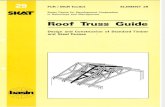

A STATE-OF-THE-ART REVIEW ON COLD- FORMED STEEL ROOF TRUSS …€¦ · The roof truss is usually...

Transcript of A STATE-OF-THE-ART REVIEW ON COLD- FORMED STEEL ROOF TRUSS …€¦ · The roof truss is usually...

http://www.iaeme.com/IJCIET/index.asp 746 [email protected]

International Journal of Civil Engineering and Technology (IJCIET)

Volume 9, Issue 9, September 2018, pp. 746–758, Article ID: IJCIET_09_09_071

Available online at http://www.iaeme.com/ijciet/issues.asp?JType=IJCIET&VType=9&IType=9

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

©IAEME Publication Scopus Indexed

A STATE-OF-THE-ART REVIEW ON COLD-

FORMED STEEL ROOF TRUSS SYSTEM

Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah

Faculty of Civil Engineering, Universiti Teknologi Mara, Cawangan Pahang,

Kampus Jengka, 26400 Bandar Jengka, Pahang

Cher Siang Tan

Faculty of Civil Engineering, Universiti Teknologi Malaysia, 81310 Skudai, Johor

ABSTRACT

The roof truss is an important structure to keep a building safe, protect it from

rain and sunshine, and protect home appliances and equipment inside it. The stability

of the roof truss system, either by using timber or steel, is necessary to study and

investigate. The roof truss material, member section, configuration, connection or

fastener, end support and span must be checked. Nowadays, cold-formed steel (CFS)

with numerous advantages is selected as chord and web truss. However, the failure of

CFS, such as buckling, must be revised to ensure that the CFS roof truss is stable.

From the observations of previous research studies, the failure of the CFS roof truss

has been broadly discussed and to determine the causes of stability. The effect of CFS

truss mainly fails or become unstable due to a slender section of the truss, especially

on the compression member. Intentionally, the slender section of the top chord must

be replaced with a short section or changed to become a curved section. The idea is to

certify the local buckling failure of the top chord and prevent the nearest section from

failing. Finally, the guideline for checking the stability of the CFS roof truss was

established to give an experience for engineers.

Key words: stability, cold-formed steel, roof truss system

Cite this Article: Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah,

Cher Siang Tan, A State-of-the-Art Review on Cold-Formed Steel Roof Truss System.

International Journal of Civil Engineering and Technology, 9(9), 2018, pp. 746-758.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=9&IType=9

1. INTRODUCTION

Roof truss is a structure constructed to protect residential houses, buildings and commercial

buildings from rain, wind and sunshine. Technically, roof truss sustains the roofs, floors and

internal loading. Internal loading covers electrical and mechanical services, water storage and

ceilings. Roof truss provides safety, long span, lightweight, support for considerable loads and

reduce deformation as compared to other structural elements. Generally, roof truss is

triangular in shape and act in tension and compression load along the truss member.

A State-of-the-Art Review on Cold-Formed Steel Roof Truss System

http://www.iaeme.com/IJCIET/index.asp 747 [email protected]

The roof truss is usually made from steel, timber or a combination of both materials. Roof

truss consists of the bottom chord, top chord, web, fastener and support, which is known as a

roof truss system. A roof truss system chord and web are available in various shapes and size,

which can be customised according to structural design and drawing. They are built as two-

dimension (2D) truss or three-dimension (3D) truss. A 2D truss is established in two axes and

used for small buildings with low-load capacity. The 3D truss is recognized as a space truss

and utilised for big buildings with high load capacity, such as a stadium, airport, auditorium

and factory. The steel space truss is connected between linear straight members that are made

of roller hollow shape or CFS section with an end connector to form a 3D structure (Bezerra

et al., 2009). Bondok and Salim (2017) mentioned that a roof truss system made of CFS is

classified as a versatile element. They are more lightweight, have economical values,

versatility and load resistance as shown in Figure 1.

Figure 1 The end connector of node system (Bezerra et al., 2009)

Space trusses are built by using steel tubular bars or rods that are connected with nodes.

