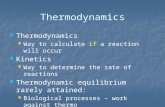

A pplied Thermodynamics

description

Transcript of A pplied Thermodynamics

Applied Thermodynamic

s

1

1. Air Standard Power Cycles Introduction

Two important applications of thermodynamics are

power generation and refrigeration.

Both are usually accomplished by systems that

operate on thermodynamic cycles.

Hence the thermodynamic cycles are usually

divided into two general categories, viz., “power

cycles” and “ refrigeration cycles”;

Power or refrigeration cycles are further classified

as “ gas cycles” and “ vapour cycles” ; 2

In case of gas cycles, the working substance will

be in gaseous phase throughout the cycle, where

as in vapour cycles, the working substance will

be in liquid phase in one part of the cyclic

process and will be in vapour phase in some

other part of the cycle;

Thermodynamic cycles are also classified as

“ closed cycles” and “ open cycles”.

In closed cycles, the working fluid is returned to

its original state at the end of each cycle of

operation and is recirculated. 3

In an open cycle, the working substance is

renewed at the end of each cycle instead of being

re-circulated.

In automobile engines, the combustion gases are

exhausted and replaced by fresh air-fuel mixture

at the end of each cycle.

Though the engine operates in a mechanical cycle,

the working substance does not go through a

complete thermodynamic cycle.

4

Basic Considerations in the Analysis of Power Cycles

The cycles encountered in actual devices are difficult to analyze because of the presence of friction, and the absence of sufficient time for establishment of equilibrium conditions during the cycle.

In order to make an analytical study of a cycle feasible, we have to make some idealizations by neglecting internal Irreversibilities and complexities.

Such cycles resemble the actual cycles closely but are made up of internal reversible processes.

These cycles are called ideal cycles.

5

Air Standard Cycles In gas power cycles, the working fluid will be in

gaseous phase throughout the cycle.

Petrol engines (gasoline engines), diesel engines and gas turbines are familiar examples of devices that operate on gas cycles.

All these devices are called “ Internal combustion engines” as the fuel is burnt within the boundaries of the system.

Because of the combustion of the fuel, the composition of the working fluid changes from a mixture of air and fuel to products of combustion during the course of the cycle.

6

However, considering that air is predominantly

nitrogen which hardly undergoes any chemical

reaction during combustion, the working fluid

closely resembles air at all times.

The actual gas power cycles are complex.

In order that the analysis is made as simple as

possible, certain assumptions have to be made.

These assumptions result in an analysis that is far

from correct for most actual combustion engine

processes, but the analysis is of considerable

value for indicating the upper limit of performance.

7

Air standard assumptions 1. The working medium is a perfect gas with constant specific

heats and molecular weight corresponding to values at room temperature.

2. No chemical reactions occur during the cycle. The heat addition and heat rejection processes are merely heat transfer processes.

3. The processes are reversible.

4. Losses by heat transfer from the apparatus to the atmosphere are assumed to be zero in this analysis.

5. The working medium at the end of the process (cycle) is unchanged and is at the same condition as at the beginning of the process (cycle).

i.e Changes in kinetic and potential energies of the working substance are very small and hence negligible.

8

Air standard Carnot Cycle

The Carnot cycle is represented on P-v and T-s diagrams as in Fig.

The Carnot cycle is composed of four totally reversible processes: isothermal heat addition, isentropic expansion, isothermal heat rejection, and isentropic compression.

The Carnot cycle is the most efficient cycle that can be executed between a heat source at temperature and a sink at temperature , and its thermal efficiency is expressed as

9

Process 1 – 2: Reversible Adiabatic CompressionProcess 1-2: In this, air is compressed isentropically from

volume During this process heat rejected is zero. i.e.,

P: Increases from p1 to p2

V: Decreases from V1 to V2

T: Increases from T1 to T2

S: Remains same.

1W2 = =

1Q2 = 0 or

12211

VPVP

1

)( 21

TTmR

10

Process 2 -3: Isothermal Heat AdditionIn this air is heated isothermally

so that volume increases and

Temperature remains constant.

Amount of heat supplied is equal

to the work done by the gas.

P: Decreases from p2 to p3

V: Increases from V2 to V3

T: Remains same.

S: Increases from S2 to S3

2W3= p2V2 ln = mRT2 ln

2Q3 = p2V2 ln 11

Process 3 – 4: Reversible Adiabatic Expansion

This is isentropic(Adiabatic) expansion

process.

Heat supplied during the process is zero. i.e.,

P: Decreases from p3 to p4

V: Increases from V3 to V4

T: Decreases from T3 to T4

S: Remains same.

3W4 = =

3Q4 = 0

14433

VPVP

1

)( 43

TTmR

12

Process 4 – 1:

Isothermal Heat Rejection

P: Increases from p4 to p1

V: Decreases from V4 to V1

T: Remains same.

S: Decreases from S4 to S1

4W1= p4V4 ln = mRT4 ln

4Q1 = p4V4 ln

13

14

15

max

minmax

max

minmax

ln

ln

T

TT

TrR

TTrRth

And also,

16

17

Mean Effective Pressure

Mean effective pressure may

be defined as the theoretical

pressure which, if it is maintained

constant throughout the volume

change of the cycle, would give the

same work output as that obtained from the cycle.

Or it is the constant pressure which produces the same work

output while causing the piston to move through the same

swept volume as in the actual cycle.

18

Mean effective Pressure:When the piston moves from TDC to BDC, the air inside expands

resulting in work output. If Pm1 is the average pressure on the piston during

this stroke, the average force on the piston is

Where d = diameter of piston or cylinder bore

Work output = average force on piston X stroke length

During the return stroke, as the piston moves from BDC to TDC, air is

compressed requiring work input of the average pressure on the piston

during this stroke is Pm2, the work input is given by;

Where Pm is known as mean effective pressure and is the swept volume.

Usually the net work output is in kJ, volume in m3 and mean effective

pressure in bar.

19

Stirling cycleWhen a confined body of gas (air, helium, whatever) is

heated, its pressure rises.

This increased pressure can push on a piston and do work.

The body of gas is then cooled, pressure drops, and the

piston can return.

The same cycle repeats over and over, using the same

body of gas.

That is all there is to it. No ignition, no carburetion, no valve

train, no explosions.

Many people have a hard time understanding the Stirling

because it is so much simpler than conventional internal

combustion engines.

20

Stirling Cycle:

The Stirling cycle is represented on P-v and T-s diagrams as in Fig.

It consists of two isothermal processes and two isochors.

Process 1-2: In this air is heated isothermally so that volume increases from Temperature remains constant.

Amount of heat supplied is equal to the work done by the gas.

21

Stirling Cycle:Process 2-3: This is constant volume heat rejection process. Temperature decreases from pressure decreases from the heat rejected during the process is given by,

Process 3-4: In this air is compressed isothermally from volume

During this process heat rejected is equal to the work done by the gas.

22

Stirling Cycle:

Process 4-1:

This is constant volume heat addition process.

Temperature increase from The heat added during the process is given by,

23

24

The Efficiency of the cycle:

Due to heat transfers at constant volume processes, the efficiency of the Stirling cycle is less than that of the Carnot cycle.

However if a regenerative arrangement is used such that,

i.e., the area under 2-3 is equal to the area under 4 -1 on T-s diagram, then the efficiency,

25

Otto cycle OR Constant

volume cycle: The Otto cycle is the ideal

cycle for spark-ignition reciprocating engines.

