5102037E_120_User ManualTX,TXS,TXR.pdf

-

Upload

abhijeet-sahu -

Category

Documents

-

view

379 -

download

38

Transcript of 5102037E_120_User ManualTX,TXS,TXR.pdf

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

1/76

User Manual

X-MET3000TXSeries handheld XRF analyzersX-MET3000TX / TXS / TXR

^å~äóíáÅ~äP.O. Box 85 (Nihtisillankuja 5)FI-02631 ESPOO, FinlandTel: 09 329 411Fax: 09 3294 1300Email: [email protected]

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

2/76

2

X-MET3000TX / TXS / TXRUser Manual

5102 037-4VEEdition 1.20March 2006

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

3/76

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

4/76

4

Contents

SAFETY INFORM ATION

.......................................................................................................................... 3

DESCRIPTION OF THE X-MET3000TX..................................................................................................... 7

PRINCIPAL COM PO NENTS OF THE X-MET3000TX ...............................................................................9

2.1. PRINCIPAL PARTS...........................................................................................................................................9

2.2. THE A NALYZER ...........................................................................................................................................11

2.3. THE PDA COMPUTER ..................................................................................................................................12

2.4. E NVIRONMENTAL OPERATING CONDITIONS FOR THE X-MET3000TX.........................................................13

2.5. POWER SUPPLY ............................................................................................................................................14

Battery power .................................................................................... .......................................................... ..14

Line (A/C) power ............................................................... ................................................................. ...........14

Charger..........................................................................................................................................................14

2.6. HOT SURFACE ADAPTER .............................................................................................................................15

PRE-OPERATING INSTRUCTIONS.......................................................................................................... 17

3.1. PREPARING THE X-MET FOR USE................................................................................................................17

3.2. SWITCHING BACKLIGHT ON/OFF................................................................................................................17

3.3. CALENDAR AND CLOCK ADJUSTMENT .........................................................................................................17

3.4. CHARGING THE BATTERIES ..........................................................................................................................18

3.4.1. Charging instrument batteries ............................................................ ................................................. 18

3.4.2 Charging the PDA internal battery.......................................................................................................18

3.5. BENCH TOP OPERATION ...............................................................................................................................18

3.6 TO TURN OFF THE INSTRUMENT ....................................................................................................................19

3.7. SAMPLE PREPARATION ................................................................................................................................19

ANALYSIS MEASUREMENTS

................................................................................................................. 21

4.1. START UP.....................................................................................................................................................21

4.2. MAKING MEASUREMENTS............................................................................................................................21

4.2.1. General ........................................................... ........................................................ .............................21

4.2.2. Name Sample ........................................................... ........................................................ ....................23

4.2.3. Select Method.......................................................................................................................................24

4.2.4. Display spectra ........................................................... .............................................................. ...........26

4.2.5. Configuration Backup..........................................................................................................................27

INSTRUMENTSETTINGS........................................................................................................................ 29

5.1 GENERAL......................................................................................................................................................29

5.2. FP METHOD SETTINGS .................................................. ........................................................... ....................29

5.2.1. Set Measurement Time.........................................................................................................................29

5.2.2. Output Settings.....................................................................................................................................30

5.2.3 Test Measurement.................................................................................................................................30

5.2.4. Method Type Parameters.....................................................................................................................30

5.2.5. User Setup............................................................................................................................................355.2.6. Assay Screen Settings...........................................................................................................................35

5.2.7. Energy Calibration ........................................................... ................................................................. ..36

5.3. EMPIRICAL ASSAY METHOD SETTINGS.........................................................................................................37

5.3.1. Set Measurement Time.........................................................................................................................37

5.3.2. Output Settings.....................................................................................................................................37

5.3.3. Test Measurement................................................................ .............................................................. ..37

5.3.4. Method Type Parameters.....................................................................................................................38

5.3.5. User Setup, See Section 5.2.5...............................................................................................................39

5.3.6. Screen Settings, See Section 5.2.6........................................................................................................39

