5S-Priya and Sushant

-

Upload

sushant-kumar -

Category

Documents

-

view

223 -

download

0

Transcript of 5S-Priya and Sushant

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 1/28

PRESENTED BY:Sushant KumarPriya Gautam

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 2/28

Developed by the Japanese

Workplace Organisation and Housekeeping System

Helps Create a Better Working Environment and a

Consistently High Quality Process

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 3/28

5S is short for: Sort, Set in Order, Shine, Standardize

and Sustain

5S represents 5 disciplines for maintaining a visual workplace

(visual controls and information systems).

These are foundational to Kaizen (continuous improvement)and a manufacturing strategy based "Lean Manufacturing"(waste removing) concepts.

5S is one of the activities that will help ensure our company’s

survival.

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 4/28

Before 5S

After 5S - Cleaned, organized anddrawers labeled (less time andfrustration hunting)

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 5/28

1. Sort - All unneeded tools, parts and supplies areremoved from the area

2. Set in Order - A place for everything and everything isin its place

3. Shine - The area is cleaned as the work is performed4. Standardize - Cleaning and identification methods are

consistently applied5. Sustain - 5S is a habit and is continually improved

Also - Work areas are safe and free of hazardous ordangerous conditions

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 6/28

See the difference?1. Sort - All unneeded tools, parts and supplies are removed from the area2. Set in Order - A place for everything and everything is in its place

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 7/28

3. Shine - The area is cleaned as the work is performed (best) and\or thereis a routine to keep the work area clean.

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 8/28

4. Standardize - Cleaning and identification methodsare consistently applied

Departments have weekly 5S tours

Every job has duties that use Sort, Set in Order andShine

We all have common duties to do our part to keepall areas of the plant in shape - break room,restrooms, locker area, parking lot, etc

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 9/28

5. Sustain - 5S is a habit and is continually improved

5S is a simple concept with powerful results.

we will get additional information on 5S so that we willbe well equipped.

Our experience is that the more we do 5S the betterthe work environment becomes: cleaner, safer, more

organized, the work is easier, less confusion and lessstress.

Use the 5S (work\home\play) - The more we use it theeasier it becomes and life just gets better and better.

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 10/28

QUALITY EFFICIENCY

SAFETY ELIMINATINGBREAKDOWNS

5S

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 11/28

Time is wasted looking for tools, equipment and

paperwork, etc

A clean and tidy workplace leads to greater well beingand increased motivation

Team working makes unexciting work more rewarding

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 12/28

Breakdowns caused by the elimination of dirt need

never occur

Clear labelling and routine maintenance areessential disciplines

A clean workplace highlights problems early

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 13/28

Dirty cluttered workplaces are not safe

Safety depends on good care and organisation

Safety should become second nature

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 14/28

Decide what you need

Remove unnecessary clutter

All tools, gauges, materials, classified and stored

Remove items which are broken, unusable or onlyoccasionally used

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 15/28

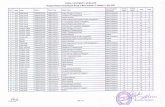

PRIORITY FREQUENCY OF USE HOW TO USE

Low Less than once per year

Once per year

Throw away

Store away fromthe workplace

Average At least 2/6 months

Once per month

Once per week

Store together butoffline

High Once Per Day Locate at theworkplace

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 16/28

Organise layout of tools and equipment

Designated locations

Use tapes, labels and silhouettes

Ensure everything is available as it is needed and at the“point of use”

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 17/28

Workplace Checkpoints:-

Positions of aisles and storage places clearly

marked?

Tools classified and stored by frequency of use? Pallets stacked correctly?

Safety equipment easily accessible?

Floors in good condition?

Lights / Reflectors clean?

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 18/28

Create a spotless workplace

Identify and eliminate causes of dirt andgrime – remove the need to clean

Sweep, dust, polish and paint

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 19/28

Divide areas into zones

Define responsibilities for cleaning

Tools and equipment must be owned by anindividual

Focus on removing the need to clean

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 20/28

Keep it clean and/or organised

Replace items in designated areas

Continue to assess the use and disposal of items Regularly audit using checklists and measures of

housekeeping

Real challenge is to keep it clean

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 21/28

Make it a way of life

Part of health and safety

Involve the whole workforce Follow the rules and procedures

Develop and keep good habits

Think and share ideas with others

Encourage teams to set their own standards

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 22/28

Area ResponsiblePerson

Auditors: Audit to be carried out by

3rd week of each month by namedperson and an assistant…

July Sept Nov

BoilerHouse,Site, Carpark

BrianSutherland

Ronnie

Wilson

Linda

Johnstone

Neal

Robertson

Stockroom Kevin McEwen Linda

Johnstone

Neal

Robertson

Brian

Sutherland

Sales Sandra Collins Neal

Robertson

Brian

Sutherland

Helen

Graham

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 23/28

Visual Control & the Workstation

The 5

S

To Sort

Eliminate what’s

not absolutely

necessary

To Sanitize

Improvement of the workstation.Be organized toreduce clutter.

To Straighten

Ensure space for eachthing, and a thing foreach space. No moresearching.

To Sweep

Maintain a clean

and orderly space tomake problemseasily identifiable.Eliminate rejects andscrap..

To Sustain

Maintain

continuous effort.

This is a way of

life.

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 24/28

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 25/28

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 26/28

Improvements in:-

Workforce morale

Company image

Health and Safety Machine maintenance

Quality

Productivity

Leading to Increased Competitiveness

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 27/28

5-S is for you.

Clean-up and organize your work area every day so thateach new day is easier and safer than the day before

Share your input with your leaders so that the tools youneed will be available to you, increasing your efficiency.

Volunteer to help with the 5S tours and 5S events.

Take a good look around...Imagine zero waste/zeroconfusion!

.

8/3/2019 5S-Priya and Sushant

http://slidepdf.com/reader/full/5s-priya-and-sushant 28/28

Thank you