It is named after Nikolaus A. Otto, who built a successful four-stroke engine in 1876.

This cycle is also known as constant volume cycle as the heat is received and rejected at constant volume.

The cycle consists of two adiabatic processes and two constant volume processes as shown in P-v and T-s diagrams.

26

Otto cycle OR Constant

volume cycle: Process 1-2:

In this air is compressed isentropically from V1 to V2 Temperature increases from T1 to T2.

Since this is an adiabatic process heat rejected is zero. i.e.

Process 2-3:

In this air is heated at constant volume and temperature increases from T2 to T3

.

Heat supplied during this process is given by,

27

Otto cycle OR Constant

volume cycle: Process 3-4:

In this air is expanded isentropically from V3 to V4 and temperature decreases from T3 to T4. Since this is an adiabatic process, the heat supplied is zero. i.e.,

Process 4-1:

In this air is cooled at constant volume and temperature decreases from T4 to T1. Heat rejected during this process is equal to change in internal energy and is given by,

28

The Efficiency of the cycle: Efficiency of the cycle is given by,

Considering isentropic expansion process 3-4,

Or

Considering isentropic compression process 1-2,

Or

Substituting for in eqn (1)

Or

Where, r = compression OR expansion ratio and

.

129

Mean effective pressure:

We know that for Otto cycle,

the pressure ratio

30

31

Diesel cycle OR Constant pressure cycle:

The Diesel cycle is the ideal cycle for Compression Ignition reciprocating engines.

The CI engine was first proposed by Rudolph Diesel.

The Diesel cycle consists of one constant pressure heating process, one constant volume cooling process and two adiabatic processes as shown in P-v and T-s diagrams.

This cycle is also known as constant pressure cycle because heat is added at constant pressure.

32

Diesel cycle OR Constant pressure cycle:

Process 1-2:

During this process air is compressed adiabatically and volume decreases from V1 to V2 Heat rejected during this process is zero. i.e.,

Process 2-3:

During this process air is heated at constant pressure and temperature rises from T2 to T3 Heat supplied during this process is given by,

33

Diesel cycle OR Constant pressure cycle:

Process 3-4:

During this process air is expanded adiabatically and volume increases from V3 to V4

.

Heat supplied during the process is zero. i.e.,

Process 4-1:

In this air is cooled at constant volume and temperature decreases from T4 to T1

.

Heat rejected during this process is given by,

34

The Efficiency of the cycle:

The efficiency of the cycle is given by,

Let, compression ratio, Cut-off ratio,

Expansion ratio,

Considering process 1-2,

35

Considering process 3-4,

Substituting for in eqn (1), we get

Considering process 2-3,

36

Mean effective pressure:

we know that work done per kg in Diesel cycle is given by,

And the mean effective pressure is given by:

37

Expression for cut-off ratio:Let ‘k’ be the cut-off in percentage of stroke (from

We know that,

38

Dual combustion or Limited pressure or Mixed cycle:This cycle is a combination of Otto and Diesel cycles.

It is also called semi-diesel cycle because semi-diesel engines work on this cycle.

In this cycle heat is absorbed partly at constant volume and partly at constant pressure.

It consists of two reversible adiabatic or isentropic, two constant volume and a constant pressure processes as shown in P-v and T-s diagrams.

4

5

3

39

Dual combustion or Limited pressure or Mixedcycle:

Process 1-2:

The air is compressed reversibly and adiabatically from temperature T1 to T2 .

No heat is rejected or absorbed by the air.

Process 2-3:

The air is heated at constant volume from T2 to T3.

Heat absorbed by the air is given by,

3 4

5

40

Dual combustion or Limited pressure or Mixed cycle:

Process 3-4:

The air heated at constant pressure from temperature T3 to T4.

The heat supplied by the fuel or heat absorbed by the air is given by,

Process 4-5:

The air is expanded reversibly and adiabatically from temperature T4 to T5

. No heat is absorbed or rejected during the process.

Process 5-1: The air is now cooled at constant volume from temperature T5 to T1 . Heat rejected by the air is given by,

3 4

5

41

The Efficiency of the cycle:

The efficiency of the cycle is given by,

Let, compression ratio,

Cut-off ratio,

Pressure ratio,

Expansion ratio,

5

42

Considering process 1-2,

Considering process 2-3,

Considering process 3-4,

Considering process 4-5,

Substituting for in (1)

43

Mean effective pressure:

We know that work done per kg in dual cycle is given

by,

And the mean effective pressure is given by:

Note:1) For Otto cycle

2) For Diesel cycle

44

Comparison between Otto, Diesel and Dual combustion cycles

The important variables which are used as the basis for comparison of the cycles are compression ratio, peak pressure, heat supplied, heat rejected and the net work output.

In order to compare the performance of the Otto, Diesel and Dual combustion cycles some of these variables have to be fixed.

45

Comparison with same compression ratio and heat supply:

46

The comparison of these cycles for the same compression ratio and same heat supply are shown in on both p – V and T – S diagrams.

In these diagrams, cycle 1-2-3-4-1 represents Otto Cycle, cycle 1-2-3’-4’-1 represents diesel cycle and cycle 1-2”-3”-4”-1 represents the dual combustion cycle for the same compression ratio and heat supply.

47

From the T-S diagram, it can be seen that area 5236 = area 522”3”6” = area 523’6’ as this area represents the heat supply which is same for all the cycles.

All the cycles start from the same initial point 1 and the air is compressed from state 1 to state 2 as the compression ratio is same.

48

It is seen from the T-s diagram, that for the same heat supply, the heat rejection in Otto cycle (area 5146) is minimum and heat rejection in Diesel cycle (area 514’6’) is maximum. Consequently Otto cycle has the highest work output and efficiency. Diesel cycle has the least efficiency and dual cycle has the efficiency between the two.

49

Therefore for the same compression ratio and same heat rejection, Otto cycle is the most efficient while the Diesel cycle is the least efficient.

It can also be seen from the same diagram that q3>q2>q1We know that thermal efficiency is given by 1 – heat rejected/heat suppliedThermal efficiency of these engines under given circumstances is of the following orderDiesel>Dual>OttoHence in this case it is the diesel cycle which shows greater thermal efficiency.

50

Problem 1

In an Otto cycle, the upper and lower limits for the absolute temperature respectively are T1 and T2.

Show that for the maximum work, the ratio of compression should have the value

25.1

1

3

TTrc

51

Solution: Process 1-2 is reversible adiabatic

....(1)..........

12

2

1

1

2

c

c

rTT

rVV

TT

Process 3-4 is reversible adiabatic

(2)..........

33

4

2

1

3

4

cc

c

rTrTT

rVV

TT

52

Work done = Heat added - Heat rejected

In the above equation T3, T1 and Cv are constants.

Therefore for maximum work

11

313

1423

- C - - C

- C - - C

TrTrTT

TTTT

cc

0 drdW

53

25.1

1

3

14.1

1

31

1

1

3

TTr

TT

TTr

c

c

1

2

1

2

32

1

32

1

131

11

313

0 1C - C-

0 1C - C-

0 - C - - C

c

ccc

c

cc

cc

cc

cc

r

rrrr

TT

rTrT

rTrT

rTrT

TrTrTTdrd

54

Problem 2

An engine working on Otto cycle in which salient points are 1,2,3 and 4 has upper and lower temperature limits T3 and T1.