5.3.7. Method Parameters..............................................................................................................................40

5.4. IDENTIFICATION METHOD SETTINGS ............................................................................................................43

5.4.1. Set Measurement Time.........................................................................................................................43

5.4.2. Output Settings.....................................................................................................................................435.4.3. Test Measurement................................................................ .............................................................. ..43

5.4.4. Method Type Parameters.....................................................................................................................43

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

5/76

5

5.4.5. User Setup .......................................................... ............................................................ ..................... 44

5.4.6. Screen Settings............................................................... ........................................................... ........... 44

5.4.7. Method Parameters ................................................................ ........................................................... .. 44

INSTRUMENTCALIBRATION................................................................................................................ 47

6.1. GENERAL .......................................................... ........................................................... ............................... 47

6.2. CALIBRATING WITH X-MET 3000 CALIBRATION SOFTWARE .......................................................... ........... 47

6.3. MSG AND FP CALIBRATION............................................................ ........................................................... . 47

6.4. ADDING A REFERENCE TO AN IDENTIFICATION METHOD ........................................................ ..................... 47

6.4.1. Adding a reference sample to a predetermined identification method ................................................ 47

6.4.2. Setting screening conditions for a reference ....................................................................................... 48

6.4.3. Adding a sample to the identification library when sample type is not known........................ ............ 49

SAFETY INFORM ATION ........................................................................................................................ 49

7.1. R ADIATION SAFETY .................................................... ........................................................... ..................... 49

7.1.1. Customer Responsibilities ....................................................... ........................................................... . 49

7.2. DESCRIPTION AND USE OF THE SAFETY INTERLOCKS .................................................... ............................... 51

7.2.1. Precautions to take when analysing Small samples ............................................................................ 52

7.2.2. Precautions to take when analyzing thin samples ...................................................................... ......... 53

7.3. R ADIATION PROTECTION DOS AND DONTS ...................................................... ......................................... 53

7.4. R ADIATION DOSE R ATES....................................................... ........................................................... ........... 547.4.1. The intensity of the primary beam ............................................................... ........................................ 54

7.4.2. Scattered Radiation dose rates ....................................................... ..................................................... 55

7.5. WHAT TO DO I N CASE OF EMERGENCIES .................................................... .................................................. 57

7.5.1. Minor damage .......................................................... ................................................................ ........... 57

7.5.2. Major damage ....................................................... ......................................................... ..................... 57

7.5.3. Loss or theft ...................................................... .............................................................. ..................... 57

7.6. CUSTOMER MAINTENANCE ................................................... ........................................................... ........... 57

APPENDIX 1: TROUBLESHOOTING ...................................................................................................... 59

8.1. IF MEASUREMENT WILL NOT START ........................................................... .................................................. 59

8.2. IF THE X-MET PROGRAM ”LOCKS UP” ..................................................... ................................................... 59

APPENDIX 2: X-MET3000TXS – SOIL MEASUREMENTS ..................................................................... 619.1. DESCRIPTION OF THE X-MET3000TXS..................................................... ................................................. 61

9.2 R ADIATION SAFETY ...................................................... ........................................................... ..................... 62

9.3 DETECTING HEAVY ELEMENTS IN SOIL ....................................................... .................................................. 63

9.3.1 Heavy elements............................................................. ............................................................ ............ 63

9.3.2 Typical soil remediation project...................................................................... ..................................... 63

9.3.3 Sampling........................................................... ............................................................... ..................... 64

9.4 SELECTING OPERATING MODE .......................................................... ........................................................... . 65

9.5 MEASUREMENTS .......................................................... ........................................................... ..................... 65

9.6 SAMPLE PREPARATION ........................................................... ........................................................... ........... 65

9.6.1 Sample cups.................................................. ................................................................... ..................... 66

9.6.2 Sample Bags .................................................. ........................................................... ............................ 68

