Ultimate strength design of longitudinally stiffened plate panels.pdf

A new formulation for longitudinally stiffened webs subjected to patch loading using stepwise...

Click here to load reader

-

Upload

abdulkadir-cevik -

Category

Documents

-

view

230 -

download

15

Transcript of A new formulation for longitudinally stiffened webs subjected to patch loading using stepwise...

Advances in Engineering Software 41 (2010) 611–618

Contents lists available at ScienceDirect

Advances in Engineering Software

journal homepage: www.elsevier .com/locate /advengsoft

A new formulation for longitudinally stiffened webs subjected to patchloading using stepwise regression method

Abdulkadir Cevik a,*, M. Tolga Gögüs� a, _Ibrahim H. GüzelbeY b, Hüzeyin Filiz b

a Department of Civil Engineering, University Of Gaziantep, Turkeyb Department of Mechanical Engineering, University Of Gaziantep, Turkey

a r t i c l e i n f o

Article history:Received 26 May 2009Received in revised form 25 September2009Accepted 25 November 2009Available online 8 January 2010

Keywords:Patch loadingStepwise regressionFormulationGirdersWebs

0965-9978/$ - see front matter � 2009 Elsevier Ltd. Adoi:10.1016/j.advengsoft.2009.12.001

* Corresponding author. Tel.: +90 342 3172409; faxE-mail address: [email protected] (A. Cevik).

a b s t r a c t

This study proposes a new formulation for patch loading of longitudinally stiffened webs using stepwiseregression (SR) for the first time in literature. The database for the SR formulation is based on extensiveexperimental results from literature. The results of the SR formulation are compared with existing mod-els and design codes. It is found that SR formulation gives more accurate results than existing models anddesign codes.

� 2009 Elsevier Ltd. All rights reserved.

1. Introduction

Patch loading is a significant phenomenon for steel girderswhich has been the scope of numerous studies for the last threedecades. As a result of extensive theoretical and experimentalinvestigations [1–24], it has been observed that longitudinal stiff-eners increase the resistance of steel girder webs subjected to con-centrated loads or so-called patch loading (Fig. 1). In the past, it hasbeen common to compute the effect of longitudinal stiffeners onpatch loading resistance of girder webs by multiplying the corre-sponding resistance of the unstiffened girder web with a correctionfactor obtained by regression analysis. Most of the proposalsregarding that longitudinal stiffener on patch load resistance areempirical based on regression analysis of experimental studieswhere the increase in ultimate patch load is calculated by the mul-tiplication of unstiffened ultimate load with a magnification factor.On the other hand, there are also failure mechanisms solutionsavailable in literature observed in experiments that have been car-ried out at various research centers [17]. There have been variousattempts for the regression formulation of the problem. This studyproposes a novel approach for the formulation which has no beenused in literature so far: stepwise regression (SR). SR results arecompared with existing test results, existing models found inliterature and related design codes and they are found to be more

ll rights reserved.

: +90 342 3601107.

accurate. The proposed SR formulation includes the effects of allparameters on the ultimate resistance of steel girder webs topatch loading which has not been considered in existing modelsso far.

2. Patch loading

Steel beams or girders are often subjected to concentrated loadscommonly named as patch loading which directly determines theproportioning of the section. Thus, the calculation of the ultimatepatch load becomes of significant importance for economical andsafety reasons. In the case of crane and bridge girders during incre-mental launching it is not possible to solve the problem with ver-tical stiffeners as the concentrated load is free to move along thegirders. Especially, in large bridge girders, longitudinal stiffenersare used close to the compression flange of plate girders undernegative bending to increase the resistance of deep plate girderssubjected to bending and/or shear and to prevent lateral webdeflections, thereby reducing secondary effects that can lead topremature failure due to web breathing [17].

2.1. Review of experimental studies

Extensive experimental research has been conducted all aroundthe world on the effect of longitudinal stiffening to the patch load-ing resistance [1–12]. Number and details of tested specimen aregiven are given in Table 1.

Fig. 1. Longitudinally stiffened plate girder with related cross-section parameterssubjected to patch loading.

612 A. Cevik et al. / Advances in Engineering Software 41 (2010) 611–618

2.2. Models for patch load resistance

2.2.1. Regression models (Model I)Some researchers [2,6,10] have related the patch loading resis-

tance of longitudinal stiffened webs with that of by multiplyingpatch load resistance of unstiffened girders with a correction fac-tor, which is in general a function of the position of the stiffener.The approach presented in this section is based on the design mod-el for the patch loading resistance of unstiffened plate girdersdeveloped by Lagerqvist and Johansson [14]. Validation studiesindicate that this method gives the lowest scatter and the mostuniform safety when comparing test results with theoretical pre-dictions [24]. Accordingly, the patch loading resistance for unstiff-ened plate girders Fco is given by:

Fro ¼ FyvðkÞ ð1Þ

where Fy is yield resistance, k is slenderness parameter and v isresistance function of slenderness parameter.

Fy ¼ fywtwly ð2Þ

where fyw and tw are yield stress and thickness of web and ly theeffective loaded length is calculated as,

ly ¼ ss þ 2tf 1þffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffim1 þm2p� �

ð3Þ

where ss is length of patch load, tf is thickness of flange and thedimensionless parameters m1 and m2 are

m1 ¼ fyf bf =fywtw;m2 ¼ 0:02ðhw=tf Þ2 ð4Þ

where fyf, bf and tf are yield stress, width and height of flange and hw

is depth of web panel.It should be noted that m2 should be taken as zero for welded

girders if k < 0.5The resistance function vðkÞ is vðkÞ ¼ 0:06þ 0:47

k � 1 and k is theslenderness parameter,

Table 1Summary of data used in experiments [17] (details are given in Table A1).

Researcher (year) N a/hw

Rockey et al. [1] (1978) 2 1.0Bergfelt [2] (1979) 11 0.75–3.24Bergfelt [3] (1983 6 1.5–4.08Galea et al. [4] (1987) 2 1.40Shimizu et al. [5] (1987) 1 1.0Janus et al. [6] (1988) 101 1.0–2.0Dubas and Tschamper et al. [7] (1989) 24 1.76–2.48Dogaki et al. [8] (1988) 2 1.0Salkar [9] (1992) 2 1.0Carretero and Lebet [11] (1998) 6 1.31–2.21Walbridge and Lebet [12] (2001) 5 1.43

k ¼

ffiffiffiffiffiffiFy

Fcr

sð5Þ

where Fcr is the buckling load which is expressed as:

Fcr ¼ kfp2E

12ð1� v2Þt3

w

hwð6Þ

and the buckling coefficient kf is given by:

kf ¼ 5:82þ 2:1hw

a

� �2

þ 0:46ffiffiffib4

pð7Þ

where b is flange stiffness parameter and expresses as b ¼bf t3

f

hwt3w.

