A - Title Bar · 5) This truss has been designed for a 10.0 psf bottom chord live load...

Transcript of A - Title Bar · 5) This truss has been designed for a 10.0 psf bottom chord live load...

Job

SAMPLE5

Truss

T01

Truss Type

COMMON

Qty

1

Ply

3 0 0

Job Reference (optional) 6.300 s Nov 10 2005 MiTek Industries, Inc. Tue Jan 03 16:31:47 2006 Page 1

Scale = 1:36.7

1

2

3

4

5

6

7

12 11 10 9 8 13 14 15 16 17 18 19 20 21

4x12 MII20

4x6 MII20

4x12 MII20 6x6 MII20 6x6 MII20

1x4 MII20

3x6 MII20

7x6 MII20 7x6 MII20

3x6 MII20

6x6 MII20

1x4 MII20

EHUH26

EHUH26

EHUH26 EHUH26 EHUH26

EHUH26

EHUH26

EHUH26 EHUH26 EHUH26 EHUH26

JL24

53 6

53 6

96 2

42 1 2

138 1 4

42 1 2

171 11 0

42 1 2

233 0

53 6

46 1 4

46 1 4

81 3

36 5

117 8

36 5

151 1 3

36 5

188 2

36 5

233 0

46 1 4

041

523

041

5.00 12

Plate Offsets (X,Y): [1:039,0 24], [7:0 39,0 24], [8:0 30,0 44], [9:0 30,0 44], [10: 03 0,04 4], [12:03 0,04 4]

LOADING (psf) TCLL TCDL BCLL BCDL

30.0 10.0

0.0 10.0

SPACING Plates Increase Lumber Increase Rep Stress Incr Code

20 0 1.15 1.15 NO

IBC2000/ANSI95

CSI TC BC WB (Matrix)

0.76 0.81 0.68

DEFL Vert(LL) Vert(TL) Horz(TL)

in 0.25 0.40 0.09

(loc) 910 910

7

l/defl >999 >692

n/a

L/d 240 180 n/a

PLATES MII20

Weight: 400 lb

GRIP 249/190

LUMBER TOP CHORD 2 X 4 SYP No.2 BOT CHORD 2 X 6 SYP SS WEBS 2 X 4 SYP No.3

BRACING TOP CHORD Sheathed or 4 45 oc purlins. BOT CHORD Rigid ceiling directly applied or 100 0 oc bracing.

REACTIONS (lb/size) 1=9010/03 9 (input: 03 8), 7=8862/03 8 Max Horz 1=64(load case 5) Max Uplift1= 659(load case 5), 7= 627(load case 6)

FORCES (lb) Maximum Compression/Maximum Tension TOP CHORD 12=1859 4/1359, 23=1846 1/1376, 3 4= 14239/1065, 4 5= 14211/1063, 5 6= 18364/1368, 6 7= 18497/1352 BOT CHORD 113= 1280/17112, 1314= 1280/17112, 1214= 1280/17112, 1112= 1010/14032, 1115= 1010/14032, 1015= 1010/14032, 1016= 730/10779, 1617= 730/10779, 9 17= 730/10779,

918= 943/13994, 1819= 943/13994, 8 19= 943/13994, 820= 1209/17018, 2021= 1209/17018, 721= 1209/17018 WEBS 212= 269/87, 312= 366/4617, 310= 2356/245, 410= 458/5809, 49= 452/5744, 59= 2326/243, 58= 360/4540, 68= 251/86

NOTES 1) 3 ply truss to be connected together with 10d (0.131"x3") nails as follows:

Top chords connected as follows: 2 X 4 1 row at 0 90 oc . Bottom chords connected as follows: 2 X 6 3 row s at 0 40 oc . Webs connected as follows: 2 X 4 1 row at 0 90 oc .

2) All loads are considered equally applied to all plies, except if noted as front (F) or back (B) face in the LOAD CASE(S) section. Ply to ply connections have been provided to distribute only loads noted as (F) or (B), unless otherwise indicated.

3) Unbalanced roof live loads have been considered for this design. 4) Wind: ASCE 798; 90m ph; h=25ft; TCDL=6.0psf; BCDL=6.0psf; Category II; Exp B; enclosed; MWFRS gable end zone; cantilever left and right exposed ; end

vertical left and right exposed; Lumber DOL=1.33 plate grip DOL=1.33 Plate metal DOL=1.33. 5) This truss has been designed for a 10.0 psf bottom chord live load nonconcurrent with any other live loads. 6) WARNING: Required bearing size at joint(s) 1 greater than input bearing size. 7) Two RT7 USP connectors recommended to connect truss to bearing walls due to uplift at jt(s) 1 and 7. 8) Use USP EHUH26 (With 16d nails into Girder & NA9D nails into Truss) or equivalent spaced at 20 0 oc max. starting at 12 4 from the left end to 21 24 to

connect truss(es) T05B (1 ply 2 X 4 SYP) to back face of bottom chord. 9) Use USP JL24 (With 16d nails into Girder & NA9D nails into Truss) or equivalent at 2314 fr om the left end to connect truss(es) T05 (1 ply 2 X 4 SYP) to back

face of bottom chord. 10) Fill all nail holes where hanger is in contact with lumber.

LOAD CASE(S) 1) Regular: Lumber Increase=1.15, Plate Increase=1.15

Uniform Loads (plf) Vert: 1 4= 80, 47=80, 1 7= 20

Concentrated Loads (lb) Vert: 7= 411(B) 11= 1379(B) 12= 1378(B) 13= 1378(B) 14= 1378(B) 15= 1379(B) 16= 1379(B) 17= 1379(B) 18= 1379(B) 19= 1379(B) 20= 1379(B) 21= 1379(B)

2) IBC BC Live: Lumber Increase=1.25, Plate Increase=1.25 Uniform Loads (plf)

Vert: 1 4= 20, 47=20, 1 7= 40 Concentrated Loads (lb)

Vert: 7= 240(B) 11= 759(B) 12= 759(B) 13= 759(B) 14= 759(B) 15= 759(B) 16= 759(B) 17= 759(B) 18= 759(B) 19= 759(B) 20= 759(B) 21= 759(B) 3) MWFRS Wind Left: Lumber Increase=1.33, Plate Increase=1.33 Plt. metal=1.33

Continued on page 2

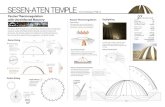

MiTek Drawing Explainedfrom A -to - Z

Heel

Bearing

Hangers

Plates

Top Chord

Bottom Chord

A - Title Bar

B - Cumlative Dimentions

C - Panel Length (feet - inches - Sixteenths)

D - Slope

E - Plate Size and Orientation

F - Overall Height

G - Bearing Location

H - Truss Span (feet - inches - sixteenths)

I - Plate Offsets

J - Design Loading (PSF)

K - Spacing O.C. (feet - inches - sixteenths)

L - Duration of Load for Plate and Lumber Design

M - Code

N - TC, BC, and Web Maximum Combined Stress Index

O - Deflections (inches and Span to Deflection Ratio)

P - Input Span to Deflection Ratio

Q - MiTek Plate Allowables (PSI)

R - Truss Weight

S - Lumber requirements

T - Reaction (pounds)

U - Maximum Bearing Required (inches)

V - Maximum Uplift and/or Horzontal Reaction if Applicable

W - Required Member Bracing

X - Member Axial Forces

Y - Notes

Z - Additional Load Cases