPONENTS OF THE COMPLETED CONSTRUCTION ARE DESIGN DELEGATED TO

THE MANUFACTURER OF THE COMPONENT. THE MANUFACTURER'S SSE SHALL BE

RESPONSIBLE FOR THE DESIGN OF THE COMPONENT. THE FOLLOWING ARE DESIGNATED TO BE

DESIGN DELEGATED COMPONENTS ON THIS PROJECT:

b PRECAST PLANKS

c STRUCTURAL STEEL CONNECTIONS

d [not used]

e MISCELLANEOUS METALS (STAIRS, GUARDRAIL, HANDRAIL, LADDERS, ETC.)

f WOOD TRUSSES, OPEN WEB COMPOSITE TRUSSES, ENGINEERED WOOD PRODUCTS, STAIRS

g TEMPORARY SHORING AND BRACING

h TEMPORARY EARTH RETENTION SYSTEMS

i CURTAIN WALLS

j WINDOW WALLS

k [not used]

l OTHER WORK AS LISTED ON DRAWINGS, SPECIFICATIONS AND CUSTOMARY INDUSTRY

STANDARDS. WHERE DELEGATION OF DESIGN IS SPECIFIED,

m THE MANUFACTURER SHALL BE RESPONSIBLE FOR RETAINING THE SERVICES OF A

LICENSED SPECIALTY STRUCTURAL ENGINEER (SSE) IN THE STATE HAVING JURISDICTION.

THE SSE SHALL DESIGN AND DETAIL COMPONENTS TO MEET GOVERNING BUILDING

CODES, STANDARDS AND THE SPECIFIED PERFORMANCE CRITERIA. SIGNED AND SEALED

CALCULATIONS SHALL BE SUBMITTED FOR RECORD. THE DESIGN DELEGATED SSE SHALL BE SOLELY

RESPONSIBLE FOR THE DESIGN OF THE COMPONENT.

n SSE SUBMITTALS WILL BE REVIEWED BY THE SER FOR LOADING CRITERIA AND GENERAL

CONFORMANCE TO THE PRIMARY STRUCTURAL SYSTEM.

1.8 STRUCTURAL TESTS AND INSPECTIONS (IBC 2012)

a AN INDEPENDENT APPROVED AGENCY SHALL PROVIDE SPECIAL INSPECTIONS AND TESTS DURING CONSTRUCTION

IN ACCORDANCE WITH CHAPTER 17 OF IBC 2012.

b THE APPROVED AGENCY'S SPECIAL INSPECTOR SHALL OBSERVE THE WORK ASSIGNED FOR CONFORMANCE TO THE

APPROVED DESIGN DRAWINGS AND SPECIFICATIONS.

c THE APPROVED AGENCY SHALL KEEP RECORDS OF ALL SPECIAL INSPECTIONS AND TESTS AND SUBMIT REPORTS

TO THE BUILDING OFFICIAL AND THE SER.

d ALL DISCREPANCIES SHALL BE IMMEDIATELY BROUGHT TO THE ATTENTION OF THE DRC FOR CORRECTION. IF

UNCORRECTED, THE APPROVED AGENCY SHALL NOTIFY THE BUILDING OFFICIAL AND THE SER.

e REFER TO IBC 2012 1704 FOR SUBMITTALS TO THE BUILDING OFFICIAL IN ADDITION TO THE REPORTS.

f THE APPROVED AGENCY SHALL SUBMIT A FINAL REPORT STATING WHETHER THE WORK REQUIRING SPECIAL

INSPECTION WAS IN CONFORMANCE WITH THE APPROVED CONTRACT DOCUMENTS AND THE APPLICABLE

WORKMANSHIP PROVISIONS OF THIS CODE.

g QUALITY CONTROL SHALL BE THE RESPONSIBILITY OF THE FABRICATOR/ERECTOR IN

ACCORDANCE WITH AISC360-10 CHAPTER N.

h JOB SITE VISITS BY THE SER DO NOT CONSTITUTE AN OFFICIAL SPECIAL INSPECTION.

STATEMENT OF SPECIAL INSPECTIONS:

a REFER TO THE REFERENCED DOCUMENTS (IBC 2012 CHAPTER 17, AISC 360-10 CHAPTER N, ACI530-13 CHAPTER 3)

FOR ADDITIONAL DESCRIPTIONS OF REQUIREMENTS.

b STRUCTURAL OBSERVATIONS FOR SEISMIC NOT REQUIRED

c STRUCTURAL OBSERVATIONS FOR WIND NOT REQUIRED

d THE FOLLOWING LIST OF MATERIALS AND WORK REQUIRE SPECIAL INSPECTIONS (P) PERIODIC; (C) CONTINUOUS

CONCRETE CONSTRUCTION (IBC 2012 TABLE 1705.3)

1 REINFORCEMENT PLACEMENT (P)

2 REINFORCING BAR WELDING (P)

3 ANCHORS CAST IN CONCRETE (P)

4 POST INSTALLED ANCHORS

a ADHESIVE (C)

b MECHANICAL (P)

5 VERIFY USE OF REQUIRED MIX (P)

6 STRENGTH, SLUMP, AIR, TEMPERATURE TEST OF CONCRETE PRIOR TO PLACEMENT (C)

7 CONCRETE PLACEMENT (C)

8 VERIFY MAINTENANCE OF SPECIFIED CURING TEMPERATURE AND TECHNIQUES (P)

9 INSPECT ERECTION OF PRECAST MEMBERS INCLUDING CONNECTIONS (P)

10 INSPECT FORMWORK (P)

WOOD CONSTRUCTION (IBC 2012 1705.5)

1 VERIFY MATERIAL GRADE (P)

2 MEMBER SIZES, FRAMING AND DETAILS CONFORM TO CONTRACT DOCUMENTS (P)

3 DIAPHRAGM AND SHEAR WALL SHEATHING SIZE/GRADE AND NAIL SIZE AND PATTERNS CONFORM TO CONTRACT

DOCUMENTS. (P)

4 HOLD DOWNS/STRAPS INSTALLED PER MANUFACTURER INSTRUCTIONS AND PER CONTRACT DOCUMENTS.

SOILS (IBC 2012 TABLE 1705.6)

1 VERIFY BEARING CAPACITY BELOW SHALLOW FOUNDATIONS (P)

2 VERIFY EXCAVATIONS EXTEND TO PROPER DEPTH AND REACHED PROPER MATERIAL (P).

3 PERFORM CLASSIFICATION AND TESTING OF COMPACTED MATERIAL (P)

4 VERIFY USE OF PROPER MATERIALS, DENSITIES AND LIFT THICKNESSES DURING PLACEMENT AND COMPACTION OF

COMPACTED MATERIAL (C).

5 PRIOR TO PLACEMENT OF COMPACTED FILL, INSPECT SUBGRADE AND VERIFY THAT SITE HAS BEEN PROPERLY

PREPARED (P)

6 VERIFY SOIL IMPROVEMENT HAS BEEN PERFORMED PROPERLY (P)

2 FOUNDATIONS

2.1 GENERAL

a THE FOUNDATION DESIGN IS BASED ON THE GEOTECHNICAL REPORT PREPARED BY GHL AND DATED

APRIL 19, 2016. REFER TO GEOTECHNICAL REPORT FOR ADDITIONAL GEOTECHNICAL

REQUIREMENTS.

b SUMMARY OF GEOTECHNICAL DESIGN VALUES

SHALLOW STRIP AND SPREAD FOOTINGS

ALLOWABLE SOIL BEARING PRESSURE 4,500 PSF

DEPTH OF FOOTING BELOW FINISHED GRADE 42”.