Various correction factors are proposed by researchers [2,6,10]where the effect of longitudinal stiffeners were related to relativeposition of the stiffener. On the other hand, Graciano [25] statedthat besides the location of the stiffener, flange to web thicknessand flange to web yield strength ratios also influenced patch loadresistance [17]. Graciano [25] presented the resistance of longitu-dinal stiffened web Frl as:

Frl ¼ Frofs ð8Þ

where Fro is the resistance of without longitudinal stiffened and thecorrection factor fs is obtained by regression analysis as:

fs ¼ 0:556� 0:277 lnb1

hw

fyf =fyw

tf =tw

� �� �ð9Þ

where bl is distance between flange and longitudinal stiffner and Fro

is obtained by Eqs. (1)–(9).It should be noted that this model is limited for girder webs

where the longitudinal stiffener is placed at a distance bl 6 0.3 hw.

2.2.2. Failure mechanism model (Model II)Roberts and Rockey [26] have used yield line mechanism meth-

od to describe the failure mode of plate girders subjected to con-centrated loading which is extracted from the deformedconfiguration of the plate girder at failure. Furthermore, they pro-posed a solution for the ultimate capacity of unstiffened plate gird-ers with slender webs subjected to concentrated loading based ona yield line mechanism composed of four plastic hinges in theflange and three yield lines in the web [17] (see Fig. 2). The provi-sions for concentrated loading contained in BS 5400 Part 3 [27] isbased on the work carried out by Roberts and Rockey [26].

Roberts and Rockey’s model was modified by Roberts and New-ark [28] where the position of the yield lines was assumed, lengthof web panel, a = 20tw, in comparison to a = 25tw used previously.Therefore, the position of the yield lines in the web is limited to2a, which is approximately 40 times the web thickness. Experi-mentally, a similar failure mechanism has been identified for plategirders subjected to concentrated loading and stiffened with flex-ural rigid stiffeners [17].

b1/hw b1/tw cs MS/MR

0.2 80 88–301 60.050.2 52–84 88–336 0.01–0.130.20–0.35 50–83 144 0.04–0120.20–0.35 44–55 132 0.67–0.690.20 33 44 0.770.1–0.5 12–125 3–247 <0.30.15–0.2 39–53 133–178 0.08–0.840.2 56 14–26 0.15–0.160.2 40 216 60.050.20–0.38 27–50 55–169 <0.20.1–0.18 15–25 73–98.5 0.08–0.11

β βsS

θθ θ δθ−

fδδ

α

α

Fig. 2. Failure mechanism proposed by Roberts and Rockey [26].

β βsS

θθ θ δθ−

fδδ

Longitudinal stiffener

α

α

Fig. 3. Failure mechanism modified by the presence of a longitudinal stiffener [17].

A. Cevik et al. / Advances in Engineering Software 41 (2010) 611–618 613

Roberts and Newark’s [28] model was later improved by Graci-ano and Edlund [19]. Fig. 3. shows the assumed collapse mecha-nism for longitudinally stiffened webs of this model is shown inFig. 3. The location of the yield lines, a, is restricted by a flexuralrigid stiffener placed at a distance bl measured from the loadedflange. In this failure mechanism model, an assumption was maderegarding the flexural rigidity of the stiffener, which results in theonset of a yield line within the upper subpanel of the web but alsoin a lower yield line. The central part of the lower yield line maydevelop at either the junction of the web with the longitudinalstiffener, or within the directly loaded subpanel as indicated inFig. 3 [17].

2.2.3. Post-critical resistance approach (Model III)This methodology is based on the post-critical strength of the

plate girders which is adopted by Lagerqvist and Johansson [14]by the use of stability checks using buckling curves for the patchloading resistance. In this sense, Graciano and Johansson [20] pro-posed a model according to the design philosophy of the Eurocode3 Part 1.5 [29] in order to include the effect of longitudinal stiffen-ing which has not been stated in Eurocode till then [17].

2.2.4. Design procedure in BS 5400The design procedure in BS 5400 Part 3 [27] is based on regres-

sion analysis conducted by Markovic and Hajdin [10] where theultimate strength of the stiffened plate girder subjected to concen-trated loading Frl is given as:

Frl ¼ 0:5t2w

ffiffiffiffiffiffiffiffiffiffiffiffiEfywtf

tw

s1þ 3ss

hw

tw

tf

� �3=2" # ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

1� rb

fyw

� �2s8<

:9=;fs ð10Þ

where rb is bending stress and the corresponding correction factorfs is given as

fs ¼ 1:28� 0:7ðbl=hwÞ ð11Þ

It should be noted that fs is limited between 1.0 and 1.21 for thisformulation.

2.2.5. Soft computing modelsPatch load resistance has been also been modeled by soft

computing techniques such as neural networks and fuzzy logic.Fonseca et al. developed a neural network system for patch load

prediction [30]. Fonseca et al. have also carried out parametricstudies based on the neural network model [31], and furthermorethey have proposed a neuro-fuzzy system for the parametric anal-ysis of patch load resistance [32]. On the other hand, Çevik has re-cently proposed a genetic programming-based formulation forload resistance [33].

3. Brief overview of stepwise regression

While dealing with large number of independent variables, it isof significance importance to determine the best combination ofthese variables to predict the dependent variable. Stepwise regres-sion serves as a robust tool for the selection of best subset models,i.e. the best combination of independent variables that best fits thedependent variable with considerably less computing than is re-quired for all possible regressions [34].

The determination of subset models are based on consecutivelyby adding or deleting, the variable/variables that has the greatestimpact on the residual sum of squares. The selection of variablesmay be either forward, backward or a combination of them. In for-ward selection, the subset models are chosen by adding one vari-able at a time to the previously chosen subset. At each successivestep, the variable in the subset of variables not already in the mod-el that causes the largest decrease in the residual sum of squares isadded to the subset. Without a termination rule, forward selectioncontinues until all variables are in the model. On the other hand,backward stepwise selection of variables chooses the subset mod-els by starting with the full model and then eliminating at eachstep the one variable whose deletion will cause the residual sumof squares to increase the least and continues until the subset mod-el contains only one variable [35].

Regarding forward and backward procedures, it should be notedthat the effect of adding or deleting a variable on the contributionsof other variables to the model is not being considered. Thus step-wise regression is actually a forward selection process that re-checks at each step the importance of all previously includedvariables. If the partial sums of squares for any previously includedvariables do not meet a minimum criterion to stay in the model,the selection procedure changes to backward elimination and vari-ables are dropped one at a time until all remaining variables meetthe minimum criterion. Stepwise selection of variables requiresmore computing than forward or backward selection but has anadvantage in terms of the number of potential subset modelschecked before the model for each subset size is decided. It is rea-sonable to expect stepwise selection to have a greater chance ofchoosing the best subsets in the sample data, but selection of thebest subset for each subset size is not guaranteed. The stoppingrule for stepwise selection of variables uses both the forward andbackward elimination criteria. The variable selection process ter-minates when all variables in the model meet the criterion to stayand no variables outside the model meet the criterion to enter [35].