APPENDIX 3: X-MET3000TXR – MEASUREMENTOF ELECTRONIC COMPONENTS .......................... 69

10.1 DESCRIPTION OF X-MET3000TXR....................................................................... ..................................... 69

10.2 METHODS......................................................... ........................................................... ............................... 69

10.2.1 Auto Detect ................................................................ ............................................................. ............ 69

10.2.2 Alloy FP................ ................................................................ ........................................................... ... 71

10.2.3 Plastic FP ....................................................... ............................................................... ..................... 71

10.3 A NALYZING DIFFERENT MATERIALS......................................................... .................................................. 71

10.3.1 Measuring time............................................................ ........................................................... ............ 71

10.3.2 Non-homogeneous material........................ ................................................................ ........................ 71

10.3.3 Metals ............................................................. ............................................................... ..................... 72

10.3.4 Solders ............................................................ .............................................................. ..................... 72

10.3.5 Plastics ............................................................ .............................................................. ..................... 73

10.3.6 Printed circuit boards and semiconductor chips........ ................................................................ ........ 73

10.3.7 Powders, pellets, etc. ............................................................... ........................................................... 74

APPENDIX 4: ENERGIES OF K AND L LINES

........................................................................................ 75

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

6/76

6

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

7/76

7

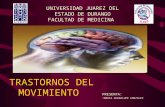

Descript ion o f t he X-MET3000TX

The X-MET3000TX series analyzers are portable elemental analyzers intended for various differentapplications. The X-MET3000TX is primarily intended for metal alloy analysis, the X-MET3000TXS for soil and mining analysis, and the X-MET3000TXR for electronic industry applications. The basic

configuration of all these models is the same and this manual covers operation instructions for allthese analyzers. Application specific information for use of the TXS and TXR model can be found inthe appendices.

The X-MET3000TX series analyzers are based on energy dispersive X-ray fluorescence technologyand use an X-ray tube as the source of excitation. The X-MET3000TX provides a method for chemicalanalysis or sample identification (sorting) directly from samples in various forms. The instrument is afully portable analyzer with an integrated PDA (Personal Digital Assistant) computer. Within the X-MET3000TX analysis program, the user may select analytical modes, view spectra and save data.

Figure 1.1.Field portable conf iguration of X-MET3000TX

The analyzer is battery operated with A/C operation as an option. In some cases, it may be moreconvenient to use the X-MET3000TX in a stationary bench top configuration. The picture below (Fig

1.2) shows the X-MET in the stand provided. There are grooves in the body and the handle whichslide into the stand. Note that for bench top operation, the instrument can be used with battery or A/C(line voltage) power.

Figure 1.2.Bench top installation of X-MET3000TX

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

8/76

8

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

9/76

9

Principa l co mpo nent s o f t he X-MET 3000TX

2.1. Principal parts

Analyzer Battery (*2)

Battery charger Standard shipping

case

Instrument standfor bench top use

AC adapter PDA computer Stylus

Included accessories:

USB Synchronisationcable

PDA AC adapter PDA AC adapter plug

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

10/76

10

Remote extensioncable for PDA

Safety shield for small samples

Kapton window filmki t Shoulder strap

PDA display shieldset

Protection cover

User Manual

Optional accessories: (depending on analyzer type)

Sample bag holder Background plate Sample cup holder Sample cups

Sample bags Sample pressingtool

Remote trigger cable

Sample cup fi lm

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

11/76

11

Pistol holster Rod adapter Weld beam adapter

2.2. The Analyzer

The excitation source in the X-MET3000TX is an X-ray tube. The standard target material is

Silver. The analyzer contains a high resolution Si-PIN diode detector with Peltier cooling.

Figure 2.2.1

Figure 2.2.2

Figure 2.2.3

Figure 2.2.4

There are two (round) connection ports onthe instrument.The one on the front is for connection to thePDA, using the remote PDA extension cable,during bench top operations (see Figure 1.2).(The second port, located on the handle is for connecting the remote trigger cable.

