A Flexible Porous Carbon Nanofibers‐Selenium Cathode with...

Transcript of A Flexible Porous Carbon Nanofibers‐Selenium Cathode with...

FULL P

APER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (1 of 10) 1401377wileyonlinelibrary.com

A Flexible Porous Carbon Nanofi bers-Selenium Cathode with Superior Electrochemical Performance for Both Li-Se and Na-Se Batteries

Linchao Zeng , Wencong Zeng , Yu Jiang , Xiang Wei , Weihan Li , Chenglong Yang , Yanwu Zhu ,* and Yan Yu*

L. Zeng, W. Zeng, Y. Jiang, X. Wei, W. Li, C. Yang, Prof. Y. Zhu, Prof. Y. Yu CAS Key Laboratory of Materials for Energy Conversion Department of Materials Science and Engineering University of Science and Technology of China Anhui Hefei 230026 , China E-mail: [email protected]; [email protected]

DOI: 10.1002/aenm.201401377

storage. [ 5–14 ] Lithium-sulfur (Li-S) batteries have attracted particular interest and are regarded as promising next-generation rechargeable battery due to its high theo-retical specifi c capacity (1672 mAh g −1 ) and high energy density (2600 Wh kg −1 ). [ 15–20 ] Additionally, sulfur is cheap, abundant, and environmentally friendly. [ 19–22 ] How-ever, the practical application of Li-S bat-tery has been hampered by two major issues: [ 23–26 ] (1) Sulfur has a low electronic conductivity (5 × 10 −30 S cm −1 at 25 °C), which results in poor electrochemical accessibility and low utilization of the sulfur in the electrode. (2) The electrolyte-soluble polysulfi de intermediate products formed during the charge/discharge pro-cess can dissolve in the liquid electrolyte, which causes the well-known shuttle effect and leads to the rapid loss of capacity. Var-ious strategies have been used to address these issues, including using optimized electrolyte, [ 27 ] conducting polymer-coated sulfur cathodes, [ 28,29 ] constructing porous carbon matrix. [ 30,31 ] and designing new

confi guration. [ 32 ] However, the intrinsic drawbacks of Li-S bat-teries have not been completely solved.

Recently, many efforts have been made to explore novel electrode materials. [ 33 ] Selenium, owing to its similar chemical properties with sulfur, has been regarded as the most promising electrode material for Li-Se batteries because of its higher elec-tronic conductivity (1 × 10 −3 S m −1 ) and high volumetric capacity of Se (3253 Ah L −1 ). [ 25,33–38 ] In addition, Na-Se batteries have recently regained many interests due to the abundance, low cost, and environmentally benign of sodium. Similar to S, how-ever, the Se cathodes also have the issues of poor cycle perfor-mance and low Coulombic effi ciency (CE), which are ascribed to the dissolution of high-order polyselenides. [ 25,33,34,38,39 ]

Several approaches have been used to address these problems of Li-Se and Na-Se batteries. Combination of mesoporous carbon with Se has been demonstrated as one of the most effective approaches to increase the utilization of Se and to alleviate the shuttle effect of polyselenides. [ 25,33,34 ] Recently, Guo et al. [ 34 ] con-fi ned Se in the form of cyclic Se 8 in ordered mesoporous carbon by a facile melt-diffusion route. Cyclic Se 8 molecules converted

A fl exible and free-standing porous carbon nanofi bers/selenium composite electrode (Se@PCNFs) is prepared by infi ltrating Se into mesoporous carbon nanofi bers (PCNFs). The porous carbon with optimized mesopores for accommodating Se can synergistically suppress the active material dissolu-tion and provide mechanical stability needed for the fi lm. The Se@PCNFs electrode exhibits exceptional electrochemical performance for both Li-ion and Na-ion storage. In the case of Li-ion storage, it delivers a revers-ible capacity of 516 mAh g −1 after 900 cycles without any capacity loss at 0.5 A g −1 . Se@PCNFs still delivers a reversible capacity of 306 mAh g −1 at 4 A g −1 . While being used in Na-Se batteries, the composite electrode main-tains a reversible capacity of 520 mAh g −1 after 80 cycles at 0.05 A g −1 and a rate capability of 230 mAh g −1 at 1 A g −1 . The high capacity, good cyclability, and rate capability are attributed to synergistic effects of the uniform distri-bution of Se in PCNFs and the 3D interconnected PCNFs framework, which could alleviate the shuttle reaction of polyselenides intermediates during cycling and maintain the perfect electrical conductivity throughout the elec-trode. By rational and delicate design, this type of self-supported electrodes may hold great promise for the development of Li-Se and Na-Se batteries with high power and energy densities.

1. Introduction

Rechargeable lithium-ion batteries (LIBs) are critical power sources for portable electronic devices applications as well as large-scale stationary energy storage. [ 1 ] Conventional LIBs based on traditional-metal-oxides cathodes (e.g., LiCoO 2 , [ 2 ] LiMn 2 O 4 , [ 3 ] LiFeO 4 , [ 4 ] etc.) and graphite anode with low theoretical specifi c energy density cannot meet the crucial demands in electric vehicles (EVs), plug-in hybrid vehicles (HEVs), and grid energy

Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

FULL

PAPER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim1401377 (2 of 10) wileyonlinelibrary.com

to chain-like Se n molecules during charge and displayed excel-lent cycling performance (600 mAh g −1 at a current density of 67 mA g −1 after 50 cycles). The excellent electrochemical perfor-mance was attributed to the strong interaction between chain-like Se n molecules and mesoporous carbon, thus alleviating the dis-solution and shuttle effect of polyselenides. Luo et al. [ 25 ] reported remarkable electrochemical performance of Se/mesoporous carbon composites for both of the Li-Se batteries (480 mAh g −1 for 1000 cycles without any capacity loss at 0.25 C) and Na-Se bat-teries (340 mAh g −1 after 380 cycles at 0.25 C). The mesoporous carbon has stabilized polyselenide intermediates, preventing the shuttle reaction of polyselenides and leading to the improved electrochemical performance. [ 25,34 ] For these reported Se-based electrode, auxiliary additives (such as carbon black and binders) are often introduced to electrode for improving the mechanical integrity and electronic conductivity of the electrodes, which has decreased the relative proportion of active material (Se) and thus led to lower energy density of Li-Se or Na-Se batteries. [ 32,40,41 ] In order to further improve the volumetric energy and power den-sity of batteries, it is ideal to design a fl exible, free-standing, and binder-free electrode, in which all the materials could participate in lithium (or sodium) storage. [ 32,40,42 ] In addition, this confi gura-tion can signifi cantly simplify the cell packing process.

Herein, we have designed and developed an additive-free fl exible fi lm electrode by confi ning Se in the 3D interconnected mesoporous carbon nanofi bers (denoted as Se@PCNFs) for high-performance Li-Se and Na-Se batteries. As a cathode mate-rial for Li-Se batteries, it delivered a reversible specifi c capacity

of 643 mAh g −1 after 100 cycles at 0.05 A g −1 and remained a capacity of ≈535 mAh g −1 at 1 A g −1 . Meanwhile, it also displayed outstanding long cycle stability. The Se@PCNFs delivered charge capacities of 555 mAh g −1 for the fi rst cycle and 516 mAh g −1 for the 900th cycle at a current density of 0.5 A g −1 , corresponding to an extremely low decay rate (0.0078% per cycle after initial capacity loss). In the case of sodium storage, it exhibits a high reversible capacity (520 mAh g −1 after 80 cycles at 0.05 A g −1 ) and improved rate performance (≈230 mAh g −1 at 1 A g −1 ). The excellent cyclability and rate capability can be attributed to the following reasons: Firstly, the fl exible and free-standing porous carbon with optimized mesopores for Se accommodation can synergistically suppress the active material dissolution and pro-vide mechanical stability of the fi lm. [ 43 ] Secondly, the mesopores could increase the energy barrier between carbon pore walls and polyselenide, which reduce the driving force of the polyselenide diffusion into the electrolyte, thereby decreasing the Se cathode dissolution. [ 34 ] Finally, the excellent electronic conductivity of 3D interconnected PCNFs framework will profoundly reduce the time required for electron and ion transport during the cycling, while the high porosity of the PCNFs facilitates ion diffusion in the electrolyte, all of which are essential for high power density.

2. Results and Discussion

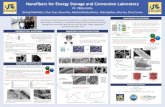

Figure 1 schematically illustrates the experimental process. The precursor solution of polyacrylonitrile(PAN)-triblock copolymer

Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

Figure 1. A,B) Schematic illustration of the synthesis process of the Se@PCNFs electrode. C,D) Photograph of free-standing and fl exible Se@PCNFs electrode.

FULL P

APER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (3 of 10) 1401377wileyonlinelibrary.com

Pluronic F127/N,N-dimethylformamide (PAN-F127/DMF) was electrospun into fi bers (Figure 1 A). Then, the fi bers were stabi-lized in air at 280 °C, followed by carbonization in N 2 at 800 °C. During the carbonization process, the triblock copolymer Plu-ronic F127 acts as soft template to create more pores in the fi bers. Subsequently, the obtained fi bers were chemically acti-vated with KOH in N 2 atmosphere to further create pores [ 44 ] and to obtain mesoporous carbon nanofi bers (denoted as PCNFs). Finally, after heating the mixture of Se and PCNFs, Se infi l-trated into the pores of PCNFs and Se/carbon composite (Se@PCNFs) was obtained (Figure 1 B). For comparison, a simulta-neous electrospun, carbonization–activation, and selenation process was sequentially carried out to prepare Se@f-PCNFs by using an F127-free solution of PAN/DMF for the electrospin-ning process. The obtained Se/carbon composites (Se@PCNFs or Se@f-PCNFs) were directly used as fl exible cathode mate-rials for Li-Se (or Na-Se) batteries (Figure 1 C,D).

Figure 2 A reveals morphologies of the electrospun PAN-F127 nanofi bers with fi eld-emission scanning electron microscopy (FESEM). The PAN-F127 nanofi bers exhibit long, continuous, and interconnected structure. The diameter of PAN-F127 fi bers is about 400 nm. After carbonization and activation under N 2 atmosphere, the morphology of PAN-F127 fi bers keeps intact except that the diameter is decreased to about 250 nm, which results from the decomposition of organic components of the PAN and F-127 (Figure 2 B). [ 45 ] After Se diffuses into PCNFs, the PCNFs maintain the macromorphology and no Se residues are observed on the surfaces of the nanofi bers (Figure 2 C). Figure 2 D, E, F reveals the morphology of PAN nanofi bers, f-PCNFs, and Se@f-PCNFs, showing a similar morphology with PAN-F127 nanofi bers, PCNFs, and Se@PCNFs, respectively.

The transmission electron microscopy (TEM) and high-res-olution transmission electron microscopy (HRTEM) images ( Figure 3 A, B) reveal that the large quantities of micropores and mesopores are homogeneously distributed within amorphous PCNFs. Scanning transmission electron microscopy (STEM) image of Se-PCNFs in Figure 3 C exhibits a smooth surface, indicating that the Se successfully infi ltrates into the carbon

nanofi bers. In addition, element mapping of Se and carbon reveals a uniform distribution of Se in PCNFs (Figure 3 D, E).

