A Review- Pharmaceutical and Pharmacokinetic Aspect of Nanocrystalline Suspensions

-

Upload

dhaval-shah -

Category

Documents

-

view

198 -

download

5

Transcript of A Review- Pharmaceutical and Pharmacokinetic Aspect of Nanocrystalline Suspensions

REVIEW

A Review: Pharmaceutical and Pharmacokinetic Aspectof Nanocrystalline Suspensions

DHAVAL A. SHAH,1 SHARAD B. MURDANDE,2 RUTESH H. DAVE1

1Arnold & Marie Schwartz College of Pharmacy and Health Sciences, Long Island University, Brooklyn, New York 112012Drug Product Design, Pfizer Worldwide R&D, Groton, Connecticut 06340

Received 7 August 2015; revised 23 September 2015; accepted 25 September 2015

Published online in Wiley Online Library (wileyonlinelibrary.com). DOI 10.1002/jps.24694

ABSTRACT: Nanocrystals have emerged as a potential formulation strategy to eliminate the bioavailability-related problems by enhancingthe initial dissolution rate and moderately super-saturating the thermodynamic solubility. This review contains an in-depth knowledge of,the processing method for formulation, an accurate quantitative assessment of the solubility and dissolution rates and their correlation toobserve pharmacokinetic data. Poor aqueous solubility is considered the major hurdle in the development of pharmaceutical compounds.Because of a lack of understanding with regard to the change in the thermodynamic and kinetic properties (i.e., solubility and dissolutionrate) upon nanosizing, we critically reviewed the literatures for solubility determination to understand the significance and accuracy of theimplemented analytical method. In the latter part, we reviewed reports that have quantitatively studied the effect of the particle size andthe surface area change on the initial dissolution rate enhancement using alternative approaches besides the sink condition dissolution.The lack of an apparent relationship between the dissolution rate enhancement and the observed bioavailability are discussed by reviewingthe reported in vivo data on animal models along with the particle size and food effect. The review will provide comprehensive informationto the pharmaceutical scientist in the area of nanoparticulate drug delivery. C© 2015 Wiley Periodicals, Inc. and the American PharmacistsAssociation J Pharm SciKeywords: nanocrystals; nanosuspensions; nanoparticles; solubility; dissolution; pharmacokinetics; food interactions; bioavailability;particle size reduction

INTRODUCTION

Recent advances in synthetic, analytical, and purificationchemistry, along with the development of specialized toolssuch as high-throughput screening, combinatorial chemistry,and proteomics, have led to a sharp influx of discovery com-pounds entering into development. Many of these compoundsare highly lipophilic, as the in vitro screening techniques placeconsiderable emphasis on the interaction of compounds with de-fined molecular targets. In recent years, it has been estimatedthat up to 70% of the new drugs discovered by the pharmaceu-tical industry are poorly soluble or lipophilic compounds. Pooraqueous solubility is one of the major hurdles in the develop-ment of new compounds into oral dosage forms, as absorptionis limited by dissolution for these compounds.1

The well-known Biopharmaceutics Classification System(BCS) is frequently used to categorize pharmaceutical com-pounds. According to the BCS system, poorly soluble com-pounds belong to Class II (low solubility, high permeability)or Class IV (low solubility, low permeability). In another words,we can also say that Class II and IV compounds provide moreopportunities for the development of newer technologies toovercome the solubility- or dissolution-related issues based onchemical and physical properties of the compounds. This per-ception is widely used and well established within the pharma-ceutical industry. However, using the BCS system for guidancein formulation selection may sometimes oversimplify the com-

Correspondence to: Rutesh H. Dave (Telephone: +718-488-1660; Fax: +718-780-4586; E-mail: [email protected])

Journal of Pharmaceutical SciencesC© 2015 Wiley Periodicals, Inc. and the American Pharmacists Association

plex nature of drug dissolution, solubility, and permeability.Poorly water-soluble compounds can possess such a low aque-ous solubility that the dissolution rate, even from micronizedparticle, is very slow. In this case, it is not possible to reach suf-ficiently high drug concentrations in the gastrointestinal tractfor an effective flux across the epithelial membrane. Other fac-tors, such as efflux transport or pre-systemic metabolism, canalso negatively influence oral bioavailability.

Therefore, it is recommended to classify compounds intoslightly different categories, as they can show dissolutionrate-limited, solubility-limited, or permeability-limited oralbioavailability. Butler and Dressman2 designed the “Developa-bility Classification System (DCS),” as another way to catego-rize compounds in a more bio-relevant manner. This system dis-tinguishes between dissolution rate-limited compounds (DCSClass IIa) and solubility-limited compounds (DCS Class IIb).

In order to select the right formulation approach and to ad-dress the compound-specific issues with a suitable formulationtype, it is imperative to first understand the bioavailability lim-iting factors. Selection of the right formulation approach is oneof the key activities for formulators in the pharmaceutical in-dustry. Key factors include the physicochemical properties ofactive pharmaceutical ingredient (API), such as aqueous solu-bility, the melting point temperature, and chemical stability. Inaddition, the formulator needs information about the potencyof the compound and the desired route of administration to de-termine the type of final dosage form as well as the requireddrug load. All these factors can be considered in decision trees,which are often used in the industry to guide the formulator.

However, there are some biopharmaceutical-relevant as-pects that need more attention in order to avoid false nega-tive results. In addition, it is also important to note that there

Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES 1

2 REVIEW

is no uniform approach that solves all the formulation-relatedproblems. Each technology has its own advantages and disad-vantages. Depending on the formulator’s understanding of theinterplay between the physicochemical properties of the drug,the special aspects of the various formulation options and therequired in vivo performance, the higher the chance that the op-timal formulation approach will be chosen. This minimizes therisk of late failures in the human clinical trials, for example, dueto insufficient or highly variable drug exposures. Compoundsshowing dissolution rate limited bioavailability may be referredto as DCS Class IIa compounds, but they represent only onepart of the BCS Class II compounds. The extent of the oralbioavailability of such compounds directly correlates with theirdissolution rate in vitro. The fraction of the dose that dissolvesin the lumen is readily absorbed through the intestinal mem-brane. Consequently, the bioavailability of such compounds canbe improved by any technique that increases the primarily thedissolution rate. Various formulation approaches are known tolead to increased dissolution rate and bioavailability, includ-ing salt formation, the use of cocrystals, particle size reduction,complexing with cyclodextrins,3 microemulsions,4 and solid dis-persion technologies.5,6 The formulator has to select the optimalformulation approach based on the properties of a specific drugmolecule. However, all these technologies have certain limita-tions and cannot be used as universal formulation techniquesfor all the poorly soluble compounds, especially those whichare insoluble in both aqueous as well as non-aqueous solvents.7

To prevent the removal of poorly soluble compounds from thepharmaceutical pipeline, a broad-based technology is requiredfor drug molecules that are insoluble or poorly soluble in bothaqueous and non-aqueous solvents. This will have the tremen-dous impact in discovery sciences and will improve the perfor-mance of existing molecules suffering from formulation-relatedissues.8

In the last two decades, after the introduction of Nanocrystal R© technology, particle-size reduction approaches havegrown to a commercial level. Several formulation ap-proaches have been reported to formulate the nanoparticles,such as nanocrystalline suspensions, Poly Lactic-co-Glycolicacid(PLGA)based nanoparticles, nanosphears, and solid-lipidnanoparticles. By the virtue of their large surface area (SA)

dcdt = AD(Cs−C)

hln SS0

= 2MYDrRT hH = k

(√L/

√V

)

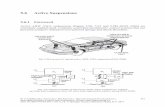

Noyes–Whitney Equation Ostwald–Freundlich Prandtl Equation

dc/dt = Dissolution velocity S = Solubility at Temp T hH = Hydrodynamic boundary layer thicknessA = Surface area S0 = Solubility of infinite big particle k = ConstantD = Diffusion coefficient M = Molecular weight L = length of surface in flow directionCs = Saturation solubility D = Density V = relative velocity of flowing liquidC = Drug concentration in U = Interfacial tensionSolution at time t R = Gas constanth = Thickness of diffusion layer r = Radius

T = Temperature

to volume ratio, nanocrystals provide an alternative methodto formulate poorly soluble compounds. Nanosizing refers tothe reduction of the APIs’ particle size down to the sub-micronrange. Nanosuspensions are sub-micron colloidal dispersions ofdiscrete particles that have been stabilized using a surfactantand a polymer or a mixture of both.9 Stabilized sub-micron

particles in nanosuspensions can be further processed intostandard dosage forms, such as tablets or capsules, which arebest suited for oral administration.