Caglayan and Yuksel (2008) stated that the space truss is known as a lightweight rigid

structure that has interlocking struts in a special pattern. The nodes show the significant

function for structural safety, weight and cost of space structure (Alinia and Kashizadeh,

2006). Alinia and Kashizadeh (2006) reported that the space trusses have high value of

indeterminacy degree and multiple redundancies, and thus with the 3D section it provides an

additional limit of safety and prohibit sudden collapse if one or more sections is locally failed

. This happens when the overall loading that is applied to the space truss is still below the

service load. In addition, Alinia and Kashizadeh (2006) reported that the space truss did not

affect the flexibility of the substructure section when subjected to elevated temperature. There

are many researchers who studied the steel space trusses, such as Bezerra et al. (2009), Kaveh

and Talatahari (2009).

Bezerra et al. (2009) reported the relation between roof truss span and height is referred to

the chord and web arrangements, end support conditions, loading and also rigidity of the

linking system. CFS roof truss span for residential houses and small buildings is reported

from 7.0 m to 15.0 m, while more than 15.0 m is classified as wide-span trusses (Mohammad

et al., 2012).

Piroglu and Ozakgul (2016) stated that building with large span structures, such as airport

terminals and shopping mall are dealt with flat or low-sloped roof system by using

lightweight steel. The spatially truss arch is another type of truss that be used for long span

buildings. Normally, the spatially truss arch is constructed from three surfaces of the web and

is connected by a diagonal and dividing section to support the three surfaces. The diagonal

and dividing section acts as a lattice configuration. Guo et al. (2013) studied the out-of-plane

inelastic strength and design of the spatially truss circular arch. Meanwhile Han et al. (2015)

studied the failure mechanism of the steel arch truss due to earthquake.

Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah, Cher Siang Tan

http://www.iaeme.com/IJCIET/index.asp 748 [email protected]

Truss moment frames are another type of truss that combined between the truss and frame.

Pekcan et al. (2009) have established the innovative concept of truss moment frame by using

energy dissipating devices. This concept acts as diagonal internal braces in the truss moment

frame. Bondok and Salim (2017) reported that the American Iron and Steel Institute (AISI)

and Light Gauge Steel Engineers Association have published a complete documentation of

design guide for CFS truss in 1995 but the information of ultimate strength, failure mode

shape and end connection still raises the question.

The main objective of the study is to define the roof truss system parts and other issues

that perform the stability of the roof truss. The second objective is to check and review the

previous study on CFS roof truss and provide a few comments about it. Finally, the new ideas

and recommendations for constructing the stability of the CFS roof truss is established.

2. ROOF TRUSS SYSTEM MATERIAL, MEMBER SECTIONS AND

CONFIGURATION

Nowadays, the roof truss system is shifted from timber to steel and lastly reformed from hot-

rolled steel for CFS. This is because the timber usages have affected environmental issues and

provided air pollution. Next, the sustainable development and green technology principles

could not be achieved in construction activity. CFS is popular as compared to hot-rolled steel

because of its advantages, such as lightweight, easy fabrication, easy erection and corrosion

resistant.

The roof truss member section is divided into two categories. The first category is for light

structural buildings and second category is for heavy structural buildings. The selection of

roof truss member sections is important to avoid failure due to section selection, depending on

the internal load, ease of connection between members, ease of installation on support, and

comply with the architectural demands. Besides, the out-of-plane buckling and uplift loading

resistance must also be considered for light structural buildings, in which the member section

is by using a channel, which is the small size of rectangular or circle hollow section, zed,

angle or a combination. Utilisation of unsymmetrical or singly symmetrical section is allowed

in roof truss because small span of trusses and light load capacity. The unsymmetrical

member section is tended to twist or buckle if the loads are transversely applied on it. As for

the second category, normally the selection of member section for longer span and heavy load

is the symmetrical member section and the bigger size hollow section, either rectangular or

circle. For example, member section which is I-section, built-up, boxed-up and hollow.

Hollow sections are more reliable for longer span because of their structural effectiveness and

thermal resistance. Ezeagu et al. (2012) assured that the selection of the suitable roof truss

depends on the failure strength, especially deflection and load bearing capacity.

The types of roof truss configuration with respect to construction are pitched truss,

bowstring truss, flat truss, Pratt truss, Howe truss, warren truss, k-truss, Fink truss, scissor

truss, as shown in Figure2. In general, the Pratt truss, Howe truss, warren truss and k-truss are

suitable for bridge structure. Roof truss parts are shown in Figure 2.