If the maximum work per kg of air is to be done, show that the intermediate temperatures are given by

3142 TTTT

55

Solution: For maximum work/kg in an Otto cycle

•

31

21

1

31

11

1

3 112

11

1

3

1) problemin proved (as

TTTTT

TTTrTT

TTr

c

c

56

11

1

3

334

TT

TrTTc

3142

313

13

1

TTTT

TTTTT

Again

57

Problem 3

An engine working on the otto cycle has a suction pressure of 1 bar and a pressure of 14 bar at the end of compression.

Find Compression ratio, Clearance volume as a percentage of cylinder volume

The ideal efficiency and MEP if the pressure at the end of combustion is 21 bar.

Solution:

Given: P1 = 1 bar, P2 = 14 bar, P3 = 21 bars

58

11

1

2

2

1

2

1

1

2

14

P

Prv

v

vv

PP

c

53% 58.6

11

11 efficiency Ideal

15.18%

1006.58

1 100 x

4.

1

2

1

2

1

c

cc

r

xvv

vv

vvr

59

bar 1.65 )158.6)(14.1(

)11)(6.58-1x6.58(1.5

1

1..

1.5 1421

ratio

1-1.4

1

2

3

c

c

r

rpPEM

pppressureExplosion

60

Problem 4

In a constant volume cycle the pressure at the end of compression is 15 times that at the start, the temperature of air at the beginning of compression is 37° C and the maximum temperature attained in the cycle is 1950°C. Find,

(i) the compression ratio

(ii) thermal efficiency of the cycle

(iii) heat supplied per kg of air

(iv) the work done per kg of air

Solution:

Given:

P2/P1 = 15 , T1 = 37ºC = 310 K

T3 = 1950ºC = 2223 K

61

6.91

15

r

11

1

2

c2

1

1

2

c

c

r

P

Pr

vv

PP

54%

0.54 91.611

11

4.

cr

K 671.66 (31096.91) 1-1.412

crTT62

Heat supplied = Cv(T3-T2) = 0.72(2223 - 671.66)

=1116.96 KJ/kg of air

Work done = 0.54 x 1116.96

= 603.16 KJ/kg of air

suppliedHeat doneWork

63

Problem 5

An air standard Diesel cycle has a compression ratio of 18 and the heat transferred to the working fluid per cycle is 2000 kJ/kg.

At the beginning of the compression stroke, the pressure is 1 bar and the temperature is 300 K.

Calculate the thermal efficiency.

Given:

rc = 18

P1 = 1 bar

T1 = 300 K

K 953.3 300(18) 1-1.4

12

crTT64

Heat transferred = Cp(T3 – T2)

2000 = 1.005(T3 -953.3)]

T3 = 2943.34 K

3.08 953.3

2943.34 ratio offcut 2

3 TT

58.6% 0.586 08

108.181

11

4.

cr

65

Problem 6

An engine with 200 mm cylinder diameter and 300 mm stroke length, works on the theoretical Diesel cycle. The initial pressure and temperature of air are 1 bar and 27° C. The cut off is at 8% of the stroke and compression ratio is 15. Determine

(i) Pressure and temperatures at all salient points of the cycle.

(ii) theoretical air standard efficiency.

(iii) mean effective pressure.

(iv) power developed if there are 400 working strokes per minute.

66

Solution:

Given:

rc = 15,

P1 = 1 bar,

T1 = 27º C

d = 200 mm, L = 300 mm

3m .009424

.3 2.0 sV

V

2

s

x

dLvolumeSwept

67

3

23

23

2sc2

cc

s

c

s

c

sc

2

1c

c2

m 0.001427

009424.008.00006731.008.0 100

8 )(

stroke of 8%at place takesoff

m 0.0006731 14

0.009424

14

V V

14 1)-(15 )1(r V

V

V

V1

V

VV

V

V r

volumeclearance V

xVVV

VVV

Cut

V

V

s

s

68

kPaPEM

x

cr

r

rpPEM

c

c

cr

cut

2

4.114.1

4.11

2

3

10 x 7.41bar 7.14 ..

112.1512.4.115.

151

11

1..

59.8% 0.598

12.

112.15

1 1

1

2.12 0.00067310.001427

VV

ratio off

69

bar 44.3 3

2

3.441.4

1x15 1

2

25.8861-1.4300x15 1

2

kW 46.53 Power 60

400 x 6.98 Power

sec / cycles ofNumber x cycle / done Power Work

kJ/cycle 6.98 0.00942 10 x 7.41 cycle / done

meSwept volu

cycledonework ..

2

PP

barcrPP

KcrTT

xWork

PEM

70

barP

rV

V

V

V

V

V

V

V

V

V

P

P

x

VceV

V

V

V

V

V

V

V

V

V

c

86.215

12.23.44

x x

K 858.99 15

12.285.1878

r

1

V sin x x

K 1878.85 2.12 x 886.25

4.1

14.1

1

14

111

71

Problem 7

In a dual combustion cycle the compression ratio is 14, maximum pressure is limited to 55 bar.

The cut-off ratio is 1.07. Air is admitted at a pressure of 1 bar. Find the thermal efficiency and M.E.P of the cycle.

Solution: (Given):

rc = 14

P1 = 1 bar

P3 = 55 bar

Cut off ratio = =1.07

72

62.18%

)107.1(1.4 367.1)1367.1(

11.07 x 367.1

14

11

)1()1(

111

367.123.40

55

P

P ratio pressureExplosion

bar 40.23

)14(1

4.1

14.1

1

2

3

4.112

x

r

rPP

c

c

73

112

2

323

3

33

2

22

112

2

32

3

43p

2334p

TP

PP

process lumecontant vo is 3-2 Pr

T T

1 1C

)()(C added

c

c

rTP

TT

T

V

T

V

ocess

r

T

TTC

T

TT

TTCTTHeat

74

kgm

c

cc

rP

RTSwept

xWork

T

rTCrT

/21

21

1

1

1

2121

1

1

1

14.11

14.11

11

11p

T 0.003091

14

11

10 x 1

T 0.287

11

V

V1VVV Volume

T 0.6439

6218.0T 1.0356 x addedHeat done

1.0356T

1367.11472.0107.114T 1.367 x 1.005

11C addedHeat

75

bar 083.2 ..

kPa 208.3

0.003091T

0.6439T

volume/kg

/kgdoneWork ..

1

1

PEM

SweptPEM

76

Problem 8

From the PV diagram of an engine working on the Otto cycle, it is found that the pressure in the cylinder after 1/8th of the compression stroke is executed is 1.4 bar. After 5/8th of the compression stroke, the pressure is 3.5bar. Compute the compression ratio and the air standard efficiency. Also if the maximum cycle temperature is limited to 1000.C, find the net work out put

77

ration compressio where-(1)--- 8

1

8

788

78

18

1

300)(27

12732731000

5.3 ,4.1

2

21

211

211

1

3

cca

a

a

a

ba

rrV

V

VVV

VVVV

VVVV

Solution

KassumedT

KT

barPbarP

Given

78

85

83

81

87

have we2 and 1equation From

-(1)--- 8

5

8

38

58

5

2

211

211

c

c

b

a

cb

b

b

r

r

V

V

rV

V

VVVV

VVVVAgain

79

7

924.1

85

83

81

87

4 and 3 from

(4)----- 1.924

4.1

5.3

PP

4.1

11

ba

c

c

c

b

a

b

a

b

a

ba

r

r

r

V

V

P

P

V

V

VVBut

80

kJ/kg 240.6

445 x 0.5408

suppliedheat x output Network

kJ/kg 445

653.4)-0.718(1273

)(C addedHeat

K 653.4

7300

%08.547

11

11

23

14.1

1

2

112

14.11

TT

V

VTT

rc

81

Problem 9An air standard diesel cycle has a compression ratio of 16.