There are two indicator lightson the analyzer:The yellow light is always onwhen the power is on.The red light is on when

X-rays are being generated.

To turn on the instrument,turn the X-MET3000TXinterlock key to the “ON”position.

The second lock is for removing the palmtopcomputer from theinstrument.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

12/76

12

Figure 2.2.5

2.3. The PDA computer

The removable PDA computer in the X-MET includes the user interface for operating the

instrument. The computer is installed in the cradle of the instrument. The display is a 320×240pixel color touch screen, which can be operated either with a fingertip or the stylus provided.For further information about the computer refer to the HP iPAQ Pocket PC instruction guide.The guide can be found with the CD delivered with the instrument.

The infrared safety sensor on theinstrument nose operates bydetecting IR reflected from thesample surface. It is designed toprevent accidental X-ray activationwhile no sample is in place in front of the analyzer.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

13/76

13

2.4. Environmental operating conditions for the X-MET3000TX

Temperature

Analyzer -10 to 50 °C

Charger -10 to 45 °C, operating

-40 to 70 °C, non-operating

Humidity

Continuous operation at 20 to 95 % RH, non condensing.

The charger is designed for indoor use only.

Shock resistance

In transport and operation the instrument must not be dropped or left in exceptionalconditions, which might damage its sensitive components.

During the measurement, small vibrations may lead to inaccuracies if the vibrationsinfluence the detector.

Line voltage

Analyzer 90 – 240 V, 50 – 60 Hz.

PDA 100 – 240 V, 50 – 60 Hz

Charger 85 - 265 V, 47 - 63 Hz

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

14/76

14

2.5. Power supply

Battery power

The X-MET batteries are situated inside the handle. To remove the battery, push the switchand pull to remove the battery. Each fully charged battery will operate the X-MET for

approximately 4 hours.

Line (A/C) power

Line operation of the X-MET is possible by connecting the AC adapter to the instrument. Todo this, remove the battery and connect the AC adapter to the plug in the bottom of thehandle.

Charger

The battery charger is provided for charging X-MET batteries. To charge a battery, remove itfrom the X-MET and connect the battery to the charger. Charging the X-MET batteries cantake up to 2 hours if they are fully discharged.

Note: the PDA has internal batteries. Be sure to fully charge the PDA batteries using theiPAQ AC adapter prior to using the instrument for the first time. The PDA draws power bothfrom the X-MET battery and its own internal battery, but will not charge from the X-METbattery.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

15/76

15

2.6. Hot Surface Adapter

The hot surface adapter is a standard feature of the X-MET3000TX. It is designed for measurement at hot surfaces like hot tubes or plates. The adapter lowers the heat conductionand radiation from the hot sample to the detector. This is necessary because the detector crystal has to be cooled and stabilized to maintain its analytical performance. However, theheat conduction can not be prevented completely, thus there are limitations on themeasurement times. Table 1 illustrates the limitations – surface temperatures withmeasurement and cooling times between measurements.

Table 1

Sample Temperature Measurement time Cooling time betweenmeasurements

300oC 15 s 10 min

300oC 5 s 5 min

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

16/76

16

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

17/76

17

Pre-o pera t ing inst ruct io ns

3.1. Preparing the X-MET for use

1. Insert a fully charged battery into instrument.

2. Remove stylus from the PDA computer.

3. Unlock the PDA computer lock with the key (Figure 2.2.2).

Slide the PDA computer snugly into the cradle on the instrument. Take care to seat the PDAon the connector correctly

4. Lock PDA computer into place.

5. Turn the X-MET power key to “ON” position (Figure 2.2.1). The yellow power indicator isswitched on. Wait 1-2 minutes for the peltier cooler and X-ray tube to stabilize.

6. Push PDA power switch “ON”.

3.2. Switching backlight ON/OFF

From the ”Start” menu on the PDA main screen, tap ”Settings”, then ”System” and then”Backlight”. Set the parameters according to your need.