A State-of-the-Art Review on Cold-Formed Steel Roof Truss System

http://www.iaeme.com/IJCIET/index.asp 749 [email protected]

Figure 2 The example of the roof truss configuration (Truss Craft, 2014)

Figure 3 Roof truss system parts

3. ROOF TRUSS CONNECTION/ FASTENERS

Normally, the roof truss system is designed as fasteners by using bolts or welded connection.

Sometimes for a short span, the recommended connection is a self-drilling screw or self-

tapping screw. Testing of all connections is established by shear and pullout testing to

determine the connection performance. Some examples of bolt connection that were reformed

Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah, Cher Siang Tan

http://www.iaeme.com/IJCIET/index.asp 750 [email protected]

are self-piercing rivets, where Rosette tube joint and press-joining are used. Normally, bolted

connections are utilised for medium and large span trusses.

Recently, new techniques for the connections of CFS were proposed, for example self-

piercing rivets, rosettes and mechanical clinching (Pedreshchi and Sinha, 2008). Another

connection that was lately introduced is the Howick Rivet Connector (HRC) and is purposely

designed for CFS section. This connector is used by comprising a hollow rivet from one

section to another section and through the flange by clamping them together (Mathieson et al.,

2016). Some examples of connection are normally inspired from other mechanical

engineering, such as automotive engineering and industrial manufacture. So with the

development of new techniques and improvisation of the traditional method for the

connections, all these are created to enhance quality, fabrication and installation speed and

provide a safe environment. Additionally, the connector that is selected must be attributable to

fast assemblage, easy to dismantle, expand and transport with reduced costs (Bezerra et al.,

2009).

Lennon et al. (1999) explained several factors that must be considered when selecting the

connection techniques. They are the local environmental effects, connection cost, strength,

available in generic analysis and design method, manoeuvrability of apparatus and reliable

with quality control methods (Lennon et al., 1999). Bolted connections in CFS roof truss

systems with rigid jointed behaviour are not suitable because deformability of the joint

attributed to bearing failure. This is because the CFS with thin section is associated with the

elongation in hole, slippage and bolt tilting (Zaharia and Dubina, 2006). All connections must

be checked and their behaviour determined by shear and pull out testing.

End connection of the roof truss system is also an important issue that must be determined

to avoid failure. Bondok and Salim (2017) reported that premature failure occurred when the

end connection was not properly designed. Sivapathasundaram and Mahendran (2017)

reported that the premature failure of a roof truss connection or batten existed when the high

uplift load by wind is acted upon the roof truss system. There are two end connections that are

always studied, such as fixed and pinned end connections. The fixed end connection, which is

fully restrained, is classified a stronger end connection and is always utilised in the load

bearing wall.

4. ROOF TRUSS SYSTEM FAILURE

Roof truss failures normally occur due to deterioration, overload, improper and poor design,

inadequate material, inappropriate construction, structural integrity losses, workmanship error

and unexpected weather. Structural integrity is dealt with overall structure ability to sustain

and support a designed load, such as self-weight of structure and other load without any

failure and collapse. A structural integrity loss means that the structure has lost its load-

carrying capacity or its component. In addition, the material that was used in the structure had

also influenced the structural integrity loss when the material is stressed further than its

strength limit. Mechanical behaviour or structural performance of the material, such as

strength, hardness, elasticity, durability and weight must be first considered and finally

examined for suitable thickness, size and shape that can support the load for a long period.

Kozlowski et al. (2004) have stated the most common reason for the steel structure

collapse and failure, especially if the roof truss is the instability factor. Improper buckling

length evaluation of the upper chord in the roof truss design will influence instability problem

(Kozlowski et al., 2004). Piroglu et al., 2014 reported that the roof truss failure in industrial

hall building in Marmara Region, Turki was caused by improper fabrication and did not

follow the basic design principles for the support assemblies. Guo et al. (2015) reported that

A State-of-the-Art Review on Cold-Formed Steel Roof Truss System

http://www.iaeme.com/IJCIET/index.asp 751 [email protected]

one of the failures of a steel truss building occurs due to bending failure because the carrying

capacity steel column and trusses are not adequate, as shown in Figure 4.