The temperature before compression is 27°C and the temperature after expansion is 627°C. Determine:

i) The net work output per unit mass of air

ii) Thermal efficiency

iii) Specific air consumption in kg/kWh.

82

(1)--- T x T

PP and PP

have we3-2 processFor

K 909.43

x16300T

TT have we2-1 process

300)(27

900273627

16

22

33

323

33

2

22

0.4

1

2

112

122

111

1

4

2

1

V

V

T

V

T

V

V

VTOr

VVFor

Solution

KassumedT

KT

rV

V

Given

c

83

1

2

11243

1

3

2

1

2

143

3

2

1

3

2

2

143

1

3

14

1

3

443

144

133

T

T

have we(1)Eqn from for

T

T

TT have we4-3 process

V

VTT

T

T

V

VT

V

VngSubstituti

V

V

V

VT

V

VT

V

VTOr

VVFor

84

kwhkgW

Specific

W

W

TTCHeat

k

V

VTT

p

/57.55.658

36003600 n consumptioair

%45.606045.03.1089

5.658

q efficiency Thermal

658.5kJ/kg

8.4303.1089 doneWork

g1089.3kJ/k

909.43]-[1993.3 x 1.005

)(q massunit per supplied

3.199361 x 09.439 x 900

T

3-2

233-2

4.11

4.04.0

11

2

11243

85

Problem 10

The compression ratio of a compression ignition engine working on the ideal Diesel cycle is 16. The temperature of air at the beginning of compression is 300K and the temperature of air at the end of expansion is 900K. Determine

i) cut off ratio

ii) expansion ratio and

iii) the cycle efficiency

86

1

3

2c

4

3

1

3

2

2

1

4

3

1

3

2

2

4

1

3

4

4

3

14.1112

1

4

x T

T

x T

T

x T

T

42.90961 x300T

300)(27

900273627

16

V

Vr

V

V

V

V

V

V

V

V

V

V

KrT

Solution

KassumedT

KT

r

Given

c

87

1993.28K

)909.42 x 61 x 009(

)T(

T

T x T

x T

T

T

T

PP and PP

4.1114.114.1

112

143

12

143

12

14

133

13

121

1

3

2c

4

3

3

2

3

2

323

33

2

22

TrT

TrT

TrT

T

Tr

T

Tr

V

V

T

V

T

V

c

c

c

c

88

29.7900

28.1993

r ratioExpansion

60.46%

119.2

119.2

4.1

61-1

1

1r-1

19.2

42.909

28.1993

T

T ratio offcut

14.1

1

1

1

4

3

3

4E

4.11.4-1

1c

2

3

T

T

V

V

89

Problem 11

An air standard limited pressure cycle has a compression ratio of 15 and compression begins at 0.1 MPa, 40°C. The maximum pressure is limited to 6 MPa and heat added is 1.675 MJ/kg. Compute

(i) the heat supplied at constant volume per kg of air

(ii) the heat supplied at constant pressure per kg of air

(iii) the work done per kg of air

(iv) the cycle efficiency

(v) cut off ratio and

(vi) the m.e.p of the cycle

90

354.12.4431

6000

P

26.443151 x100P

1675kJ/kgMJ/kg 1.675 added

60006

40

1001.0

15

2

3

14.112

43

1

1

P

KParP

Solution

Heat

KPaMPaPP

CT

KPaMPaP

r

Given

c

c

91

/kg1439.286kJ235.71-1675

olumeconstant vat addedheat -

addedheat Total pressureconstant at addedHeat

g235.71kJ/k

)65.924251.9910.72(

)0.72( olumeconstant vat addedHeat

K 1251/99

1.354 x 6.924

924.65k

)15(313

23

23

14.1112

TT

JTT

rTT C

92

60.56%

11438.21.4 x 354.11354.1

12.1438 x 354.1

15

1-1

11

1

r

1-1 effeciency standard

11.2684T

)99.12511.005(T1439.286

C pressureconstant at added

4.1

14.1

1-c

4

4

34p

Air

K

TTHeat

KPa 2000.13

1.14382 x 354.11511438.2.3541 x 4.11354.111514.1

15 x 100

11111

..

4.14.114.1

11

c

c

rr

rPPEM

93

94

3. GAS TURBINES AND JET PROPULSION Introduction:

Gas turbines are prime movers producing mechanical power from the heat generated by the combustion of fuels.

They are used in aircraft, some automobile units, industrial installations and small – sized electrical power generating units.

A schematic diagram of a simple gas turbine power plant is shown below.

This is the open cycle gas turbine plant.

95

Working:

Air from atmosphere is compressed adiabatically (idealized) in a compressor (usually rotary) i.e., Process 1–2.

This compressed air enters the combustion chamber, where fuel is injected and undergoes combustion at constant pressure in process 2–3.

The hot products of combustion expand in the turbine to the ambient pressure in process 3–4 and the used up exhaust gases are let out into the surroundings. 96

The compressor is usually coupled to the turbine, so that the work input required by the compressor comes from the turbine.

The turbine produces more work than what is required by the compressor, so that there is net work output available from the turbine.

Since the products of combustion cannot be re–used, real gas turbines work essentially in open cycles. The p–v and T–s diagrams of such a plant are shown above.

97

The compressor is usually coupled to the turbine, so that the work input required by the compressor comes from the turbine.

The turbine produces more work than what is required by the compressor, so that there is net work output available from the turbine.

Since the products of combustion cannot be re–used, real gas turbines work essentially in open cycles. The p–v and T–s diagrams of such a plant are shown above.

98

Brayton Cycle:

This is the air–standard cycle for the gas turbine plant.

It consists of two reversible adiabatic processes and two reversible isobars (constant pressure processes).

The p–v and T–s diagrams of a Brayton Cycle are as shown.

99

Process 1 - 2: Reversible adiabatic compression.

2 – 3: Reversible constant pressure heat addition.

3 – 4: Reversible adiabatic expansion.

4 – 1: Reversible constant pressure heat rejection.

A schematic flow diagram of this somewhat hypothetical gas turbine plant is shown below.

100

Though this plant works on a closed cycle, each of the four devices in the plant is a steady–flow device, in the sense that there is a continuous flow of the working fluid (air) through each device.

Hence, the steady–flow energy equation is the basis for analysis, and can be applied to each of the four processes.

Neglecting changes in kinetic and potential energies, the steady flow energy equation takes the from

Q – W = ∆h = Cp.∆T (Since air is assumed to be an ideal gas)

Process 1 – 2 is reversible adiabatic, hence Q1-2 = 0

W1-2 = - Cp.∆T = - Cp (T2 – T1): - ve, work input

Work of compression

Wc = |W1 – 2| = Cp (T2-T1)

101

Process 2–3 is a constant pressure process

Heat added,

Process 3-4 is again reversible adiabatic,

+ve work output.