The crystallographic structure and phase purity of Se@PCNFs and Se@f-PCNFs were analyzed by X-ray powder dif-fraction (XRD) ( Figure 4 A). All characteristic peaks of Se in the XRD patterns of Se@PCNFs disappear after the selena-tion process, indicating a fi ne dispersion of Se into PCNFs. [ 34 ] In the case of Se@f-PCNFs, the characteristic peaks of Se can be clearly detected, which results from incomplete infi ltra-tion of Se into f-PCNFs. Compare the Raman peak of Se, Se@ f-PCNFs, and Se@PCNFs, the intensity of the characteristic peak of Se remarkably reduced and blueshifted in the Se@PCNFs sample (inset of Figure 4 B), which maybe a result from the Se infi ltrated in the pores of PCNFs and a possible change in the existing form of Se (Figure 4 B). [ 34 ] Two broad peaks at about 1580 cm −1 (G-band) and 1350 cm −1 (D-band) are detected from both Se@PCNFs and Se@f-PCNFs, corresponding to the E 2g2 graphitic mode and the defect-induced mode, respec-tively. [ 44 ] The defective nature of the materials is refl ected from the intensity ratio ( R = I D / I G ) in Raman spectra. The R value of Se@PCNFs and Se@f-PCNFs is 0.997 and 0.993, respectively. This indicates that both PCNFs and f-PCNFs contain amor-phous carbon, which is in good agreement with the HRTEM results. The Se content in the Se@PCNFs and Se@f-PCNFs is 52.3% and 50.0%, respectively (Figure S1, Supporting Informa-tion), determined by thermogravimetry (TG) analyses.

Nitrogen adsorption–desorption tests were used to fur-ther examine the surface and to characterize the pore size of the samples. Figure 4 C, D shows the Brunauer-Emmett-Teller (BET) adsorption/desorption curves and pore-size distribu-tion of the PCNFs and Se@PCNFs, respectively. The spe-cifi c surface area of PCNFs is 936 m 2 g −1 (Figure 4 C), which is much larger than that of the F127-free sample (f-PCNFs) (623 m 2 g −1 ) (Figure 4 E), implying the Pluronic F127 plays an important role in the synthesis of the carbon nanofi bers with microporous structure. After Se loading, the BET surface area of PCNFs (Figure 4 C) decreases to 85 m 2 g −1 , accompanied by a signifi cantly reduction in pore-size distribution in the

Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

Figure 2. FESEM images of A) as electrospun PAN-F127 nanofi bers, B) PCNFs, C) Se@PCNFs, D) PAN nanofi bers, E) f-PCNFs, and F) Se@f-PCNFs. The insets are corresponding high magnifi cation images.

FULL

PAPER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim1401377 (4 of 10) wileyonlinelibrary.com

mesoporous region (2–8 nm) (Figure 4 D). This change is attri-buted to the impregnation of Se into the mesoporous channels of PCNFs and most of the Se existence would like to be cyclic Se 8 molecules. [ 34 ] In the case of Se@f-PCNFs, the BET sur-face (Figure 4 E) and pore-size distribution in the mesoporous region of f-PCNFs also decrease sharply (Figure 4 F), indicating the infi ltration of Se into the mesopores of f-PCNFs.

The free-standing fi lms (Se@PCNFs or Se@f-PCNFs) were directly used as cathode for Li-Se batteries. Figure 5 A, B shows cyclic voltammogram (CV) curves of Se@PCNFs and Se@f-PCNFs as cathodes for Li-Se batteries in the voltage range of 1.0–3.0 V, respectively. During the fi rst lithiation process, a cathodic peak appears at 1.75 V that shifts to a higher voltage of ≈1.8 V after the fi rst cycle, resulting from the electrochemical acti-vation behavior of Se@PCNFs during the fi rst discharge (Figure 5 A). The CV curves almost overlap after the fi rst cycle, indicating good capacity retention of Se@PCNFs. For Se@ f-PCNFs, a small anodic peak at 2.15 V can be seen in the fi rst cycle (Figure 5 B). This is due to the reduction of trace amount of cyclic Se 8 in large pores or the surface of nanofi bers to form soluble polyselenides, Li 2 Se n ( n ≥ 4). [ 25,34,46,47 ] A pair of redox peaks peaked at 1.6 and 2.3 V can also be seen after the fi rst cycle. The disappearance of lithiation peak of Se@PCNFs (Figure 5 A) at 2.15 V in the fi rst cycle means the uniform dis-persion of Se 8 in PCNFs and direct formation of nonsoluble Li 2 Se in the fi rst discharge. This result is in good agreement with Raman spectroscopy and ex situ XRD (Figure 7 ).

The charge/discharge profi les of Se@PCNFs and Se@f-PCNFs cathodes at a current density of 0.05 A g −1 for Li-Se

batteries are shown in Figure 5 C, D, respectively. The initial dis-charge and charge capacities of Se@PCNFs are 1159 mAh g −1 and 659 mAh g −1 , respectively, showing a 56.9% initial Cou-lombic effi ciency (ICE) (Figure 5 C). To get an insight view of the low ICE of Se@PCNFs electrode, we tested the cycle performance of pure PCNFs at 0.05 A g −1 (Figure S2, Sup-porting Information). Pure PCNFs electrode displays an initial discharge capacity and charge capacity of 270 mAh g −1 and 40 mAh g −1 , respectively, corresponding to a very low ICE, which may be partially response for the large initial capacity loss of Se@PCNFs. [ 34 ] In addition, the formation of irrevers-ible solid electrolyte interphase (SEI) is another reason for the low ICE. [ 25,34 ] The Se@PCNFs shows a single discharge plateau at ca. 1.90 V, which is consistent with the previous result. [ 33,34 ] In the case of Se@f-PCNFs, the initial discharge and charge capacities are 1162 mAh g −1 and 405 mAh g −1 , respectively, cor-responding to an initial CE of 34.9% (Figure 5 D). The Se@f-PCNFs electrode displays a short plateau at 2.35 V in the fi rst discharge process, which is caused by the reduction of cyclic Se 8 molecules to form soluble polyselenides, Li 2 Se n ( n ≥ 4). [ 47 ] Another long discharge plateau at 1.85 V in the fi rst discharge step is due to the lithiation of cyclic Se 8 molecules. [ 25,34 ] After the fi rst lithiation process, a long plateau starting from 2.0 V appears due to the formation of chain-like Se n instead of cyclic Se 8 . [ 25 ] Note that the higher lithiation plateau of Se@PCNFs (Figure 5 C) than that of Se@f-PCNFs (Figure 5 D) may be attrib-uted to the PCNFs that possess more open pores for electro-lyte to soak in, leading to short transport path of Li + through carbon toward the Se, which results in a lower electrochemical

Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

Figure 3. A) TEM and B) HRTEM images of Se@PCNFs. C) Images by scanning transmission electron microscopy (STEM) and corresponding element mapping (selenium (D), carbon (E)) of one part of an individual Se@PCNFs.

FULL P

APER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (5 of 10) 1401377wileyonlinelibrary.com

polarization and a higher discharge voltage than that of Se@f-PCNFs. The CV curves show that the redox peak profi le of Se@PCNFs (Figure 5 A) was more symmetric and sharper than that of Se@f-PCNFs (Figure 5 B), also demonstrating that the redox kinetics were enhanced due to the reduced diffusion length of lithium. The disappearance of 2.35 V plateau after the fi rst cycle indicates the high reversible of lithium storage in Se@f-PCNFs electrode.

Figure 6 A shows the comparison of the cycle performance of Se@PCNFs and Se@f-PCNFs electrodes at a current den-sity of 0.05 A g −1 for Li-Se batteries. For the Se@PCNFs elec-trode, a reversible capacity of 643 mAh g −1 is obtained after 100 cycles, which almost approaches the theoretical capacity of Se (678 mAh g −1 ). The CE of Se@PCNFs electrode nearly reaches 100%, indicating alleviation of the shuttle effect and the

excellent cyclabilty. For the Se@f-PCNFs electrode, it delivers only a reversible capacity of 378 mAh g −1 after 100 cycles. To get the further evidence of the improved electrochemical per-formance of Se@PCNFs for Li-Se batteries, the rate capabili-ties of both electrodes (Se@PCNFs and Se@f-PCNFs) were investigated (Figure 6 B). The Se@PCNFs electrode delivers a reversible capacity as high as 637, 604, 566, and 545 mAh g −1 when cycled at 0.1, 0.2, 0.5, and 1 A g −1 , respectively. When the current density was tuned back to 0.05 A g −1 , the reversible capacity can be recovered up to 650 mAh g −1 again, showing an excellent stability of the electrode. Even cycled at 2 A g −1 and 4 A g −1 , the Se@PCNFs electrode still displays reversible capacities as high as 460 mAh g −1 and 306 mAh g −1 , respec-tively, which correspond to 68% and 45% of the theoretical capacity. The remarkable electrochemical performance of Li-ion

Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

Figure 4. A) XRD patterns and B) Raman patterns of Se, Se@PCNFs, and Se@f-PCNFs. The inset shows the corresponding Raman spectra of Se@PCNFs and Se@f-PCNFs in the wavenumber between 100 and 500 cm −1 . C) N 2 adsorption/desorption isotherms and D) pore-size distribution curve of PCNFs and Se@PCNFs. E) N 2 adsorption/desorption isotherms and F) pore-size distribution curve of f-PCNFs and Se@f-PCNFs. The pore-size distribution was calculated from the adsorption curve using the density functional theory (DFT) method.

FULL

PAPER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim1401377 (6 of 10) wileyonlinelibrary.com

storage (especially at high rates) is unprecedented. [ 35–37,48,49 ] In the case of Se@f-PCNFs electrodes, the rate capability is much worse. It only delivers a capacity of 210 mAh g −1 when

cycled at 2 A g −1 . We also compared the rate performance of current work with other Se-based cathode for Li-Se batteries, including Se@mesoporous carbon, [ 25 ] Se/carbon composite, [ 36 ]

Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

Figure 5. A) Cyclic voltammograms of Se@PCNFs and B) Se@f-PCNFs electrode between 1 and 3 V in Li-ion batteries at a potential sweep rate of 1 mV s −1 . C) Voltage profi les of Se@PCNFs and D) Se@f-PCNFs electrodes in Li-ion batteries at a current density of 0.05 A g −1 .

Figure 6. A) Cycle performances of Se@PCNFs and Se@f-PCNFs electrodes in Li-ion batteries at a current density of 0.05 A g −1 . B) Rate capability of Se@PCNFs and Se@f-PCNFs in Li-ion batteries. C) Long-term cycling performance of Se@PCNFs electrode in Li-ion batteries at 0.5 A g −1 for 900 cycles. D) FESEM images of Se@PCNFs after 900 cycles in the fully charged condition between 1.0 and 3.0 V in Li-ion batteries at a current density of 0.5 A g −1 . The inset is the corresponding high magnifi cation image.

FULL P

APER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (7 of 10) 1401377wileyonlinelibrary.comAdv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

grapheme–Se@CNT, [ 38 ] insertion of a free-standing carbon interlayer, [ 37 ] and Se/CMK3, [ 34 ] and these results are shown in Table S1 (Supporting Information). By comparison, the free-standing and fl exible Se@PCNFs electrode exhibits comparable electrochemical performance to other common electrode with conductive additive and binder.

