6 Challenges Manufacturers Can Solve With an ERP System

description

Transcript of 6 Challenges Manufacturers Can Solve With an ERP System

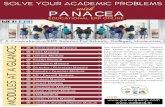

6 Challenges Manufacture

rs Can Solve With

an ERP System

Enterprise Resource Planning (ERP) Software can be vital for a growing manufacturing company.

“To facilitate information flow, ERP systems employ a software application that integrates internal and external management information across an entire organization and extends to external stakeholders.” –Forrester®

ERP can eliminate the following 6 common challenges:

1. Manual Data Entry

These errors and time delays can be costly for businesses that have not automated their manufacturing and distribution processes.

2. Reports and Queries

Manufacturers need accurate reports in real-time. A single system, will eliminate the need for spending hours of time unnecessarily validating reports and verifying data from multiple platforms.

3. Quality Issues and Concerns

Inaccurate bill of material, routing definitions and detailed production instructions contribute to reworking and scrapping of materials. Having an integrated system can prevent having to scrap material and production time.

4. Inaccuracies in Scheduling

Spreadsheet scheduling is unnecessary time spent reconciling employee schedules with what is happening on the shop floor. An integrated scheduling application is crucial for maximizing time spent working and properly utilizing resources.

Without visibility into sales forecasting, buyers will have a difficult time knowing what to purchase and when. Keep current production levels and production requirements on-hand instead of using a disjointed, non-integrated system.

5. Lack of Updated Material Plans

6. No Way to Manage Growth

Typically, as a company grows more data is produced. Older systems may not be equipped to handle the uptick in information or users accessing this data. If your system is bogged down, then productivity of every employee is affected.

Discover the advantage of a fully integrated ERP system.

Streamline operations with company-wide visibility.

Get access to information anytime on any device.

Optimize inventory and production resources to increase efficiency.

Adapt to growth, customer requirements and changing industry standards.

ERP Solves These Problems

Ready ditch antiquated systems & make your customers happy?

Choose the winning option. Contact Datix, a certified Epicor partner, today for a free consultation.

(314) [email protected]

Learn more at: Datixinc.com & follow us on Twitter @Datixinc