102

Process 4-1 is also a constant pressure process

: -ve, i.e., heat is rejected

Heat rejected,

Q2 = |Q4-1| = Cp (T4-T1)

Therefore the cycle efficiency,

103

Therefore the cycle efficiency,

For isentropic process 1-2,

& for process 3-4,

104

Since p3 = p2 and p4 = p1

Compression ratio,105

Therefore,

Pressure ratio,

Thus it can be seen that, for the same compression ratio,

A closed cycle turbine plant is used in a gas–cooled nuclear reactor plant, where the source is a high temperature gas cooled reactor supplying heat from nuclear fission directly to the working fluid (gas/air).

106

Comparison between Brayton Cycle and Otto cycle:-

For the same compression ratio, and nearly same net work output (represented by the area inside the p–v diagram), the Brayton cycle handles larger range of volume and smaller range of pressure than does the Otto cycle.

107

A Brayton cycle is not suitable as the basis for

the working of reciprocating type of devices (Piston–Cylinder arrangements).

A reciprocating engine cannot efficiently handle a large volume flow of low pressure gas.

The engine (Cylinder) size becomes very large and friction losses become excessive.

Otto cycle therefore is more suitable in reciprocating engines.

108

However, a Brayton cycle is more suitable than an Otto cycle, as a basis for a turbine plant.

An I.C. engine is exposed to the highest temperature only intermittently (for short way during each cycle), so that there is time enough for it to cool.

On the other hand, a gas turbine, being a steady flow device, is continuously exposed to the highest temperature.

109

Metallurgical considerations, therefore limit the maximum temperature that can be used.

Moreover, in steady flow machines, it is easier to transfer heat at constant pressure than at constant volume.

Besides, turbines can be efficiently handle large volume of gas flow.

In view of all these, the Brayton cycle more suitable as the basis for the working of gas turbine plants.

110

Effect of irreversibility’s in turbine/compressor:

In the ideal Brayton cycle, compression and expansion of air are assumed to be reversible and adiabatic.

In reality, however, irreversibility’s do exist in the machine operations, even though they may be adiabatic.

Hence the compression and expansion processes are not really constant entropy processes.

Entropy tends to be increase (as per the principle of increase of entropy).

111

Effect of irreversibility’s in turbine/compressor:

The T–s diagram of a Brayton cycle subject to irreversibility’s will be as shown.

Irreversibility’s result in a reduction in turbine output by (h4-h4S) and in an increase in the compressor input by (h2 – h2S).

Hence the output reduces by the amount (h4–h4S )+ (h2–h2s).

Though heat input is also reduced by (h2-h2s), the cycle efficiency is less than that of an ideal cycle. The extent of losses due to irreversibility’s can be expressed in terms of the turbine and compressor efficiencies. 112

Turbine efficiency,

Compressor efficiency,

113

Methods of improving the efficiency of Brayton cycle:

Use of regeneration:

The efficiency of the Brayton cycle can be increased by utilizing part of the energy of exhaust air from the turbine to preheat the air leaving the compressor, in a heat exchanger called regenerator.

This reduces the amount of heat supplied Q1 from an external source, and also the amount of heat rejected Q2 to an external sink, by an equal amount.

Since Wnet = Q1 - Q2 and both Q1 and Q2 reduce by equal amounts, there will be no change in the work output of the cycle.

114

115

Heat added Q1 = h3 –h2’ = Cp (T3 – T2’)

Heat rejected Q2 = h4’ – h1 = Cp (T4’ – T1)

Turbine output WT = h3 – h4 = Cp (T3 – T4)

Compressor input WC = h2 – h1 = Cp (T2 – T1)

Regeneration can be used only if the temperature of air leaving the turbine at 4 is greater than that of air leaving the compressor at 2.

In the regenerator, heat is transferred from air leaving the turbine to air leaving the compressor, thereby raising the temperature of the latter.

The maximum temperature to which compressed air at 2 can be heated is equal to the temperature of turbine exhaust at 4.

116

This, however, is possible only in an ideal regenerator.

In reality, T2’<T4.

The ratio of the actual temperature rise of compressed air to the maximum possible rise is called effectiveness of the regenerator.

117

With a regenerator, since Wnet remains unchanged, but Q1 reduces, efficiency

η = Wnet/Q1 increases.

This is also evident from the fact that the mean temperature of heat addition increases and the mean temperature of heat rejection reduces with the use of the regenerator, and efficiency is also given by

118

With regenerator,

In the regenerator,

Heat lost by hot air = Heat gained by cold airi.e.,

With an ideal regenerator,

119

therefore,

120

For a fixed ratio , the cycle efficiency decreases

with increasing pressure ratio.

In practice, a regenerator is expensive, heavy

and bulky and causes pressure losses, which may

even decrease the cycle efficiency, instead of

increasing it.

121

2.Multistage compression with inter cooling:

122

In this arrangement, compression of air is carried out in two or more stages with cooling of the air in between the stages.

The cooling takes place in a heat exchanger using some external cooling medium (water, air etc).

Shown above is a schematic flow diagram of a gas turbine plant with two-stage compression with inter cooling.

123

1-2: first stage compression (isentropic)

2-3: inter cooling

(heat rejection at constant pressure)

3-4: second stage compression (isentropic)

4-3: constant pressure heat addition

5-6: isentropic expansion

6-1: constant pressure heat rejection.

124

Air, after the first stage compression is cooled before it enters the second stage compressor.

If air is cooled to a temperature equal to the initial temperature (i.e., if T3=T1), inter cooling is said to be perfect.

In practice, usually T3 is greater than T1.

Multistage compressor with inter cooling actually decreases the cycle efficiency.

This is because the average temperature of heat addition Tadd is less for this cycle 1-2-3-4-5-6 as compared to the simple Brayton cycle 1-4’-5-6 with the initial state 1. (refer

fig).

Average temperature of heat rejection Trej also reduces, but only marginally.

125

Hence efficiency is less for the modified cycle. However, if a regenerator is also used the heat added at lower temperature

range (4 to 4’) comes from exhaust gases from the turbine.

So there may be an increase in efficiency (compared to a simple Brayton cycle) when multi–stage compression with inter cooling is used in conjunction with a regenerator.

For a gas turbine plant using 2–stage compression without a generator,

Q1 = h5 - h4 = Cp(T5 - T4)

WT = h5 - h6 = Cp(T5-T6)

WC = (h2 - h1) + (h4 - h3) = Cp [(T2 - T1) + (T4 - T3)]

126

WC = (h2 - h1) + (h4 - h3) = Cp [(T2 - T1) + (T4 - T3)]

Wnet = WT – WC

= Cp [(T5 - T6) – {(T 2- T1) + (T4 - T3)}]

127

3) Multi-Stage expansion with reheating:

128

Here expansion of working fluid (air) is carried out in 2 or more stages with heating (called reheating) in between stages.

The reheating is done in heat exchangers called Reheaters.

In an idealized cycle, the air is reheated, after each stage of expansion, to the temperature at the beginning of expansion.

The schematic flow diagram as well as T-s diagram for a gas turbine plant where in expansion takes place in two turbine stages, with reheating in between, are shown.

Multi-Stage expansion with reheating, by itself, does not lead to any improvement in cycle efficiency. In fact, it only reduces.

129

However, this modification together with regeneration may result in an increase in cycle efficiency.

It can be seen from the T-s diagram that the turbine exhaust temperature is much higher when multi stage expansion with reheating is used, as compared to a simple Brayton cycle.

This makes the use of a regenerator more effective and may lead to a higher efficiency.