Figure 6 C shows the long cycle performance of Se@PCNFs electrode at a high current density of 0.5 A g −1 for Li-Se bat-teries. After 900 cycles, the Se@PCNFs electrode could still deliver an exceptional high capacity of 516 mAh g −1 , with nearly 100% CE throughout the cycling. After extended cycling, the original textural properties in terms of shape, size, and struc-tural integrity can be well retained, showing a high structural stability (Figure 6 D). Note that the surface of fi bers becomes rough due to the SEI formation and some residual electrolyte. Different loading levels of Se in the composites (Se@PCNFs) are also investigated. When Se content increases from 52.3% to 70%, the reversible capacities of Se@PCNFs electrode decrease as well at various current densities (Figure S3, Supporting Information). Too much Se cannot completely impregnate into the pores of PCNFs, leading to the worse electrochemical per-formance due to the shuttle reaction during cycling. [ 25 ]

To get the further evidence of improved electrochemical per-formance of Se@PCNFs result from the formation of chain-like Se n , Raman spectroscopy combined with ex situ XRD was car-ried out ( Figure 7 ). The crystalline Se transferred to cyclic Se 8 molecules (peaked at 263 cm −1 ) inside the mesopores of PCNFs (Figure 7 A) after heating the mixture of Se and PCNFs. [ 34 ] After fi rst discharge to 1.0 V, Se 8 molecules react with Li and form Li 2 Se (Figure 7 B), which is in good agreement with the single plateau during the discharge process (Figure 5 C). When fi rst charged, chain-like Se n is obtained, as confi rmed by the Raman pattern of Se@PCNFs (Figure 7 A). It keeps chain-like Se n after 20 cycles in Se@PCNFs (Figure 7 A). Similar results have been demonstrated by Guo et al. [ 34 ]

Electrochemical impedance spectroscopy (EIS) was used to investigate the resistance of Se@PCNFs and Se@f-PCNFs elec-trodes (Figure S4, Supporting Information). The spectra of both samples consist of two depressed semicircles in the high- and middle-frequency regions and a straight line in the low-fre-quency region. Obviously, the charge-transfer resistance ( R ct )

of Se@PCNFs simulated from the equivalent circuits is much smaller than that of Se@f-PCNFs, indicating a better kinetic process of Se@PCNFs electrode.

The remarkable electrochemical performance of the Se@PCNFs electrode is originated from the structural merits. The introduction of F127 into the electrospun nanofi bers can act as soft template to create more mesopores during the car-bonization and activation process, which is helpful to pro-vide suffi cient host to accommodate Se molecule as well as fast migration of Li + /Na + . [ 34,50 ] Confi ning Se molecules into mesoporous PCNFs could effectively prevent polyselenide dif-fusion into the electrolyte, thereby decreasing the Se cathode dissolution. The strong interaction between chain-like Se n and carbon mesopores leads to the high electrochemical stability of Se@PCNFs. [ 34 ] In addition, the interconnected 3D network offers a continuous 3D electronic path for fast and stable charge transfer, while granting the electrode with large surface area, high porosity, and high mechanical fl exibility. [ 51–53 ] The synergistic of all these advantageous features makes this free-standing Se@PCNFs fi lm electrode highly attractive for fl exible Li-Se batteries.

Moreover, we investigated the sodium storage behavior of the free-standing Se@PCNFs fi lm electrode ( Figure 8 ). Figure 8 A shows CV curves of Se@PCNFs in the range of 1–2.5 V for Na-Se batteries. Unlike the CV curve of Se@PCNFs for Li-Se batteries, two cathode peaks can be observed at 1.4 and 1.15 V during the fi rst discharge process, respectively, indicating the full discharge product (Na 2 Se) is formed via an intermediate phase. [ 33 ] And only one anodic peak can be observed during the charge process, which is due to the conversation between Na 2 Se and Se. [ 33 ] Figure 8 B shows the charge/discharge profi les of Se@PCNFs electrode at a current density of 0.05 A g −1 in the voltage range of 1–3 V for Na-Se batteries. The discharge and charge profi les (Figure 5 C) are similar to the curves for lithium storage, only with lower voltage and capacity, which is due to the difference in the thermodynamics and kinetics of the lithiation and sodiation process. [ 25,54–56 ] The initial discharge and charge capacities are 810 mAh g −1 and 595 mAh g −1 , respectively, cor-responding to an initial CE of 73.5%. The Se@PCNFs elec-trode still maintains a reversible capacity of 520 mAh g −1 after 80 cycles at 0.05 A g −1 , with the CE almost approaching 100%

Figure 7. A) Raman spectra of pristine Se, Se@PCNFs cathode in Li-ion batteries before cycle, after the fi rst discharge, after the fi rst charge (1 dis-charge/charge cycle), and after 20 cycles. The inset is the corresponding magnify Raman spectra of Se@PCNFs before cycles. B) XRD patterns of Se@PCNFs cathode in Li-ion batteries after the fi rst discharge and before cycle.

FULL

PAPER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim1401377 (8 of 10) wileyonlinelibrary.com Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

(Figure 8 C). The excellent rate retention is shown in Figure 8 D. The specifi c capacities are 600, 551, 435, and 230 mAh g −1 for current densities of 0.1, 0.25, 0.5, and 1 A g −1 , respectively. The excellent electrochemical performance of Se@PCNFs for sodium storage indicates that the Se@PCNFs fi lm is also a promising candidate for fl exible Na-Se battery. The morphology of the Se@PCNFs electrode after 80 cycles in Na-Se battery is investigated by FESEM (Figure S5, Supporting Information). No obvious morphology change is observed after 80 cycles at 0.05 A g −1 , indicating a high structural stability of PCNFs.