It has been studied and observed that the reduction in par-ticle size in the micron or nano range have a positive impact onthe in vitro dissolution rate, which can be used to predict in vivoenhancement in bioavailability for poorly soluble compounds.10

Compound-specific properties, such as high melting point, highlog P value and poor aqueous solubility, are required to considerbefore the selection of this approach. Therefore, BCS Class IIand IV compounds would theoretically be good candidates forthe nanosizing approach, along with some exceptions, such asfenofibrate (FBT) (low melting point).11 Drug nanocrystals ex-hibit many advantages, including high efficiency of drug load-ing, easy scale-up for manufacture, relatively low cost for prepa-ration, and applicability to various administration routes, suchas oral, parenteral, ocular, and pulmonary delivery (Table 1).All these advantages have led to successful promotion of drugnanocrystals from experimental research to patients’ usage.The availability of several products on the market shows thetherapeutic and commercial effectiveness of the approach.12

The pioneering work of many academics and industrial re-searchers has laid the foundation for broad utilization and ac-ceptance of this approach within the field of pharmaceuticalsciences.

By definition, nanosizing is particle-size reduction to 1 and1000 nm. Because of their small size, these particles can varydistinctly in their properties from micronized drug particles.Similarly to other colloidal systems, drug nanocrystals tend toreduce their energy state by forming larger agglomerates orcrystal growth, which is why they are often stabilized with sur-factants, stabilizers, or with a mixture of both. Reduction of theparticle size to the nanometer range results in a substantialincrease in SA (A), thus, this factor alone will result in a fasterdissolution rate as described by Noyes–Whitney.13 In addition,the Prandtl equation shows that the drug nanocrystals showeddecreased diffusional distance “h”. This further enhances thedissolution rate. Finally, the concentration gradient (Cs − Cx) isalso of high importance. There are reports that drug nanocrys-tals have shown increased saturation/thermodynamic solubil-ity (Cs). This can be explained by the Ostwald–Freundlichequation14 and by the Kelvin equation.15

It is still not clear to what extend the saturation solubilitycan be increased solely as a function of particle size. Most prob-ably the increased solubility of drug nanocrystals is a combinedeffect of nanosized drug particles and solid-state effects causedby the particle fractionation during the process. A number ofauthors have reported improvement from a 10% increase in

Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES DOI 10.1002/jps.24694

REVIEW 3

Table 1. Advantages of Nanocrystals in Different Route ofAdministration

Route Advantages

Oral � Increase bioavailability� Decrease in fed/fast variations� Increase rate of absorption; decrease in Tmax

and increase in Cmax� Quick and easy to formulate

Parenteral � About 100% bioavailability can be achieved ifgiven as an IV formulation

� Targeting drug delivery� Avoidance of organic solvent, surfactants, pH

extremes

Pulmonary � Used in nebulizer as a liquid solution or drypowder

� A single drop can contain many nanoparticles� Increase the concentration and or loading of

nanocrystalline dispersion

saturation solubility to several folds using differentapproaches.16–20 Below are the established equations to de-scribe nanocrystals and their physicochemical properties.

Advantages of nanocrystals over conventional and specialdrug delivery systems:

1. Because of high surface enlargement factor in nanocrys-tals, there is an increase in the dissolution rate as wellas a modest increase in saturation solubility as comparedwith micronized particles.

2. With a size range in nanometers, it can be injected as aIV to get 100% bioavailability.

3. Dose reduction and patient compliance.4. Lessen or eliminate the food effect on bioavailability.5. Targeted drug delivery either by transcellular or intra-

cellular uptake.6. Molecule can be delivered via a required route with ease

in scale up.

This review focuses on the various established approachesfor the formulation of nanocrystals, the different published an-alytical methods applied for thermodynamic solubility deter-mination, assessment of dissolution properties and dissolutionrate enhancement upon nanosizing, the effect on pharmacoki-netic (PK) properties such as bioavailability, the area undercurve (AUC), and the half-life due to size reduction as well asfuture research opportunities.

FORMULATION APPROACHES FOR NANOCRYSTALS

Before the first top-down processes were developed (i.e., tech-niques reducing the size of larger crystals by means of attritionforces), nanosized drug particles were produced using a sim-ple precipitation approach known as solvent–anti-solvent ad-dition technique. It is also referred as one of the “bottom-up”approaches. However, it is often difficult to control the particlegrowth/crystal growth using this technique as well as to scaleup by maintaining all the parameters constant. Therefore, itwas suggested to perform the precipitation step in conjunctionwith immediate lyophilization, or spray-drying, in order to re-duce the risk of crystal growth.

Top-Down Approach

There are two basic approaches which are well established forthe formulation of nanocrystals:

1. Top down: Involves the mechanical reduction of the par-ticle size by wet media milling or high-pressure homoge-nization (HPH).

2. Bottom up: Involves the generation of nanosized particlesfrom dissolved molecules by means of precipitation.9

Top-down methods can be further divided in to twoapproaches—homogenization and attrition wet media milling.

Attrition Wet Media Milling

This technology was developed at the Pharmaceutical ResearchDivision of Eastman Kodak (Sterling Winthrop, Inc.), whichwas set-up as NanoSystems LLC and later acquired by Elan.An active drug substance is dispersed with an aqueous solutionin which the stabilizers were pre-dissolved. As the surface ofnanocrystals is highly cohesive and has high surface energy,it should be stabilized by a single or mixture of stabilizers.Stabilizers can be ionic or stearic and can be used as a singleand/or in a combination of polymeric as well as surfactant sta-bilizers. This solution is poured in the grinding chamber alongwith spherical beads/balls while the beads are rotated at veryhigh speed. It is believed that because of the attrition betweenmolecules’ surface and surface of the beads, particle size reduc-tion occurs; the beads/balls serving as a milling media. Beadsare available in various sizes and are of different materials,but generally are made of glass, zirconium oxide, or polymericmaterial. The type of material the beads are made of is a crit-ical factor as they can interact with the active drug substance.There is a fair chance that an impurity related to the materialof beads may contaminate the final product. Yttrium-stabilizedzirconium oxide is the most widely used type of bead by ma-jor pharmaceutical companies because in most cases, it doesnot interact with active drug substances. Although expensive,these beads are the best alternative to avoiding impurities inthe final formulation.21

The size of the beads has a direct relationship with the de-sired particle size range in the formulation of nanocrystals.22

The usual duration for conventional milling using overheadstirring is somewhere between 3 and 12 h. Certainly, these pa-rameters can change from molecule to molecule. Milling shouldbe stopped once the desired particle size range is achieved. Therotational speed of the milling media is also a critical parame-ter. With the too slow speed, the beads cannot rotate efficientlyand milling cannot be performed accurately, and with the toofast speed, the evenly rotating balls may remain at the uppersurface of the media and milling does not take place. With asystematic study by trial and error the formulator selects thestabilizers, as well as other milling parameters and optimizesthem in order to achieve the desired particle size range andstability. The final product characteristics can vary, depend-ing on the amount of beads, the ratio of active drug substanceto the amount of beads, the ratio of concentrations of activesubstance to the stabilizer, milling time, milling temperatureas well as milling duration.23 This method is simple, inexpen-sive, and easily scalable. The only drawback associated withthis technology is the contamination related to the beading

DOI 10.1002/jps.24694 Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES

4 REVIEW

material. That aside, several products have successfullyreached the commercial level using this technology.

High-Pressure Homogenization

There are several established methods for the formulation ofnanocrystals using the homogenization approach. The microflu-idization technology (Insoluble Drug Delivery-Particles IDD-PTM Technology), Dissocubes R© technology, and Nanopure R©

technology are examples of the methods that fall under thiscategory. Microfluidizers are known as high shear fluid pro-cessors that are unique in their ability to achieve monomodalparticle size reduction. It reduces particle size by a frontal colli-sion of fluid streams under pressure of up to 1700 bar.24 At veryhigh pressure, collision and cavitation occur. The major draw-back associated with this method is that it requires at least50–75 cycles to achieve the desired nanometer size range. Thismakes the method more tedious and relatively more time con-suming as compared to milling. Dissocubes R© technology workswith piston gap homogenizer, which was developed by Mullerand his colleagues. In this method, a crude aqueous suspensionof active drug substance and stabilizer is forced through a tinyhole, which can reach a pressure of up to 4000 bar. The widthof the homogenization gap is adjustable, which is typically inthe micrometer range.