4. Numerical application

The main aim in this study is to obtain a patch load formulationfor longitudinally stiffened webs as a function the followingparameters:

FSR ¼ f ðtw; a;hw; fyw; tf ; bf ; fyf ; ss; bl; tst ; bstÞ ð12Þ

where tst and bst are thickness and width of stiffners.Possible forms for all combinations of independent variables

used for the stepwise selection process are given as follows:

Xi; 1=Xi; X2 ð13Þ

where Xi stands for the independent variables given in Eq. (12).

Table 2Models considered in SR process (inputs vs. equations).

Model Inputs Equation

Linear x1, x2 y = b0 + b1 � x1 + b2 � x2

Linear + interaction x1, x2, x1 � x2 y = b0 + b1 � x1 + b2 � x2 + b3 � x1 � x2

Full quadratic x1, x2, x1 � x1, x2 � x2, x1 � x2 y = b0 + b1 � x1 + b2 � x2 + b3 � x1 � x1 + b4 � x1 � x2 + b5 � x2 � x2

Squared + interaction x1, x2, x1 � x1, x2 � x2, x1 � x2,x1 � x1 � x2, x1 � x2 � x2

y = b0 + b1 � x1 + b2 � x2 + b3 � x1 � x1 + b4 � x1 � x2 + b5 � x2 � x2 + b6 � x1 � x1 � x2 + b7 � x1 � x2 � x2

Table 3Statistical details and equations of best subsets for each stepwise regression model.

Model Equation of best subset Constants R2 COV

Linear ln F = b0 + b1 � tw + b2 � tf � tf + b3 � fyw � fyw + b4

� 1/ss + b5 � 1/tw + b6 � 1/fyf + b7 � 1/bf

+ b8 � bl + b9 � a � a + b10 � 1/fyw

b0 = 6.533, b1 = 0.232, b2 = 0.000621, 0.974 0.15b3 = �3.648e�07, b4 = �12.81, b5 = �2.230,b6 = �41.50, b7 = �30.25, b8 = �0.00130,b9 = �2.195e�08, b10 = �268.380

Linear + interaction F = b0 + b1 � fyw � tw � tw + b2 � tf � tf � fyf

� fyf + b3 � ss � 1/bl + b4 � a � 1/bl + b5 � tf � tf

� bf � bf + b6 � a � 1/ss + b7 � 1/bl � tw � tw

+ b8 � 1/hw � 1/bl + b9 � 1/tst � ss � ss + b10 � bst � a � a

b0 = �19.98, b1 = 0.02021, b2 = 4.40e�06, 0.981 0.19b3 = 106.30, b4 = �8.729, b5 = �2.78e�06,b6 = 3.808, b7 = 346.57, b8 = �1938415,b9 = 0.00388, b10 = �2.36e�07

Full quadratic F = b0 + b1 � tw � fyw + b2 � tw � tf + b3

� 1/ss � fyw � fyw + b4 � fyw � 1/tw + b5

� bl � fyw � fyw + b6 � hw � 1/ss + b7 � 1/tst � a� a + b8 � ss � 1/tf + b9 � bf � bf � bf � bf

+ b10v1/bl � bf � bf + b11 � 1/ss � a � a

b0 = �317.36, b1 = 0.275, b2 = 2.140, 0.979 0.37b3 = �0.07188, b4 = 1.516, b5 = �2.195e�06,b6 = 7.500, b7 = �4.467e�05, b8 = 3.350,b9 = �1.404e�08, b10 = 0.140, b11 = 0.000344

Squared + interaction F ¼ b0 þ b1 � ln fyf � 1= ln hw � ln ss

�1= ln a� tw � f 0:5yw � t0:5

f þ b2 � ln fyf � tw

�f 0:5yw � t0:5

f � ln hw � 1= ln tf � ln 1=bl � b0:5st

b0 = �45.06, b1 = 1.53, b2 = 0.01149 0.97 0.15

TEST vs. SR

R2 = 0.9649

0

200

400

600

800

1000

0 200 400 600 800 1000

F(TEST) (kN)

F(S

R)

(kN

)

Fig. 4. Overall performance of SR vs. experimental results.

0

0.5

1

1.5

2

2.5

3

0 25 50 75 100 125 150 175

Test No.

Test/BS5400 Test/SR

Fig. 5. Comparison of SR vs. BS 5400 Results (Test/SR) vs. (Test/BS 5400).

00.20.40.60.8

11.21.41.61.8

2

0 25 50 75 100 125 150 175

Test No.

Test/ModII Test/SR

Fig. 7. Comparison of SR vs. MODEL II Results (Test/SR) vs. (Test/MODEL II).

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

0 25 50 75 100 125 150 175

Test No.

Test/ModI Test/SR

Fig. 6. Comparison of SR vs. MODEL I Results (Test/SR) vs. (Test/MODEL I).

614 A. Cevik et al. / Advances in Engineering Software 41 (2010) 611–618

00.20.40.60.8

11.21.41.61.8

2

0 25 50 75 100 125 150 175

Test No.

Test/ModIII Test/SR

Fig. 8. Comparison of SR vs. MODEL III Results (Test/SR) vs. (Test/MODEL III).

A. Cevik et al. / Advances in Engineering Software 41 (2010) 611–618 615

Models considered for the stepwise regression process are givenin Table 2 for two independent variables (x1, x2) and one dependentvariable (y) with possible corresponding equations. All possiblecombinations of independent variables with models consideredand corresponding equation of best subset are given in Table 3.The stepwise regression analysis in this study is performed by SPSSand the following SR equation has been obtained for the best sub-set (R = 0.982):

FSR ¼ �55:000þ ln fyf tw

�ffiffiffiffiffiffiffiffiffiffifywtf

q1:530

ln ss

ln hw ln aþ 0:115

ln hw

ffiffiffiffiffiffibst

pln tf ln bl

!ð14Þ

The results of the proposed SR formulation vs. actual experimentalvalues and their comparison with current design codes are givenin Table A1. Statistical parameters of SR formulation comparedwith current design codes are also presented in Table A1. Theperformance of the proposed SR formula compared with existingtest results is presented in Fig. 4. The comparison of test to pre-dicted results for SR vs. BS 5400 Results (Test/SR) vs. (Test/BS5400), SR vs. MODEL I Results (Test/SR) vs. (Test/MODEL I), SR vs.MODEL II Results (Test/SR) vs. (Test/MODEL II), SR vs. MODEL III Re-sults (Test/SR) vs. (Test/MODEL III) are given in Figs. 5–8,respectively.