BASEMENT (RESTRAINED), RETAINING WALLS (UNRESTRAINED) WALLS

BACKFILL - GRANULAR

DENSITY - 115 PCF

ACTIVE LATERAL PRESSURE (UN RESTRAINED) - 45 PSF/FT

AT REST LATERAL PRESSURE (RESTRAINED) - 65 PSF/FT

SURCHARGE COEFFICIENT (UN-RESTRAINED) - .3 X LOAD(PSF) - PSF

SURCHARGE COEFFICIENT (RESTRAINED) - .5 X LOAD (PSF) - PSF

COEFFICIENT OF SLIDING RESISTANCE - .4

c CONTRACTOR SHALL LOCATE ALL EXISTING BELOW GRADE UTILITIES AND INTERFERENCES PRIOR

TO START OF WORK. NOTIFY THE SER OF ANY INTERFERENCE.

d REFER TO CIVIL DRAWINGS FOR ALL SOIL IMPROVEMENT, SITE PREPARATION, GRADING, EROSION

PROTECTION AND SITE UTILITY WORK.

e STRIP TOPSOIL OVER THE ENTIRE BUILDING AREA.

f PROTECT ALL EXPOSED SURFACES IN ACCORDANCE WITH THE GEOTECHNICAL REPORT.

g MAINTAIN ALL EXCAVATIONS FREE OF WATER CONTINUOUSLY

h DRC SHALL BE RESPONSIBLE FOR ALL SHORING/BRACING OF EXCAVATIONS.

i ALL SHALLOW FOUNDATIONS SHALL BE LOCATED SHALL BEAR AT SUFFICIENT DEPTH TO PROVIDE

ADEQUATE FROST COVERAGE PER LOCAL REQUIREMENTS.

j A GEOTECHNICAL TESTING SERVICE SHALL CONFIRM ALL SOIL BEARING CAPACITIES PRIOR TO

PLACEMENT OF CONCRETE FOUNDATIONS.

k DO NOT BACKFILL BEHIND BASEMENT WALLS UNTIL ALL FRAMING IS COMPLETED UNLESS

TEMPORARY BRACING/SHORING IS PROVIDED BY THE DRC'S SSE.

l ALL STRUCTURAL FILL AND GENERAL FILL SHALL MEET THE REQUIREMENTS OF THE GEOTECHNICAL

REPORT INCLUDING MATERIAL SPECIFICATION AND COMPACTION REQUIREMENTS.

m ALL BASEMENT AND RETAINING WALLS ARE DESIGNED CONSIDERING A GRANULAR BACKFILL

MATERIAL.

3 CONCRETE CONSTRUCTION

3.1 CAST IN PLACE CONCRETE

a GENERAL REQUIREMENTS

ALL WORK SHALL CONFORM TO ALL REQUIREMENTS OF ACI 301-10, SPECIFICATION FOR

STRUCTURAL CONCRETE, EXCEPT AS MODIFIED BY THE REQUIREMENTS OF THE CONTRACT

DOCUMENTS.

SUBMITTALS

CONCRETE MIXES WITH HISTORICAL TEST DATA.

MATERIAL CERTIFICATES: CEMENT, AGGREGATES, ADMIXTURES, REINFORCING STEEL

REINFORCING STEEL PLACEMENT DRAWINGS

b PRODUCTS

REINFORCING BARS: ASTM A615 GRADE 60

REINFORCING BARS WELDABLE: ASTM A706 GRADE 60

PLAIN WIRE FABRIC: ASTM A185

PORTLAND CEMENT: ASTM C150 TYPE I OR II.

AGGREGATES: ASTM C33

WATER: POTABLE ASTM C94

ADMIXTURES

AIR ENTRAINING ASTM C260

CHEMICAL ADMIXTURES ASTM C 494

AIR CONTENT FOR CONCRETE EXPOSED TO WEATHER: 4 TO 7%.

SLUMP: 4"

CONCRETE STRENGTH: F'C 3,000 PSI AT 28 DAYS

MIXING PER ASTM C94

CURING COMPOUNDS: ASTM C309 OR C1315

c EXECUTION

CONCRETE COVER

CONCRETE CAST AGAINST AND PERMANENTLY EXPOSED TO EARTH 3"

CONCRETE EXPOSED TO EARTH OR WEATHER 2"

CONCRETE NOT EXPOSED TO WEATHER 1-1/2"

ALL FOOTINGS, WALL FOOTINGS, GRADE BEAMS AND PILE/CAISSON CAPS SHALL BE FORMED

UNLESS NOTED.

LAP SPLICE LENGTHS PER ACI 318 CHAPTERS 12 USING A CLASS B SPLICE. ALL WELDED WIRE

FABRIC SHALL BE LAPPED ONE GRID MINIMUM

LOCATE JOINTS AS SHOWN ON PLANS; WHERE NOT SHOWN, CONTROL OR CONSTRUCTION JOINTS

SHALL BE PLACED IN ACCORDANCE WITH ACI RECOMMENDATIONS I.E., A MAXIMUM PANEL SIZE (IN

FEET) EQUAL TO APPROXIMATELY THREE TIMES THE THICKNESS OF THE SLAB (IN INCHES) IN BOTH

DIRECTIONS.

HOOK ENDS OF BARS INTERRUPTED BY OPENINGS.

HOOK TOP BARS AT ALL CONCRETE EDGES, AT ALL WALL AND SLAB OPENINGS,

PROVIDE 2-#5 BARS X OPENING WIDTH PLUS 4 FEET (2 FEET EACH SIDE) EACH FACE, UNLESS

SHOWN OTHERWISE.

PLACEMENT OF CONCRETE IN COLD WEATHER SHALL COMPLY WITH ACI306

PLACEMENT OF CONCRETE IN HOT WEATHER SHALL COMPLY WITH ACI305

TOLERANCES SHALL MEET ACI 117, ACI 301 AND ACI 318 AS A MINIMUM.

6 WOOD CONSTRUCTION

6.1 DIMENSIONAL LUMBER

a ALL WOOD CONSTRUCTION SHALL CONFORM TO THE "NATIONAL DESIGN SPECIFICATION FOR WOOD

CONSTRUCTION - ASD" LATEST EDITION.

b STRUCTURAL WOOD SHALL BE HEM FIR No.2 @ 19% MAX. M.C. WITH MINIMUM IN GRADE STRESS

VALUES AS FOLLOWS:

c BEAMS/POSTS < 5” WIDE DF NO 2 OR BETTER

d FB = 850 PSI FV=180 PSI E= 1,300 KSI

e POSTS >= 5”X5 HF NO 2 OR BETTER

f FB = 575 PSI FV=140 PSI E= 1,100 KSI

g ALL NAILS SHALL BE COMMON NAILS (6d - 2" LONG .113" SHANK DIA; 8d - 2-1/2" LONG .131 SHANK

DIA; 10d - 3" LONG .148" SHANK DIA; 16d - 3-1/2" LONG .162" SHANK DIA.).

h LEAD HOLES SHALL BE PRE DRILLED FOR ALL LAG SCREWS PER NDS REQUIREMENTS

i ALL POSTS FROM UPPER LEVELS SHALL BE COPIED DOWN TO THE LEVELS BELOW UNLESS NOTED

OTHERWISE.

6.2 PRE-ENGINEERED WOOD TRUSSES

a WOOD TRUSSES ARE DESIGNATED AS A DELEGATED DESIGN ITEM AND SHALL BE DESIGNED BY THE

CONTRACTOR'S LICENSED PROFESSIONAL ENGINEER.

b ALL WOOD TRUSSES SHALL CONFORM TO DESIGN SPECIFICATION FOR METAL PLATE CONNECTED

WOOD TRUSSES ANSI/TP1 1, "NATIONAL DESIGN STANDARD FOR METAL-PLATE-CONNECTED WOOD

TRUSS CONSTRUCTION. AND "THE NATIONAL DESIGN SPECIFICATION" BY THE NATIONAL FOREST

PRODUCTS ASSOCIATION.

c SUPPLIER SHALL BE RESPONSIBLE FOR BRACING AND/OR BRIDGING REQUIRED FOR THE DESIGN OF

THE TRUSS MEMBERS. SUPPLIER SHALL SUBMIT A TEMPORARY BRACING PLAN AS PART OF THE

SHOP DRAWING SUBMITTAL.

d SUPPLIER SHALL DESIGN AND PROVIDE ALL NECESSARY BEARING PLATES FOR GIRDER TRUSSES.