Compared with wet media ball milling, there are fewerchances to generate impurities with HPH. The negative aspectsof using this method are cavitation, which causes mechanicalwear, as well as noise, although fragmentation is a beneficialeffect associated with cavitation. The main source of impuritycomes from the wearing out of equipment parts. Almost all ma-chine parts are made of stainless steel, which leads to a very lowimpurity level when the nanosuspension is prepared using theHPH. Krause and Muller25 carried out a comparative study andobserved a negligible amount of iron impurities in the nanosus-pension formulated with 20 cycles at 1500 bar. Wear and tearoccurs only when very hard material is processed through thepiston gap. Using stainless steel material can also lead to wearand tear as the new type of homogenization valves used todayare made of ceramic tips which are able to withstand the harshprocessing conditions.26 Homogenizers vary in size from a smallscale to large scale production.27 Many research studies havereported minimal growth of microorganisms as a result of theHPH process.28 These improve the shelf life of the nanosuspen-sion and avoid the need for further studies that are requiredif it is administered orally. However, it is not a rule of thumb,the HPH is generally used for relatively soft material and beadmedia mill is used for relatively harder or harsh material.

Combinative Approach

In order to proceed with both the top down technology (wet me-dia milling, HPH) micronized powder is required as the startingmaterial, which leads to a long process time. In order to over-come this drawback, a combinative formulation approach wasdeveloped. The combinative approach was first developed andintroduced by Baxter Inc. as NanoedgeTM technology. Today fivecombinative methods have been successfully developed.

1. NanoedgeTM—microprecipitation + HPH2. H69—microprecipitation immediately followed by HPH

(minimization of time between two steps in order to pro-duce even smaller crystals)

3. H42—drug pre-treatment by means of spray-drying fol-lowed by standard HPH

4. H96—Freeze drying combination with HPH5. CT—Media milling followed by HPH

In the microprecipitation stage, the drug is usually dissolvedin a suitable organic solvent that is miscible with water. Thedrug solution is then added to an aqueous solution in whichstabilizers have been pre-dissolved. The drug solution is addedin a controlled manner to prevent inadequate crystal growth.After the microprecipitation step, precipitates are convertedinto more stable crystals in the nanometer size range with thehelp of top down technologies (i.e., HPH, media milling, andsonication). The amount of residual content in the final prod-uct is the major concern while using a combinational approachduring scale up. The presence of organic solvent can alter thephysicochemical properties of the active drug substance.29 Itmay also be responsible for the Ostwald’s ripening. To preventthis from happening, an alternative method was developed bySalazar et al.21 known as H 42 and H 96 technology. H42 usesthe spray drying of the microprecipitated solution that was de-veloped with the bottom-up approach, and then followed byHPH. In the case of H96, it employs the freeze drying of the mi-croprecipitated solution, followed by a top-down approach. In-deed, on the one hand, this method has more advantages thanany single step conventional method, but on the other hand,any additional steps in the procedure require more careful andmore extensive research, and control of additional parameters,which will increase the cost of the end product development. Todate, no product has been developed and marketed using thistechnology, but research papers have been published for theformulation or production of nanocrystals using the combina-tive approach. Among these, the top-down approaches are moreconvenient because of the ease of being able to govern the parti-cle size range as well as the ease of scaling up. Because of thesebenefits, several products have been successfully launched tothe commercial level.

Bottom-Up Approach

This method is also known as the precipitation approach.Hydrosols30 and Nanomorph31 techniques are examples of thebottom-up approach. The particles generated by Nanomorphtechnology are amorphous in nature, which give an advantageof both a higher supersaturation and a higher dissolution rate.It is well known that amorphous systems are high energy sys-tems; therefore, because of their high rate of crystallization, un-controllable crystal growth occurs, which leads to a reduction insolubility and eventually, reduction in bioavailability. Althoughboth technologies are scalable, they require the control of dif-ferent parameters, such as temperature and the stoichiometryof the solute, solvent, and the stabilizer.

UNDERSTANDING SOLUBILITY BEHAVIOR ANDMETHODS OF DETERMINATION

Several research papers have discussed the impact of solubilityand particle size on the PK performance of nanocrystals. Someof the literature has reported that the generation of surface cur-vature and crystal defects on the particle surface have an enor-mous impact on its solubility behavior. Another possible causemight be the development of high energy surfaces through

Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES DOI 10.1002/jps.24694

REVIEW 5

attrition during particle size reduction. According to the litera-ture, solubility may range from one-fold to several fold, based onparticle size.17–19 Bioavailability enhancement associated withnanocrystalline API is attributed to an increase in the dissolu-tion rate because of the enlargement of SA and some increasein solubility based on particle size. This solubility enhance-ment should be in fair agreement with what would be expectedbased on the Ostwald–Freundlich equation. A change in solu-bility is more significant when particle size is reduced to below100 nm, which can also be described by the Ostwald–Freundlichequation. Rapid dissolution associated with a nanoparticulatesystem is clear evidence of a generation of transient super sat-uration of a solution compared with the bulk solubility of astable crystal form. In the case of crystalline nanoparticles, thedegree of supersaturation is low compared with high energyamorphous solids, as particle size has limited impact on satu-ration solubility.

Determining accurate solubility is vital to characterize theeffectiveness of the formulation. There are several challengesassociated with the accurate determination of solubility of anyformulation, as it varies case by case. Accurate measurementis significantly more complicated in the case of nanoparticulatesystems, as they have the tendency to remain in suspendedform in the solution after using conventional approaches. It isalmost impossible to visualize the presence of nanoparticles inthe filtrate with the naked eye. The intrinsic solubility of poorlysoluble compounds is extremely low in number; therefore, thepresence of a couple of undissolved particles can lead to a signif-icant error in measurement. While reviewing the literature fordetermining solubility by a separation-based method, we havefound the absence of a validated universal method for accuratesolubility determination. This makes it even more challengingwhen dealing with particle size in the nanometer range, as com-pared with the micronized or bulk particles. The following arethe general challenges associated with solubility determinationof the nanoparticulate system.

1. No standard method is available in the literature for sol-ubility determination,

2. Difficulty in separation of the dissolved and undissolvednanocrystals/particles because of smaller size.

3. Confirmation that equilibrium is attained or not.4. Reproducibility of results.5. Validation of method for accuracy.

In addition to the above challenges, one also has to considerother process parameters which vary with the physicochemicalproperties of the active drug substance for solubility determina-tion. For instance, if the API is weakly acidic or basic, then thepH of the solution plays an important role. It is difficult to deter-mine whether or not equilibrium is attained in this particularcase. Several researches have published different approachesfor the solubility determination of nanocrystals. Although nu-merous methods for the separation of dissolved and undissolvednanoparticles have been reported in the literature, these are themost common approaches used described in Figure 1. An aque-ous solubility determination by separation-based approach iswidely accepted, has been used in industry and academia formany decades, and is the most convenient way to determinesolubility. Typically, it is a two-step process: initially, an excessamount of drug is dispersed in an aqueous or buffer solution.

The equilibrium is established by shaking or stirring the solu-tion at a specific rpm for a specific time and temperature, atwhich we want to determine the solubility. Usually the sam-ples are withdrawn after 24 and 48 h. Samples were either cen-trifuged or filtered from syringe filters. A sample analysis wasperformed using the HPLC and UV. In the case of crystallinenanoparticles, the research articles listed in the Table 2 havereported the solubility determination data for nanosuspensionsand nanocrystals by utilizing a separation-based approach astheir primary method for solubility determination. The mostcommonly reported approaches for solubility determination ofnanoparticles are by shake-flask method at a specific temper-ature. Most of them have overestimated the thermodynamicsolubility associated with nanocrystals, which is why it is im-portant to consider some additional factors during solubilitydetermination when particle size is reduced to nano from mi-cron range. The selection of appropriate pore size filters withrespect to the particle size of crystals, and the selection of anappropriate spectroscopic analytical method, is the key factorthat needs to be taken in to consideration for accurate solubilitydetermination of crystalline nanoparticles.

Bernard Van Eerdenbrugh reported that the UV spectra is areliable tool to determine the concentration of micronized par-ticles, however, it is not a reliable tool for the determinationof the concentration of nanosuspensions, as it is overestimat-ing the actual solubility data. With particles in the nanome-ter range, they itself absorbs the UV light. Therefore, the ab-sorbance data are the mixture of the dissolved and undissolvednanosized particles.32 Today, the measurement of the dissolveddrug concentration using an in situ UV probe is the preferrednoninvasive method because of its sophistication in terms ofcontingency and its ability to record data from the start of dis-solution. However, absorption of light from particles is size de-pendent and it is having a great influence on smaller particles.With felodipine as a model drug, an observation has been madethat both nanoparticulates of felodipine and free felodipine inthe solution absorb light in a similar way, which results in anoverestimation of dissolved concentration than what was actu-ally dissolved.33 The results were also dramatic, even for thesecond derivative of UV spectra. Moreover, the generation ofnanoparticles occurs when working with nanosuspensions orsupersaturated systems, so caution should be taken.