3.3. Calendar and clock adjustment

The setting of the date and time is done from the main screen of the PDA. To change thesettings, tap the date on the screen and perform the adjustments.

If the PDA battery power has been completely discharged or the PDA has been reset, it maybe necessary to adjust the date and time settings.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

18/76

18

3.4. Charging the batteries

3.4.1. Charging instrument batteries

Turn the instrument off (Section 3.7).

Remove the battery from the instrument.

Connect the charger to the battery.

The Power light on the charger is green when itis connected to the power supply.

The Status light on the charger is amber whenthe battery is charging.

When charge is complete, the Status light isgreen.

3.4.2 Charging the PDA internal battery

Turn the instrument off (Section 3.7.).

Remove the PDA from the instrument by unlockingthe PDA lock with the key.

Insert the PDA adapter plug into the charging port

on the bottom of the PDA. Plug one end of thePDA AC adapter into an electrical outlet and plugthe other end into the PDA adapter plug in thebottom of the PDA.

The amber charge light on PDA blinks while thebattery is recharging and turns solid amber (non-blinking) when the battery is fully charged.

It is recommended that the PDA battery be completely charged before use if instrument hasnot been used for several days. Battery low warning messages will be displayed when the

PDA battery charge is low.

3.5. Bench top operation

To set the instrument for bench top operation, do the following:

Place the instrument in the instrument stand provided so that the grooves in the instrumentslide into the stand. (See Figure 1.2.).

Connect the PDA to the X-MET with the remote extension cable using the port on the front of the X-MET.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

19/76

19

Turn on the instrument.

WARNING: To measure small sized samples, whic h don’t completely cover the measuring window and /or the infrared sensor, use the safety shield provided.

3.6 To turn off the instrument

To turn off the X-MET, exit the analysis program, turn the PDA power off and turn the X-MET3000TX power key to “OFF” position.

3.7. Sample preparation

The sample surface should be clean of dust, corrosion, oil etc. The analysis is done on thesurface of the sample, so the surface must be representative of the material.

If the sample is smooth and clean (no rust, oil, dirt etc.), no sample preparation is necessary.

If the sample surface is dirty it should be cleaned. Contamination on the sample surface willhave the greatest effect on light element analysis (Ti, V, Cr). Dirt and oil can be simplycleaned from the surface with a cloth. Rust, paint and coatings should be removed by grindingthe sample surface.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

20/76

20

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

21/76

21

Ana lysis Mea sureme nt s

4.1. Start up

After powering ON the X-MET (see Section 3.1) the analysis program is started from “Start”menu (Figure 4.1.). Tap “X-MET” to start the program.

Figure 4.1. Start menu

The “X-MET3000” screen (Figure 4.2.) appears with “Waiting for Connection” message in thelower left corner (this may take up to 30 sec.).

Figure 4.2. Getting connected

4.2. Making measurements

4.2.1. General

The X-MET is usually delivered to the user fully calibrated. Therefore, it can be used for dailywork without any preparation other than that described in Section 3.

After start up the X-MET will go to the measurement screen (Main menu) (Figure 4.3.).

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

22/76

22

Via this menu the user can:

1. Select the mode of operation.

2. Make a measurement.

3. Name the sample to be measured.

4. Display the spectrum of the latest measurement.

5. Access the settings to change, for example, the measurement time.

Measurements are made by putting the nose of the analyzer on the sample (or the sample onthe nose), and pressing the trigger on the analyzer. Be sure that the infrared sensor on thenose of the instrument is covered or the measurement will not start.

The red light indicates that the X-ray tube is generating X-rays. Make sure that you keep theanalyzer on the sample during the entire measurement. If the sample does not cover theinfrared sensor no data will be acquired. In that case release the trigger immediately andreposition the sample to cover the sensor. The total measurement time and the elapsedmeasurement time will show at the bottom of the measurement screen (figure 4.4.)