SUPPLIER SHALL PROVIDE ALL CONNECTORS FOR MAIN AND SUPPLEMENTAL FRAMING AS SHOWN ON

THE DRAWINGS OR AS OTHERWISE REQUIRED.

e WOOD TRUSS SHOP DRAWINGS AND CALCULATIONS, STAMPED BY AN SE, SHALL BE SUBMITTED

PRIOR TO FABRICATION.

f CALCULATIONS SHALL INCLUDE NOT ONLY A SUMMARY SHEET, BUT ALSO THE DETAILED DESIGN

FROM WHICH THE SUMMARY IS OBTAINED.

g TRUSSES SHALL BE DESIGNED FOR THE LOADS INDICATED ABOVE. IN ADDITION TO THE LIVE

LOADS LISTED ABOVE, THE BOTTOM CHORDS SHALL BE DESIGNED FOR A UNIFORM LIVE LOAD OF 10

PSF.

h HOLD-DOWNS SHALL BE PROVIDED AT THE ENDS OF ALL TRUSSES. THE HOLD DOWNS SHALL BE BY

SIMPS0N STRONG-TIE OR EQUAL AND SHALL BE CAPABLE OF RESISTING THE UPLIFT LOADS

DETERMINED BY THE TRUSS MANUFACTURER. A MINIMUM SIMPSON STRONG-TIE H2.5 SHALL BE

PROVIDED AT ALL TRUSS BEARING POINTS.

i WHEN WOOD TRUSSES ARE SUPPORTED ON WOOD STUD WALLS, A MINIMUM OF ONE STUD FOR

EACH TRUSS PLY SHALL BE PROVIDED AT BEARING POINTS UNLESS NOTED OTHERWISE.

j WOOD FOR TRUSS TOP CHORDS SHALL BE SOUTHERN PINE OR DOUGLAS FIR-LARCH, NO. 2 GRADE

OR BETTER AT 19% M.C. PER TRUSS FABRICATORS DESIGN.

k FLOOR TRUSSES SHALL BE DESIGNED WITH THE REQUIRED CAMBER TO ELIMINATE SELF WEIGHT

DEFLECTION AND BE DESIGNED SUCH THAT THE MAXIMUM DEFLECTION UNDER LIVE LOAD DOES

NOT EXCEED L/480 OF THE SPAN.

l ROOF TRUSSES SHALL BE DESIGNED SUCH THAT THE MAXIMUM DEFLECTION UNDER LIVE LOAD

DOES NOT EXCEED L/360 OF THE SPAN, AND A MAXIMUM DEFLECTION UNDER TOTAL LOAD DOES

NOT EXCEED L/240.

6.3 LAMINATED VENEER LUMBER (LVL)

a ALL LAMINATED VENEER HEADERS AND BEAMS SHALL BE THOSE SUPPLIED AND MANUFACTURED

ACCORDING TO THE SPECIFICATIONS OF REDBUILT OR APPROVED EQUAL WITH MINIMUM

PROPERTIES AS FOLLOWS:

b Fb-2900 PSI

c Fv=285 PSI

d E=2,000,000 PSI

e ALL MULTIPLE PIECE MEMBERS SHALL BE NAILED OR THROUGH BOLTED TOGETHER IN ACCORDANCE

WITH MANUFACTURERS RECOMMENDATIONS.

6.4 PARALLEL STRAND LUMBER (PSL)

a ALL PARALLEL STRAND LUMBER SHALL BE ACCORDING TO THE SPECIFICATIONS OF REDBUILT OR

APPROVED EQUAL WITH MINIMUM PROPERTIES AS FOLLOWS:

b Fb = 2900 PSI

c Fc = 2900 PSI (PARALLEL TO GRAIN)

d Fv = 290 PSI

e E = 2,000,000 PSI

6.5 WOOD SHEATHING

a ALL SHEATHING FOR ROOFS AND WALLS SHALL BE APA RATED EXTERIOR SHEATHING.

b SHEATHING FOR SHEAR WALLS SHALL BE STRUCTURAL I.

c IF NOT LISTED ON THE PLANS, THE MINIMUM RATING SHALL BE 40/20 WITH A NAILING PATTERN OF

8d @ 6" ON ALL EDGES.

d ROOF SHEATHING SHALL BE PLACED IN A STAGGERED PATTERN WITH THE LONG DIMENSION OF THE

SHEETS SPANNING PERPENDICULAR TO THE SUPPORT MEMBERS.

e FREE EDGES OF THE ROOF SHEATHING SHALL BE BLOCKED WITH 2X FRAMING IF NOTED ON THE

PLANS. IF NOT NOTED TO BE BLOCKED, EDGES SHALL HAVE A MINIMUM OF 2 "H" CLIPS BETWEEN

SUPPORTS.

f ALL EDGES OF SHEAR WALL SHEATHING SHALL BE BLOCKED WITH 2X FRAMING (3X FRAMING IF

STUDS ARE GREATER THAN 2X).

g ALL NAILS SHALL BE PLACED WITH THE HEAD FLUSH WITH SHEATHING SURFACE. DO NOT

OVERDRIVE NAILS.

h ALL NAILS SHALL BE COMMON NAILS (6d - 2" LONG .113" SHANK DIA; 8d - 2-1/2" LONG .131 SHANK

DIA; 10d - 3" LONG .148" SHANK DIA; 16d - 3-1/2" LONG .162" SHANK DIA.).

Tyson and B

illy A

rchitects, P

.C

.

40

00

M

orsa

y D

rive

Ro

ckfo

rd

, IL

6

11

07

(8

15

) 2

29

-8

22

2

FA

X: (8

15

) 2

29

-8

21

8

Sheet No:

ww

w.tyso

na

ndb

illy.co

m

Drn.

Appd.

Project N

um

ber

Date

REVISION DATE

BO

ND

IN

G C

O.

CO

NT

RA

CT

OR

OW

NE

RA

RC

HIT

EC

T

2/2

8/2

01

8 9

:5

2:4

3 A

M

MC

CI O

F IN

DIA

NA

, LLC

LIN

CO

LN

SH

IR

E P

LA

CE

M

EM

OR

Y C

AR

E F

AC

IL

TY

MU

NC

IE

, IN

DIA

NA

17

-1

12

60

02

/2

8/1

8P

CW

NM

IS

SU

ED

F

OR

B

ID

DIN

G

J A

JOH

NSO

N W

ILB

UR

AD

AM

S,

INC

.

STR

UC

TU

RA

L E

NG

INE

ER

ING

330 S

. N

aper

vill

e R

d, S

uit

e 300

Wh

eato

n, Il

lin

ois

60187

Tel

eph

on

e 630 653 9060

W

S100

ST

RU

CT

UR

AL

G

EN

ER

AL

N

OT

ES

11'-4"

18'-0"

1'-0"

1'-0"

1'-0"

1'-0"

18'-0"

2'-0"2'-0"

10 1/2"

14'-3"

10 1/2"

4'-0" 4'-0"

(2) C1 / P2

F3.0-5.0

(-)3'-6"

(2) C1 / P2

F3.0-5.0

(-)3'-6"

(2) C1 / P2

F3.0-5.0

(-)3'-6"

(2) C1 / P2

F3.0-5.0

(-)3'-6"

25'-7 1/2"

16'-0"

25'-7 1/2"

84'-3"

25'-7 1/2"

16'-0"

25'-7 1/2"

3'-0"

57'-1"

14'-8"

41'-9"

14'-8"

42'-3"

8'-10"

19'-11"

7'-4"

2'-4"

5'-0" 13'-6" 25'-11" 17'-9" 40'-1" 14'-3" 40'-1" 17'-9" 25'-11" 13'-6" 5'-0"

4'-0"

4'-0"

15'-9"

2'-0"

2'-0"

15'-9"

19'-11"

8'-10"

42'-3"

14'-8"

41'-9"

14'-8"

57'-1"

3'-0"

4'-0"

4'-0"

2'-4"

7'-4"

6'-0"

2'-0"

2'-0"

6'-0"

24'-3"

4'-9"

95'-5"

31'-3" 21'-9" 31'-3"

17'-1 1/4" 16'-8 1/4"

16'-8"

16'-8 1/4" 17'-1 1/4"

95'-5"

4'-9"

24'-3"

10'-0"

6'-0"

C1 / P1

F3.0

(-)3'-6"

C1 / P1

F3.0

(-)3'-6"

C1 / P1

F3.0

(-)3'-6"

C1 / P1

F3.0

(-)3'-6"

4" SLAB ON GRADE

T/ SLAB EL. 0'-0"

(NOTE A-S101)

4" SLAB ON GRADE

T/ SLAB EL. 0'-0"

(NOTE A-S101)

4" SLAB ON GRADE

T/ SLAB EL. 0'-0"

(NOTE A-S101)

4" SLAB ON GRADE

T/ SLAB EL. 0'-0"

(NOTE A-S101)

T/ FDN. WALL

EL. 0'-0", TYP.,

U.N.

B/ FOOTING

EL.(-)4'-0", TYP.,

U.N.

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW

1

SW

1

SW1

SW1SW1

SW1

SW1

SW1

S200

10

TYP.

S200

7

S200

4

S200

4

S200

8

S200

7

TYP.

S200

7

TYP.