Figure 4 The roof truss failure due to bending (Guo et al., 2015)

Caglayan and Yuksel (2008) reported that the reason for the Mero space truss roof

structure collapse in eastern Turkey was because the snow load intensity and a number of

mistakes from the elastic design of the truss was underestimated.

5. STABILITY OF STEEL ROOF TRUSS SYSTEM

The slenderness of CFS sections is an important issue that is determined and checked to

ensure the trusses stability is tenable when subjected to compressive loads (Wood and Dawe,

2006). Besides, the roof truss stiffness is larger in a plane than out of plane so that it should be

braced to resist lateral deformation for the overall structure and twisting of the slender section

(Krajewski and Iwicki, 2015). EC3 is required to brace against the lateral stability of the roof

truss compressed member.

Sometimes, the stability of the truss is also related to imperfection factor. The

imperfection factor is classified into three types,which are changes in joint coordinates,

imperfections in member length and member straightness (Peek, 1993). An important thing

which must be considered while designing and fabricating the CFS as roof truss structure, is

local and overall stability CFS section (Semko and Prokhorenko, 2013)

Purlin must be located on the roof truss system at least a bracing in 6 m span that is

regarded to CFS structure technical specifications (GB50018-2002) (Guo et al., 2015). Purlin

reacts as bending members when roof truss is subjected to wind loads, either uplift or downlift

load or sometimes both loads, is applied on it. This issue is one of the factors that influenced

the stability of the roof truss.

6. LATERAL-TORSIONAL BUCKLING

Normally, CFS members are subjected to fail due to local buckling, distortional buckling and

flexural-torsional buckling or sometimes in combination failure. There are several factors that

must be considered, such as the type of the truss chord load, the distance between the lateral

chord bracings, stiffness of the lateral bracings and type of lacings with their rigidity

(Jankowska-Sandberg and Kolodziej, 2013). Jankowska-Sandberg and Kolodziej (2013) have

reported the buckling length of compression chord is smaller than location and distance

between the lateral bracing of about 30% – 80 %. Awaludin et al. (2015) stated that the

Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah, Cher Siang Tan

http://www.iaeme.com/IJCIET/index.asp 752 [email protected]

buckling member failure of the CFS could be solved by using timber laminas as a slot in

material to form a composite member.

7. COLD-FORMED STEEL AS ROOF TRUSS MEMBER

Lack of understanding and structural information of connections for truss made by CFS has

led to the design of inefficient connections which reduces the ability of the truss to compete in

the construction industry (Wood and Dawe, 2006). Mathieson et al. (2016) have explained

that the CFS truss shows a rise in cost with the installation of a connector activity. CFS

structures are broadly used in construction due to their advantages, such as high strength, cost

effective and easy to use with (Tian et al., 2015). With a lot of advantages, as compared to

hot-rolled and timber structure, CFS becomes more popular. Examples of CFS advantages are

thin in thickness, corrosion resistance, anti-termites, anti-fungal, easy installation, easy

fabrication, easy transportation, less on maintenance and lightweight. Dawe et al. (2010)

reported that CFS with high strength to weight ratio is important to transport, handle and

install the CFS on-site and establish as an alternative material in roof truss. Normally, CFS

roof truss with the channel section as truss members are proposed as either inline or offset

truss design (Dawe et. al, 2010). Inline truss design is projected by all truss members, which

include web and chord in a single plane while offset truss design is established in more than a

single plane. Channel section as top chord member in roof truss is created by the bending

effects in continuous member that happened to the in-plane eccentricities of the connection

(Ibrahim et al. 1998). Besides, CFS structure is demonstrated by the reduction of labour cost

and fast erection (Zaharia and Dubina, 2006). Parent et al. (2007) reported on the prediction

of the design method for critical load of compression web truss members with periodically

shifting section properties.

8. COLD-FORMED STEEL FAILURE

The roof truss can fail due to unpredicted extreme weather events, poor construction and

inadequate design subjected to normal load conditions (Piroglu et al., 2014). CFS as a

structural element in roof truss is subjected to fail due to buckling, including global buckling,

local buckling, distortional buckling and web crippling. A slender section of CFS is exposed

to failure due to global buckling while the shorter section is ineffective in crushing. Buckling

phenomena that happened in CFS will lead to unexpected failure and lastly a sudden failure

without any warning. Cheng et al., 2013 did an analytical study of the CFS channel beam

section that is subjected to combine compression and bending at major and minor axes. The

flexural buckling and lateral-torsional buckling failure were investigated when the channel

was subjected to both actions.