The solubility associated with crystalline nanoparticles ismoderately higher (10%–15%)16 compared with what is re-ported in Table 2.34–44 In the case of indomethacin, the reportedsolubility enhancement was nearly twofold higher. The same istrue in the case of oridonin,36 reccardin D,38 and simvastatin39

where reported solubility was substantially higher as comparedwith bulk crystal solubility. One possible reason behind thismisleading data may be the use of an inappropriate separatingmethod and/or analytical method. Nanoparticles with an aver-age size of 200–400 nm can easily pass through 0.22 or 0.45 :mpore sized filters. Determining the concentration of such a fil-tered solution using UV leads to a further over-estimation ofactual data because of the mixture of absorbance of both theundissolved and dissolved particles. Moreover, centrifugationat moderate speed of about 10,000–30,000 rpm is not suffi-cient to suspend particles in the nanometer range, therefore,the resultant supernatant contains a mixture of dissolved andundissolved particles. It is noticeable that care should be takenin choosing syringe filters for appropriate pore size. Juene-mann et al.45 were able to show in their study a differentiation

DOI 10.1002/jps.24694 Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES

6 REVIEW

Tab

le2.

Exp

erim

enta

lSol

ubi

lity

Det

erm

inat

ion

wit

hS

epar

atio

n-B

ased

App

roac

h

Dru

gM

eth

odF

iltr

atio

nP

arti

cle

Siz

ean

dA

nal

ytic

alIn

stru

men

tR

epor

ted

Sol

ubi

lity

Ref

eren

ce

Indo

met

hac

in(I

ND

)S

hak

e-fl

ask

at25°C

0.2:

mU

VN

Sa:5

.86

±1.

2m

g/10

0m

L34

Ph

ysic

alm

ix:2

.30

±0.

51m

g/10

0m

LP

oly

1:0.

91±

0.26

mg/

100

mL

Pol

y2:

1.44

±0.

34m

g/10

0m

L

Indo

met

hac

in(I

ND

)S

hak

e-fl

ask

for

12h

inac

etat

ebu

ffer

pH5

NM

bU

VIN

D–p

hys

ical

mix

:4.8

9±

0.18

:g/

mL

35P.

size

:80:

mN

ano-

IND

/F68

:6.4

3±

0.06

:g/

mL

580

±30

nm

Nan

o-I

ND

/F12

7:4.

80±

0.0:

g/m

L58

0±

20n

mN

ano-

IND

/pol

ysor

bate

:80:

10.9

±1.

54:

g/m

LN

otde

term

ined

Ori

don

in(O

RI)

Con

stan

t-te

mpe

ratu

resh

aker

at37°C

and

100

rpm

inph

osph

ate

buff

erso

luti

on(p

H7.

4)

0.22

:m

mic

ropo

refi

lmU

VO

RI(

com

mer

cial

):99

±2:

g/m

L36

P.si

ze:2

00–4

00n

mO

RI

nan

ocry

stal

:170

±10

:g/

mL

How

ever

,au

thor

repo

rted

slow

decr

ease

inso

lubi

lity

afte

rac

hie

vin

gsu

per

satu

rati

onfo

rN

C.c

Can

desa

rtan

cile

xeti

l24

hst

irri

ng,

foll

owed

byce

ntr

ifu

gati

onat

25,0

00rp

min

phos

phat

ebu

ffer

con

tain

ing

0.7%

Tw

een

20(p

H6.

5)

0.2:

mU

VP.

size

:223

.5±

5.4

Bu

lk:1

25±

6.9:

g/m

LN

C:2

805

±29

.5:

g/m

L22

.44-

fold

impr

ovem

ent

37

Ric

card

inD

Sti

rrin

gin

PB

S(p

H7.

4)bu

ffer

at25°C

and

100

rpm

0.22

:m

mic

ropo

rou

sm

embr

ane

filt

er

HP

LC

P.si

ze:1

84.1

±3.

15n

mP.

size

:815

.37

±9.

65n

m

Bu

lk:0

.619

2±

0.02

45:

g/m

L38

NS

(eva

pora

tive

prec

ipit

atio

nin

toaq

ueo

us

solu

tion

):24

2.1

±12

.1:

g/m

LN

S(m

icro

flu

idiz

atio

n):

31.5

±1.

9:

g/m

L

Sim

vast

atin

Pow

der

form

:sh

ake-

flas

km

eth

odat

37°C

,0.

22:

mW

hat

man

filt

erS

upe

rnat

ant

UV

P.si

ze:3

00.3

nm

Sol

ubi

lity

enh

ance

men

t:36

.14-

fold

39

NS

:cen

trif

uga

tion

at10

,000

rpm

Fen

ofibr

ate

Sh

ake

flas

km

eth

od,s

usp

ensi

oneq

uil

ibra

ted

at37°C

for

72h

0.22

:m

mem

bran

efi

lter

HP

LC

Sol

ubi

lity

40N

S:P

.siz

e:60

6n

mC

onc.

SD

S%

(W/V

)B

ulk

-sol

ubi

lity

(:g/

mL

)0.

00.

34±

0.03

0.1

1.42

±0.

100.

1511

.95

±0.

160.

226

.38

±0.

390.

376

.11

±0.

380.

413

1.95

±1.

680.

518

3.09

±2.

170.

729

0.43

±5.

70

Con

tin

ued

Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES DOI 10.1002/jps.24694

REVIEW 7

Tab

le2.

Con

tin

ued

Dru

gM

eth

odF

iltr

atio

nP

arti

cle

Siz

ean

dA

nal

ytic

alIn

stru

men

tR

epor

ted

Sol

ubi

lity

Ref

eren

ce

Ato

rvas

tati

nca

lciu

mS

hak

efl

ask

met

hod

,for

24h

and

37°C

inD

Iw

ater

0.1:

mm

embr

ane

filt

erU

V41

P.si

ze:c

omm

erci

al:3

8.3

±0.

6:

m14

2.2

±0.

5:

g/m

L

Tu

rrax

R©=

21.5

±0.

03:

m18

5.1

±1.

2:

g/m

LH

PH

d:3

.12

±0.

05:

m29

9.8

±0.

6:

g/m

LH

PH

(20

cycl

es@

1500

bar:

=0.4

46±

0.02

:m

386.

5±

0.7:

g/m

L

Mel

oxic

amS

hak

efl

ask

met

hod

,for

24h

and

37°C

inD

Iw

ater

,sti

rred

sam

ple

wer

efu

rth

erce

ntr

ifu

ged

at10

,000

rpm

for

15m

in

0.22

:m

nyl

on-

mem

bran

efi

lter

UV

42

P.si

ze:

Raw

:4.4

±0.

50:

g/m

LR

aw:4

6.39

±7.

37:

mP

hys

ical

mix

ture

:5.8

3±

0.62

:g/

mL

Son

icat

ed:0

.259

±0.

03:

mS

pray

-dri

edN

C:2

1.84

±0.

78:

g/m

L

Son

icat

ed+H

PH

:0.2

12±

0.04

:m

Spr

ay-d

ried

:0.1

78±

0.02

:g/

mL

Lu

tein

Sam

ples

wer

eke

pton

shak

er10

0rp

man

d25°C

dist

ille

dw

ater

(pH

=5.

5)an

ddi

stil

led

wat

erco

nta

inin

gsu

rfac

tan

tso

luti

on(0

.05%

,w/w

Pla

nta

care

R©20

00,p

H=

10.5

).S

ampl

esw

ere

cen

trif

uge

dat

23,8

00g

for

2h

0.2:

mfi

lter

UV

DIw

ater

:<0.

054:

g/m

LD

Iwat

er+

surf

acta

nt:

0.54

:g/

mL

nan

ocry

stal

:up

to14

.3(>

264-

fold

than

wat

eran

d>

26.3

-fol

dw

ater

wit

hsu

rfac

tan

t)

43

P.si

ze:4

29n

m

Qu

erce

tin

Sam

ples

wer

eke

pton

ash

ake

at37°C

and

100

rpm

.Sam

ple

wer

ew

ith

draw

nan

dtr

ansf

erto

ult

rafr

eetu

bew

ith

cuto

ffof

10kD

aan

dce

ntr

ifu

ged

at20

,000

gfo

r30

min

at4°

C

NM

HP

LC

Bu

lk:1

0.28

g/m

L44

P.si

ze:

PM

:16.