Model I has been developed on basis of a stiffener placed atbl > 0.3hw, applied bending moment Ms ratio to bending resistanceMR according to Eurocode 3 is limited to 0.5 for more accurate re-sults. On the other hand, Model has been III developed on basis of

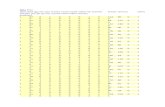

Table A1Comparative analysis of proposed SR formulation with experimental and numerical result

Nr. Ref. Test no. tw

(mm)a(mm)

hw

(mm)fyw

(MPa)tf

(mm)bf

(mm)fyf

(MPa)ss

(mm)bl

(m

1 [12] Panel 2-C1 5 1000 700 392 20 225 355 200 72 Panel 3-C2 5 1000 700 392 20 225 355 200 123 Panel 4-C2 5 1000 700 392 20 225 355 200 124 Panel 5-C3 5 1000 700 392 20 225 355 200 75 Panel 6-C3 5 1000 700 392 20 225 355 200 106 [11] Panel 1-2 4 1200 800 405 10 160 371 300 167 Panel 2-2 6 1200 800 447 15 200 364 300 308 Panel 4-4 6 1200 800 483 20 300 399 300 239 Panel 4-6 6 1800 800 483 20 300 399 300 16

10 Panel 5-1 6 1050 800 483 20 300 399 200 2311 Panel 6-2 6 1050 800 483 20 300 399 200 16

similar stiffener placing and is limited to the web panel aspect ratioa/hw < 1.0. Therefore, some of the values of Model I and Model IIIare excluded from the comparative study.

The results of the proposed SR formulation are found to bemore accurate than existing models and design code. It can be con-cluded that Model I, and Model III are not valid for some ranges ofparameters. However the proposed SR formulation is valid for allranges of parameters given in the experimental database. The pro-posed SR formulation is valid for the units of parameters given inTable A1.

5. Conclusions

Patch load formulations in literature are generally mechanicalmodels or empirical nonlinear regression formulations based onavailable test results. This paper presents an alternative novelway for the formulation of patch load resistance of longitudinallystiffened web girders using SR method which has not been usedso far. The proposed SR formulation is actually an empirical formu-lation based on a wide range of experimental database collectedfrom literature. It is quite accurate (standard deviation = 0.14)and shows a close agreement with experimental results(R = 0.993). For comparative analysis, Numerical results of thesame experimental database are obtained by existing models anddesign codes (BS 5400) and the proposed SR formulation is verifiedto be more accurate. The proposed SR formulation has significantadvantages as compared to existing models namely as Model Iand Model III so that it is valid for all ranges of variables given inthe database where these two models are not valid for some testresults for some ranges of parameters which exceed specified lim-its. The proposed SR formulation also considers the effects of allparameters on the ultimate resistance of steel girder webs to patchloading which has not been considered in existing models and de-sign codes so far. It should be noted that empirical formulations instructural engineering are mostly based on predefined functionswhere regression analysis of these functions are later performed.However in the case of SR approach there is no predefined functionto be considered, i.e. SR adds or deletes various combinations ofparameters to be considered for the formulation that best fits theexperimental results based on highest correlation coefficient.Therefore, SR may serve as a robust approach for the accurateand effective explicit formulation of many structural engineeringproblems.

Appendix A

See Table A1.

s. Exceeds limitations (—).

m)tst

(mm)bst

(mm)FTEST

(kN)FSR

(kN)Test/SR

Test/BS5400

Test/ModI

Test/ModII

Test/ModIII

5 5 60 699.1 537.92 1.30 2.31 1.37 1.29 1.845 5 60 507.4 525.53 0.97 1.75 1.1 1.19 1.225 10 80 520.6 541.74 0.96 1.79 1.12 1.22 1.375 10 80 559.9 556.05 1.01 1.85 1.1 1.03 1.60 10 80 582.1 547.60 1.06 1.96 1.21 1.23 1.590 5 60 436.5 308.98 1.41 2.56 1.64 1.73 1.60 5 60 632.1 600.13 1.05 1.75 — 1.19 —0 5 60 590.3 734.36 0.80 1.4 0.86 1.07 0.80 5 60 698 708.40 0.99 1.56 0.97 1.04 1.120 5 60 645.1 699.72 0.92 1.61 1.02 1.28 0.930 5 60 777.9 708.94 1.10 1.84 1.14 1.29 1.21

(continued on next page)

Table A1 (continued)

Nr. Ref. Test no. tw

(mm)a(mm)