S200

7

S200

7

S200

9

S200

4

S200

8

TYP.

S200

4

S200

4

S200

4

S200

4

S200

4

S200

8

S200

7

S200

7

S200

4

S200

4

S200

6

SHEAR WALLS

TYP. @

S200

6

SHEAR WALLS

TYP. @

S200

11

S200

11

S200

11

S200

11

S200

11

BRG. WALLS

TYP. @

S200

4

S200

6

SIM.

1'-0"1'-0" 1'-0"1'-0"

SW1

SW1

SW1

SW1 SW1

SW1

SW1

SW

1SW

1

SW

1

SW

1

SW

1SW

1SW

1

SW

1SW

1SW

1

SW

1SW

1

SW1SW1 SW1 SW1

(WxLxD)

FOOTING SIZE

MARK

FOOTING REINFORCING REMARKS

EACH WAY BOTTOM, U.N.

REMARKS

DETAIL 1

W

D

TIES

VERTICAL

D

18"18"P1

MARK

W

PIER

PIER SIZE

4-#6#3 @ 12"

REINFORCING

VERTICAL TIES

DETAIL 1

T/ PIER EL. 0'-0"

48"24"P2 8-#6#3 @ 12"

DETAIL 2

T/ PIER EL. 0'-0"

DETAIL 2

W

D

TIES

VERTICAL

3'-0"x3'-0"x1'-0"F3.0 4-#5

5'-0"x5'-0"x1'-0"F5.0 6-#5

SW1

SW1

-

F3.0

(-)0'-4"

-

F3.0

(-)0'-4"

-

F3.0

(-)0'-4"

SW

1

-

F3.0

(-)0'-4"

-

F3.0

(-)0'-4"

Tyson and B

illy A

rchitects, P

.C

.

40

00

M

orsa

y D

rive

Ro

ckfo

rd

, IL

6

11

07

(8

15

) 2

29

-8

22

2

FA

X: (8

15

) 2

29

-8

21

8

Sheet No:

ww

w.tyso

na

ndb

illy.co

m

Drn.

Appd.

Project N

um

ber

Date

REVISION DATE

BO

ND

IN

G C

O.

CO

NT

RA

CT

OR

OW

NE

RA

RC

HIT

EC

T

2/2

8/2

01

8 9

:5

2:4

3 A

M

MC

CI O

F IN

DIA

NA

, LLC

LIN

CO

LN

SH

IR

E P

LA

CE

M

EM

OR

Y C

AR

E F

AC

IL

TY

MU

NC

IE

, IN

DIA

NA

17

-1

12

60

02

/2

8/1

8P

CW

NM

IS

SU

ED

F

OR

B

ID

DIN

G

J A

JOH

NSO

N W

ILB

UR

AD

AM

S,

INC

.

STR

UC

TU

RA

L E

NG

INE

ER

ING

330 S

. N

aper

vill

e R

d, S

uit

e 300

Wh

eato

n, Il

lin

ois

60187

Tel

eph

on

e 630 653 9060

W

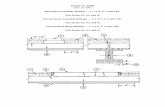

Scale: 3/32" = 1'-0"

1

FOUNDATION PLAN

Scale: 3/32" = 1'-0"

2

ENTRY CANOPY FOUNDATION PLAN

S101

FO

UN

DA

TIO

N P

LA

N

SEE 2/S101 FOR ENTRY CANOPY FOUNDATION

SEE 1/S101 FOR MAIN BUILDING FOUNDATION

DRAWING S101 KEYNOTES:

A-S101: PROVIDE 4" SLAB ON GRADE REINFORCED WITH 6x6-W2.0xW2.0 WELDED

WIRE FABRIC. PLACE SLAB ON VAPOR BARRIER OVER 6" OF COMPACTED

GRANULAR FILL. SLOPE SLAB TO FLOOR DRAINS. SEE ARCHITECTURAL

AND PLUMBING SHEETS FOR DRAIN LOCATIONS AND SLOPE.

B-S101: PROVIDE 12" THICKENED SLAB UNDER AREA OF WOOD SHEAR WALLS AND

LOAD BEARING STUD WALLS - SEE DETAILS 6&11/S200. SEE ARCH. SHTS.

FOR EXACT LOCATIONS OF BEARING WALLS.

C? / P?

F?

(-)X'-X"

DRAWING S101 GENERAL NOTES:

- INDICATES TOP OF FOUNDATION WALL TO BE DEPRESSED,

SEE APPLICABLE SECTION.

- INDICATES COLUMN MARK / PIER MARK; SEE 10/S200 & 3/S101

- INDICATES FOOTING MARK; SEE 4 / S101

- INDICATES TOP OF FOOTING ELEVATION BELOW FINISH GRADE,

SEE CIVIL SHEETS FOR GRADING PLAN.

SW1 - INDICATES WOOD SHEAR WALL MARK, SEE 12/S301 FOR SCHEDULE

HD - INDICATES HOLD DOWN ANCHOR LOCATION. COORDINATE WITH

ARCHITECTURAL SHEETS FOR EXACT LOCATION.

Scale:NONE

3

CONCRETE PIER SCHEDULE

Scale:NONE

4

FOOTING SCHEDULE

H2, P4 H2, P4

GIRDER TRUSS GIRDER TRUSS

H3

P4

P5

H3

P4

P5

PRE-EN

G. R.T.

@ 24" O

.C.

(N

OTE A-S102)

PRE-EN

G. R.T.

@ 24" O

.C.

(N

OTE A-S102)

VAULTED PRE-ENG.

R.T. @ 24" O.C.

(NOTE A-S102)

BRG. EL. 17'-1 3/16"

P5P5

H2, P2

H2, P2

H2, P2

H2, P2

H3, P4

H3, P4

H2, P4

H2, P4

H3, P4

H2, P2

H2, P2

H2, P2

H2, P2

H3, P4

H3, P4

H3, P4

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 12'-1 1/8"

H2, P2

H2, P2

H2, P2

H2, P2

H3, P4

H3, P4

H3, P4

H2, P4

H2, P4

H2, P2

H2, P2

H2, P2

H2, P2

P5

P10

P10

P11

P11

P5

H2, P4

H2, P4

PRE-EN

G. R.T. @

24" O

.C.

(N

OTE A-S102)

H2, P4

H2, P2

H2, P2

H2, P2

H2, P2

P3

H13H13H13H13H13

P8P8P8P8

GIRD

ER TRU

SS

GIRDER TRUSS

GIRDER TRUSS

GIRDER TRUSS

GIRDER TRUSS

H3, P4

H3, P4

H3, P4

H2, P2

H2, P2

H2, P2

H2, P4

H2, P2 H2, P2

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 9'-1 1/8"

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 9'-1 1/8"

H2

GIRD

ER TRU

SS

P10

P2

H2, P1

H4, P2H4, P2

P10

H3, P4 H3, P4

H3, P4

P8

P8

P8

P8

P4

GIRD

ER TRU

SS

P5

H3, P4

H3

H3

H3

H3

GIRD

ER TRU

SS

GIRDER

TRUSS

P4

H2, P4

P5

H6, P5H6, P5

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 9'-1 1/8"

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 12'-1 1/8"

GIRD

ER TRU

SS

GIRD

ER TRU

SS

GIRD

ER TRU

SS

GIRD

ER TRU

SS

H3, P4

H6 H3 (CONT.)

P4

P5 P4

P4

H6, P4

GIRD

ER TRU

SS

GIRD

ER TRU

SS

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 9'-1 1/8"

H12, P12 H9, P5

H2, P4H2, P4

GIRDER TRUSSGIRDER TRUSS

H3

P4

P5

H3

P4

P5

PRE-EN

G. R.T.

@ 24" O

.C.

(N

OTE A-S102)

PRE-EN

G. R.T.

@ 24" O

.C.

(N

OTE A-S102)

VAULTED PRE-ENG.

R.T. @ 24" O.C.

(NOTE A-S102)

BRG. EL. 17'-1 3/16"

P5 P5

H2, P2

H2, P2

H2, P2

H2, P2

H3, P4

H3, P4

H2, P4

H2, P4

H3, P4

H2, P2

H2, P2

H2, P2

H2, P2

H3, P4

H3, P4

H3, P4

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 12'-1 1/8"

H2, P2

H2, P2

H2, P2

H2, P2

H3, P4

H3, P4

H3, P4

H2, P4

H2, P4

H2, P2

H2, P2

H2, P2

H2, P2

P5

P10

P10

P11

P11

P5

H2, P4

H2, P4

PRE-EN

G. R.T. @

24" O

.C.