42g/

mL

Dri

ed-E

PA

S:2

82.6

±50

.3n

mE

PA

S(e

vapo

rati

vepr

ecip

itat

ion

into

aqu

eou

sso

luti

on):

422.

4g/

mL

HP

H:2

13.6

±29

.3n

mH

PH

:278

.6g/

mL

aN

S,n

anos

usp

ensi

ons.

bN

M,n

otm

enti

oned

.c N

C,n

anoc

ryst

aldH

PH

,hig

h-p

ress

ure

hom

ogen

izat

ion

.

DOI 10.1002/jps.24694 Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES

8 REVIEW

Figure 1. Reported approaches for the solubility determination.

between suspended submicron colloidal particles and molecu-larly dissolved particles. It has been reported that the resultsof solubility and dissolution of nanocrystals are comparablewith each other if the analysis is performed with filters havingpore size � 0.1 :m. Using larger 0.2 and 0.45 :m filters, thenanocrystalline system shows apparent supersaturated behav-ior because of the combinatory effect of dissolved and undis-solved nanocrystalline particles. In other words, it has beendemonstrated that filters with a bigger pore size may not besufficient enough to hold back the colloidal particles. An ex-cellent demonstration has been reported by carrying out thestudy of a selection of appropriate filters and their impact onobserved in vitro results. It was also compared with an in silicomodel for more precise justification of the experimental data.Overall, the conclusion and recommendation has been madefor using filters with smaller pore sizes (i.e., 0.1 and 0.02 :m)when dealing with nanoparticles.

Kinetic solubility determination by nephelometric or turbidi-metric methods during early screening of the drug molecule wasintroduced earlier by Bevan and Lloyd.46 Bernard Van Eerden-brugh critically evaluated different methods for the solubilitydetermination of nanocrystals using four model compounds:itraconazole, loviride, phenytoin, and naproxen. The data ob-tained show that separation-based methodologies were not suf-ficient to determine solubility, as the data were not in fair agree-ment with the Ostwald–Freundlich equation. Noninvasiveanalytical techniques, such as light scattering and turbidime-try, were found to be more reliable for appropriate understand-ing of the solubility behavior of crystalline nanoparticles. Inthe case of amorphous nanosuspensions, Lindfors et al.33 havedetermined the solubility by plotting scattering intensity withthe drug concentrations. Presence of excessive stabilizers innanosystems also tends to generate the scattering of intensity.Hence, the method that Lindfors demonstrated is not accurateenough because of the summation of scattering intensities thatare generated by dissolved nanoparticles and micelles. In or-der to eliminate this, Van Eerdenbrugh et al.16 have chosenthe point of intersection at which scattering is exclusively dueto the dissolved drug concentration and determine the solu-bility. Measures solubility data by scattering, for loviride wascomparable to bulk solubility data. It was not feasible to

determine solubility for itraconazole from the turbidimetrymethod, as the method cannot be distinguished because of verylow solubility. Solubility determination for phenytoin can bedetermined precisely with both light scattering and turbidime-try. In the case of naproxen, determined solubility values wereslightly less than the unmilled compound but the results werewithin the standard margin of error. Hence, this shows thatboth turbidimetry and light scattering methods can be appliedto obtain more realistic solubility data for crystalline nanopar-ticles. Scattering can be used more precisely for compoundsthat have low scattering intensities and turbidimetry can beapplied on compounds having higher scattering intensities.Moreover, the solubility enhancement was in fair agreementwith the theoretical prediction from the Ostwald–Freundlichequation. For the theoretical calculation, the interfacial ten-sion was estimated (interfacial tension of typical pharmaceu-tical API ranges between 5 and 50 mN/m) as described in thereference literature.47 Experimental data and theoretical pre-dictions were also in agreement with the Ostwald–Freundlichequation, suggesting that solubility enhancement should bemarginal in the case of crystalline nanoparticles and both thelight scattering and turbidimetry are good noninvasive meth-ods for the solubility determination of nanocrystals. However,there are certain assumptions and limitations associated withthese analytical methods. In most cases, the dynamic light scat-tering is used to measure the light scattering intensity. Theinstrument assumes each particle as a sphere and carries outthe determination. When the particles are not spherical ini-tially or if the particles tend to change shape during disso-lution or solubilization, they may have different results thanthose measured by the instrument. Therefore, the impact ofparticle shape is a factor that also needs to be considered, as itplays major role during dissolution and solubilization. Anhaltet al.48 has reported a method for the solubility determinationby real time measuring the light scattering. The main focus wasto determine the equilibrium solubility and dissolution rate ofa crystalline nanosuspension with different particle size usingFBT as a model compound. The solubility results of the lightscattering method were fair enough to justify it as a reliableanalytical tool for the solubility measurement. Reported sol-ubility enhancement for nanocrystals was around 10%–15%,

Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES DOI 10.1002/jps.24694

REVIEW 9

Table 3. Alternative Approaches for Accurate Solubility Determination

Analytical Method, Compound and Particle Size Solubility Determination Solubility Enhancement Ratio Reference

Light scattering 48

Fenofibrate 8.69 ± 0.78 :g/ml140 nm 10.38 ± 0.01 :g/ml 1.19270 nm 8.70 ± 0.24 :g/ml 1.001070 nm 9.62 ± 0.50 :g/ml 1.11

Light scattering and turbidimetry 16

Loviride (162 nm) 0.0108 mg/mL 1.10Scattering – 0.0119 mg/mL

Itraconazole (220 nm) 0.0047 mg/mL 1.15Scattering – 0.0054 mg/mL

Phenytoin (406 nm) 0.0667 mg/mL 1.07Scattering – 0.0711 ± 0.007 mg/mLTurbidity – 0.07 ± 0.0034 mg/mL 1.05

Naproxen (288 nm) 0.2116 mg/mL 0.97Scattering – 0.2053 ± 0.003 mg/mLTurbidity – 0.2083 ± 0.0024 mg/mL 0.97

Separation-based methodology (ultracentrifugation, filtration—0.1 :m, 0.02 :m, and dissolution) 51

Griseofulvin-micro 7.63 ± 0.89 :g/mL 1.10362 nm 8.40 ± 0.25 :g/mL122 nm 9.99 ± 0.15 :g/mL 1.30Compound X-micro 65.17 ± 1.58 :g/mL 0.97238 nm 63.41 ± 1.26 :g/mL93 nm 89.06 ± 6.36 :g/mL 1.36Fenofibrate-micro 0.74 ± 0.27 :g/mL 1.11290 nm 0.82 ± 0.26 :g/mLCelecoxib-micro 1.00 ± 0.03 :g/mL 1.11341 nm 1.11 ± 0.03 :g/mL

which justifies the previously reported solubility data by VanEerdenbrugh.16 However, one should consider certain limita-tions before utilizing this light scattering method. Most impor-tantly, the sample has to be ultra clean; the presence of any dustand debris may lead to the generation of scattering intensitythat affects to the observed data. The use of a plastic cuvette isalso a potential source of error. Moreover, as light scattering isless sensitive to small particles, the results are slanted towardsthe larger sized particles as they have a tendency to generatemore scattering of light. Besides these methods, other analyti-cal techniques like potentiometry and pulse polarography havealso been reported for real time solubility measurement.49,50

However, these methods are not universal and can be used fora fewer number APIs with certain properties (i.e., electroac-tive). In the case of potentiometric measurement, each time aspecific electrode has to use for the specific API.