Dubina and Zaharia (1997) explained in detail that the bearing deformation is caused by

the connection between bolt and thin plate, such as CFS like local buckling on the section and

the bolt slippage. Besides, Sivapathasundaram and Mahendran (2017) have studied about the

premature localised pull-through failures which existed on the batten to truss connections.

9. LITERATURE REVIEW OF COLD-FORMED STEEL ROOF TRUSS

SYSTEM

Wood and Dawe (2006) tested and analysed the full scale roof truss specimens that were built

by a span of 6,096 mm, roof pitch 4:12 and overhang span of 500 mm. The self-drilling

screws and four types of section, with different cross-section, are used in the testing. They

were constructed inverted in the roof truss specimens and loads were applied at every joint of

the bottom chord. Mohammad et al. (2012) reported on the testing of wide-span CFS roof

truss with 25 m of length and analysed its structural performance. Below is the example of the

A State-of-the-Art Review on Cold-Formed Steel Roof Truss System

http://www.iaeme.com/IJCIET/index.asp 753 [email protected]

study that has been investigated and Table 1 represents the information and review analysis of

the study.

Table 1 The review of the cold-formed roof truss from a previous study

Author Span Section Connector

and Support Pitch Loads & Overhang

Harper et al.

(1995)

6096 mm

(Fink

Truss)

Channel section

Top and bottom chord =

92.71 mm x 41.53 mm x

1.143 mm (306.13 N/mm2)

Truss web = 64.77 mm x

42.16 mm x 1.016 mm

(303.4 N/mm2)

19.05 mm self-

drilling screw 4:12

Load: Uniformed

distributed load by using

common masonry brick

Overhang: 101.6 mm

Failure

A combination failure of local buckling at the top chord above the heel connection and

extreme rotation of the top chord near the heel connection.

Prior to buckled top chord, the self-drilling screw at heel connection is pulled out and rotated.

The top chord is buckled in the area between the ridge connection and the truss web.

Review

The usage of the masonry brick as a load is not suitable because the mass of masonry brick is

not similar to each other. It is difficult to get the same mass of left and right hand sides. The

heel connections on both sides are not placed the wood block to avoid the initial local

buckling and failure of the geometry of the channel. The study has not explained about that

the load from left and right hand sides was uniform and checked the lateral movement of the

overall trusses. In construction reality load support is normally not established and the mass

must be taken.

Dawe et. al,

2010

6156 mm

(off-set

truss)

Channel (Chords & Webs)

10 hexagonal-

washer head

Self-drilling

screws

Steel plates

4:12

6:12

8:12

Load: Concentrated load

(consider as up-lift load)

Overhang: 500 mm

Failure

The failure of all specimens was reported as local buckling at the top chord adjacent to the

heel plate, either left or right side of the trusses that was nearest to point load location.

The bottom chord was initiated by the local buckling and crushing at the same part of top

chord local buckling failure or parallel to it.

Review It was good to have different pitch to check the location of local buckling and relationship

between pitch and deformation. The load applied wasnot the uniformly distributed load.

Mohammad et

al. (2012)

25 m

(length)

4.7 m

(height)

1.2 m

(width)

Channel section,

Chords = 150

(D)x66(B)x1.6(t), 365

N/mm2

Webs =74x34x0.8, 550

N/mm2

Hat section =

35x18x0.48,550

(as purlin)

4.5 mm

diameter tag-

screws

(truss member)

12 mm

diameter grade

8.8 galvanised

holding down

bolts (truss &

rigid steel

beam)

5:1

Load: Uniformed

distributed load (UDL) by

cement bags

Total load = 63.77 kN

Overhang: None

Failure

Embossed at the connection between truss member and bottom chord under compression.

Shear failure and tearing off of the tag screw at splice joint at bottom chord.

The connection on both ends at top chord is twisted and buckled.

Buckling at diagonal truss web.