(N

OTE A-S102)

H2, P4

H2, P2

H2, P2

H2, P2

H2, P2

P4

GIRD

ER TRU

SS

GIRDER TRUSS

GIRDER TRUSS

GIRDER TRUSS

GIRDER TRUSS

H3, P4

H3, P4

H3, P4

H2, P2

H2, P2

H2, P2

H2, P4

H2, P2H2, P2

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 9'-1 1/8"

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 9'-1 1/8"

H2

GIRD

ER TRU

SS

P10

P2

H2, P1

H4, P2 H4, P2

P10

H3, P4H3, P4

H3, P4

P8

P8

P8

P8

P4

GIRD

ER TRU

SS

P5

H3

H3

H3

H3

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 9'-1 1/8"

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 12'-1 1/8"

GIRD

ER TRU

SS

GIRD

ER TRU

SS

GIRD

ER TRU

SS

GIRD

ER TRU

SS

H3, P4

P4

P4

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 12'-1 1/8"

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 12'-1 1/8"

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 9'-1 1/8"

GIRD

ER TRU

SS

GIRDER

TRUSS

P4

H2, P4

P5

H6, P5 H6, P5

H6H3 (CONT.)

P5P4

P4

H6, P4

GIRD

ER TRU

SS

GIRD

ER TRU

SS

H9, P5

H2, P4

H2, P4

H3 H3 H3

P5 P5

P4P4

(B/HDR. 15'-0 1/2")

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 13'-0"

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 13'-0"

H7 (CO

NT.)

H9, P5

P5

P4

H3, P4

H3, P4

H3, P4

H7, P5H7, P5

H4, P2H4, P2H4, P2 H4, P2

H2, P4

H2, P4

H2, P4

H3, P6

H10

(FLUSH)

H10, P5

(FLUSH)

T/ WALL

EL. 12'-1 1/8"

T/ WALL

EL. 12'-1 1/8"

PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

BRG

. EL. 12'-1 1/8"

PRE-ENG. ROOF

TRUSSES @ 16" O.C.

(NOTE A-S102)

BRG. EL. 12'-1 1/8"

3 PT. BRG

. PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

3 PT. BRG

. PRE-EN

G. RO

OF

TRU

SSES @

24" O

.C.

(N

OTE A-S102)

P4

H13

H13

P4

H13

H13

H13

H13

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 12'-10 3/8"

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

P8, TYP.

GIRDER TRUSS

GIRDER TRUSS

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 27'-10 1/4"

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 27'-10 1/4"

PRE-ENG. ROOF

TRUSSES @ 24" O.C.

(NOTE A-S102)

BRG. EL. 27'-10 1/4"

H1, P5 (HI)

H1, P5 (LO)

H1, P5 H1, P5 H1, P5 H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

H1, P5

PRE-ENG. R.T.

@ 24" O.C.

(NOTE A-S102)

PRE-ENG. R.T.

@ 24" O.C.

(NOTE A-S102)

T/ WALL

EL. 9'-1 1/8"

T/ WALL

EL. 9'-1 1/8"

NOTE E-S102, TYP.

2x6 @ 16" O.C.

STUD BRG. WALL

NOTE E-S102,

TYP., U.N.

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NOTE F-S102

NOTE F-S102

NO

TE

F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NO

TE F-S102

NOTE F-S102

NOTE F-S102

NO

TE

F-S102

NOTE F-S102

NOTE F-S102

NOTE F-S102

NOTE F-S102

S300

1

S301

1

S301

8

S301

8

S302

7

S302

7

S300

3

3

S300

H3, P4

S301

1

S301

1

S301

1

S301

5

S301

5

S301

4

S301

4

S301

4

S301

4

S301

13

TYP.

S301

4

S301

4

S301

9

S301

9

S300

7

S300

8

S301

1

S301

1

S301

1

S301

1

S301

1

S300

2

S301

6

S301

13

S301

11

S301

13

S301

6

P5P5

S301

3

S301

1

S301

1

S301

1

S301

1

S301

1

S301

1

S301

1

S301

1

S301

3

S301

2

S301

2

S301

2

S301

2

S301

1

H3, P6H1, P5 H1, P5

(HI&LO)(HI&LO) (HI&LO)

H3, P6H1, P5 H1, P5

(HI&LO)(HI&LO) (HI&LO)

S301

10

SHEAR WALLS

TYP. @

STRUCTURAL SCHEDULE

HEADER

H10

H12

H11

H9

H8

H1

H4

H7

H6

H5

H3

H2

MK

(3)-2x10

(3)-2x8

5-1/4"x14" TREATED PSL

(2)-1 3/4"x11 1/4" LVL

(3)-1 3/4"x11 1/4" LVL

(2)-2x10

HEADER / BEAM SIZE

(3)-1 3/4"x9 1/4" LVL

(2)-1 3/4"x9 1/4" LVL

(3)-2x12

(2)-2x12

(2)-1 3/4"x20" LVL

(3)-1 3/4"x20" LVL

(2)-1 3/4"x16" LVL

H13

P5

P10

P11

P12

P13

P6

P8

P7

P9

P1

P3

P2

P4

MK

POST

(4)-2x4

5 1/4"x7 1/4"PSL

5 1/4"x5 1/4"PSL

3 1/2"x3 1/2"PSL

3 1/2"x5 1/4"PSL

3 1/2"x7"PSL

(1)-6x6 TREATED W/ SIMPSON ABW66Z POST BASE

(2)-2x6

(4)-2x6

(3)-2x6

(1)-4x4

(3)-2x4

(2)-2x4

POST/COLUMN SIZE

NOTE: CONTRACTOR TO PROVIDE 1/2" PLYWOOD SHIMS

AS NEEDED TO MATCH WALL THICKNESS.

SW

1

SW

1SW

1

SW1

SW1 SW1

SW

1

SW

1SW

1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW

1

SW

1

SW1SW1

SW1

SW1

SW1

SW1

SW1

SW

1

SW

1

SW

1

SW1SW1 SW1 SW1

SW1

H11

GIRD

ER TRU

SS

SW

1

SW1

SW1

SW1

SW1

SW1

S301

10

SHEAR WALLS

TYP. @

OVERFRAMING

NOTE D-S102

OVERFRAMING

NOTE D-S102

OVERFRAMING

NOTE D-S102

OVERFRAMING

NOTE D-S102

OVERFRAMING

NOTE D-S102

P1

P1

P1

PRE-ENG. R.T.

@ 24" O.C.

(NOTE A-S102)

GIRDER TRUSS

P2

P5P10

P1

P1

PRE-ENG. R.T.

P1

@ 24" O.C.

(NOTE A-S102)

PRE-EN

G. R.T.

@ 24" O

.C.

(N

OTE A-S102)

SIM

1 3/4"x14" LVL

RAFTERS @

16" O

.C.

4'-0"

Tyson and B

illy A

rchitects, P

.C

.

40

00

M

orsa

y D

rive

Ro

ckfo

rd

, IL

6

11

07

(8

15

) 2

29

-8

22

2

FA

X: (8

15

) 2

29

-8

21

8

Sheet No:

ww

w.tyso

na

ndb

illy.co

m

Drn.

Appd.

Project N

um

ber

Date

REVISION DATE

BO

ND

IN

G C

O.

CO

NT

RA

CT

OR

OW

NE

RA

RC

HIT

EC

T

2/2

8/2

01

8 9

:5

2:4

3 A

M

MC

CI O

F IN

DIA

NA

, LLC

LIN

CO

LN

SH

IR

E P

LA

CE

M

EM

OR

Y C

AR

E F

AC

IL

TY

MU

NC

IE

, IN

DIA

NA

17

-1

12

60

02

/2

8/1

8P

CW

NM

IS

SU

ED

F

OR

B

ID

DIN

G

J A

JOH

NSO

N W

ILB

UR

AD

AM

S,

INC

.