In general, separation-based methods are universally ac-cepted as they do not require a high level of experimental skill.Murdande et al.51 has reported three different approaches (ul-tracentrifugation, ultracentrifugation with filter, dissolution) todetermine the accurate solubility. Ultracentrifugation was usedafter optimizing different parameters such as speed, time, andtemperature for the satisfactory separation of dissolved andundissolved nanocrystals. Syringe filters were also used (i.e.,0.1 and 0.02 :m) based on the particle size to determine sol-ubility from the supernatant of the ultra-centrifuged sample.In addition, dissolution data at the end of the experiment wasalso evaluated for the total dissolved concentration based on the

theoretical knowledge that nanocrystals should reach the satu-ration level at equilibrium. Results from all three methods weresimilar and in fair agreement with the Ostwald–Freundlichequation. The results from the solubility determination usingthe separation-based approach described above are in Table 3.Interfacial solubility (the concentration in a boundary layer of aspherical particle) plays an important role. As the particle sizedecreases, the SA increases proportionally, along with the in-terfacial tension. Sun et al.52 have determined the equilibriumsolubility of coenzyme Q10 nanocrystals and bulk drug in threedifferent dissolution media, which were mixtures of differentconcentrations of tween 20 and isopropanol. Solubility usuallyleads via diffusion and the driving force would be the differencebetween the solubility at the boundary layer and the bulk drugconcentration. Based on observations, they had also proposeda solubility model for nanocrystals and bulk drugs.52

Another separation-based approach is the determination ofsolubility and/or drug release with the application of equi-librium dialysis. The published research has applied thisconcept, mainly for the nanoparticle-based formulation oflarge molecules and a few for small molecules, and de-termined the equilibrium solubility and drug release fromnanoparticulate formulation. The most common approaches in-clude: sac dialysis,53,54 side by side dialysis,55–57 and reversedialysis.58,59 In dialysis, separation is achieved by means ofa semi-permeable membrane using molecular weight cut-offmembrane. Assuming that the dialysis membrane is perme-able to free API only, Frank et al.60 reported the quantification

DOI 10.1002/jps.24694 Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES

10 REVIEW

of molecularly dissolved, poorly soluble drug by using the equi-librium dialysis method and determined the apparent solubility(molecularly dissolved API + miscellany solubilized drug). Thesolubility of the drug in both the Hanks Balance salt solutionsand the supplementary salts (HBSS++) and fasted-state sim-ulated intestinal fluid (FaSSIF) buffer were nearly the samewithin the margin of error.60 It is well known that nanoparti-cles have a rapid release dissolution kinetics. Efforts have beenmade to determine the interplay of the diffusion rate, size ofthe molecular weight cutoff (MWCO) membrane, and concen-tration difference of the donor and receiver compartment byMoreno-Bautista and Tam.61 Decreasing the dialysis cassettesto smaller MWCO showed a reduction in the diffusion rate. Thecompounds having a molecular weight of around 200–400 Dashowed a diffusion rate profile several times higher with 10 kDamembrane compared to 2 kDa membrane MWCO. The cassetteshaving a pore size smaller than the drug molecule should besuitable for the evaluation of the dissolution rate of nanopar-ticles. Furthermore, the release profile from the dialysis cas-settes failed to catch some necessary events, such as the bursteffect and lag time, which leads to a question the suitability ofthe method for true discrimination of the rapid release kineticsof submicron size colloidal particles. This situation promptedZambito et al.62 to ask question whether the dialysis is a re-liable method for studying drug release from nanoparticulatesystems. Their study concluded that for nanoparticles, the dial-ysis method was insufficient in expressing the discriminationand founded results were deceptive. Because of a reversible in-teraction between the drug and dispersed nanoparticles, therate of permeation through the dialysis membrane was neg-ligible as compared with the plain drug solution. Hence, thekinetic release was found to be far less and unrealistic. Withsuch a study, the release kinetic is governed by the dialysismembrane (not dependent on the drug release from colloidalparticles), which makes it unreliable for the in vitro predictionsand means the data may not be very discriminative.

DISSOLUTION

Dissolution is known as a significant tool for the analysis ofpharmaceutical formulations. Indeed, it has somewhat poten-tial to predict the in vivo performance. Prediction of the extentof absorption can be made from the rate of drug release in thegastrointestinal tract.63 A drug candidate has to pass throughsome pre-requisites steps before being absorbed into the sys-temic circulation. Dissolution is one of the essential steps foreffective absorption of a drug candidate and is a key parame-ter for assessing the onset of action of an oral dosage form. Asper the well-known BCS, classification compounds belonging toClass II and IV are poorly soluble in nature, especially onesbelonging to Class II, which have a dissolution rate of limitedabsorption because of their low aqueous solubility.64 In anotherwords, the rate of absorption is proportional to the rate of disso-lution in the gastrointestinal tract. For a given drug moiety thatdissolves in the gastrointestinal tract, its dissolution can be tai-lored by either generating amorphous systems or reducing theparticle size to the micron or submicron level (i.e., nanometer).The motivation for the development of nanosystems has beengenerated from the increased number of new chemical entitieswith poor aqueous solubility. For such low aqueous-soluble com-pounds, even micronization is not sufficient enough to eliminate

the problem. The reduction of particle size leads to an increasein the SA of the drug particle. The SA enhancement factor frommicron to nanoparticle is about 10-fold. Thus, significant en-hancement in SA has a positive impact on the dissolution rateof a drug particle. This positive effect on the dissolution ratecan create a higher concentration difference between the gut lu-men and the blood, which increases the absorption via passivediffusion and leads to an improved therapeutic response. Directproportionality of the rate of dissolution with respect to specificSA has been well documented by the Noyes–Whitney equation.As a follow up to this, Nernst–Brunner and Danckwerts alsoproposed modified equations to describe the dissolution behav-ior a solid powder.

Noyes − Whitney Equation :dMdt

= k(Cs − C) (1)

Nernst − Brunner Equation :dMdt

= SDh

(Cs − C) (2)

Danckwerts′ surface − renewal model :dMdt

= S√

DP (Cs − C)

(3)

This section will provide an overview of the different estab-lished methods to assess the dissolution for nanocrystals. Asof now, it is well understood that particle size is inversely pro-portional to SA and the dissolution rate has a direct relation-ship with the change in SA. The major challenge is to developa discriminative dissolution method for poorly water-solubledrugs. Earlier reports have indicated that there is an alterationof wetting behavior with particle size reduction. In the caseof nanoparticles, the wetting phenomenon is more prominent,which leads the dissolution rate to increase more quickly. More-over, the reduction in the diffusional distance upon size reduc-tion generates a moderate spring effect that quickly achievessupersaturation level with respect to particle size during dis-solution (Fig. 2). Therefore, the traditional methods are inad-equate to determine the actual dissolution rate enhancementfor nanoparticles which intensify the need for an appropriatemethod to perform the dissolution study of nanoparticles.

Sink Condition (Conventional) Dissolution

Sink condition dissolution condition is defined as the volumeof the dissolution medium which can dissolve more than threetimes the amount of the dose used in the dissolution study.65

In most cases, the dissolution study is performed using a USPtype – I or II apparatus. Usually for a study of a drug releaseprofile, the dissolution is carried out in 900 mL of dissolutionmedia (i.e., in a different pH or in deionized water) at 37 ± 0.5°Ctemperature and by rotating at a specific rpm (i.e., 100 rpm).Samples are withdrawn at specific time intervals throughoutthe dissolution study. After each sample withdrawal, the sameamount of the fresh dissolution media, which is equilibrated atthe same temperature, is introduced to maintain perfect sinkcondition. In most cases, samples will be filtered prior to anal-ysis. However, for the nanoparticles, sink condition dissolutionwill provide good qualitative and less quantitative informationregarding the dissolution behavior of the formulation. So, thecomparison of dissolution profiles between nanosuspension andmicrosuspension will show the impact of particle size on disso-lution velocity. The literature has reported a higher dissolution

Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES DOI 10.1002/jps.24694

REVIEW 11

Figure 2. In vitro surface dissolution, (A) surface image dissolution in correspondence with diffusional layer thickness (h), and (B) intrinsicdissolution profile in correspondence with the surface image dissolution.

rate for the nanosuspensions,66,67 which dissolve instanta-neously as compared with micronized suspension. Hence, sinkcondition dissolution is an appropriate tool for QC analysis.However, because of the instantaneous dissolution behavior ofnanocrystals during sink condition, it is challenging to quan-titatively discriminate dissolution rate enhancement with re-spect to particle size. In addition, the long sampling intervalduring conventional dissolution also adds to the difficulty. Inresponse to these problems, few scientists have tried alterna-tive approaches.

