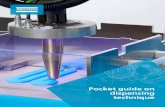

Liquid Chemical Dispensing System cost effective liquid dispensing

6 beer dispensing mistakes that cripple bar profits and what to do about 'em

Transcript of 6 beer dispensing mistakes that cripple bar profits and what to do about 'em

. 6 Beer Dispensing Mistakes

that Cripple Bar Profits and What to Do About ‘Em

An Awareness Guide For Bar and Restaurant Operators & Service Providers

by the team at Liberty Systems

www.Beer.LibertySystemsCompany.com

A quick note before we dive into the content… We just wanted to let you know about our FREE HELP DESK for bar & restaurant businesses and service providers

3 Get questions answered by our help desk - [email protected] - 888-240-6994

u Get all your beer generator & dispensing questions

answered and stop your beer losses and management

headaches forever. u Call the help desk: 888-240-6994

u Email the help desk: [email protected]

TABLE OF CONTENTS I. The 6 Dispensing Mistakes – What, Why, & Cost Impact

1. Over-Pouring Draught Beer in the Dispense Process

2. Over-Carbonation in Draught Beer

3. Under-Carbonation in Draught Beer

4. Dispensing Draught Beer with 100% CO2 vs. Properly Blended Gas

5. Using Nitrogen Cylinders Instead of Generating Nitrogen on Demand

6. Deploying the “Wrong” Nitrogen Generator instead of the “Right” Nitrogen Generator

II. Appendix – Bonus Dispensing Tips & Insights

u A - What is needed achieve a perfect pour

u B - How does improper carbonation affect draught beer – part 1

u C - How does improper carbonation affect draught beer - part 2

u D - Details of temperature, pressure, gas blend

u E - What happens when baseline pressure is exceeded

u F - How does improper gas blend affect draught beer

3 Get questions answered by our help desk - [email protected] - 888-240-6994

A. Over-pouring of draught beer, simply stated, is pouring any amount greater than prescribed by the perfect pint. What causes an over-pour? i. Improper carbonation

ii. Incorrect pressure

iii. Incorrect temperature

iv. Bartender behavior

B. What is the effect of over-pouring? (See APPENDIX ‘A’ and ‘C’ for more information) i. Wasted beer = wasted $$$

ii. The typical over-pour is 25% waste or greater a. Considering each ounce represents about $0.06 (cost), a 25% over-pour in a pint glass is

equivalent to 3.5 oz or $0.21 per pint.

b. There are 142 pint equivalents in a keg; therefore, the average retailer loses $29.82 per keg

in wasted beer due to over-pour.

c. Based on 10 kegs per week (small-to-medium retailer), the annual Dollar-value of wasted

beer due to over-pour is $15,506!

Dispensing Mistake #1- Over-pouring draught beer during the dispense process

3 Get questions answered by our help desk - [email protected] - 888-240-6994

Dispensing Mistake #2- Over-carbonation in draught beer

3 Get questions answered by our help desk - [email protected] - 888-240-6994

A. Over-carbonation is simply the presence of too much CO2 in beer. i. Beer naturally contains CO2 as a result of the breakdown of sugars, but a precise volume of CO2 is

prescribed by the brewers.

ii. Brewers take great care to maintain the volume of CO2 and, therefore, the quality of the beer.

B. What causes over-carbonation? i. Incorrect pressure (too high)

ii. Incorrect temperature (too warm)

iii. Incorrect gas blend (too much CO2 in blend)

C. What is the effect of over-carbonation? (See APPENDIX B, C, D for more on carbonation) i. Very similar results to an ‘over-pour’

ii. Over-carbonation equals over-pour due to increased foam

iii. Foaming increases as time passes

a. The longer the beer sits in the keg on the wrong pressure or blend, the more over-

carbonated it becomes

b. As much as 1/3 of the keg may go to waste due to foam!

D. Incorrect carbonation also changes the flavor profile and theater of the draught

beer pour. The quality changes and beer drinkers notice, which leads to less sales and less

repeat customers.

Dispensing Mistake #3- Under-carbonation in draught beer

3 Get questions answered by our help desk - [email protected] - 888-240-6994

A. Under-carbonation is simply the presence of too little CO2 in beer.

i. Just as with over-carbonation, the volume of CO2 does not meet the specification of the brewer.

B. What causes under-carbonation? i. Incorrect pressure (too low)

ii. Incorrect temperature (too cold)

iii. Incorrect gas blend (too little CO2 in blend)

C. What is the effect of under-carbonation? (See APPENDIX B, C, D for more on carbonation) i. As with over-carbonation, it can result in an over-pour

a. Too little CO2 in the beer will cause it to go flat over time ii. Flat beer has no head (foam) and, therefore, is poured to the top of the glass

a. This results in an over-pour of 2 ounces per pint at a cost of up to $8,861 annually.

iii. Incorrect carbonation also changes the flavor profile and theater of the draught beer pour

a. Under-carbonation has the greatest effect on the flavor and appearance

b. Flat beer has no bubbles so not only does it look unappetizing, but it has poor taste

c. Poor-tasting beer also affects the retailer’s bottom line as customers do not reorder

beer that does not appeal to them. This results in fewer beer sales overall.