hw

(mm)fyw

(MPa)tf

(mm)bf

(mm)fyf

(MPa)ss

(mm)bl

(mm)tst

(mm)bst

(mm)FTEST

(kN)FSR

(kN)Test/SR

Test/BS5400

Test/ModI

Test/ModII

Test/ModIII

12 [7] VT07-1 3.8 2480 1000 375 8.35 150 296 40 150 2 80 130 162.23 0.80 1.17 — 1.04 0.9113 VT07-2 3.8 1760 1000 375 8.35 150 296 40 150 2 80 176 168.04 1.05 1.52 1.07 1.4 1.1714 VT07-3 3.8 1760 1000 375 8.35 150 296 40 150 2 80 172 168.04 1.02 1.49 1.04 1.37 1.1415 VT07-4 3.8 2480 1000 375 8.35 150 281 40 200 2 90 135 160.58 0.84 1.25 — 1.07 0.9916 VT07-5 3.8 1760 1000 375 8.35 150 281 40 200 2 90 165 166.34 0.99 1.47 1.05 1.31 1.1417 VT07-6 3.8 1760 1000 375 8.35 150 281 40 200 2 90 170 166.34 1.02 1.51 1.09 1.35 1.1718 VT08-1 3.8 2480 1000 358 8.3 150 292 240 150 2 80 160 216.33 0.74 1.29 — 0.75 0.8819 VT08-2 3.8 1760 1000 358 8.3 150 292 240 150 2 80 280 224.71 1.25 2.11 1.33 1.3 1.4620 VT08-3 3.8 1760 1000 358 8.3 150 292 240 150 2 80 300 224.71 1.34 2.26 1.42 1.4 1.5621 VT08-4 3.8 2480 1000 358 8.3 150 328 240 200 2 90 199 221.93 0.90 1.71 — 1.02 1.1322 VT08-5 3.8 1760 1000 358 8.3 150 328 240 200 2 90 229 230.48 0.99 1.78 1.18 1.17 1.2323 VT08-6 3.8 1760 1000 358 8.3 150 328 240 200 2 90 235 230.48 1.02 1.82 1.21 1.2 1.2624 VT09-1 3.8 2480 1000 371 12 150 286 40 150 2 80 130 186.65 0.70 0.98 — 0.89 0.8825 VT09-2 3.8 1760 1000 371 12 150 286 40 150 2 80 198 193.53 1.02 1.46 1.07 1.35 1.2726 VT09-3 3.8 1760 1000 371 12 150 286 40 150 2 80 210 193.53 1.09 1.55 1.14 1.43 1.3527 VT09-4 3.8 2480 1000 371 12 150 283 40 150 2 90 145 191.17 0.76 1.1 — 0.99 1.0928 VT09-5 3.8 1760 1000 371 12 150 283 40 150 2 90 184 198.04 0.93 1.35 1 1.26 1.329 VT09-6 3.8 1760 1000 371 12 150 283 40 150 2 90 180 198.04 0.91 1.32 0.97 1.23 1.2730 VT10-1 3.8 2480 1000 380 12 150 282 240 150 2 80 247 262.38 0.94 1.79 — 1.07 1.2731 VT10-2 3.8 1760 1000 380 12 150 282 240 150 2 80 330 272.70 1.21 2.17 1.33 1.42 1.6132 VT10-3 3.8 1760 1000 380 12 150 282 240 150 2 80 315 272.70 1.16 2.07 1.27 1.36 1.5433 VT10-4 3.8 2480 1000 380 12 150 275 240 150 2 90 161 266.00 0.61 1.14 — 0.69 —34 VT10-5 3.8 1760 1000 380 12 150 275 240 150 2 90 275 276.27 1.00 1.81 1.11 1.17 1.2335 VT10-6 3.8 1760 1000 380 12 150 275 240 150 2 90 288 276.27 1.04 1.9 1.16 1.23 1.2636 [3] 731 3 3000 735 252 12 250 277 40 250 6 60 93.3 93.78 0.99 1.34 — 1.12 —37 732 3 1100 735 252 12 250 277 40 250 6 60 92.4 107.98 0.86 1.33 — 1.11 —38 733 3 1100 735 252 12 250 277 120 250 6 60 101 141.73 0.71 1.4 — 1.13 —39 734 3 3000 735 252 12 250 277 40 150 6 60 104.7 97.83 1.07 1.38 1.08 1.25 1.440 735 3 1100 735 252 12 250 277 40 150 6 60 101.8 112.03 0.91 1.34 1 1.22 1.1241 736 3 1100 735 252 12 250 277 120 150 6 60 106.3 145.78 0.73 1.35 0.93 1.19 1.0442 [6] TG 1-1 2 505 505 236 5 50 439 50 250 5 12 30 31.19 0.96 1.25 — 0.93 —43 TG 1-2 2 505 505 239 5 50 439 50 250 5 20 35 35.08 1.00 1.45 — 1.08 —44 TG 1-3 2 505 505 231 5 50 453 50 250 5 30 33.5 37.50 0.89 1.41 — 1.06 —45 TG 2-1 2 505 505 234 5 50 453 50 100 5 12 36.5 33.58 1.09 1.34 1.13 1.14 1.146 TG 2-2 2 505 505 232 5 50 446 50 100 5 20 35.6 37.08 0.96 1.31 1.1 1.12 147 TG 2-3 2 505 505 233 5 50 458 50 100 5 30 41 41.67 0.98 1.51 1.27 1.29 1.1248 TG 3-1 2 505 505 236 5 50 485 50 50 5 12 35 37.31 0.94 1.21 0.92 0.91 1.1149 TG 3-1 2 505 505 234 5 50 466 50 50 5 12 42 36.43 1.15 1.45 1.1 1.09 1.3450 TG 3-2 2 505 505 239 5 50 467 50 50 5 20 39 42.19 0.92 1.34 1.01 1 1.1951 TG 3-2 2 505 505 232 5 50 471 50 50 5 20 42 41.02 1.02 1.46 1.11 1.1 1.352 TG 3-3 2 505 505 231 5 50 461 50 50 5 30 47.5 45.30 1.05 1.66 1.26 1.24 1.4353 TG 3-3 2 505 505 233 5 50 481 50 50 5 30 42.5 46.31 0.92 1.48 1.13 1.11 1.2754 TG 11-1 2 1005 502.5 191 5 50 293 100 250 5 12 32 22.27 1.44 1.39 — 0.89 —55 TG 11-2 2 1005 502.5 210 5 50 472 100 250 5 20 34 34.70 0.98 1.41 — 0.89 —56 TG 11-3 2 1005 502.5 215 5 50 476 100 250 5 30 37.5 39.02 0.96 1.53 — 1.05 —57 TG 12-1 2 1005 502.5 204 5 50 295 100 100 5 12 32.5 26.62 1.22 1.2 0.98 1.86 1.0858 TG 12-2 2 1005 502.5 218 5 50 461 100 100 5 20 38 38.79 0.98 1.35 1.2 1.05 1.1559 TG 12-3 2 1005 502.5 218 5 50 470 100 100 5 30 38.2 42.99 0.89 1.36 1.21 1.06 1.160 TG 13-1 2 1005 502.5 191 5 50 303 100 50 5 12 29 26.71 1.09 1.04 0.79 0.68 1.0461 TG 13-1 2 1005 502.5 204 5 50 293 100 50 5 12 33 28.68 1.15 1.14 0.85 0.73 1.1462 TG 13-2 2 1005 502.5 210 5 50 475 100 50 5 20 44 40.69 1.08 1.5 1.21 1.08 1.4663 TG 13-2 2 1005 502.5 218 5 50 469 100 50 5 20 34 42.13 0.81 1.14 0.91 0.81 1.164 TG 13-3 2 1005 502.5 215 5 50 478 100 50 5 30 43 46.41 0.93 1.45 1.16 1.04 1.3965 TG 13-3 2 1005 502.5 218 5 50 473 100 50 5 30 40 46.89 0.85 1.34 1.07 0.96 1.2866 TG 31-1 6 622.5 500 256 12 120 242 62 200 5 40 315 305.89 1.03 1.49 — 1.22 —67 TG 31-18 6 622.5 500 256 12 120 242 62 200 5 40 300 305.89 0.98 1.42 — 1.16 —68 TG 31-2 6 622.5 500 256 12 120 242 62 125 5 40 342 311.99 1.10 1.46 1.14 1.13 1.0769 TG31-28 6 622.5 500 256 12 120 242 62 125 5 40 327 311.99 1.05 1.4 1.09 1.08 1.0370 TG 31-3 6 622.5 500 256 12 120 242 62 75 5 40 370 320.12 1.16 1.49 1.1 1.04 1.2771 TG31-38 6 622.5 500 256 12 120 242 62 75 5 40 395 320.12 1.23 1.59 1.17 1.11 1.3572 TG 32-1 6 622.5 500 256 12 120 242 62 200 5 40 285 305.89 0.93 1.35 — 1.1 —73 TG32-18 6 622.5 500 256 12 120 242 62 200 5 40 295 305.89 0.96 1.4 — 1.14 —74 TG 32-2 6 622.5 500 256 12 120 242 62 125 5 40 290 311.99 0.93 1.24 0.97 0.96 0.9175 TG32-28 6 622.5 500 256 12 120 242 62 125 5 40 299 311.99 0.96 1.28 1 0.99 0.9476 TG 32-3 6 622.5 500 256 12 120 242 62 75 5 40 351 320.12 1.10 1.41 1.04 0.99 1.277 TG32-38 6 622.5 500 256 12 120 242 62 75 5 40 338 320.12 1.06 1.36 1 0.95 1.1678 TG 33-1 6 622.5 500 256 12 120 242 62 200 5 40 296 305.89 0.97 1.4 — 1.15 —79 TG33-18 6 622.5 500 256 12 120 242 62 200 5 40 276 305.89 0.90 1.31 — 1.07 —80 TG 33-2 6 622.5 500 256 12 120 242 62 125 5 40 300 311.99 0.96 1.28 1 0.99 0.9481 TG33-28 6 622.5 500 256 12 120 242 62 125 5 40 282 311.99 0.90 1.21 0.94 0.93 0.8982 TG 33-3 6 622.5 500 256 12 120 242 62 75 5 40 372 320.12 1.16 1.5 1.1 1.05 1.2883 TG33-38 6 622.5 500 256 12 120 242 62 75 5 40 399 320.12 1.25 1.61 1.18 1.12 1.3784 TG 021-0 2.4 500 500 224 5.1 100 292 50 100 5.2 13.3 40 42.31 0.95 1.11 0.86 0.99 0.8885 TG 021-1 2.2 500 500 238 6.1 119.9 309 50 100 5.2 31.5 55 52.57 1.05 1.59 1.18 1.42 1.1886 TG 021-2 2.2 500 500 238 6 119.8 309 50 100 5 40.5 57.5 55.08 1.04 1.67 1.25 1.49 1.24