Flow-Through Cell

The flow-through cell dissolution apparatus demonstrated thecapability of studying the dissolution of all kinds of formula-tions, such as tablets, capsules, and powders.68,69 Heng et al.70

have carried out dissolution studies and compared the dissolu-tion rate by asking the question, “What is the suitable disso-lution method for drug nanoparticles?” Initial dissolution rateswere determined for the paddle, basket, and flow-through ap-paratus. The initial dissolution rate was calculated from thefollowing equation:

( dMdt

)Nanoparticles( dM

dt

)Unprocessed

=[slope

( %dissolvedtime

)]nanoparticles[

slope( %dissolved

Time

)]unprocessed

The paddle and basket dissolution apparatus were describedas inappropriate for nanoparticles because of their tendency toform aggregates. The ratios obtained for the initial dissolutionrate enhancement in both cases did not agree with the modelpredicted values. Dissolution studies via the dialysis process(membrane with MWCO 12–14 kDa) were found to be very slowand having a limited ability for size discrimination. As a result,there was no significant difference noted in the dissolution pro-files between nanoparticles and the unprocessed powder. Basedon the analysis, the flow-through cell set-up was described asappropriate for dissolution of nanoparticulate powder by mini-mizing the wetting problems.71 The experimental data for thedissolution profiles were able to discriminate well with the un-processed powder. The initial reported dissolution rate ratiowas the average number of the triplicate study and was inagreement (6.95 vs. 7.97) with model predicted value. The au-thors concluded it as the most suitable analytical process forthe dissolution of nanoparticulate powders. However, selection

of an appropriate flow rate is required for proper discriminationbecause a change in the flow rate can generate change in therelease behavior. Note that the presence of air can also affectthe flow rate during the study, which may alter the dissolu-tion behavior. Therefore, the study should be carried out withcaution.

Alternative Approaches

Nanosuspensions/nanocrystals exhibit instantaneous dissolu-tion behavior, making it difficult to monitor them with conven-tional methods, which requires sample withdrawals, as well asdilution and filtration steps before quantitative analysis. In situfiber optic probes are not able to provide an accurate quantita-tive determination because of the generation of absorbance byboth the dissolved and undissolved nanocrystalline particles.32

Recently, Kayaert et al.72 reported an alternative approach bystudying the dissolution behavior of nanosuspensions using asolution calorimeter. The use of a solution calorimeter for dis-solution study has been previously reported for polymer andpolymeric blends.73 This dissolution study was examined basedon appraising the change in the heat throughout the process. Inother words, heat required for the dissolution process is mea-sured. The methodology consists of sealing the breakable glassampoule along with nanosuspension using bees wax. The glassvial should be kept in the sample cell, surrounded by the me-dia in which the dissolution study is intended to perform. Afterreaching the required temperature, the glass vial should bebroken, and the dissolution process is started. The rate of dis-solution can be then assessed by converting the raw data (i.e.,temperature vs. time and cumulative heat vs. time) to percent-age dissolved versus time. The dissolution process for nanosus-pensions was observed to be extremely fast. It takes just 20 s tocomplete the dissolution process for nanosuspension, whereasin the case of crude suspension, it was found to be between8 and 15 min For the traditional dissolution apparatus (i.e.,basket and paddle), the earliest sample one can withdraw isat 2 min. Hence, the solution calorimeter unquestionably pro-vides the advantage of real time measurement compared withtraditional methods. Consumption and/or production of heatcan be monitored from the beginning of the dissolution processwithout disturbing (i.e., sample withdrawal) the system. Thereare drawbacks with this method, which need to be consideredfor an accurate evaluation of the data generated. The method

DOI 10.1002/jps.24694 Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES

12 REVIEW

measures the summation of the total heat change, which in-cludes contributions from the breakage of the glass ampoule,heat change from other excipients in the formulations, and heatchange due to the dissolution process. Therefore, a careful eval-uation of the data is warranted by considering all these con-tributing factors. In addition, the reported dissolution time isfar shorter (i.e., 20 s to 15 min) using this method, but a singleexperiment requires additional time for the equilibration beforethe test and also requires post-test time after the dissolution,making it more time consuming than the conventional dissolu-tion methods. Furthermore, the instrument is very subtle andrequires a skilled operator. Recently, another separation-basedapproach was reported by Shah et al.74 using a modified dial-ysis method known as pulsatile microdialysis (PMD)75 for thecharacterization of supersaturation and precipitation behaviorof poorly soluble drugs. Here, the pore size for the dialysis probewas approximately 18 kDA (�2 nm). Hence, the final sampleshould contain only the dissolved drug. This analytical methodcan be useful for characterization of high energy solid forms(amorphous) or nanoamorphous33 forms because of the advan-tage of quick sampling (i.e., 10 s). As a more convenient directsampling method, PMD may not be much useful for the study ofnanocrystals with the size range of 150–400 nm because of theavailability of the syringe filters with pore size 0.1 :m. The useof 0.02 :m (�20 nm) anotop syringe filters for the dissolutionstudy has also been reported in the literature.45 As a result, itmay be of great interest if the comparison of the sample anal-ysis from PMD and the sample analysis from 0.02 :m syringefilters has been carried out to describe the usefulness of themethod more precisely.

Another separation-based approach has been reported byMurdande et al.51 by modifying the traditional sink dissolu-tion to various non-sink conditions. Non-sink conditions canbe generated by pre-dissolving API in the dissolution me-dia prior to perform the dissolution experiment. Recently, an-other literature has also reported the dissolution of nanocrys-talline suspension for poorly soluble molecules using non-sinkconditions.76 Because of the lack of discrimination during theinitial phase of dissolution by sink dissolution, the goal wasto slow down the dissolution velocity of nanocrystals and mi-cronized crystals in such way that the initial dissolution phasebecomes more discriminative. Here, the samples were filteredwith both 0.02 :m (for nano) and 0.1 :m (for micro) after es-tablishing the filter binding capacity of the each model com-pounds. As the saturation level increases, the rate of disso-lution decreases, creating a more discriminating portrayal ofthe initial dissolution rate enhancement (i.e., at 75% satura-tion level the initial rate of dissolution, 10 :m:362 nm:122 nmwere 1.0:1.8:3.6). The observed data look more promising com-pared with the data obtained under sink conditions. However,filtration from 20 nm pore size of filters should be performedcarefully because of the chance of blockage or clogging of thepores by larger size particles. From our knowledge, all theseapproaches are reported specifically for nanocrystals. One canselect any analytical method listed above based on their re-quirements and the availability of resources.

PK BEHAVIOR OF CRYSTALLINE NANOPARTICLES

Different formulations have different effects on the PK profileof the same drug. Besides chemical properties, a change in the

physical property (i.e., particle size reduction) may also have aconsiderable impact on altering the PK behavior of a molecule.The reduction of the particle size increases the dissolution ve-locity and may have some effect on in vitro solubility. Similarbehavior was observed in the case of in vivo parameters, suchas AUC (+ve), Cmax (+ve), Tmax (−ve), and fed/fast variability(−ve). A reduction of particle size improves the dissolution rate,which increases the absorption of the drug in the body, and itleads to an increase in PK performance. Compounds belong-ing to the BCS Class II have issues related to poor solubility,dissolution-rate-limited absorption, and bioavailability. Parti-cle size reduction can improve the bioavailability of such com-pounds by improving the dissolution rate. For the nanocrystals,an increase in the oral bioavailability of the compounds can beattributed to an increase in the SA.77

Improvement in Oral Bioavailability

An improvement in the dissolution rate and adhesion to thegut wall can be considered the main contributing factors forenhancing bioavailability and overall PK performance. Afteroral administration, the formulation disintegrates and beginsthe dissolution process. The dissolution rate resembles theconcentration gradient in the physiological environment. Asa result, an improvement in the dissolution rate leads to anenhancement in the absorption, and finally, in the bioavail-ability of the compound. Because of the smaller size of thenanoparticles, they tend to adhere to the gut wall.78 Bioavail-ability enhancement can be achieved both actively and pas-sively. The classic example for bioavailability enhancement hasbeen represented in the case of danazol, which is poorly sol-uble (<1 :g/mL) and one of the most challenging compoundto work within the pharmaceutical industry.79 In vivo studiesof nanosuspensions of danazol (169 nm) in beagle dogs haveshown enormous enhancement in Cmax and a 16-fold enhance-ment in relative bioavailability, compared with the micronizedsuspension.12 Therefore, it is understood that by reducing theparticle size, the solubility issue associated with danazol canbe solved. Moreover, it can also be delivered at a lower dose byenhancing the therapeutic outcome of the compound. FBT isanother classic example of a poorly soluble drug with a high logP (i.e., 5.3) value. FBT is used in hypercholesterolemia and hasa solubility and dissolution-rate-limited absorption property.Bioavailability of FBT is attributed to the dissolution behaviorof particles in the gastric environment. A comparison of the PKprofile of nanocrystals and coarse powder demonstrated signif-icant enhancement in the rate of absorption after oral adminis-tration. The Cmax of nanocrystals was observed to be five timeshigher than that of the coarse powder, along with a higher AUCand Tmax.80 Zuo et al.40 made an effort to compare formulatednanocrystalline particles with the commercial nanocrystallineformulation LipidilTM-ez with respect to in vitro and in vivobehavior. No significant difference was observed between thetwo nanocrystalline formulations, suggesting that variabilitywill be less when particle size is reduced to nanometer range.Certainly, the re-dispersion behavior of dried nanocrystals alsoplays a contributing role by demonstrating reversible or irre-versible aggregation behavior. Bioavailability can be altered byseveral factors in the gastric environment, such as pH change,food effect, the presence of salts, and so on. In all the reportedcases reported in the Table 4,12,40,80–88 a significant enhance-ment in dissolution rate was observed for the nanocrystals,

Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES DOI 10.1002/jps.24694

REVIEW 13

Table 4. Effect on In Vivo Parameters

Compound Animal Model PK Parameters Comment Reference

Aripiprazole Beagle dogs NSa (350 nm) Coarse suspension 71% enhancement inrelative bioavailability

81Tmax (h) 1.04 ± 0.24 3.33 ± 1.50

Cmax (ng/mL) 137.37 ± 17.38 43.10 ± 11.68AUC (ng h/mL) 618.15 ± 81.28 386.06 ± 78.54

Nitrendipine Rat NS (209 nm) Tablet Fivefold enhancement inrelative bioavailability

82Tmax (h) 1 ± 0 2.2 ± 1.17

Cmax (:g/mL) 3.65 ± 0.43 0.60 ± 0.11AUC (:g h/mL) 17.12 ± 2.59 3.44 ± 0.47

Danazol Beagle dogs NS (169 nm) Coarse suspension 16-fold enhancement inrelative bioavailability

12Tmax (h) 1.5 ± 0.3 1.7 ± 0.4

Cmax (:g/mL) 3.01 ± 0.80 0.20 ± 0.06AUC (:g h/mL) 16.5 ± 3.2 1.0 ± 0.4

Naproxen Rat NS (270 nm) Unmilled suspension �1.25-fold enhancement inrelative bioavailability

83Tmax (min) 23.7 ± 5.1 33.5 ± 2.9

Cmax (:g/mL) 187 ± 18 126 ± 4AUC (:g min/mL) 19,062 ± 573 15228 ± 994

Apigenin Rat NCb (400—800 nm) Coarse powder �3.5-fold enhancement inrelative bioavailability

84Tmax (min) 90 ± 14 120 ± 16

Cmax (:g/mL) 5.4 ± 0.6 1.5 ± 0.2AUC (:g min/mL) 1509 ± 196 445 ± 45

Cefpodoxime proxetil Rabbit SDNSc (<300 nm) Microsuspension �1.6-fold enhancement inrelative bioavailability

85Tmax (h) 0.75 ± 0.11 1.75 ± 0.68

Cmax (:g/mL) 18.36 ± 2.03 10.88 ± 1.01AUC (mg h/mL) 47.55 ± 4.33 29.78 ± 3.47

Baicalein Rat Baicalin NC (335 nm) Coarse powder �1.6-fold enhancement inrelative bioavailability

86Tmax (h) 0.92 ± 0.38 1.67 ± 0.29

Cmax (:g/mL) 11.12 ± 1.25 7.18 ± 1.25AUC (:g h/mL) 119.25 ± 20.26 71.41 ± 4.38

Simvastatin Rat NC (387 nm) Coarse powder �1.5-fold enhancement inrelative bioavailability

87Tmax (h) 1.99 ± 0.05 2.88 ± 0.08

Cmax (ng/mL) 450.3 ± 140.5 300.2 ± 67.01AUC (ng h/mL) 1110.3 ± 280.62 770.9 ± 110.3

Fenofibrate Rabbit NC (460 nm) Coarse powder �4.7-fold enhancement inrelative bioavailability

80Tmax (h) �0.4 �1

Cmax (:g/mL) 536.66 ± 35.09 113.46 ± 29.05AUC (:g h/mL) 134.38 ± 6.47 28.41 ± 5.52

BMS-347070 Beagle dog NC Micronized �2.7-fold enhancement inrelative bioavailability

88Tmax (h) 2 3

Cmax (ng/mL) 1475 ± 375 483 ± 79AUC (ng h/mL) 28,613 ± 3850 10,870 ± 1651

Fenofibrate Beagle dog SDNCd LipidilTM-ez No significant difference inrelative bioavailability

40Tmax (h) 2.8 ± 1.8 5.2 ± 9.2

Cmax (ng/mL) 2075.2 ± 1101.1 2349.5 ± 1050.5AUC (ng h/mL) 30,496 ± 6541 34,035.9 ± 19,286.4

aNS, nanosuspension.bNC, nanocrystal.cSDNS, spray-dried nanosuspension.dSDNC, spray-dried nanocrystals.

which caused a significant reduction in the time to reach max-imum concentration, an improvement in the rate of absorp-tion, peak plasma concentration, and enhancement in relativebioavailability.

Food Effect

In most cases, food increases the bioavailability of the drug byincreasing bile secretion and increasing the duration of gas-tric emptying time. For a drug molecule’s clinical efficacy and

DOI 10.1002/jps.24694 Shah, Murdande, and Dave, JOURNAL OF PHARMACEUTICAL SCIENCES

14 REVIEW

Table 5. Food Effect

PK Parameter

Fed Fast

Compound NSa Refb NS Ref Reference

ELND-006 Tmax (h) 1.4 3 1.4 1.8 90Cmax (ng/mL) 365 159 294 49.4

AUC (ng h/mL) 3063 1767 2430 315Fc 110 63.4 87.2 11.3

Fed Fast

NCd Jetmilled NC Jetmilled

Cilostazole Tmax (h) 1 1 1.3 ± 0.5 1 91Cmax (ng/mL) 4872 ± 112 2901 ± 314 5371 ± 1173 1029 ± 218

AUC (ng h/mL) 13,589 ± 3895 10,669 ± 3417 17,832 ± 4994 2875 ± 587F 0.67 ± 0.22 0.53 ± 0.21 0.86 ± 0.29 0.15 ± 0.04

Fed Fast

SNCDe SDDf SNCD SDD

Ziprasidone Cmax (ng/mL) 260 285 416 140 92AUC (ng h/mL) 1911 1949 2044 879

aNS, nanosuspensions.bRef, reference sample.cRelative bioavailability.dNC, nanocrystal.eSNCD, solid nanocrystalline dispersion.fSDD, solid amorphous spray-dried dispersion.

future success, persistence in oral bioavailability can only beachieved by eliminating the food effect.89 The presence of bilesalts in the gastric environment also has an impact on the dis-solution behavior of the molecule. It has been reported that thepresence of food reduces the dissolution behavior of micronizedparticles in certain cases as reported in Table 5.90–92 The ratioof bioavailability of the fed to fast state was observed to be closeto 1 in the case of nanocrystals, while micronized formulationof the same drug showed a significantly higher ratio (approx.sixfold) of the fed to fast state by demonstrating the poten-tial food effect after oral administration to an animal modelwith the same dosing. Bile salt secretion usually increasesin the fed state.93 A change in concentration of the bile saltin the stomach leads to a change in dissolution behavior andslows down or enhances absorption of the drug as depicted inFigure 3. This phenomenon causes a large variability from pa-tient to patient and also from fed state to fast state. Micronizedor larger particles that have shown improved absorption in thefed state might be because of the micelle formation. For thenanocrystals though, they are not helping in improving the in-trinsic solubility, but they provide an advantage by enhancingthe initial dissolution rate because of the larger SA. The higherrate of dissolution leads to an increased rate of absorption, andeventually, enhancement in the overall bioavailability, irrespec-tive of the fed or fast state. Hence, it can be stated that the bilesalts concentrations have significantly less effect on the absorp-tion behavior of nanoparticles. The same observation has beenreported for cilostazole91 [fed/fast ratio—0.78 (nano vs. 3.53jet-milled)]. Thombre et al.92 have reported the PK behavior ofan anti-psychotic drug ziprasidone in beagle dogs by conduct-ing the fed- and fasted-state bioavailability experiment for the

both solid nanocrystalline dispersion and the commercial blend(amorphous spray dried dispersion). The commercial blend hasshown a twofold improvement in bioavailability in the fed stateas compared with the fasted state, indicating the failure of thecommercial blend to prevent variability in absorption behaviorirrespective of the food state. A similar food effect was observedwith human data. On the other hand, nanocrystals have provento be efficient enough to prevent the variability from fed to faststate by generating a similar bioavailability profile in beagledogs. From the reported literature, it can be concluded that vul-nerability in the variation of oral bioavailability for potentialdrugs can be avoided with reduction in particle size to nanome-ter scale.

Particle Size Effect: Micro Versus Nano