After the measurement time has elapsed, release the trigger. The calculation takes a fewseconds, depending on the selected method, sample type and grade identification. When themeasurement is completed and results are shown (Figure 4.5) a new measurement can bestarted.

To hide the menus in the measurement screen tap once in the white area above the menuboxes. To unhide the menus tap the screen again.

Note: The instrument will take 1-2 minutes to stabilize after switching the instrument power on. During this stabilization time it is not possible to perform measurements.

WARNING: When the X-MET3000TX is operating, ensure that t he samplecompletely covers the aperture and IR sensor or use the small parts shield.This prevents stray radiation from exiting the instrument.

WARNING: Never point the ins trument at yourself or another perso n even witha sample in place.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

23/76

23

4.2.2. Name Sample

The user can give a name to the sample to be measured. If the result is saved, the name willbe also saved. To name a measurement, tap “Name Sample” on the main menu. This bringsyou to the screen where you are prompted to input the name using the keyboard (Figure 4.6.).

If the name consists of a continuous string, a space and a number (for instance PIPE 5), thenumber is automatically increased after every measurement (PIPE 6, PIPE 7 etc.).

Note: You can only name a sample before it is measured. Entering a sample Name bytapping on the name box in the results screen will name the next sample.

Figure 4.6. Name sample.

Figure 4.3.Measurementscreen, Main menu.

Figure 4.4. Measurementin progress.

Figure 4.5.Measurement resultsscr een.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

24/76

24

4.2.3. Select Method

To select the desired method tap “Select Method” from the main screen. This will activate ascreen where you will find all the methods stored in the instrument memory (Figure 4.7). Themethod name and type are shown. To select a method, highlight the method and tap “SelectMethod”.

Figure 4.7. Selecting a method.

There are three method types available:

‘Empirical Assay’.

‘Identification’.

‘Fundamental Parameters’.

4.2.3.1. ‘Empirical Assay’ method type

‘Empirical Assay’ is an Assay & Grade method for measuring the elemental concentrations of unknown samples. An empirical assay method is a set of calibration curves and other parameters that calculate the concentration of a specific set of elements in an unknownsample. It is the result of a calibration procedure. The calibration procedure assay method iscreated using a set of standards which have assay values for the elements being analysed inthe unknown samples. The standards have concentrations that vary from one another andspan the range of concentrations expected in the unknown samples. Analysis of samplesoutside the calibration range can result in erroneous results.

Figure 4.8. Result of an empir ical assay method measurement

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

25/76

25

The X-MET software automatically checks to see if the analysis results are outside thecalibration range. If this occurs, the results are displayed with an arrow next to the number. If the arrow is pointing to left, the result is below the calibration range. If it is pointing to the right,the result exceeds the range. In either instance, the results should be reviewed beforeaccepting them. If the out of range indicator shows often for an analyte, it may be necessaryto recalibrate the method for the new range of concentrations.

4.2.3.2. ‘Identification’ method type

Often it is not necessary to find out the actual assay values for an unknown sample, but onlynecessary to identify or verify the sample grade, or proprietary alloy name. This is done bycomparing the X-ray spectrum of the unknown sample to the spectra of known samples,which have been recorded in the memory during the calibration.

If a similar sample is stored in the reference library, the X-MET will simply give the name of the sample as it is stored in the memory. The name can be the grade of the alloy e.g. SS 316,or any other name under which that sample was stored. Where a positive identification ismade, the identified sample name is shown together with the note Good Match.

Figure 4.9. Result of positive identification of 2 ¼ Cr 1Mo

If the measured sample is slightly different from any reference in the memory then PossibleMatch is displayed, together with the closest reference name(s). Where a Possible Match isidentified one or two reference names can be given by the instrument.

Note: The first given reference name is a closer match to the measured sample.

When the measured sample is not similar to any of the references stored in the memory, themessage No match is given.

Figure 4.10. Result of negative identification.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

26/76

26

A test value called Difference shows the closeness of the measured sample to the referencein the memory. The closer the value is to zero the more exact the measured sample and thestored reference signatures are to each other. The threshold values between good, possibleand no match can be set during the calibration of the instrument.