616 A. Cevik et al. / Advances in Engineering Software 41 (2010) 611–618

Table A1 (continued)

Nr. Ref. Test no. tw

(mm)a(mm)

hw

(mm)fyw

(MPa)tf

(mm)bf

(mm)fyf

(MPa)ss

(mm)bl

(mm)tst

(mm)bst

(mm)FTEST

(kN)FSR (kN) Test/

SRTest/BS5400

Test/ModI

Test/ModII

Test/ModIII

87 TG 021-3 2.2 500 500 238 6 120.2 309 50 100 5.3 50.2 62 58.05 1.07 1.8 1.34 1.61 1.3388 TG 022-1 2.2 500 500 238 11.7 119.9 239 50 100 5.7 30.9 65 75.77 0.86 1.41 0.99 1.26 1.2189 TG 022-2 2.2 500 500 238 11.9 119.3 239 50 100 5 40.5 66.5 79.88 0.83 1.43 1.01 1.28 1.2390 TG 022-3 2.2 500 500 238 11.9 119.7 239 50 100 5.1 50.1 59 82.75 0.71 1.27 0.89 1.13 1.0991 TG 041-0 4.4 500 500 362 8.5 118.6 262 50 100 5.1 17.2 192 206.45 0.93 1.29 0.89 1 1.0592 TG 041-1 4 500 500 360 8.4 119.3 262 50 100 8.1 40.7 190 201.73 0.94 1.51 1.03 1.17 1.0893 TG 041-2 4 500 500 360 7.8 119.1 262 50 100 8.1 50 202 200.89 1.01 1.64 1.13 1.28 1.1794 TG 041-3 4 500 500 360 8.5 119.2 262 50 100 8.5 60.5 193.5 215.36 0.90 1.53 1.05 1.19 1.195 TG 042-1 4 500 500 360 20 120.9 285 50 100 7.8 39.3 315 314.58 1.00 1.73 1.18 1.28 1.4796 TG 042-2 4 500 500 360 20 120.6 285 50 100 8.4 50.7 290 323.03 0.90 0.95 1.06 0.67 1.3297 TG 042-3 4 500 500 360 20 120.4 285 50 100 8.4 60.4 276 329.50 0.84 0.9 1.01 0.64 1.2698 TG 061-0 5.6 500 500 426 11.9 120.2 239 50 100 7.9 22.8 339 358.69 0.95 1.25 0.82 1.02 1.0399 TG 061-1 5.6 500 500 426 12.3 89.7 277 50 100 10 32.2 387 388.25 1.00 1.42 0.97 1.1 1.12