STR

UC

TU

RA

L E

NG

INE

ER

ING

330 S

. N

aper

vill

e R

d, S

uit

e 300

Wh

eato

n, Il

lin

ois

60187

Tel

eph

on

e 630 653 9060

W

Scale: 3/32" = 1'-0"

1

ROOF FRAMING PLAN

Scale: 3/32" = 1'-0"

2

ENTRY CANOPY ROOF FRAMING PLAN

S102

RO

OF

F

RA

MIN

G P

LA

N

SEE 2/S102 FOR ENTRY CANOPY FRAMING PLAN

Scale: 3/32" = 1'-0"

3

HIGH ROOF FRAMING PLAN

DRAWING S102 GENERAL NOTES:

SW? - INDICATES WOOD SHEAR WALL MARK, SEE 12/ S301 FOR SCHEDULE

TRUSS BEARING EL. 9'-1 1/8", TYP. UNLESS NOTED

H?, P? - INDICATES WOOD HEADER MARK, POST MARK (EACH SIDE); SEE SCHEDULE ON THIS SHEET

DRAWING S102 KEYNOTES:

A-S102: PROVIDE PRE-ENGINEERED WOOD ROOF TRUSSES AT SPACING SHOWN.

TRUSS MANUFACTURER SHALL PROVIDE NECESSARY CLEARANCE IN

TRUSSES FOR MECHANICAL & ELECTRICAL EQUIPMENT AND SUPPORT OF

EQUIPMENT LOADS. TRUSS MANUFACTURER SHALL DESIGN TRUSS FOR

LOADS INDICATED IN GENERAL NOTES.

B-S102: TRUSS MANUFACTURER SHALL PROVIDE ALL NECESSARY GIRDER & HIP

TRUSSES AND CONNECTIONS FOR TRUSSES TO GIRDER TRUSSES.

C-S102: PROVIDE 5/8" EXTERIOR APA SPAN RATED PLYWOOD ROOF SHEATHING.

NAIL WITH 8d NAILS @ 6" O.C. AT EDGES AND 12" O.C. AT INTERMEDIATE

SUPPORTS.

D-S102: PROVIDE OVERFRAMING STUD WALLS SPACED @ 24" O.C., MAX.. 2x4

STUDS @ 24" O.C. WITH 2x4 PLATES, TOP & BOTTOM. PROVIDE 1/2"

PLYWOOD SHEATHING (ONE SIDE) WHEN WALL EXCEEDS 10 FOOT

VERTICAL HEIGHT. SHEATH OVERFRAMING PER NOTE C-S102.

E-S102: PROVIDE 2x6 @ 16" O.C. SPF #2 WOOD STUD BEARING WALL WITH CONT.

TREATED 2x6 SILL PLATE W/ 1/2"Ø ANCHOR RODS @ 48" O.C.. PROVIDE

CONT. (2) 2x6 TOP PLATE.

F-S102: PROVIDE 2x4 @ 16" O.C. SPF #2 WOOD STUD BEARING WALL WITH CONT.

TREATED 2x4 SILL PLATE W/ 1/2"Ø ANCHOR RODS @ 48" O.C.. PROVIDE

CONT. (2) 2x4 TOP PLATE.

Scale: NONE

1

TYP. WALL CORNER

NORMAL WALL REINF.

SEE WALL SECTIONS

#3 SUPPORT BARS AS

REQUIRED, TYP.

PROVIDE A CORNER BAR

OR DOWEL FOR EACH WALL

BAR, SIZE TO MATCH

WALL REINF.

STANDARD ACI HOOK

3'-0"

MIN. LAP

#4, #5 BAR @ 20" O.C.

3'-0"

2'-0" LAP

2'-0" LAP

NORMAL WALL REINF.

SEE WALL SECTIONS

CONT. 2x4 KEYWAY CENTERED

IN WALL

STD. ACI HOOK

PROVIDE CONTINUOUS

WATERSTOP AT WALLS

ENCLOSING BELOW GRADE

SPACES, TYP.

PROVIDE CONCRETE WALL JOINTS @ 40'-0" O.C., MAX.

Scale: NONE

2

TYP. WALL JOINTS

CONT. 2x2 KEYWAY CENTERED

IN SLAB

CONSTRUCTION JOINT (CJ)

STOP WWF AT JOINT

VAPRO BARRIER (VB)

COMPACTED GRANULAR FILL (CGF)

SAWCUT JOINT (SJ) OR

TOOLED JOINT (TJ)

SEE PLAN FOR JOINT TYPES & LOCATIONS

400 SQ. FT. SLAB AREA WITHIN JOINTS MAX., U.N.

T

1/4 T

Scale: NONE

3

TYP. SLAB JOINTS

SEE PLAN

4'-0" M

IN

.

8"

8"

1'-0"

6"

TYP.

8"

4"

CONT. 4-#5

#5@12" O.C. DWLS. (24x24)

#5@12" O.C. x 3'-0" CENTERED

ON JOINT

WWF

VB

CGF

CONT. 2x4 KEYWAY

FOUNDATION WALL, SEE

APPLICABLE SECTIONS

CONT. 4-#5

#5@12" O.C. DWLS. (24x24)

WWF

CONT. 2x2 KEYWAY

Scale: NONE

4

TYP. STOOP SECTION

2x WOOD SHEAR WALL, SEE

SCHEDULE FOR STUD SIZE

& SPACING

WWF

CONT. (2) #5 BARS

VB

CGF

SEE PLAN

1'-0"

4"

1'-4"

SEE PLAN

FOUNDATION WALL

WALL BARS, SEE WALL

SECTIONS

FOOTING

DIAGONAL BARS TO MATCH

WALL BARS

TF

TF

3 x TF

Id

I

d

1

Scale: NONE

5

STEPPED FOOTING

SHEATHING, SEE SCHEDULE

CONT. 2x SILL PLATE, SEE SCHED.

FOR SIZE AND ANCHORS

Scale: NONE

6

SECTION @ SHEAR WALL

Scale:1/2" = 1'-0"

7

SECTION

Scale:1/2" = 1'-0"

8

SECTION

S200

7

SEE

Scale:1/2" = 1'-0"

9

SECTION

Scale:1/2" = 1'-0"

10

SECTION

-

3'-6" M

IN

.

1'-0"

1'-0"6" 1'-0" 6"

TREATED 6x6 SYP #1 DENSE

W/ MITERED CORNERS AT STEEL

CONN. BASE FOR TIGHT FIT

HSS6x6x1/4

5/8"Ø GALV. S307 THRU-BOLTS

ANCHOR RODS, SEE SCHED.

GALV. BASE PLATE, SEE SCHED.

GALV. SETTING PL. 1/4"

3/4"± NON-SHRINK GROUT

CONC. PIER, SEE PLAN & SCHED.

FOOTING, SEE PLAN & SCHED.

4"

2"

PLYWOOD SHEATHING

2x6 D.F. #2 @ 16" O.C.

CONT. TREATED 2x PLATE W/

1/2"Ø HKD. A.B.S. @ 32" O.C.

BEVEL SLAB EDGE @ 45°

WWF

VB

INSULATION, SEE ARCH. SHTS.

SEE PLAN

CGF

2'-0"

6"

#4 HOOKED BARS @ 18" O.C.

2'-0"

3'-6" M

IN

.

1'-0"

CGF

2'-0"

6"

#4 HOOKED BARS @ 18" O.C.

1'-0"

3'-6" M

IN

.

CONT. #4

#4@12" O.C. DWLS. (24x24)

SLOPE

WWF

CGF

8"

CONT. (2) #5 TOP

-

3'-6" M

IN

.

1'-0"

9" 9"

WOOD POST, SEE PLAN & SCHED.

SIMPSON POST BASE, SEE SCHED.

CONC. PIER, SEE PLAN & SCHED.

FOOTING, SEE PLAN & SCHED.

CONT. 2x2 KEYWAY

& BOT.

CONT. (2) #5 TOP

& BOT.

CONT. (2) #5 TOP

& BOT.

CONT. (2) #5 TOP

& BOT.

CONT. (2) #5 TOP

& BOT.

2x WOOD BEARING WALL, SEE

PLAN

WWF

CONT. (3) #5 BARS

VB

CGF

SEE PLAN

1'-0"

4"

SHEATHING, SEE PLANS

CONT. 2x SILL PLATE, SEE SCHED.

FOR SIZE AND ANCHORS

Scale: NONE

11

SECTION @ BEARING WALLS

3'-0"

Scale:1/2" = 1'-0"

12

SECTION

#5 VERTICAL BARS @ 24" O.C.

CONCRETE SIDEWALK, SEE ARCH.

SEE PLAN

CGF

1'-10"

HOOKED BARS, MATCH WALL REINF.

3'-6" M

IN

.

CONCRETE TRASH PAD, SEE ARCH.

CONT. (2) #5 TOP

& BOT.

CMU BOND BEAM W/ (2) #5 BARS

IN FULLY GROUTED CELLS

CONCRETE SIDEWALK, SEE ARCH.