Heat added Q1 = (h3 - h2) + (h5 - h4)

= Cp(T3 - T2) + Cp(T5 - T4)

Turbine output WT = (h3 - h4) + (h5 - h6)

= Cp(T3 - T4) + Cp(T5 - T6)

Compressor input WC = h2 - h1 = Cp(T2 - T1)

130

Ideal Regenerative cycle with inter cooling and reheat:

Considerable improvement in efficiency is possible by incorporating all the three modifications simultaneously. Let us consider a regenerative gas turbine cycle with two stage compression and a single reheat.

The flow diagram and T-S diagram of such an arrangement is shown.

Idealized Regenerative Brayton cycle with two stage compression with inter cooling and also two stage expansion with reheating – ideal regenerator, equal pressure ratios for stages, no irreversibilities, perfect inter cooling and reheating.

131

Heat added Q1 = Cp(T5 - T4’) + Cp(T7 - T6)

Turbine output WT = Cp(T5 - T6) + Cp(T7 - T8)

Compressor input WC = Cp(T2 - T1) + Cp(T4 - T3)

If perfect inter cooling, no irreversibilities, equal pressure ratios for stages and ideal regenerator are assumed,

T1=T3, T2=T4=T8’, T5=T7 and

T6=T8=T4’ 132

Then, Q1 = Cp(T5 - T4’) + Cp(T7 – T6)

= Cp (T5 - T6) + Cp(T5 - T6)

= (T5 - T6)

Q2 = Cp(T8’ - T1) + Cp(T2 - T3)

= Cp(T2 - T1) + Cp(T2 - T1)

=2 Cp(T2 - T1)

133

.

134

It can be seen from this expression that the efficiency decreases with increasing pressure ratio rp.

135

Effect of pressure Ratio rp on simple Brayton Cycle:-

That means, the more the pressure ratio, the more will be the efficiency. Temperature T1 (=Tmin) is dependent on the temperature of surroundings.

Temperature T3 (=Tmax) is limited by metallurgical considerations and heat resistant characteristics of the turbine blade material.

For fixed values of Tmin and Tmax, the variation in net work output, heat added and efficiency with increasing pressure ratio rp can be explained with the help of a T-s diagram as shown.

136

For low pressure ratio, the net work output is small and the efficiency is also small (Cycle 1 – 2 – 3 - 4).

In the limit, as rp tends 1, efficiency tends to zero (net work output is zero, but heat added is not zero).

As the pressure ratio increases, the work output increases and so does the efficiency.

However, there is an upper limit for rp when the compression ends at Tmax.

As rp approaches this upper limit (rp)max, both net work output and heat added approach zero values.

However, it can be seen that the mean temperature heat addition Tadd approaches Tmax, while the mean temperature of heat rejection approaches Tmin, as rp

comes close to (rp)max. 137

Hence cycle efficiency, given by

approaches the Carnot efficiency i.e.,

rp - (rp)max When the compression ends at Tmax i.e., when state point 2 is at Tmax.

When rp=rpmax,138

The variation of net work output Wnet with pressure

ratio rp is shown below.

As rp increases from 1 to (rp)max, Wnet increases from

zero, reaches a maximum at an optimum value of rp

i.e., (rp)opt and with further increase in rp, it reduces

and becomes zero when rp = rpmax

139

Pressure Ratio for maximum net work output:-

Wnet= Cp[(T3 - T4) - (T2 - T1)]

T3 = Tmax & T1= Tmin

140

Condition for maximum Wnet is

i.e.,

It can be seen that,

141

Maximum net work output

Corresponding to rp = (rp)opt i.e., when Wnet is maximum, cycle

efficiency is

142

Open Cycle Gas Turbine Plants:

In practice, a gas turbine plant works on an open cycle.

Air from atmosphere is first compressed to a higher pressure in a rotary compressor, which is usually run by the turbine itself, before it enters the combustion chamber.

Fuel is injected into the combustion chamber where it undergoes combustion.

The heat released is absorbed by the products of combustion and the resulting high temperature; high pressure products expand in the turbine producing work output.

143

The used up combustion products (exhaust gases) are let out into the atmosphere.

In the ideal case, compression and expansion are assumed to be isentropic and combustion is assumed to take place at constant pressure.

The schematic flow diagram and p-v and T-s diagrams of an open cycle gas turbine plant are as shown.

144

Advantages and disadvantages of closed cycle over open cycle

Advantages of closed cycle:

1.Higher thermal efficiency

2.Reduced size

3.No contamination

4. Improved heat transmission

5. Improved part load 6.Lesser fluid friction

7.No loss of working medium

8.Greater output and

9. Inexpensive fuel.145

Disadvantages of closed cycle: 1.Complexity

2.Large amount of cooling water is required. This limits its use of stationary installation or marine use

3.Dependent system

4.The wt of the system pre kW developed is high comparatively, not economical for moving vehicles

5.Requires the use of a very large air heater.

146

Problems: 1. In a Gas turbine installation, the air is taken in at 1

bar and 150C and compressed to 4 bar. The isentropic of turbine and the compressor are 82% and 85% respectively. Determine (i) compression work, (ii) Turbine work, (iii) work ratio, (iv) Th. .

What would be the improvement in the th. if a regenerator with 75% effectiveness is incorporated in the cycle. Assume the maximum cycle temperature to be 8250K.

Solution: P1 = 1 bar T1 = 2880K P2 = 4 bar

T3 = 8250K C = 0.85 t = 0.82

147

Case1: Without Regeneration:Process 1-2s is isentropic i.e.,

But

Process 3-4s is isentropic

But

r

r

s

P

P

T

T1

1

2

1

2

KT s0

4.1

4.0

2 14.4284288

KTT

eiTT

TT sC

02

212

12 87.452288

28814.42885.0.,.

96.5544

1825.,.

4.1

4.0

4

1

3

4

3

4

s

r

r

s TP

P

T

Tei

KTT

eiTT

TT

st

04

4

43

43 57.60396.554825

82582.0.,.

148

(i) Compressor work,

WC = CP (T2 – T1)

= 1.005 (452.87 – 288) = 165.69 kJ/kg

(ii) Turbine work,

Wt = CP (T3 – T4)

= 1.005 (825 – 603.57) = 222.54 kJ/kg

(iii) Work ratio = = 0.255

(iv) Thermal Efficiency ,

= 15.2%149

Case2: With Regeneration:

We have effectiveness,

T5 = 565.890K

Heat supplied,

Q H1 = Q5-3 = CP(T3 – T5)

= 1.005 (825 – 565.89)

= 260.4 kJ/kg

= 0.218

Improvement in th due to regenerator = 0.436

i.e., 43.6%

87.45257.603

87.45275.0.,. 5

24

25

T

eiTT

TT

4.260

85.561

H

CTth

Q

WW

152.0

152.0218.0

150

2.The maximum and minimum pressure and temperatures of a gas turbine are 5 bar, 1.2 bar and 1000K and 300K respectively. Assuming compression and expansion processes as isentropic, determine the th

(a)when an ideal regenerator is incorporated in the plant and (b) when the effectiveness of the above regenerator is 75%.

