54 BceCe 116:m 2/1/12 2:04 PM Page 54 Bruce Crower · At the time there was little hint that a few...

-

Upload

trinhxuyen -

Category

Documents

-

view

216 -

download

2

Transcript of 54 BceCe 116:m 2/1/12 2:04 PM Page 54 Bruce Crower · At the time there was little hint that a few...

54 VINTAGE MOTORSPORT Nov/Dec 2011 www.vintagemotorsport.com

Prior to World War II, California was aplace offering freedom and opportunity

for those with vision. It was also the genesisfor a new and exciting phenomenon calledhot rodding. Besides the weather, Californiahad one advantage over all other locations;the great expanse of dry lakebeds thatspread across the Mojave desert. On thosebarren and windswept sands, young mengathered to race their own creationswithout limits or restrictions.

At the time there was little hint that a fewof the young men laboring on theirhomebuilt hot rods would someday form thenucleus of an industry that would sweep thenation. The idea of creating highperformance parts for use in racing grew likewildfire and with its growth cameinnovations never imagined by its pioneers.In essence, the performance industry

allowed enthusiasts to fulfill their dreams ofspeed with unlimited potential.

Among those early hot rodders wasBruce Crower who, like many of the youngmen found on the dry lakes, possessed theurge to go fast. Crower took his dreams tothe limit and not only built fast cars, butcreated the special parts that allowed othersto pursue their speed quest. Over the years,Crower racing products became one of themost respected names in the highperformance industry.

Crower recounted his early days as a hot rodder and how his enthusiasmturned into a legendary career in theperformance industry.

“I was born in March of 1930 in Phoenix,Arizona just as the Great Depression wasgetting underway. My dad owned a Model TFord with 4-banger equipped with a Rajo

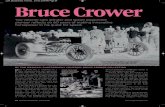

One of the first dragster racers to use the CrowerU-Fab manifold was Dallas Martinson, who set atrack record at Paradise Mesa with a 7.90 e.t.

Crower checks sparkplugs on a front-blowerdragster at Chandler,Arizona in 1955.

BY TOM MADIGAN. PHOTOGRAPHY COURTESY BRUCE CROWER COLLECTION

Bruce Crowerp54_BruceCrower_116:vms_ 2/1/12 2:04 PM Page 54

www.vintagemotorsport.com Nov/Dec 2011 VINTAGE MOTORSPORT 55

8-valve cylinder head. It wasn’t a true hotrod but it was faster than most cars on theroad and I truly believe that riding in that carset me on the road to loving fast cars.”

Crower talked about how living in thePhoenix area provided stimulus for a youngman interested in cars. “When I was about10 or 11 years old my curiosity about fastcars became much stronger. Phoenix was ahotbed for racing on the track as well as onthe street. Like California, we had year-roundgood weather so it was only natural thatracing would blossom.”

Like most of the early hot rod pioneers,World War II irrevocably affected Crower.Although only 11 years old at the War’sonset, through the newspapers of the day hebecame immersed in the air battles andpursued the advances in aircraft developmentfaithfully throughout the conflict.

“I was interested in the war because backthen, everyone was involved. For me, the airbattles captured my interest. I was young butI had neighbors and friends who were draftedand many went into the Air Corps. A youngman who was a local hot rodder that some ofus kids looked up to ended up flying a B-25and to me, that was really cool.”

At the conclusion of the war, Croweradvanced his interest in racing by buildingone of the fastest ’32 Ford roadsters in town.And by 1948, he opened a small shop in thePhoenix area doing general auto repairs aswell as body and fender work with somecustom painting tossed in for good measure.

“I had taken auto shop in high school so Ifigured, why not put the knowledge to gooduse? I got a reputation for doing good workat my shop and for kicking butt running inillegal drag races out of town at a place calledBlack Canyon Road. My ’32 was one of thefastest around.”