4.2.3.3. ‘Fundamental Parameters’ method type

‘Fundamental Parameters’ (FP) is an Assay & Grade method for measuring the elementalconcentrations of unknown samples. FP analysis provides assays based on fundamentalknowledge of X-ray physics, the detector response, and the basic spectra of a few standards.

There are three different FP methods available depending on instrument configuration.

Alloy FP provides chemical analysis of elements commonly found in alloys. Theconcentration range for each element can vary from 0% up to 100%. The program normalisesthe results to 100%.

Soil FP is for analysing heavy element concentrations in soil.

Plastic FP is for analysing heavy elements in plastic or other low density material.

Low concentrations of elements are not shown if their value is less than 2 standard deviations(STD). The elements are shown in decreasing order of magnitude, thus making it easier toread the results (Figure 4.5).

4.2.4. Display spectra

The user can view the spectrum of the latest measurement by tapping “Display Spectra”(main menu). Figure 4.11 shows the screen used to plot spectral data. The data on the right

side of the spectrum shows information relating to the Cursor position in the spectrum.Cursor Energy displays the energy value in keV. Channel is the cursor’s position in channels.Count gives the number of counts at the cursor’s position.

Select “Zoom In” to view any part of the spectrum in more detail. Once an area has beenenlarged, a new area can be enlarged again. To restore to the previous scale select “ZoomOut”. To restore to original settings select “Fit to Window”. To zoom on the Y-axis enable“Zoom on Y-Axis”.

Figure 4.11. Spectral display.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

27/76

27

Select “XRF Line Display” to place markers on the spectrum identifying the α and β lines for the K and L series of the X-ray lines. To select an element, tap the element symbol (Figure4.12.) and tap “Ok” to view. The markers for the selected elements will be shown as inexample Figure 4.13.

4.12. Selection of element for line identification

4.13. Spectral disp lay XRF line markers

4.2.5. Configuration Backup

This feature backs up all files associated with calibrated methods. To start the backupprocedure, select Configuration Backup from the Main menu (Figure 4.3.) and then “StoreConfiguration” in the menu shown in Figure 4.14.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

28/76

28

4.14. Configuration Backup Settings

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

29/76

29

Instrumen t sett ing s

5.1 General

A user can select different choices and options related to the instrument operation and dataoutput. To start these functions first tap “Settings” in the main menu. The content of the“Settings” menu is different depending on the selected method type.

5.2. FP method Settings

Figure 5.1. Settings menu of a FP method

5.2.1. Set Measurement Time

The measurement time can be changed by selecting “Set Measurement Time:” on theSettings menu. This brings you to the screen where you are prompted to set the time usingthe keyboard (Figure 5.2). Tapping “Del” deletes the last character entry and tapping “Clear”empties the edit field.

Figure 5.2. Measurement time setting.

If the measurement time is set to 0 (zero), the measurement time elapses until the trigger is

released. The result is updated in the screen at intervas of couples of seconds. the final resultis calculated after releasing the trigger.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

30/76

30

5.2.2. Output Settings

Data produced during analysis can be stored to the PDA. To activate saving of data select“Output Settings” on the Settings menu.

There are two different file formats for saving analysis results. The logfile stores the datadisplayed in routine analysis in text format. The table file uses a worksheet format, and thestored results can be processed further with Excel program.

To save results tap either “Write logfile?” or “Write tablefile?”, depending on the desiredformat. The button changes to YES (results will be saved) if it was earlier NO and vice versa.The selected value (YES/NO) is shown in bold font.

To specify the directory path and filename where the analysis results will be stored, select“Log filename:” or “Table filename:” depending on what was selected as an output format.

Spectra of the analysis measurements can be saved by tapping the “Write spectra?” button.The directory where the spectra will be stored can be changed by selecting “Set spectradirectory:”.

Figure 5.3. Output settings.