Solution:

P2 = P3 = 5 bar P1 = P4 = 1.2 bar

T3 = 1000K T1 = 300K

151

Process 1-2s is isentropic i.e.,

r

r

s

P

P

T

T1

1

2

1

2

KT s04.1

4.0

2 21.4512.1

5300

Process 3-4s is isentropic i.e.,

r

r

s

P

P

T

T1

3

4

3

4

KT s04.1

4.0

4 88.6645

2.11000

152

Ideal regenerator: i.e., T5 = T4

Heat supplied = CP (T3 – T5)

= 1.005 [1000 – 664.88] = 336.79 kJ/kg

Wnet = WT – WC = CP (T3 – T4) – CP (T2 – T1)

= 1.005 [1000 – 664.88 – 451.21 + 300] = 183.91

= 0.546 or 54.6%

79.336

91.183

H

netth Q

W

153

Regenerator with = 0.75 i.e.,

i.e.,

Heat supplied, QH = CP (T3 – T5)

= 1.005 (1000 – 611.46) = 390.48kJ/kg

= 0.471 or 47.1%

dropetemperaturideal

dropetemperaturactual

TT

TT

24

2575.0

KTT 0

55 46.611

21.45188.664

21.45175.0

48.390

91.183

H

netth Q

W

154

3.Solve the above problem when the adiabatic efficiencies of the turbine and compressor are 90% and 85% respectively.

4. A gas turbine plant uses 500kg of air/min, which enters the compressor at 1 bar, 170C. The compressor delivery pressure is 4.4 bar. The products of combustion leaves the combustion chamber at 6500C and is then expanded in the turbine to 1 bar. Assuming isentropic efficiency of compressor to be 75% and that of the turbine to be 85%, calculate (i) mass of the fuel required /min, of the CV of fuel is 39000KJ/Kg. (ii)net power output (iii)Overall thermal efficiency of the plant. Assume CP=1.13KJ/Kg-K,=1.33 for both heating and expansion.

155

Solution:

P1 = 1 bar T1 = 2900K P2 = 4.4 bar T3 = 9230K

C = 0.75 t = 0.85 , WN = ? , th ?

Calorific Value = 39000 kJ/kg

Process 1-2s is isentropic compression

i.e.,

sec/33.8min/500 kgkgma

?fm

C

T

PorVTVTorVPVP

1

122

1112211

KP

PTT s

04.1

4.0

1

1

212 02.4434.4290

But

12

12

TT

TT sC

i.e., KT

T0

22

03.494290

29002.44375.0

156

Process 3-4s is isentropic expansion i.e.,

KTP

P

T

Ts

s 033.1

32.0

4

1

3

4

3

4 18.6394.4

1923

But

sT TT

TT

43

43

i.e., KTT 0

44 76.68118.639923

92385.0

(i) ?fm

We have 03.49492313.1

39000500.,.

23

fPf

a

mei

TTC

CV

m

m

fm = 6.21kg/min 157

(ii) WN = ?

Compressor work, WC = CP (T2 – T1)

= 1.005 (494.03 – 290)

= 205.05 kJ/kg

Turbine work, WT = CP (T3 – T4)

= 1.13 (923 – 681.76)

= 272.6 kJ/kg

WN = WT – WC = 67.55 kJ/kg

Net work output per minute =

= (500+6.21) (67.55) = 34194.49 kJ/min

Power output = 569.91 kW

Nfa Wmm

158

(iii) th = ?

Heat supplied, QH = CP (T3 – T2)

= 1.33 (923 – 494.03)

= 570.53 kJ/kg

= 0.118 or 11.8%

53.570

55.67

H

Nth Q

W

159

5. A gas turbine cycle having 2 stage compression with intercooling in between stages and 2 stages of expansion with reheating in between the stages has an overall pressure ratio of 8.

The maximum cycle temperature is 14000K and the compressor inlet conditions are 1 bar and 270C. The compressors have s of 80% and turbines have s of 85%.

Assuming that the air is cooled back to its original temperature after the first stage compression and gas is reheated back to its original temperature after 1st stage of expansion, determine (i) the net work output

(ii) the cycle th.

160

Solution: T5 = 14000K T1 = 3000K, P1= 1 bar

C1= 0.8 = C2, t1 = t2 = 0.85 ,T3 = T1 ,T7 = T5For maximum work output,

88

5

1

4

8

7

6

5

3

4

1

2 P

P

P

P

P

P

P

P

P

P

P

P

barPPPP

essureteIntermedia

83.2

,Pr

7632

For process 1-2, 1

1

212

P

PTT s

= 300 (2.83)0.286 = 403.950K

But KTTTT

TT sc

02

212

121 9.429

300

30095.4038.0

161

Since T3 = T1 and 1

2

3

4

P

P

P

P

We have T4s = T2s = 403.950K

Also since C1 = C2, T4 = T2 = 429.90K

Compressor work, WC = CP (T2 – T1) + CP (T4 – T3)

= 2 CP (T2 – T1)

= 2 (1.005) (429.9 – 300) = 261.19 kJ/kg

For process 5 – 6,

KTP

P

T

Ts

s 0286.0

6

1

5

6

5

6 72.103983.2

11400

162

But

KTT

eiTT

TT

st

06

6

65

651 76.1093

72.10391400

140085.0.,.

Since T7 = T5 and

8

7

6

5

P

P

P

P

, then T8 = T6

Since t1 = t2,T6 = T8 = 1093.760K

Turbine work, Wt = CP (T5 – T6) + CP (T7 – T8)

= 2 CP (T5 – T6)

= 2 (1.005) (1400 – 1093.76)= 615.54 kJ/kg

WN = WT – WC = 354.35 kJ/kg

163

th = ?

Heat Supplied,

QH = CP (T5 – T4) + CP (T7 – T6)

= 1.005 (1400 – 429.9 + 1400 – 1093.76)

= 1282.72 kJ/kg

72.1282

35.354 th = 0.276 or 27.6%

164

6. Determine the of a gas turbine having two stages of compression with intercooling and two stages of expansion with reheat. Given that the pressure ratio is 4, minimum temperature of the cycle 270C and maximum temperature of the cycle is 6000C, when t, C and regenerator are equal to 80%.

( Home work)

7. A two stage gas turbine cycle receives air at 100 kPa and 150C. The lower stage has a pressure ratio of 3, while that for the upper stage is 4 for the compressor as well as the turbine. The temperature rise of the air compressed in the lower stage is reduced by 80% by intercooling. Also, a regenerator of 78% effectiveness is used. The upper temperature limit of the cycle is 11000C. The turbine and the compressor s are 86%. Calculate the mass flow rate required to produce 6000kW.

165

Solution:

P1 = 1 bar T1 = 2880K

IC = 0.8 ε = reg = 0.78, T5 = 13730K,

C1 = C2 = t1 = t2 = 0.86, if P = 6000 kW

4,33

4

1

2 P

P

P

P

?m

Process 1-2s is isentropic compression

1

1

2

1

2

P

P

T

T s T2s = 288 (3)0.286

= 410.750K

But KTT

eiTT

TT sC

02

212

121 73.430

288

28875.41086.0.,.

Also, KT

Tei

TT

TTIC

03

3

12

32 54.31628873.430

73.4308.0.,.

166

Process 3-4s is 2nd stage isentropic compression

T4s = 316.54 (4)0.286 = 470.570K

1

3

4

3

4

P

P

T

T s

But KTT

eiTT

TT sC

04

434

342 64.495

54.316

54.31657.47086.0.,.