Crower was not only influenced by hotrodding, he had stimulus from the circletrack crowd. “Back in the late 1940s before

he became a household name at Indianapolis,Clint Brawner ran a V8-60 midget withBobby Ball driving. That car was really quickand Clint would take it to Gilmore inCalifornia and qualify with the Offys. Ibecame friends with Brawner, Ball and JimmyBryan and learned a lot about how to raceand the art of building a quality race engine.At one point, Brawner took me under hiswing and I was considered his protégé.”

As a sidebar to his early career andlearning experiences, Crower points to EdWinfield as the one person he held as aninspiration when it came to going fast. “EdWinfield was a pioneer in camshaft grindingand in carburetor enhancement. Hiscarburetors were works of art. In later yearsI got to spend time with Winfield at hishome and he would open up about the olddays and how he developed the camshaftsand carburetors. He was proud of his workand that of his brother Bud, who helpeddesign and develop the Novi V8 Indyengine. Winfield, in my opinion, had the

mind of a great engineer. He would alwaystell you how to solve problems using logicand engineering.”

Uncle Sam CallsIn June of 1950 the United States becameinvolved in the Korean War and shortlythereafter Crower received his greetings fromUncle Sam. Crower tells the details, “Myparents had moved to San Diego and I wasrunning my shop in Arizona when I got mydraft notice. Rather than go into the Army asa grunt, I enlisted in the Air National Guardand spent most of the Korean War at LukeField in Arizona doing machine work as partof the ground crew. When I was discharged,I sold off my shop and followed my folks toSan Diego. I landed a job with Paul Schieferwhere I machined aluminum flywheels andran his dynamometer equipment.”

Through his relationship with Schiefer,Crower was introduced to the world of drylakes racing—Muroc and El Mirage—andsoon began mingling with the pioneers who

5The revolutionary U-Fab manifold allowed fuel-burningdragsters to construct handmade manifolds offering theoption of running four, six or eight Stromberg carburetors withthe popular Chrysler Hemi. The concept was an instant hit.

Bruce Crower (with flashlight)is one of the few speed

industry pioneers who ran thedry lakes and early drag races

using Ford flathead power.

5With a blown Chrysler Hemi stuffed under its hood, Crower’s ’48 Hudson reached 157mph at Bonneville in 1954.

p54_BruceCrower_116:vms_ 2/1/12 2:04 PM Page 55

56 VINTAGE MOTORSPORT Nov/Dec 2011 www.vintagemotorsport.com

made up the core of the hot rod industry.They included Vic Edelbrock Sr., Stu Hilborn,Yam Oka, Earl Evans, Tom and Bill Spaldingand Schiefer himself, who ran a record-breaking 1925 Model T modified roadster.

During his tenure with Schiefer, Crowercontinued to build engines and compete atlocal dragstrips. By the mid-1950s he beganto see the potential in the speed equipmentindustry, but it would take somethingextraordinary to launch his daydreams intoreality. The launch came in the form of a 1954excursion to the Bonneville Salt Flats. Crowershowed up with a street-driven HudsonHornet powered by a 331cid Chrysler Hemiequipped with a 6:71 GMC supercharger andfour carburetors running through a hand-builtmanifold. The result of the effort was a recordfor stock-bodied cars of 157mph. The back-story to the Bonneville excursion is the factthat the handmade manifold used on theHudson was the precursor to the CrowerU-Fab manifold, the product that wouldchange the world of drag racing.

The “U” Is FabIn 1955, Crower opened a small shop inSan Diego—Bruce Crower AutomotiveService. He also placed a small ad in HotRod magazine offering his newly developedmanifold. The U-Fab manifold as it wasnamed, consisted of two cylindrical runnersjoined with hoses and clamps presentingthe option of using four, six, or eightStromberg carburetors. The U-Fab conceptwas the hot ticket for use on fuel-burningdragsters and became what could beclassified as an instant hit.