100 TG 061-2 5.5 500 500 455 12.3 89.7 277 50 100 11 51.1 408 415.84 0.98 1.49 1 1.16 1.1101 TG 061-3 5.5 500 500 455 12.1 89.4 277 50 100 9.9 60.1 420 421.36 1.00 1.54 1.04 1.2 1.14102 TG 062-1 5.6 500 500 426 30.4 99 254 50 100 10 32.4 564 593.15 0.95 1.4 0.91 1.02 1.27103 TG 062-2 5.6 500 500 426 30.5 100 254 50 100 10 50.7 592 617.02 0.96 1.47 0.95 1.06 1.25104 TG 062-3 5.6 500 500 426 30 100.1 254 50 100 10 60.5 610 622.63 0.98 1.52 0.99 1.11 1.3105 TG 121-1 2 500 500 244 6 119.6 274 50 100 5.2 16.6 55 36.67 1.50 1.84 1.32 1.62 1.47106 TG 121-2 2 500 500 244 6 119.9 274 50 100 5.2 20.2 50 38.23 1.31 1.67 1.2 1.47 1.29107 TG 121-3 2 500 500 244 6.1 119.9 274 50 100 5.2 24.9 57 40.61 1.40 1.89 1.36 1.67 1.44108 TG 122-1 2 500 500 244 12.1 120.7 254 50 100 5.1 15.8 84 63.09 1.33 2.05 1.42 1.83 1.87109 TG 122-2 2 500 500 244 12.1 120.7 254 50 100 5.2 20.2 72 65.04 1.11 1.76 1.22 1.57 1.54110 TG 122-3 2 500 500 244 12.1 120.8 254 50 100 5.1 25.2 76 67.01 1.13 1.86 1.28 1.65 1.6111 TG 141-1 4 500 500 283 8.4 120.1 294 50 100 8.1 20.2 171 163.06 1.05 1.53 1.13 1.17 1.21112 TG 141-2 4 500 500 283 8.5 120.2 294 50 100 8.3 30.6 156 172.47 0.90 1.39 1.03 1.07 1.03113 TG 141-3 4 500 500 283 8.3 120.4 294 50 100 8.1 34.4 185 173.08 1.07 1.66 1.23 1.28 1.19114 TG 142-1 4 500 500 283 20.3 120.9 270 50 100 8.2 19.8 256.5 256.94 1.00 1.58 1.08 1.17 1.42115 TG 142-2 4 500 500 283 20.4 120.9 270 50 100 8.4 30.2 248 266.77 0.93 1.52 1.04 1.13 1.29116 TG-142-3 4 500 500 283 20.2 120.7 270 50 100 8 35.9 257 269.73 0.95 1.58 1.08 1.18 1.3117 TG-161-1 5.4 500 500 396 12.4 90.7 272 50 100 10 25 336 349.07 0.96 1.35 0.93 1.03 1.1118 TG-161-2 5.4 500 500 396 12.3 90.8 272 50 100 11 30.2 387.5 354.16 1.09 1.56 1.08 1.2 1.24119 TG 161-3 5.4 500 500 396 12.4 90.7 272 50 100 11 34.7 399 360.71 1.11 1.6 1.11 1.23 1.25120 TG 162-1 5.4 500 500 396 30.4 99.6 269 50 100 10 25.6 610 544.92 1.12 1.66 1.09 1.17 1.54121 TG 162-2 5.4 500 500 396 30.6 99.3 269 50 100 11 30.3 600 553.42 1.08 1.63 1.07 1.15 1.48122 TG 162-3 5.4 500 500 396 30.6 100.2 269 50 100 11 33.9 605 558.21 1.08 1.64 1.07 1.15 1.46123 TG 241-1 4.1 500 500 304 8.3 120.3 278 50 50 5.2 16 201 174.58 1.15 1.57 1.04 1.02 1.43124 TG 241-18 4.1 500 500 304 8.3 120.4 278 50 50 5.1 16 196 174.58 1.12 1.54 1.02 1 1.4125 TG 241-2 4.1 500 500 304 8.2 120.8 278 50 50 8.1 20.8 186 179.09 1.04 1.46 0.97 0.95 1.31126 TG 241-28 4.1 500 500 304 8.1 120.6 278 50 50 8.1 21.5 199 178.74 1.11 1.57 1.04 1.02 1.4127 TG 241-3 4.1 500 500 304 8.2 120.3 278 50 50 8.3 25.5 199 183.98 1.08 1.57 1.04 1.02 1.38128 TG 241-38 4.1 500 500 304 8.2 120.8 278 50 50 8.2 25.5 186 183.98 1.01 1.46 0.97 0.95 1.29129 TG 241 -4 4.1 500 500 304 8.1 120.7 278 50 50 8.2 30.3 187 187.41 1.00 1.48 0.98 0.96 1.28130 TG 241-48 4.1 500 500 304 8.4 120.6 278 50 50 8.2 30.4 210 190.81 1.10 1.64 1.08 1.06 1.43131 TG 241-5 4.1 500 500 304 8.1 120.7 278 50 50 7.9 35.1 192 191.61 1.00 1.52 1 0.99 1.3132 TG 241-6 4.1 500 500 304 8.2 120.7 278 50 50 8.1 40.5 208 197.11 1.06 1.64 1.08 1.06 1.38133 TG 242-1 4.1 500 500 304 19.7 118.2 244 50 50 5.2 15.4 243 267.22 0.91 1.33 0.85 0.83 1.4134 TG 242-18 4.1 500 500 304 19.7 118.6 244 50 50 5.2 15.8 237 267.76 0.89 1.29 0.83 0.8 1.36135 TG 242-2 4.1 500 500 304 19.8 118.5 244 50 50 8.1 20.6 267 274.51 0.97 1.45 0.93 0.9 1.51136 TG 242-28 4.1 500 500 304 19.9 118.4 244 50 50 8.1 20.4 259 275.00 0.94 1.41 0.9 0.87 1.46137 TG 242-3 4.1 500 500 304 19.8 118.6 244 50 50 8.3 24.6 255 279.01 0.91 1.39 0.89 0.86 1.42138 TG 242-38 4.1 500 500 304 19.9 118.7 244 50 50 8.3 24.5 261 279.63 0.93 1.42 0.91 0.88 1.45139 TG 242-4 4.1 500 500 304 19.7 118.6 244 50 50 8.3 30.2 264 284.00 0.93 1.44 0.92 0.9 1.45140 TG 242-48 4.1 500 500 304 19.6 118.3 244 50 50 8.2 30.9 266 283.94 0.94 1.46 0.93 0.91 1.46141 TG 242-5 4.1 500 500 304 19.6 118.3 244 50 50 8 35.1 270 287.85 0.94 1.48 0.95 0.92 1.47142 TG 242-6 4.1 500 500 304 19.6 118.4 244 50 50 8.1 40.4 285 292.45 0.97 1.56 1 0.86 1.53143 [1] R2 2.1 802 798 266 15.55 300.5 286 40 168 6.1 60 71 83.76 0.85 1.39 0.86 1.23 1.12144 R4 2 800 798 266 5.07 120.4 285 40 162 4 40 45 31.82 1.41 1.6 1.11 1.39 1.15145 [2] R22 ss 2 800 800 266 15 300 295 40 168 6.1 60 68.5 76.51 0.90 1.47 0.91 1.3 1.18146 R42 ss 2 800 800 266 5 120 285 40 162 4 40 42.5 31.49 1.35 1.52 1.05 1.32 1.09147 A12 s 2 2500 800 300 15 300 295 40 160 6 60 80 70.32 1.14 1.6 1.04 1.44 1.49148 A14 s 2 1200 800 300 15 300 295 40 160 6 60 78 78.85 0.99 1.56 0.99 1.4 1.34149 A16 s 2 600 800 300 15 300 295 40 160 6 60 92 88.70 1.04 1.84 — 1.64 —150 A22 s 3 2500 800 245 12 250 265 40 160 6 60 132.6 95.73 1.39 1.77 1.39 1.61 1.75151 A24 s 3 1200 800 245 12 250 265 40 160 6 60 97.5 105.87 0.92 1.3 0.98 1.18 1.12152 A26 s 3 600 800 245 12 250 265 40 160 6 60 121.4 117.58 1.03 1.62 — 1.47 —153 A32 s 2 2200 680 354 5 120 290 40 136 4 40 45.8 37.19 1.23 1.41 1 1.2 1.23154 A34 s 2 1020 680 354 5 120 290 40 136 4 40 54.4 43.15 1.26 1.68 1.14 1.43 1.25155 A36 s 2 510 680 354 5 120 290 40 136 4 40 54.7 49.78 1.10 1.68 — 1.44 —156 [8] Model 4 3.2 897.1 899.1 270 8 181.2 266 90 180 4.7 29.7 105.42 111.35 0.95 1.92 1.49 1.75 —157 Model 5 3.2 892.2 901.5 270 8 180.4 266 90 180 4.7 38.2 110.36 115.81 0.95 1.94 1.41 1.5 —158 [4] P2 6 1780 1274 279 40 230 244 690 327 12 110 720 746.84 0.96 1.41 0.97 1.19 1.08159 P3 6 1780 1274 286 40 230 267 690 264 12 110 730 775.40 0.94 1.48 1.02 1.24 1.08

(continued on next page)

A. Cevik et al. / Advances in Engineering Software 41 (2010) 611–618 617

Table A1 (continued)

Nr. Ref. Test no. tw

(mm)a(mm)

hw

(mm)fyw

(MPa)tf

(mm)bf

(mm)fyf

(MPa)ss

(mm)bl

(mm)tst

(mm)bst

(mm)FTEST

(kN)FSR (kN) Test/

SRTest/BS5400

Test/ModI

Test/ModII

Test/ModIII

160 [5] EL1 6 1000 1000 325 9 300 235.2 300 200 6 80 438.2 387.12 1.13 1.68 — 1.19 1.17161 [9] Test 4 3.2 635 635 303 12.7 152.4 303 127 127 4.8 74.4 130 215.74 0.60 1.63 — 1.21 1.2162 Test 5 3.2 635 635 275 6.35 152.4 275 127 127 4.8 74.4 85 142.28 0.60 1.42 — 0.9 0.96

Mean: 1.011 1.517 1.092 1.155 1.256Std. Dev. 0.155 0.250 0.175 0.216 0.198

COV 0.154 0.165 0.160 0.187 0.158

618 A. Cevik et al. / Advances in Engineering Software 41 (2010) 611–618

References

[1] Rockey K, Bergfelt A, Larsson L. Behaviour of longitudinally reinforced plategirders subjected to in-plane patch loading. Rep. S78:19, Chalmers Univ. ofTechnology, Division of Steel and Timber Structures, Göteborg, Sweden;1978.