3. Conclusion

In summary, we have rationally designed a fl exible elec-trode (Se@PCNFs) by infusing Se into electrospun-derived mesoporous carbon nanofi bers for both Li-Se and Na-Se bat-teries. The Se@PCNFs electrode exhibits excellent electro-chemical performance for both lithium and sodium storage. For Li-Se batteries, the Se@PCNFs can deliver a reversible capacity of 516 mAh g −1 after 900 cycles without any capacity loss at 0.5 A g −1 . Even at 4 A g −1 , the Se@PCNFs can deliver a reversible capacity as high as 306 mAh g −1 . In the case of Na-Se batteries, it delivers a reversible capacity of 520 mAh g −1 after 80 cycles at 0.05 A g −1 and a rate capability of 230 mAh g −1 at 1 A g −1 . The good performance of Se@PCNFs is due to (i) uni-form distribution of Se molecule in mesoporous carbon nano-fi bers which allows most Se molecules to react with Li ions (or Na ions) and to protect polyselenides from side reaction with carbonate electrolyte; (ii) The 3D interconnected nanofi bers structure can provide continuous electron transportation path

and short ion transfer length. By rational and delicate design, this type of self-supported electrodes may hold great promise for the development of fl exible Li-Se and Na-Se batteries with high power and energy densities.

4. Experimental Section Electrospinning of PAN-F127 Nanofi bers : In a typical process, 0.85 PAN

(PAN, MW = 150 000, Aldrich) and 0.034 g Pluronic F127 g (Aldrich) were dissolved in 9.15 g N , N -dimethylformamide (DMF, SCRC). The obtained precursor solution was loaded into a 10 ml syringe with a 19-gauge blunt tip and the fi bers were spun at 18 kV. The syringes were pushed by a syringe pump with a feeding rate of 19.00 µL min −1 . The distance between the tip of the needle and the rotating cylinder was kept 26 cm. For comparison, F127-free PAN nanofi bers were prepared according to the same condition.

Formation of Mesoporous Carbon Nanofi bers (PCNFs or f-PCNFs) : Typically, the as-collected electrospun PANs-F127 was stabilized in air at 280 °C for 3 h with a heating rate of 2 K min −1 . Then, the above-stabilized fi bers were carbonized at 800 °C for 5 h with a heating rate of 5 K min −1 to prepare carbon nanofi bers (CNFs). Subsequently, a mixture of CNFs (0.05 g) and KOH (0.5 g) (CNFs: KOH = 1:10, weight ratio) was added into 20 ml deionized water and then the mixture was stirred for 12 h. The mixture product was fi ltered and dried at 80 °C in an oven. After that the CNFs was chemical active at 800 °C with a heating rate of 5 °C min −1 for 0.5 h under N 2 . Then the product was washed with the deionized water until the fi ltrate is neutral and was dried in an oven at 80 °C. Finally, the result in mesoporous CNF nanofi bers (denoted as PCNFs) was obtained. For comparison, the F127-free porous CNFs (denoted as f-PCNFs) was also prepared under the same procedure.

Preparation of Flexible Free-Standing Se@PCNFs (or Se@f-PCNFs) : The obtained PCNFs were cut into several small pieces (≈1.5 × 1 cm). Then the mixture of Se and PCNFs paper in the weight ratio of 1:1 was co-heated at 260 °C for 12 h in an autoclave under argon atmosphere to

Figure 8. A) Cyclic voltammograms of Se@PCNFs electrode between 1 and 3 V in Na-ion batteries at a potential sweep rate of 1 mV s −1 . B) Voltage profi les of Se@PCNFs electrode in Na-ion batteries at a current density of 0.05 A g −1 . C) Cycle performances of Se@PCNFs electrode in Na-ion bat-teries at a current density of 0.05 A g −1 . D) Capacities of Se@PCNFs electrodes in Na-ion batteries as a function of charge–discharge cycles at different charge–discharge current densities of 0.05, 0.1, 0.25, 0.5, 1 Ah g −1 , respectively.

FULL P

APER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim (9 of 10) 1401377wileyonlinelibrary.comAdv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

get Se@PCNFs. For comparison, Se impregnating into F127-free porous CNFs (denoted as Se@f-PCNFs) was also fabricated under the same procedure.

Materials Characterization: The structure of the obtained samples was characterized by XRD (Philips X'Pert PRO SUPER X-ray diffractometer with Cu-Kα radiation) and Raman tests. FESEM (JEOL, Tokyo, Japan), TEM (JEOL, Tokyo, Japan), and HRTEM were employed to characterize the morphologies of the samples. TG was used to determine the Se contents in the Se@PCNF and Se@f-PCNFs under N 2 . An ASAP 2020 Accelerated Surface Area and Porosimetry instrument was used to measure the products’ nitrogen adsorption/desorption isotherms. Raman tests were conducted using a DXR Raman microscope from Thermo Scientifi c with a laser wavelength of 532 nm.

Electrochemical Characterization : The free-standing Se@PCNFs (or Se@f-PCNFs) thin fi lm was directly used as the working electrode to perform batteries with 2032 coin cells with Li metal (or Na metal) as counter and reference electrodes. The areal Se loading in the Li-Se (or Na-Se) cell electrode is about 0.8 mg cm −2 . For Li-Se batteries, the electrolyte consists of 1 M LiPF 6 in ethylene carbonate-dimethyl carbonate ( W EC : W DMC = 1:1, Guotai Huarong New Chemical Materials Co., Ltd). For Na-Se batteries, the electrolyte consists of 1 M NaClO 4 in ethylene carbonate-diethyl carbonate ( W EC : W DEC = 1:1). Glass fi ber (Whatman) was used as a separator fi lm. The cells were assembled in an argon-fi lled glove box (MBRAUN LABMASTER 130), where both moisture and oxygen levels were kept below 1 ppm. The galvanostatic charge–discharge tests were conducted at a voltage interval of 1.00–3.00 V. The specifi c capacity was calculated on the basis of the active Se material. Cyclic voltammetry (CV) measurements were conducted at a scan rate of 0.2 mV s −1 . Electrochemical impedance spectrum (EIS) measurements were performed on a CHI 660D electrochemical workstation (Chenhua Instrument Company, Shanghai, China) in the frequency range from 100 kHz to 0.01 Hz.