Review

It was good to check the vertical deformation on bottom chord and top chord and horizontal

deformation. But the usage of the cement bag as a uniformly distributed load is not suitable

because the load was started with higher load and was unsafe for the instructor and lab

technician after failure or collapse. The failure is occurring in splice joint and on the

compression part of the top chord and truss web. The connection of the splice joint is not

sufficient and must be further studied. The horizontal deformation between left and right side

was not similar due to height and not enough lateral bracing and stiffness. The truss web

section was small and not appropriate in size as compared to chord. So the suggestion was to

construct with the same size as the chord to establish stability. The strain of the member that

Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah, Cher Siang Tan

http://www.iaeme.com/IJCIET/index.asp 754 [email protected]

calculated the relationship between member and load is not taken.

Wood and

Dawe (2006) 6096 mm

Channel Section

Top chord

92.1(d)x40.9(b)x13.2(c)x1.

21(t)

Bottom chord & web

member

92.1(d)x40.9(b)x13.2(c)x0.

98(t)

Number 10

self-drilling

screws

4:12 Concentrated

load 500 mm

Failure

Full-scale specimens with reinforcement tied down and stiffened failed due to local buckling

at the top chord adjacent to the heel plate with total load of 16.4 kN. This failure was close to

loading part that was nearest to the end support.

The large deflections are occurring at loading part that started under the same total load with

other loading parts.

Review The section that be used for the chord and web member is not uniform. Concentrated load is

considered in the testing and not uniformly distributed load.

10. DISCUSSION

From the failure observations, either in concentrated load or uniformly distributed load, the

truss has become unstable and failed on the slender section of compression member,

especially at top chord. The failure occurred at the top chord in local buckling and over the

web and bottom chord. The location of failure, whether right or left hand side, is shown in

Figure 5. Some idea are existed to organise the failure is by using the bowstring truss or

avoided by using the slender section on the compression member. Bowstring truss is

recognised with a curved section at the top chord and straight section at bottom chord and

other truss members. Sometimes, the top chord section can be used as a short section to

replace the slender section that is joined by a web truss with a short top chord. Besides, the

failure due to lateral-torsional buckling of unstable trusses can be solved by using the

adequate lateral bracing. But the main important issue to make the truss stable is to first

strengthen the roof truss itself.

The use of the CFS channel as roof truss member has become a popular section that is

utilised to replace the hollow section due to economic purpose. The CFS channel with several

advantages, such as lightweight, flexible, high strength-to-weight ratio and easy to modify has

been seriously studied by a researcher and manufacturer. With changes in the shape from

normal channel section to various modification, such as channel with lipped section and

channel with intermediate stiffeners or both so that the arrangement of the CFS roof truss

member by using channel is significant to ensure the section and overall structure are stable.

Normally, to give symmetrical roof truss system, the channel must be faced in different ways,

such as bottom and top chord in a same face way and the web truss on the other face way.

Figure 5 Example of failure on the top chord

A State-of-the-Art Review on Cold-Formed Steel Roof Truss System

http://www.iaeme.com/IJCIET/index.asp 755 [email protected]

For an established roof truss system stability, it is suitable to form it in the same

arrangement and a diagram like bending moment diagram; thus, the roof truss system

normally react as a simple supported beam with a uniformly distributed load, as shown in

Figure 6. From the observation, the roof truss is constructed by following the diagram of

bending moment that curved at the top chord. This is because the part of truss section from

support is classified as a weaken section is possible to resist compression load. Besides, the

top chord of the roof truss system is generally built in a slender section that usually fails due

to buckling.

Figure 6 The relation between the roof truss configuration and bending moment diagram

Figure 7 The guidelines of the stability of the cold-formed steel

Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah, Cher Siang Tan

http://www.iaeme.com/IJCIET/index.asp 756 [email protected]

Hui et al., 2008 have discussed and observed the intelligent methods for the safe

monitoring of integer behaviour on a large span space truss under wind-excited through data

acquisition. This method was established for an early warning safety technique for a large

span space truss (Hui et al., 2008). These are some examples for new ideas and techniques to

provide truss safety. A lot of improvement ideas are being investigated and discussed to make

the roof truss more stable and safe.