Dispensing Mistake #4 – Dispensing draught beer with 100% CO2 vs. using properly blended gas

3 Get questions answered by our help desk - [email protected] - 888-240-6994

A. Draught beer system parameters vary widely

i. The further the bar is from the cooler, the more the system design changes ii. Longer distances = more restriction in the beer line iii. More restriction requires higher pressure

a. Conversely shorter distance = less restriction = less pressure

B. High pressure systems require blended gas i. As pressure increases, so does the volume of CO2 in the keg ii. Partial pressure of CO2 above the brewer’s specification will cause foam iii. Therefore, CO2 must be removed from the head space as pressure increases

C. A proper gas blend of nitrogen and CO2 helps control the volume of CO2 in the keg (See APPENDIX ‘D’ and ‘F’) i. The higher the pressure becomes, the greater the blend of nitrogen in order to remove CO2 ii. The most popular blend is 60% CO2 / 40% N2 (“60/40”), but some systems require custom blends

based upon the temperature and applied pressure in the keg

D. Most ‘direct draw’ systems require blended gas i. Even shorter beer lines require nitrogen in order to ensure CO2 volume is correct ii. The blend is entirely reliant upon the pressure and temperature of the beer iii. Distance is a factor, but ultimately it is pressure and temperature that drive the blend

Dispensing Mistake #5- Using high-pressure nitrogen cylinders instead of generating nitrogen (GN2) on demand

3 Get questions answered by our help desk - [email protected] - 888-240-6994

A. Lower Cost with Generated Nitrogen (GN2) i. As the cost of bottled gases continues to increase, the value of generated nitrogen (GN2) increases ii. No cylinder rentals or delivery / hazmat charges

iii. Rule of thumb is, if you use 1.5 N2 cylinders / month, nitrogen generators pay for themselves

B. More Convenience with Generated Nitrogen (GN2) i. With GN2, you will never run out of nitrogen

a. Never change another N2 cylinder

b. Never worry about running out of N2 late at night, shutting the bar down and the owner or

manager getting called at home for assistance…costing your high margin beer sales. c. Free up valuable floor space by eliminating multiple cylinders

C. More Safety with Generated Nitrogen (GN2) –- LESS WORKERS COMP RISK i. High-pressure N2 cylinders contain up to 2,200 psi of gas

A. Mishandling cylinders can cause severe injury to staff and customers

ii. HP cylinders are very heavy

a. Employees frequently injure themselves while moving or replacing them

b. It is also common for them to fall over, injuring bystanders or destroying equipment

D. The convenience and safety factors alone more than pay the cost of GN2

Why nitrogen? See APPENDIX ‘E’ for

more information

Dispensing Mistake #6 – Deploying the “wrong” nitrogen generator instead of the “right” nitrogen generator

3 Get questions answered by our help desk - [email protected] - 888-240-6994

A. Unreliable Build Attributes of a “Wrong” Nitrogen Generator

I. Cheap, undersized, dental compressors that cause units to burn up / shut down II. Cheap, undersized filter/flow systems that limit output capabilities and will require floor storage tank to make N2 during non

peak times….often without enough recovery time...so many times still running out of nitrogen even if generator working. III. Poor technical design, causing inconsistent nitrogen purity levels. IV. Poor physical design requires big space footprint in tight restaurant / bar real-estate.

B. Costly Problems Caused by a “Wrong”, Unreliable Nitrogen Generator I. Way too much down time, causing the need for cylinder usage and doubling your N2 costs, while at the same time disrupting tap

beer flow at busy bar times…causing the loss of high margin draught beer sales and disappointing customers, plus creating plenty of managmenet headaches.

II. Inconsistent nitrogen purity – negatively affecting beer flavor, disappointing customers, and depressing sales C. Reliable Build Attributes of the “Right” Nitrogen Generator

I. Use a real, industrial grade, compressor, built to last 10+ years, with extra power for peak pub times and long term durability II. Need to size generator with enough protective capacity to handle peak flow situations….never stop flow when needed for beer dispensing. III. Use trade secret technical design to ensure consistent nitrogen purity, and low cost. IV. Use a simple, wall mounted, small footprint space confuguration

D. Profitable Benefits Delivered by the Right, Reliable Nitrogen Generator. i. Have always available nitrogen no matter peak or slow pub time…sell more high margin draught beer and keep customers happy....also,

reduce beer waste. ii. Always consistent nitrogen purity to optimize beer taste...sell more high margin draught beer and keep customers happy...also, reduce

beer waste.

u What is needed achieve a perfect pour? 1. Perfect pour defined: The draught system is balanced to

maintain the brewer’s intended level of carbonation; delivered at correct flow rate and temp; no system waste.

2. Elements of a perfect pour: A. 14 oz of beer in a 16-oz pint glass.

i. 13.5 oz of liquid ii. 0.5 oz of foam

B. Delivered at a rate of 2 oz/second (industry standard for decades). C. ¾” to 1” collar of foam (head). D. 36°- 38° F in the glass.