Ex Situ Characterization : The self-supported Se@PCNFs electrodes in coin cells were disassembled in the glove box after cycling. The self-supported Se@PCNFs were taken out and then washed by dimethyl carbonate (DMC) three times to remove the residual electrolyte. Then, Se@PCNFs were transferred to some home-made devices for ex situ SEM, XRD, or Raman investigation. For XRD and Raman characterization, the self-supported Se@PCNFs were sealed in argon to prevent exposing to air.

Supporting Information Supporting Information is available from the Wiley Online Library or from the author.

Acknowledgements This work was fi nancially supported by the National Natural Science Foundation of China (21171015 and 21373195), the Recruitment Program of Global Experts, the Program for New Century Excellent Talents in University (NCET), and the Fundamental Research Funds for the Central Universities (WK2060140014 and WK2060140016), and the Collaborative Innovation Center of Suzhou Nano Science and Technology.

Received: August 9, 2014 Revised: September 18, 2014

Published online: November 12, 2014

[1] J. B. Goodenough , K.-S. Park , J. Am. Chem. Soc. 2013 , 135 , 1167 . [2] T. Ohzuku , A. Ueda , M. Nagayama , Y. Iwakoshi , H. Komori , Electro-

chimica Acta 1993 , 38 , 1159 .

[3] J. M. Tarascon , E. Wang , F. K. Shokoohi , W. R. McKinnon , S. Colson , J. Electrochem. Soc. 1991 , 138 , 2859 .

[4] L. Aldon , A. Perea , M. Womes , C. M. Ionica-Bousquet , J. C. Jumas , J. Solid State Chem. 2010 , 183 , 218 .

[5] Y. Yu , L. Gu , C. Wang , A. Dhanabalan , P. A. van Aken , J. Maier , Angew. Chem. Int. Ed. 2009 , 48 , 6485 .

[6] Y. Zhang , L. Wang , A. Zhang , Y. Song , X. Li , H. Feng , X. Wu , P. Du , Solid State Ionics 2010 , 181 , 835 .

[7] Y. Zhang , A.-Q. Zhang , Y.-H. Gui , L.-Z. Wang , X.-B. Wu , C.-F. Zhang , P. Zhang , J. Power Sources 2008 , 185 , 492 .

[8] V. Etacheri , R. Marom , R. Elazari , G. Salitra , D. Aurbach , Energy Environ. Sci. 2011 , 4 , 3243 .

[9] B. Scrosati , J. Hassoun , Y.-K. Sun , Energy Environ. Sci. 2011 , 4 , 3287 . [10] J. Song , S. Chen , M. Zhou , T. Xu , D. Lv , M. L. Gordin , T. Long ,

M. Melnyk , D. Wang , J. Mater. Chem. A 2014 , 2 , 1257 . [11] S.-B. Son , T. A. Yersak , D. M. Piper , S. C. Kim , C. S. Kang , J. S. Cho ,

S.-S. Suh , Y.-U. Kim , K. H. Oh , S.-H. Lee , Adv. Energy Mater. 2014 , DOI: 10.1002/aenm.201300961 .

[12] X. Li , Y. Zhong , M. Cai , M. P. Balogh , D. Wang , Y. Zhang , R. Li , X. Sun , Electrochimica Acta 2013 , 89 , 387 .

[13] X. Li , A. Dhanabalan , L. Gu , C. Wang , Adv. Energy Mater. 2012 , 2 , 238 .

[14] X. Li , C. Wang , J. Mater. Chem. A 2013 , 1 , 165 . [15] G. Zheng , Y. Yang , J. J. Cha , S. S. Hong , Y. Cui , Nano Lett. 2011 , 11 ,

4462 . [16] Y. Yang , G. Zheng , Y. Cui , Chem. Soc. Rev. 2013 , 42 , 3018 . [17] A. Manthiram , Y. Fu , S.-H. Chung , C. Zu , Y.-S. Su , Chem. Rev. 2014 ,

DOI:10.1021/cr500062v . [18] S. Zheng , P. Han , Z. Han , P. Li , H. Zhang , J. Yang , Adv. Energy

Mater. 2014 , DOI: 10.1002/Aenm.201400226 . [19] J. Song , T. Xu , M. L. Gordin , P. Zhu , D. Lv , Y.-B. Jiang , Y. Chen ,

Y. Duan , D. Wang , Adv. Funct. Mater. 2014 , 24 , 1243 . [20] Z. Zhang , Z. Li , F. Hao , X. Wang , Q. Li , Y. Qi , R. Fan , L. Yin , Adv.

Funct. Mater. 2014 , 24 , 2500 . [21] J. Fanous , M. Wegner , J. Grimminger , Ä. Andresen ,

M. R. Buchmeiser , Chem. Mater. 2011 , 23 , 5024 . [22] A. Patil , V. Patil , D. Wook Shin , J.-W. Choi , D.-S. Paik , S.-J. Yoon ,

Mater. Res. Bull. 2008 , 43 , 1913 . [23] L. Ji , M. Rao , H. Zheng , L. Zhang , Y. Li , W. Duan , J. Guo ,

E. J. Cairns , Y. Zhang , J. Am. Chem. Soc. 2011 , 133 , 18522 . [24] P. G. Bruce , S. A. Freunberger , L. J. Hardwick , J.-M. Tarascon , Nat.