The guideline for checking and initial investigation on the CFS roof truss stability is as

shown in Figure 7. This guideline is important for new engineers and manufacturer to ensure

the CFS roof truss is stable

11. CONCLUSIONS

It is very important to ensure the arrangement of the truss member to avoid failure between

them by constructing or fabricating in a symmetrical and stable section. This issue is solved

by forming the roof truss system in two ways of facing, a top and bottom chord is facing in

one way, and other section includes truss member by facing another way. So they form in a

different way and face to resist roof truss system failure. The selected channel must have the

lipped and intermediate web stiffener, whether one or more, to cater the local buckling failure

of the roof truss system. Additionally, the top chord must be avoided from using a slender

section, but can be replaced by using a curved or short section. This issue is proven by

checking the relationship between the roof truss systems with beam in shear force and

bending moment diagram. The simple guidelines are established to help the engineer to

checkthe cold-formed roof truss system stability.

After discussing stability in detail, the second part that must be studied for further work is

truss optimisation. Truss optimisation is about cost saving, fast erection and truss weight.

Truss optimisation has three categories that are known as size, shape and topology function

(Kaveh and Khayatazad, 2013).

REFERENCES

[1] Wood, J.V. and Dawe, J.L. (2006). Full-scale test behaviour of cold-formed steel roof

trusses. Journal of Structural Engineering 132(4), pp 616 - 623.

[2] Krajewski, M. and Iwicki, P. (2015). Analysis of Brace Stiffness Influence on Stability of

the Truss. International Journal of Applied Mechanics and Engineering 20 (1), pp 97 –

108.

[3] Peek, R. (1993). Worst shapes of imperfections for space trusses with multiple global and

local buckling modes. International journal of solids structures 30, pp. 2243-2260.

[4] Semko, V. and Prokhorenko, D. (2013). Effect of bracing systems on overall stability and

deformability of cold-formed steel roofing structures. International conference of design,

fabrication and economy of metal structures, Miskolc, Hungary, April 24-26, pp 229-234.

[5] Kozlowski, A., Fonseca, J. and Kowalszyk, R. (2004). Stability analysis of a steel roof

truss. 8th International Conference modern building materials, structures and techniques.

May 19-22, 2004, Vilnius, Lithuanian.

[6] Piroglu, F., Ozakgul, K., Iskender, H., Trabzan, L. and Kahya, C. (2014). Site

investigation of damages occurred in a steel space truss roof structure due to ponding.

Engineering Failure Analysis 36, pp 301-313.

[7] Cheng, S-S, Kim, B. and Li, L-Y (2013). Lateral-torsional buckling of cold-formed

channel sections subject to combined compression and bending. Journal of Constructional

Steel Research 80, pp 174-180.

A State-of-the-Art Review on Cold-Formed Steel Roof Truss System

http://www.iaeme.com/IJCIET/index.asp 757 [email protected]

[8] Dubina, D. and Zaharia, R. (1997). Cold-formed Steel Trusses with Semi-rigid joints.

Thin-walled structures 29, pp 273-287.

[9] Mathieson, C., Clifton, G.C. and Lim J.B.P (2016). Novel pin-jointed connection for cold-

formed steel trusses. Journal of Constructional Steel Research 116, pp 173-182.

[10] Tian, H-W., Li, Y-Q. and Yu, C. (2015). Testing of steel sheathed cold-formed steel

trussed shear walls. Thin-Walled Structures 94, pp 280-292.

[11] Harper, M.M., LaBoube, R.A. and Yu, W-w. (1995). Behaviour of cold-formed steel roof

trusses. Centre for Cold-formed Steel Structure Library, Paper 47.

[12] Dawe, J. L., Liu, Y. And Li, J.Y. (2010). Strength and behaviour of cold-formed steel

offset trusses. Journal of Constructional Steel Research 66, pp 556-565.

[13] Ibrahim, T.M., Laboube, R.A. and Yu, W.W. (1998). Behaviour of Cold-formed steel roof

trusses under concentrated loads. Journal of Constructional Steel Research 46, pp 176-177

[14] Pedreschi, R.F. and Sinha, B.P. (2008). An experimental study of cold formed steel trusses

using mechanical clinching. Construction and Building materials 22, pp 921-931.

[15] Zaharia, R. and Dubina, D. (2006). Stiffness of joints in bolted connected cold-formed

steel trusses. Journal of Constructional Steel Research 62, pp 240-249.

[16] Parent, S., Pote, J.J. and Neale, K.W. (2007). Design of cold-formed compression web

members with periodically varying section properties. Canadian Journal of Civil

Engineering 34, pp 253-265.