CONCRETE SLAB, SEE ARCH.

6"

6"

CONTRACTOR TO COORDINATE

NOTCHES FOR DOWNSPOUTS

Tyson and B

illy A

rchitects, P

.C

.

40

00

M

orsa

y D

rive

Ro

ckfo

rd

, IL

6

11

07

(8

15

) 2

29

-8

22

2

FA

X: (8

15

) 2

29

-8

21

8

Sheet No:

ww

w.tyso

na

ndb

illy.co

m

Drn.

Appd.

Project N

um

ber

Date

REVISION DATE

BO

ND

IN

G C

O.

CO

NT

RA

CT

OR

OW

NE

RA

RC

HIT

EC

T

2/2

8/2

01

8 9

:5

2:4

3 A

M

MC

CI O

F IN

DIA

NA

, LLC

LIN

CO

LN

SH

IR

E P

LA

CE

M

EM

OR

Y C

AR

E F

AC

IL

TY

MU

NC

IE

, IN

DIA

NA

17

-1

12

60

02

/2

8/1

8P

CW

NM

IS

SU

ED

F

OR

B

ID

DIN

G

J A

JOH

NSO

N W

ILB

UR

AD

AM

S,

INC

.

STR

UC

TU

RA

L E

NG

INE

ER

ING

330 S

. N

aper

vill

e R

d, S

uit

e 300

Wh

eato

n, Il

lin

ois

60187

Tel

eph

on

e 630 653 9060

W

S200

FO

UN

DA

TIO

N D

ET

AIL

S &

S

EC

TIO

NS

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

2x6 @ 16" O.C.

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

HEADER, SEE PLAN

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

2x6 @ 16" O.C.

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

2x6 @ 16" O.C.

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

12'-1 1/8"

27'-10 1/4"

9'-1 1/8"

9'-1 1/8"

12'-1 1/8"

13'-0"

S300

4

S301

9

S300

5

SIM

S300

4

S300

4

GIRDER TRUSS GIRDER TRUSS

PRE-ENG. ROOF TRUSS

2x8 BLOCKING BETWEEN TRUSSES

2x6 @ 16" O.C. BRG. WALL

(FULL HT. STUDS)

PRE-ENG. ROOF TRUSS

CONT. 1 3/4x7 1/4 LVL LEDGER W/

(3)-SIMPSON SDS25412 WOOD SCREWS

@ EACH STUD

CONN. BY TRUSS MFR.

SOLID 2x BLOCKING BTN. STUDS

AT LEDGER LOCATION

ROOF SHEATHING, SEE PLAN

PRE-ENG GIRDER TRUSS

PRE-ENG ROOF TRUSS

CONN. BY TRUSS MFR.

2x6 @ 16" O.C. STUD BRG. WALL

HEADER, SEE PLAN

CONN. BY TRUSS MFR. TYP.

6x6 POSTS W/ SIMPSON LPCZ

POST CAP AT MID POSTS AND

SIMPSON LCE4 AT END POSTS

S300

6

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

SOLID 2x BLOCKING BTN. TRUSSES

1/2" EXT. PLYWOOD SHEATHING

PLATE

LINE

PLATE

LINE

TRUSS BRG.

EL. 12'-1 1/8"

TRUSS BRG.

EL. 13'-0"

PLYWOOD ROOF SHEATHING

SOLID 2x BLOCKING BTN. TRUSSES

PRE-ENG. ROOF TRUSS

2x6 BLOCKING BTN. TRUSSES

2x6 KNEE WALL

CONN. BY TRUSS MFR.

CONN. BY TRUSS MFR.

CONT. (2) 2x PLATE

2x6 @ 16" O.C. STUD BRG. WALL

TRUSS BRG.

EL. 12'-1 1/8"

TRUSS BRG.

EL. 13'-0"

PRE-ENG. ROOF TRUSS

PLYWOOD ROOF SHEATHING

PRE-ENG. ROOF TRUSS

SOLID 2x6 BTN. TRUSSES

2x6 KNEE WALL

(2) 2x6 PLATE

2x6 STUD WALL

TRUSS BRG.

PLATE

LINE

CONT. 2x FASCIA

PLYWOOD ROOF SHEATHING

2x OUTRIGGERS BY TRUSS MFR.

PRE-ENG. ROOF

TRUSS

CONN. BY TRUSS MFR.

CONN. BY TRUSS MFR.

END WALL TRUSS

BEAM, SEE PLAN

TRUSS BRG.

PLATE

LINE

CONT. 2x FASCIA

PLYWOOD ROOF SHEATHING

2x OUTRIGGERS BY TRUSS MFR.

PRE-ENG. ROOF

TRUSS

CONN. BY TRUSS MFR.

CONN. BY TRUSS MFR.

END WALL TRUSS

HEADER, SEE PLAN & SCHED.

SIMPSON JOIST HANGER

HEADER, SEE PLAN & SCHED.

ROOF SHEATHING

2x6 @ 16" O.C.

SOLID BLOCKING

CONT. 2x6 W/ 3-SDS25

@ 16" O.C.

SIMPSON JOIST

HANGER, E.E.

PRE-ENG. ROOF TRUSS

(2) 2x PLATE

2x POST, SEE PLAN

& SCHED.

Tyson and B

illy A

rchitects, P

.C

.

40

00

M

orsa

y D

rive

Ro

ckfo

rd

, IL

6

11

07

(8

15

) 2

29

-8

22

2

FA

X: (8

15

) 2

29

-8

21

8

Sheet No:

ww

w.tyso

na

ndb

illy.co

m

Drn.

Appd.

Project N

um

ber

Date

REVISION DATE

BO

ND

IN

G C

O.

CO

NT

RA

CT

OR

OW

NE

RA

RC

HIT

EC

T

2/2

8/2

01

8 9

:5

2:4

3 A

M

MC

CI O

F IN

DIA

NA

, LLC

LIN

CO

LN

SH

IR

E P

LA

CE

M

EM

OR

Y C

AR

E F

AC

IL

TY

MU

NC

IE

, IN

DIA

NA

17

-1

12

60

02

/2

8/1

8P

CW

NM

IS

SU

ED

F

OR

B

ID

DIN

G

J A

JOH

NSO

N W

ILB

UR

AD

AM

S,

INC

.

STR

UC

TU

RA

L E

NG

INE

ER

ING

330 S

. N

aper

vill

e R

d, S

uit

e 300

Wh

eato

n, Il

lin

ois

60187

Tel

eph

on

e 630 653 9060

W

S300

FR

AM

IN

G D

ET

AIL

S &

S

EC

TIO

NS

Scale: 1/4" = 1'-0"

1

SECTION

Scale: 1/4" = 1'-0"

2

SECTION

Scale: 3/4" = 1'-0"

4

SECTION

Scale: 3/4" = 1'-0"

5

SECTION

Scale: 3/4" = 1'-0"

6

SECTION

Scale: 3/4" = 1'-0"

7

SECTION

Scale: 3/4" = 1'-0"

8

SECTION

Scale: 3/4" = 1'-0"

3

SECTION

SHEAR WALL END POST,

SEE SCHEDULE

SCHEDULE FOR SIZE

HOLDDOWN ANCHOR BOLT, SEE

SCHEDULE

SIMPSON HOLDDOWN ANCHOR, SEE

SCHEDULE

STUD SPACING, SEE SHEAR WALL

PLYWOOD SHEATHING

ANCHOR BOLT AT HOLDDOWN

10d NAILS:

SHEAR

WALL

SW1

WALL STUD SIZE & SPACING

2x4 or 2x6 @ 16"

1/2" OSB

SHEATHING

AT 6" O.C. @ PANEL PERIMETER SUPPORTS

NAIL SIZE AND SPACING

ANCHOR

SILL PLATE ANCHOR

SIZE & SPACING

SIMPSON HOLD DOWN

POSTS

ENDWALL

(2) 2x

AT 12" O.C. @ INTERIOR SUPPORTS

NOTE 1: PROVIDE BLOCKING AT ALL OSB PLYWOOD SHEAR WALL PANEL EDGES.

NOTE 2: WHEN PANELS ARE NAILED AT 2" OC, FRAMING MEMBERS AT ADJOINING PANEL EDGES SHALL BE 3" NOMINAL OR (2) 2X AND NAILS SHALL BE STAGGERED.

NOTE 3: 1/2" Ø SILL PLATE ANCHORS SHALL BE EMBEDDED A MINIMUM OF 7 INCHES.