Then, the team of Cliff Bedwell andEmery Cook, using a U-Fab on their nitro-burning Chrysler Hemi dragster, shatteredthe quarter-mile record, laying down an ETof 8.89 seconds and 166.97mph. Crowerwas on the map. Within weeks, the U-Fabwas put into full production as a casting withcarburetor flange mounts for the carburetors;gone were the hoses and clamps. Thedemand continued to grow and when racerslike Don Garlits and the infamous Maynard-

Greth-Fisher Speed Sport roadster got theU-Fab, sales went off the chart.

“When we came out with the U-Fabmanifold there was nothing like it out therethat would even touch it,” Crower says. “Infact, we used to beat the blower guys all thetime; eight carburetors on a Chrysler Hemirunning 98% nitro was hard to beat.Remember back in those days the GMC 6-71blowers were only slightly modified fromstock and they were heavy, so teams runningmy U-Fab would run off and leave them.”However, as is the case in racing, hot ticketsdon’t seem to last long. When the top-mounted Hilborn injection system appeared,the U-Fab, which did not work well with ablower, faded from the scene.

Gaining TractionWhen Top Fuel dragsters were at the top oftheir popularity in the mid-1960s, Crowerhad established his name and he had a lotmore to offer the industry than onemanifold. As Bruce puts it, “Our first realmass-produced product was the U-Fabmanifold kit, but then the dragsters began toput out so much horsepower that tractionbecame a problem and I wanted to improvethe situation.”

Crower had gathered a substantialeducation while working for Schiefermachining flywheels and assembling clutchpackages. Crower took the knowledge onestep further and began developing a clutchpackage of his own design. Bruceremembers, “The major clutch issue wasgetting the horsepower produced by nitro-burning engines to the ground withoutblowing the tires up in smoke. To correct theproblem, I designed a multi-disc clutchpackage that would allow slippage of theclutch, thereby engaging the horsepower tothe rear wheels in a somewhat controlledmanner. The result of my research was calledthe “Crowerglide” automatic clutch. It was acombination of my design and Schieferclutch components.”

Crower continues, “The Crowerglide is aself-engaging multi-disc clutch incorporatingfrom two to six floating discs. Not only didTop Fuel dragsters use the system, but alsoFunny Cars, modified cars and tractorpullers loved the system. I never attemptedto go into production with a blower versionof the U-Fab, because we knew it was a lowvolume item so we shifted our efforts intothe Crowerglide system.”

As for why the Crowerglide system wasso popular, Bruce explained how it worked.“The way I made the “Glide” was the carremained freewheeling until you pusheddown on the clutch pedal. When the pushtruck started rolling, the driver would apply

5At Indianapolis in 1958 pictured with the Kuzma Helse Spl.are (from left to right) John Ludwig, Bruce Crower, car ownerH.H. Johnson and other crew. Jimmy Daywalt is the driver.

5Crower poses with his Hudson after his record runat Bonneville. He used Firestone tires designed forIndy roadsters.

5No idea was too far out of the box for Crower during his most productive years. This is an experimental 350cid Chevysmall block with the intake ports outside of the head. The concept was to flow air directly into the port adding more topend horsepower.

p54_BruceCrower_116:vms_ 2/1/12 2:04 PM Page 56

58 VINTAGE MOTORSPORT Nov/Dec 2011 www.vintagemotorsport.com

the pedal, which would allow the discs tolock up and the engine to turn over. Whenthe engine started you simply took your footoff the clutch pedal and the system would gointo neutral. The crew would roll the car upto the starting line and when the driver camedown on the throttle the rpm would buildup causing the centrifugal weights to engagethe clutch package and you were gone.”

At the SpeedwayFor many, the development of the U-Fabmanifold and the Crowerglide system definewhat they know about Crower; however thereis much more beneath the surface. As early as1954, Crower was making an impact atIndianapolis as a crew member of the DeanVan Lines Champ car driven to second placeby Jimmy Bryan. In 1960 Crower was a keymember of the Ken-Paul team winning the500 with Jim Rathmann as the driver. Crowercontinued working at Indy with the AmericanRed Ball team and winning driver GrahamHill in 1966 and A.J. Foyt in 1967. As asideline to his Indy involvement with Foyt,Crower supplied camshafts for Foyt-owneddirt Champ cars, midgets and sprint cars.