[17] Mohammad, S., Tahir, M.M., Tan, C.S. and Shek, P.N. (2012). Experimental

Investigation on wide-span cold-formed steel roof truss system. Applied Mechanics and

Materials 166-169, pp 1304-1307.

[18] Guo, H., Chen, L., Yang, D. And Tang, H. (2015). Collapse Reason analysis of a steel

truss building under snow disaster. Applied Mechanics and Materials 744-746, pp 13-16.

[19] Lennon, R., Pedreschi, R. and Sinha, B.P. (1999). Comparative study of some mechanical

connections in cold formed steel. Construction and Building Materials 13, pp 109-116.

[20] Bezerra, L.M., de Freitas, C.A.S., Matias, W.T. and Nagato, Y. (2009). Increasing load

capacity of steel space trusses with end-flattened connections. Journal of Constructional

Steel Research 65, pp 2197-2206.

[21] Caglayan, O. and Yuksel, E. (2008). Experimental and finite element investigations on the

collapse of a Mero space truss roof structure – A case study. Engineering Failure Analysis

15, pp 458 – 470.

[22] Alinia, M.M. and Kashizadeh, S. (2006). Effect of flexibility of substructures upon

thermal behaviour of spherical double layer space truss domes. Part I: Uniform thermal

loading. Journal of Constructional Steel Research 62, pp 359-368.

[23] Kaveh, A and Talatahari, S. (2009). Size optimization of space trusses using Big Bang-

Big Crunch algorithm. Computers and Structures 87, pp 1129-1140.

[24] Guo, Y-L., Zhao, S-Y., Dou, C. And Pi, Y-L. (2013). Out-of-plane strength design of

spatially trussed arches with a rectangular lattice section. Journal of Constructional Steel

Research 88, pp 321-329.

[25] Pekcan, G., Linke, C. and Itani, A. (2009). Damage avoidance design of special truss

moment frames with energy dissipating devices. Journal of Constructional Steel Research

65, pp 1374-1384.

[26] Ezeagu, C.A, Umenwaliri, S.N., Aginam, C.H. and Joseph, C.A. (2012). Comparative

Overview of Timber and Steel Roof Truss Systems. Research Journal in Engineering and

Applied Sciences 1(3), pp 177-183.

Mohd Syahrul Hisyam Mohd Sani, Fadhluhartini Muftah, Cher Siang Tan

http://www.iaeme.com/IJCIET/index.asp 758 [email protected]

[27] Truss Craft (2014). Roof Truss Systems. http://www.trusscraft.com/products1.html.

Retrieved on 20 November 2015.

[28] Han, Q-H., Xu, Y., Lu, Y., Xu, J. and Zhao, Q-H. (2015). Failure mechanism of steel arch

trusses: Shaking table testing and FEM analysis. Engineering Structures 82, pp 186-198.

[29] Jankowska-Sandberg, J. and Kolodziej, J. (2013). Experimental study of steel truss lateral-

torsional buckling. Engineering Structures 46, pp 165-172.

[30] Kaveh, A and Khayatazad, M. (2013). Ray optimization for size and shape optimization of

truss structures. Computer and structures 117, pp 82-94.

[31] Hui, L., Weilian, Q. and Jinwen, W. (2008). Intelligent monitoring technique for working

status of Shenzhen citizen center roof truss structure under wind load. Advanced Materials

Research 33-37, pp 1141-1148.

[32] Bondok, D.H. and Salim, H.A. (2017). Failure Capacities of Cold-formed Steel Roof

Trusses End-connections. Thin-walled Structures 121, pp 57-66.

[33] Sivapathasundaram, M. and Mahendran, M. (2017). Numerical Studies and Design of

Thin Steel Roof Battens Subject to Pull-through Failures. Engineering Structures 146, pp

54-74.

[34] Piroglu, F. and Ozakgul, K. (2016). Partial Collapses Experienced for a Steel Space Truss

Roof Structure Induced by Ice Ponds. Engineering Failure Analysis 60, pp 155-165.

[35] Awaludin, A., Rachmawati, K., Aryati, M. and Danastri, A.D. (2015). Development of

Cold-formed Steel-timber Composite for Roof Structures: Compression Members.

Procedia Engineering 125, pp 850-856.