3. Other elements of a perfect pour: A. Clean beer lines B. Clean glassware C. Bartender behavior and training D. Properly rotated keg stock

III. APPENDIX ‘A’

6

14 oz

total

0.5 oz foam

13.5 oz liquid beer

¾” collar of foam

7 second pour

36°-38°

Get questions answered by our help desk - [email protected] - 888-240-6994

u How does improper carbonation affect draught beer – 1? 1. Beer is naturally carbonated during the brewing process. It

is one of the most important ingredients in the ‘recipe’.

A. Too much carbonation (CO2 content) will cause beer to foam.

q This causes significant waste. Why?

B. Too little carbonation will cause beer to go flat.

q This also causes significant waste. Why?

III. APPENDIX ‘B’

FOAMY POUR FLAT POUR PERFECT POUR!

4

CO2 is an ingredient? Yes!

q Consumers can actually ‘taste’ different levels of carbonation in beer.

q Maintaining the natural level of carbonation in the keg ensures the beer will taste the way the brewer intended.

Get questions answered by our help desk - [email protected] - 888-240-6994

u How does improper carbonation affect draught beer-2? 1. Improper balance of pressure, temperature, and gas blend

will result in waste and cost the retailer $1,000s annually.

A. Cost of a keg of beer averages roughly $120…and rising.

B. Avg waste due to improper balance is about 15%, or $18 per keg.

C. The average retailer sells about 30-40 kegs/month.

D. This is equivalent to $720/month or $8,640/year!

III. APPENDIX ‘C’

4

Why is CO2 important to beer? q CO2 gas preserves beer when

pressure is applied properly. q Correct pressure maintains

equilibrium in head space and solution.

q Gas replaces solution as keg empties.

q Keg pressure also pushes beer from keg to faucet to dispense tower.

FOAMY POUR FLAT POUR PERFECT POUR!

Get questions answered by our help desk - [email protected] - 888-240-6994

u Details of temperature, pressure, gas blend: 1. Temperature:

A. Cooler - 34°- 38° B. Glycol - 27°- 31° (More on glycol later) C. Glass - 36°- 38°

2. Pressure: A. Very simply, the pressure required to push the beer through the

draught system at a rate of 2 oz/second. B. Pressure can be compromised by incorrect gas blend.

q Often adjusted to increase/decrease foam which affects the flow rate.

3. Gas Blend: A. A mix of CO2 and N2.

i. Ale-, lager-, and pilsner-style beers require 60%-80% CO2, depending on the system configuration (more on configuration later).

ii. Nitrogenated stout beers (i.e., Guinness) always require 25% CO2.

B. Dependent upon temperature and pressure. q Must be surveyed and calculated to select the correct blend

III. APPENDIX ‘D’

7 Get questions answered by our help desk - [email protected] - 888-240-6994

u What happens when baseline pressure is exceeded? 1. Whenever CO2 pressure is increased to achieve the flow rate of 2 oz/second,

that pressure will also increase carbonation. A. The additional carbonation will eventually cause foaming. B. CO2 dissolves in beer so the head space and solution will always seek to equalize.

2. To avoid over-carbonation, an inert gas must be used to create the additional pressure required…nitrogen.

3. N2 does not easily dissolve in solution.

III. APPENDIX ‘E’

12

WHY NITROGEN GAS?

1. Abundance • There is more nitrogen gas in our atmosphere than any other noble gas. • About 78% of the Earth's atmosphere is nitrogen gas.

2. Largest molecule • Enables efficient, cost-effective production of N2 gas using PSA or high-tech membrane.

3. Inert gas • Nitrogen blankets the CO2 in solution and keeps it from escaping into the head space.

4. Why not Argon, Helium or Compressed Air?

• Argon is very expensive and can only be acquired from an air separation unit in liquid form. • Helium is also very expensive and in short supply worldwide. • Compressed air is economical, but contains Oxygen and impurities:

o Oxygen causes stale flavors and aromas o Air compressors concentrate aromas and flavors from their surroundings and transmit

them into the beer

16 mins

10,080 mins

Keg Life/Time taken to empty keg

Preserve and Push Beer

0.1%

99.9%

Preserves Beer Pushes Beer

Get questions answered by our help desk - [email protected] - 888-240-6994

u How does improper gas blend affect draught beer?

III. APPENDIX ‘F’

4

After One Day

Time Matters, too! Wrong Blend Ruins Beer!

Example from misapplication of ‘G-Mix’ or 25%/75% blend.

New Keg

After Five Days After Two Days

13

Pure CO2 22 PSIG

146% of CO2 required

68% CO2 22 PSIG

100% of CO2 required*

30% CO2 22 PSIG

35% of CO2 required

Gas Blend Matters!

100% CO2

Incorrect Blend

(CO2/N2)

Perfect Pint!

*Based on 36⁰ temperature Get questions answered by our help desk - [email protected] - 888-240-6994

A quick note before we dive into the content… We just wanted to let you know about our FREE HELP DESK for bar & restaurant businesses and service providers

3 Get questions answered by our help desk - [email protected] - 888-240-6994

u Get all your beer generator & dispensing questions

answered and stop your beer losses and management

headaches forever. u Call the help desk: 888-240-6994

u Email the help desk: [email protected]