For many years, Crower worked behindthe scenes grinding camshafts for thelegendary Offy Indy engine, both thenormally-aspirated version and theturbocharged version. Opting to step asidefrom conventional thinking, Crowerdesigned a straight-8 engine to run at theSpeedway using Cosworth heads, earninghim the coveted SAE “Louis SchwitzerAward” for race car design in 1977.

Other, out-of-the-box design ideas fromthe mind of Crower include a 1927 ModelT roadster using a 700hp straight-8 Nashengine, and a Bonneville streamlinerequipped with a turbocharged Chevy smallblock featuring four-valve heads that hedesigned and built. That engine wasinstalled in the aforementioned streamlinerwith an additional Crower innovation: thetires used on the vehicle were actuallyKevlar belts similar to the type used on TopFuel and Funny Car superchargers. Thebelts were attached to machined-cutaluminum wheels. The wheels were testedto 8000rpm or good for 400mph.

By the late 1960s, Crower as a companyhad branched out into many areas;camshafts, locking roller lifters, rods,crankshafts and engine kits. In other words,the company had become a full-serviceperformance manufacturer.

According to Crower he didn’t realizehow fast the company was growing until itevolved into a major player in theperformance industry with more than 160employees. The one aspect he does

Crower machinist BennyTravis (left) Bruce Crower(center) and son SteveCrower pose in 1970 withChrysler Hemi whendeveloping Ram TubeInjection.

For Bonneville Crower built amodified roadster powered by astraight-8 Nash engine. Testinghere at El Mirage, it later ran thesalt flats at 235mph.

Crower (left) and Curt Walters prepare a Crower-built Hemi to be installed in a USAC Champ car.

p54_BruceCrower_116:vms_ 2/1/12 2:04 PM Page 58

60 VINTAGE MOTORSPORT Nov/Dec 2011 www.vintagemotorsport.com

expound about is the fact that all of his products are made in theUnited States using only American-made steel—manufactured toextremely high quality standards.

Crower says, “Our products are the finest quality we canproduce and they are all-American. The quality is appreciated notonly by racers in the U.S. but markets in South America and in theMiddle East.”

Asking the Drag Racing Hall of Fame member what he enjoyedmost, the early days or the high-tech present, Crower responded,“Looking back over the years, I lean toward the early days. Itcertainly wasn’t like it is today with those giant 18-wheelers,designer-dressed pit crews, well-rehearsed drivers and multi-million dollar budgets. Back in the day guys like Garlits or[Connie] Kalitta would tow out to California with a pickup truckand an open-wheeltrailer and stay over atmy house to savemoney. They would runmatch races for $1200.Nowadays it takes 1200bucks just to warm up aTop Fuel car. When I goto a National eventtoday all I see is money.It seems to me thatthose with the mostmoney go the fastest. Imarvel at the technology and the speed, but I still like the olddays—there was more pure fun without the pressure of answeringto sponsors or TV audiences.

“I consider myself very lucky to have been around at thebeginning and watched the performance industry grow into a huge part of the economy, but in some ways it has gotten so bigthat I think the business has lost a little of its soul. I think they callthat progress.”

Crower’s San Diego headquartersis very different from the tinyArizona garage where BruceCrower started his business in 1948.

5One of the more radical projects created by Crower wasthis Bonneville streamliner that used machine-groovedaluminum wheels fitted with Kevlar belts instead of tires.

Bruce and Barbara Crower enjoytheir scratch-built ’28 Ford T-roadster powered by a vintageDonovan aluminum small blockfitted with a full array of Crower products.

p54_BruceCrower_116:vms_ 2/1/12 2:04 PM Page 60