1

5

6

5

6

P

P

T

T s

KT s0

286.0

6 59.9234

11373

Process 5-6s is 1st stage isentropic expansion

167

But

Process 6-7 is reheating, assume T7 = T5 = 13730K

KTT

eiTT

TT

st

06

6

65

651 51.986

59.9231373

137386.0.,.

1

7

8

7

8

P

P

T

T s

KT s0

286.0

8 79.10023

11373

Process 7-8s is 2nd stage isentropic expansion i.e.,

But KTT

eiTT

TT

st

08

8

87

872 63.1054

79.10021373

137386.0.,.

Regenerator is used to utilizes the temperature of exhaust gases i.e.,

48

4

TT

TTx

64.49563.1054

64.49578.0.,.

xTei Tx = 931.650K168

We have, Compressor work: WC = CP (T2 – T1) + CP (T4 – T3)

= 1.005 (430.73 – 288 + 495.64 – 316.54)

= 323.44 kJ/kg

Also, Turbine work : WT = CP (T5 – T6) + CP (T7 – T8)

= 1.005 (1373 – 986.51 + 1373 – 1054.63)

= 708.38 kJ/kg

Net work output, WN = WT - WC

= 384.95 kJ/kg

But, power produced,

i.e., 6000 x 1000 = 384.95 x 1000

= 15.59 kg/sec

We have, heat supplied, QH = CP (T5 – Tx) + CP (T7 – T6)

= 1.005 (1373 – 931.65 + 1373 – 986.51)

= 831.98 kJ/kg

NWmP

m

%3.46463.0 orQ

W

H

Nth 169

8. In a gas turbine plant working on Brayton cycle, the inlet conditions are 1 bar and 270C. The compression of air is carried out in two stages with a pressure ratio of 2.5 for each stage with intercooling to 270C.

The expansion is carried out in one stage with a pressure ratio of 6.25.

The maximum temperature in the cycle is 8000C. The of turbine and both compression stages are 80%. Determine (i) compressor work, (ii) Turbine work, (iii) Heat supplied, (iv) cycle , (v) cycle air rate.

Hint: P1 = 1 bar P4 = P5 = 6.25 bar, P3 = P2 = 2.5 bar

170

9. The pressure ratio of an open cycle constant pressure gas turbine is 6. The temperature range of the plant is 150C and 8000C. Calculate (i) th of the plant, (ii) Power developed by the plant for an air circulation of 5 kg/s, (iii) Air fuel ratio, (iv) specific fuel consumption. Neglect losses in the system. Use the following data: for both air and gases: CP 1.005 kJ/kg0K and = 1.4. Calorific value of the fuel is 42000 kJ/kg, C = 0.85, t = 0.9 and combustion of 0.95.

10. In a G.T. unit with two stage compression and two stage expansion the gas temperature at entry to both the turbines are same. The compressors have an intercooler with an effectiveness of 83%. The working temperature limits are 250C and 10000C, while the pressure limits are 1.02 bar and 7 bar respectively. Assuming that the compression and expansion processes in the compressors and turbine are adiabatic with C of 84% and t of 89% for both the stages. Calculate (i) the air-fuel ratio at the combustion chambers if the calorific value of the fuel is 38500 kJ/kg, (ii) Power output in kW for an air flow rate of 1kg/s and (iii) overall cycle .

171

11. In a reheat gas turbine cycle, comprising one compressor and two turbine, air is compressed from 1 bar, 270C to 6 bar. The highest temperature in the cycle is 9000C. The expansion in the 1st stage turbine is such that the work from it just equals the work required by the compressor. Air is reheated between the two stages of expansion to 8500C. Assume that the isentropic s of the compressor, the 1st stage and the 2nd stage turbines are 85% each and that the working fluid is air and calculate the cycle .

Solution: P1 = 1 bar T1 = 300K P2 = 6 bar

T3 = 1173K WT1 = WC T5 = 1123K C = 0.85

t1 = t2 = 0.85

172

We have process 1-2 is isentropic i.e.,

1

1

2

1

2

P

P

T

T S

KT S 5.5001

6300

4.1

4.0

2

KTT

eiTT

TTBut S

C 536300

3005.50085.0.,. 2

212

12

Compressor work, WC = CP (T2 – T1)

= 1.005 (536 – 300) = 237 kJ/kg

From data, WT1 = WC = 237 kJ/kg

= CP (T3 – T4) T4 = 937 kJ/kg173

KTT

eiTT

TTBut S

SSt 895

1173

937117385.0.,. 4

443

431

Process 3-4 is isentropic i.e., 1

3

4

3

4

T

T

P

P S

barP 328.21173

8956

4.0

4.1

4

From T-S diagram, intermediate pressure, P4 = P5 = 2.328 bar

Process 5-6s is isentropic in the 2nd stage turbine

KTP

P

T

Tei S

S 882328.2

11123.,.

4.1

4.0

6

1

5

6

5

6

KTT

eiTT

TTBut

St 918

8821123

112385.0.,. 6

6

65

652

174

WT2 = CP (T5 – T6)

= 1.005 (1123 – 918) = 206 kJ/kgNet work output = WT – WC

= (WT1 + WT2) – WC = 206 kJ/kg

Net heat transfer or heat supplied, Q = QH + QR

= CP (T3 – T2) + CP (T5 – T4)

= 640 + 187 = 827 kJ/kgCycle efficiency,

%25827

206

net

netcycle Q

W

175

12. In a simple gas turbine unit, the isentropic discharge temperature of air flowing out of compressor is 1950C, while the actual discharge temperature is 2400C. Conditions of air at the beginning of compression are 1 bar and 170C. If the air-fuel ratio is 75 and net power output from the unit is 650kW. Compute (i) isentropic of the compressor and the turbine and (ii) overall . Calorific value of the fuel used is 46110 kJ/kg and the unit consumes 312 kg/hr of fuel. Assume for gases CP = 1.09 kJ/kg-K and = 1.32 and for air CP = 1.005 kJ/kg-K and = 1.4.

176

Solution:

T2S = 195+273 = 468 K T2 = 240+273 = 513K T1 = 290K P1=1bar A/F = 75, Power output = Wnet = WT – WC = 650kW C = ? T = ? cycle = ? CV = 46110 kJ/kg, CPg = 1.09 kJ/kg-k, g = 1.30, CPa = 1.005 kJ/kg-K, a = 1.4

skghrkgm f /0867.0/312

We have, Compressor Efficiency,

79.0290513

290468.,.

12

12

eiTT

TT SC

Also, fa mF

Am

= 75 (0.0867) = 6.503 kg/s 177

34.5290

468Pr

4.0

4.11

1

2

T

TRratioessure S

Applying SFEE to the constant pressure heating process 2-3,

23 TTCmmCVm Pgfaf

0.0867 (46110) = (6.503 + 0.0867) 1.09 (T3 – 513)

T3 = 1069.6KAlso,

32.1

132.1

4

1

3

4

3

4 34.56.1069

S

S TP

P

T

T g

g

T4S = 712.6K. Further,

1243 TTCmTTCmmWWW PaaPgfaCTnet

i.e., 650 = (6.503 + 0.0867) 1.09 (1069.6 – T4) – 6.503 (1.005) (513 – 290)

T4 = 776K 178

822.06.7126.1069

7766.1069

43

43

S

T TT

TT

163.0461100867.0

650

CVm

W

f

netcycle

162.09.3997

650650

23

TTCmmQ

W

PgfaH

netcycle

Now, Turbine Efficiency,

And,

Or

179