[2] Bergfelt A. Patch loading on a slender web—influence of horizontal and verticalweb stiffeners on the load-carrying capacity. Rep. S79:1, Chalmers Univ. ofTechnology, Division of Steel and Timber Structures, Göteborg, Sweden; 1979.

[3] Bergfelt A. Girder web stiffening for patch loading. Rep. S83:1, Chalmers Univ.of Technology, Division of Steel and Timber Structures, Göteborg, Sweden;1983.

[4] Galea Y, Godart B, Radouant I, Raoul J. Test of buckling of panels subjected toin-plane patch loading. In: Proc ECCS colloquium on stability of plate and shellstructures, Ghent, Belgium; 1987. p. 65–71.

[5] Shimizu S, Yoshida S, Okuhara H. An experimental study on patch loaded webplates. In: Proc ECCS colloquium on stability of plate and shell structures,Ghent, Belgium; 1987. p. 85–94.

[6] Janus K, Kutmanova I, Skaloud M. Experimental investigation into the ultimateload behaviour of longitudinally stiffened steel webs under partial edgeloading. Acta Tech CSAV Prague 1988;2:158–95.

[7] Dubas P, Tschamper H. Stabilité des âmes soumises à une charge concentré et àune flexion globale. Constr Metall 1990;2:25–39 [in French].

[8] Dogaki M, Murata M, Kishigami N, Tanabe T, Yonezawa H. Ultimate strength ofplate girders with longitudinal stiffeners under patch loading. Technol. Rep.Kansai Univ., Japan, vol. 33; 1990. p. 121–32.

[9] Salkar R. Strength and behavior of webs, with and without stiffeners underlocal compressive in-plane and eccentric loads, vols. I and II. PhD thesis, Univ.of Maine, Orono, Maine; 1992.

[10] Markovic N, Hajdin N. A contribution to the analysis of the behaviour of plategirders subjected to patch loading. J Constr Steel Res 1992;21:163–73.

[11] Carretero A, Lebet J-P. Introduction des forces concentrées dans les poutresélancées. Constr Metall 1998;1:5–18 [in French].

[12] Walbridge S, Lebet J-P Patch loading tests of bridge girders with longitudinalweb stiffeners. Rapport d’essais École Polytechnique Fédérale de Laussane,ICOM 447; 2001 [in French].

[13] Lagerqvist O, Johansson B. Resistance of plate edges to concentrated forces. JConstr Steel Res 1995;32(1):69–105.

[14] Lagerqvist O, Johansson B. Resistance of I-girders to concentrated loads. JConstr Steel Res 1996;39(2):87–119.

[15] Granath P. Behavior of slender plate girders subjected to patch loading. JConstr Steel Res 1997;42(1):1–19.

[16] Grogan W, Surtees JO. Experimental behaviour of end plate connectionsreinforced with bolted backing angles. J Constr Steel Res 1999;50(1):71–96.

[17] Graciano C. Patch loading – resistance of longitudinally stiffened steel girderwebs. PhD thesis, Lulea University Of Technology; 2002.

[18] Graciano C, Edlund B. Nonlinear FE analysis of longitudinally stiffened girderwebs under patch loading. J Constr Steel Res 2002;58(9):1231–45.

[19] Graciano C, Edlund B. Failure mechanism of slender girder webs with alongitudinal stiffener under patch loading. J Constr Steel Res2003;59(1):27–45.

[20] Graciano C, Johansson B. Resistance of longitudinally stiffened I-girderssubjected to concentrated loads. J Constr Steel Res 2003;59(5):561–86.

[21] Lucic D. Experimental research on I-girders subjected to eccentric patchloading. J Constr Steel Res 2003;59(9):1147–57.

[22] Carlos Graciano, Ove Lagerqvist. Critical buckling of longitudinally stiffenedwebs subjected to compressive edge. J Constr Steel Res 2003;59(9):1119–46.

[23] Carlos Graciano, Euro Casanova. Ultimate strength of longitudinally stiffened I-girder webs subjected to combined patch loading and bending. J Constr SteelRes 2005;61(1):93–111.

[24] Graciano C. Strength of longitudinally stiffened Webs subjected toconcentrated loading. J Struct Eng 2005;131(2):268–78.

[25] Graciano C. Ultimate resistance of longitudinally stiffened webs subjected topatch loading. Thin-Walled Struct 2003;41(6):529–41.

[26] Roberts TM, Rockey KC. A mechanism solution for predicting the collapse loadsof slender plate girders when subjected to in-plane patch loading. Proc Inst CivEng Struct Build 1979;67(2):155–75.

[27] British Standards Institution (BSI). Steel, concrete, and composite bridges. BS5400, Part 3, British Standards Institution, Milton Keynes, UK; 2000.

[28] Roberts TM, Newark ACB. Strength of webs subjected to compressive edgeloading. J Struct Eng 1997;123(2):176–83.

[29] European Committee for Standardization (CEN). Design of steel structures—general rules, part 1.5. prENV 1993-1-5:1997E, Eurocode 3, Brussels; 1997.

[30] Fonseca ET, Vellasco PCG da S, de Andrade SAL, Vellasco MMBR. Neuralnetwork evaluation of steel beam patch load capacity. Adv Eng Softw2003;34(11–12):763–72.

[31] Fonseca Elaine T, Vellasco Pedro CGda S, de Andrade Sebastião AL, VellascoMarley MBR. A patch load parametric analysis using neural Networks. J ConstrSteel Res 2003;59(2):251–67.

[32] Fonseca ET, de Andrade SAL, Vellasco PCGD, et al. A parametric analysis of thepatch load behaviour using a neuro-fuzzy system. J Constr Steel Res2007;63:194–210.

[33] Çevik A. A new formulation for longitudinally stiffened webs subjected topatch loading. J Constr Steel Res 2007;63:1328–40.

[34] Campbell MJ. Statistics at square two: understanding modern statisticalapplications in medicine. London, GBR: BMJ Publishing Group; 2001.

[35] Rawlings John O. Applied regression analysis: a research tool. NewYork: Springer-Verlag; 1998.