Mater. 2012 , 11 , 19 . [25] C. Luo , Y. Xu , Y. Zhu , Y. Liu , S. Zheng , Y. Liu , A. Langrock , C. Wang ,

ACS Nano 2013 , 7 , 8003 . [26] J. Guo , Y. Xu , C. Wang , Nano Lett. 2011 , 11 , 4288 . [27] D.-R. Chang , S.-H. Lee , S.-W. Kim , H.-T. Kim , J. Power Sources 2002 ,

112 , 452 . [28] Z. Dong , J. Zhang , X. Zhao , J. Tu , Q. Su , G. Du , RSC Adv. 2013 , 3 ,

24914 . [29] R. Xu , I. Belharouak , J. C. M. Li , X. Zhang , I. Bloom , J. Bareño , Adv.

Energy Mater. 2013 , 3 , 833 . [30] X. Ji , K. T. Lee , L. F. Nazar , Nat. Mater. 2009 , 8 , 500 . [31] N. Jayaprakash , J. Shen , S. S. Moganty , A. Corona , L. A. Archer ,

Angew. Chem. Int. Ed. 2011 , 50 , 5904 . [32] J. Song , Z. Yu , T. Xu , S. Chen , H. Sohn , M. Regula , D. Wang , J.

Mater. Chem. A 2014 , 2 , 8623 . [33] A. Abouimrane , D. Dambournet , K. W. Chapman , P. J. Chupas ,

W. Weng , K. Amine , J. Am. Chem. Soc. 2012 , 134 , 4505 . [34] C.-P. Yang , S. Xin , Y.-X. Yin , H. Ye , J. Zhang , Y.-G. Guo , Angew.

Chem. Int. Ed. 2013 , 52 , 8363 . [35] L. Liu , Y. Hou , X. Wu , S. Xiao , Z. Chang , Y. Yang , Y. Wu , Chem.

Commun. 2013 , 49 , 11515 . [36] L. Liu , Y. Hou , Y. Yang , M. Li , X. Wang , Y. Wu , RSC Adv. 2014 , 4 ,

9086 .

FULL

PAPER

© 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim1401377 (10 of 10) wileyonlinelibrary.com Adv. Energy Mater. 2015, 5, 1401377

www.MaterialsViews.comwww.advenergymat.de

[37] Z. Zhang , Z. Zhang , K. Zhang , X. Yang , Q. Li , RSC Adv. 2014 , 4 , 15489 .

[38] K. Han , Z. Liu , H. Ye , F. Dai , J. Power Sources 2014 , 263 , 85 . [39] C. Luo , Y. Zhu , Y. Wen , J. Wang , C. Wang , Adv. Funct. Mater. 2014 ,

24 , 4082 . [40] W. Li , L. Zeng , Z. Yang , L. Gu , J. Wang , X. Liu , J. Cheng , Y. Yu ,

Nanoscale 2014 , 6 , 693 . [41] K. Jin , X. Zhou , L. Zhang , X. Xin , G. Wang , Z. Liu , J. Phys. Chem. C

2013 , 117 , 21112 . [42] K. Xi , P. R. Kidambi , R. Chen , C. Gao , X. Peng , C. Ducati ,

S. Hofmann , R. V. Kumar , Nanoscale 2014 , 6 , 5746 . [43] S. Lu , Y. Cheng , X. Wu , J. Liu , Nano Lett. 2013 , 13 , 2485 . [44] L. Zeng , W. Li , J. Cheng , J. Wang , X. Liu , Y. Yu , RSC Adv. 2014 , 4 , 16920 . [45] L. Wang , Y. Yu , P.-C. Chen , C.-H. Chen , Scr. Mater. 2008 , 58 , 405 . [46] S. Xin , L. Gu , N.-H. Zhao , Y.-X. Yin , L.-J. Zhou , Y.-G. Guo , L.-J. Wan ,

J. Am. Chem. Soc. 2012 , 134 , 18510 . [47] S. Xin , Y.-X. Yin , L.-J. Wan , Y.-G. Guo , Part. Part. Syst. Charact. 2013 ,

30 , 321 .

[48] D. Kundu , F. Krumeich , R. Nesper , J. Power Sources 2013 , 236 , 112 . [49] Y. Cui , A. Abouimrane , C.-J. Sun , Y. Ren , K. Amine , Chem. Commun.

2014 , 50 , 5576 . [50] Y. Yu , L. Gu , C. Zhu , P. A. van Aken , J. Maier , J. Am. Chem. Soc.

2009 , 131 , 15984 . [51] H.-J. Peng , J.-Q. Huang , M.-Q. Zhao , Q. Zhang ,

X.-B. Cheng , X.-Y. Liu , W.-Z. Qian , F. Wei , Adv. Funct. Mater. 2014 , 24 , 2772 .

[52] K. Tang , L. Fu , R. J. White , L. Yu , M.-M. Titirici , M. Antonietti , J. Maier , Adv. Energy Mater. 2012 , 2 , 873 .

[53] K. Tang , Y. Yu , X. Mu , P. A. van Aken , J. Maier , Electrochem. Commun. 2013 , 28 , 54 .

[54] V. Palomares , P. Serras , I. Villaluenga , K. B. Hueso , J. Carretero-Gonzalez , T. Rojo , Energy Environ. Sci. 2012 , 5 , 5884 .

[55] J. Qian , X. Wu , Y. Cao , X. Ai , H. Yang , Angew. Chem. Int. Ed. 2013 , 52 , 4633 .

[56] Y. Cao , L. Xiao , W. Wang , D. Choi , Z. Nie , J. Yu , L. V. Saraf , Z. Yang , J. Liu , Adv. Mater. 2011 , 23 , 3155 .