NOTE 4: 1/2" DIAM. x 8" LONG SIMPSON TITEN HD ANCHORS CAN BE USED AS AN ALTERNATE TO CAST IN PLACE SILL PLATE ANCHORS.

NOTE 5: AS AN ALTERNATE, HOLD DOWN ANCHORS MAY BE DRILLED AND EPOXIED USING HILTI HIT RE500 W/HAS-E RODS. ANCHORS SHALL HAVE THE FOLLOWING EMBEDMENT:

5/8" DIAM. = 7 1/2" EMB.

7/8" DIAM. =10 1/2" EMB

1" DIAM.=12" EMB

1/2" Ø BOLTS @ 48" O.C.HDU4

5/8" Ø

ROOF SHEATHING, SEE PLAN

CONN. BY TRUSS MFR.

CONT. (2)2x PLATE

2x6 @ 16" O.C. STUD BRG. WALL

PRE-ENG ROOF TRUSS

1

SECTION

2

SECTION

CONN. BY TRUSS MFR. TYP.

2x BRG. WALL

CONT. (2)2x PLATE

CONT. (2)2x PLATE, TYP.

TRUSS BRG., SEE PLAN

TRUSS BRG., SEE PLAN

PRE-ENG ROOF TRUSS W/

SEAT FOR HIGH TRUSS

PRE-ENG ROOF TRUSS

ROOF SHEATHING, SEE PLAN

3

SECTION

CONN. BY TRUSS MFR.

2x6 @ 16" O.C. BRG. WALL

TRUSS BRG., SEE PLAN

TRUSS BRG., SEE PLAN

PRE-ENG ROOF TRUSS

ROOF SHEATHING, SEE PLAN

CONT. (2)2x PLATE, TYP.

(FULL HEIGHT STUDS)

5

SECTION

2x BRG. WALL

CONT. (2)2x PLATE

TRUSS BRG., SEE PLAN

PRE-ENG ROOF TRUSS W/

SEAT FOR HIGH TRUSS

ROOF SHEATHING, SEE PLAN

TRUSS BRG., SEE PLAN

PRE-ENG ROOF TRUSS

4

SECTION

ROOF SHEATHING, SEE PLAN

PRE-ENG GIRDER TRUSS

PRE-ENG ROOF TRUSS

CONN. BY TRUSS MFR.

CONN. BY TRUSS MFR. TYP.

CONT. (2)2x PLATE, TYP.

6

SECTION

ROOF SHEATHING, SEE PLAN

PRE-ENG GIRDER TRUSS

PRE-ENG ROOF TRUSS

CONN. BY TRUSS MFR.

OVERFRAMING BY TRUSS MFR.

7

SECTION

TRUSS BRG., SEE PLAN

ROOF SHEATHING, SEE PLAN

PRE-ENG ROOF TRUSS

OVERFRAMING BY TRUSS MFR.

TRUSS BRG., SEE PLAN

CONN. BY TRUSS MFR.

CONT. (2)2x PLATE

2x6 @ 16" O.C. STUD BRG. WALL

2x8 BLOCKING BTWN.

TRUSSES

TRUSS BRG., SEE PLAN

12

SHEAR WALL SCHEDULE

Scale:1/2" = 1'-0" Scale:1/2" = 1'-0" Scale:1/2" = 1'-0"

Scale:1/2" = 1'-0" Scale:1/2" = 1'-0"

Scale:1/2" = 1'-0" Scale:1/2" = 1'-0"

Scale:NONE

8

SECTION

2x6 EXT. WALL, FULL HEIGHT

2x OUTRIGGERS BY TRUSS MFR.

EL. VARIES, SEE ARCH

PRE-ENG ROOF TRUSS

CONT. (2)2x PLATE, TYP.

Scale:1/2" = 1'-0"

ROOF SHEATHING, SEE PLAN

STUDS

WINDOW HEADER, SEE PLAN

2x WOOD POSTS, SEE PLAN

ROOF SHEATHING, SEE PLAN

PRE-ENG ROOF TRUSS

OVERFRAMING BY TRUSS MFR.

9

SECTION

TRUSS BRG., SEE PLAN

Scale:1/2" = 1'-0"

CONN. BY TRUSS MFR.

BEAM, SEE PLAN

10

SECTION

Scale:1/2" = 1'-0"

2x SHEAR. WALL

CONT. (2)2x PLATE

TRUSS BRG., SEE PLAN

WALL, BY MFR., 150 PLF MIN.

CONN. FROM TRUSS TO SHEAR

PRE-ENG ROOF TRUSS

ROOF SHEATHING, SEE PLAN

11

SECTION

Scale:

TO TOP CORD OF TRUSS

EXTEND SHEAR WALL SHEATHING

4'-0"

2x4 KEEN WALL

AT EACH STUD

CONT. 2x6 W/ (2) 10d NAILS

TO TRUSS BY MFR.

CONT. 2x8 LEDGER, CONN.

BY TRUSS MFR.

CONT. 2x8 LEDGER, CONN.

2x10 @ 16" O.C.

TO TRUSS BY MFR.

CONT. 2x8 LEDGER, CONN.

3/4" FLOOR SHEATHING

HEADER, SEE PLAN

TRUSS BRG., SEE PLAN

SEE PLAN ARCH.

SILL PLATE ANCHORS, SEE SCHEDULE

FOR SIZE AND SPACING

SCHEDULE FOR SIZE

ANCHOR BOLT FOR SIMPSON

HOLD DOWN ANCHOR, SEE

B

TOP OF FDN. WALL

BLOCKING AT ALL PANEL PERIMETER

2x STUDS @ 16" O.C., U.N.O.

END POST W/E.N. AND

HOLD DOWNS, U.N.

2x TRIMMER OR HEADER POST

HOLD DOWN W/ ANCHORS AT EACH

SUPPORTS WITH EDGE NAILING

END OF WALL, SEE SCHED.

PANEL PERIMETER SUPPORT NAILING

PANEL INTERIOR SUPPORT NAILING

WINDOW OPENING

AT ALL PANEL EDGES

FASTEN LAST TRUSS TO STUD WALL

W/ (2) 10d NAILS AT EACH STUD,

TOP AND BOT.

1/2" = 1'-0"

13

SECTION

Scale:1/2" = 1'-0"

ROOF SHEATHING, SEE PLAN

CONN. BY TRUSS MFR.

CONT. (2)2x PLATE

2x6 @ 16" O.C. STUD BRG. WALL

PRE-ENG ROOF TRUSS

2x8 BLOCKING BTWN.

TRUSSES

FASTEN LAST TRUSS TO STUD WALL

W/ (2) 10d NAILS AT EACH STUD,

TOP AND BOT.

PRE-ENG ROOF TRUSS OR JOISTS,

ROOF SHEATHING, SEE PLAN

HEADER, SEE PLAN

SW1

SEE PLAN

WHERE APPLICABLE

6x6 POSTS W/ SIMPSON PCZ

POST CAP AT MID POSTS AND

SIMPSON EPCZ AT END POSTS

SEE PLAN

Tyson and B

illy A

rchitects, P

.C

.

40

00

M

orsa

y D

rive

Ro

ckfo

rd

, IL

6

11

07

(8

15

) 2

29

-8

22

2

FA

X: (8

15

) 2

29

-8

21

8

Sheet No:

ww

w.tyso

na

ndb

illy.co

m

Drn.

Appd.

Project N

um

ber

Date

REVISION DATE

BO

ND

IN

G C

O.

CO

NT

RA

CT

OR

OW

NE

RA

RC

HIT

EC

T

2/2

8/2

01

8 9

:5

2:4

3 A

M

MC

CI O

F IN

DIA

NA

, LLC

LIN

CO

LN

SH

IR

E P

LA

CE

M

EM

OR

Y C

AR

E F

AC

IL

TY

MU

NC

IE

, IN

DIA

NA

17

-1

12

60

02

/2

8/1

8P

CW

NM

IS

SU

ED

F

OR

B

ID

DIN

G

J A

JOH

NSO

N W

ILB

UR

AD

AM

S,

INC

.

STR

UC

TU

RA

L E

NG

INE

ER

ING

330 S

. N

aper

vill

e R

d, S

uit

e 300

Wh

eato

n, Il

lin

ois

60187

Tel

eph

on

e 630 653 9060

W

S301

FR

AM

IN

G D

ET

AIL

S &

S

EC

TIO

NS