5.2.3 Test Measurement

The test measurement function provides a means to measure an arbitrary sample and displaythe recorded X-ray spectrum on the screen. Select the desired current / voltage pair andpress the trigger to start the measurement. During the measurement the elapsed and totalmeasurement time is shown, as usual. After the measurement is finished the spectrum isshown (see Section 4.2.4 Display Spectra).

5.2.4. Method Type Parameters

This screen allows the changing of various parameters related to the selected measurementmethod.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

31/76

31

Figure 5.4. Method type parameters of FP method.

5.2.4.1. STD Display

Standard deviation (STD) is the precision of the measurement based on the counting

statistics. To display the measurement’s statistical error for each analysed quantity select“STD Display” ON.

5.2.4.2. Concentration

The measurement unit can be changed either to percent (%) or parts per million (ppm).

5.2.4.3. Invisible Element Correction

The X-MET3000 cannot measure the elements with a lower atomic number than Ti (22).Those elements are called “invisible elements”. If their concentrations are significant, theanalysis will be distorted because of the normalization to 100%.

If the concentrations of invisible elements are known beforehand, the user can input the

values manually. If the invisible element correction is not needed, it can be switched off.

To enable invisible correction select “Invisible Element Correction” ON from the “MethodParameters” screen (Figure 5.4).

5.2.4.4. Set Invisible Element

If the concentrations of invisible elements of the sample are known, select the “Set InvisibleElements” button. The Invisible Element screen is shown, see Figure 5.5.

To choose an element select “Add Element”, this will open the screen shown in Figure 5.6.Choose the element you want to add and select “Ok”.

To set the known concentration choose “Change Element Value”. Figure 5.8. shows theadded element list.

Figure 5.5. Manual input of invisible elements.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

32/76

32

Figure 5.6. Adding elements. Figure 5.7. Set concent ration .

Figure 5.8. Added elements

Individually add all the elements you want to include as invisible elements. An element can beremoved by first highlighting the element and then selecting “Delete Element”.When the user has manually input the concentration of invisible elements, they are used untilthe input is changed.

5.2.4.5. Grade tables

On the result screen, the X-MET is able to show the grade name(s), or trade name(s) of themeasured sample. The instrument does this by comparing the assays of the measuredsample with those in a grade table. A grade table is a list of grade names with associatedupper and lower assay limits for the analytes.

Grades for the FP methods are automatically inserted in the system. The FP chooses theappropriate grade table according to the matrix element. Matrix elements are the elements

which usually form the biggest part of the sample. For instance, low alloy steels containabout 95% iron, the rest (5 %) being alloying elements. Thus Fe is the matrix element of lowalloy steels.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

33/76

33

5.2.4.6. Grade Expansion Coefficient:

In this screen you may expand the grade identification limits. A value, which expands thelower and upper limit of grades , is calculated from n*STD. N is a discrete value, 0,1,2,3 or 4,and this can be changed by the user.

Figure 5.9. Grade expansion coefficient.

5.2.4.7. Grade Table Editor

To create or edit grade files in the X-MET use the built-in grade editor. To access the gradeeditor, select “Grade Table Editor” from the Method Type Parameters screen (Figure 5.4.) andthe ‘Select Matrix Element’ screen, shown in Figure 5.10, is displayed.

Figure 5.10. Select Matrix Element

An FP method chooses the right grade table according to the matrix element. Choose thedesired matrix element by tapping the element symbol. The ‘Add/Edit/Remove Grade’ screenwill be displayed (Figure 5.11).

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

34/76

34

5.11. Grade editor , grade lis t screen.

All the existing grade names for the selected matrix element will be listed. There may not beany grade names if a grade table for the selected matrix element has not yet been created.

To add a new grade, tap “Add”. The user is prompted to give a name to the grade (see Figure5.12). The name can have a maximum of 15 characters. Tapping “Remove” deletes thehighlighted grade. The deletion is confirmed before the actual operation.

5.12. Edit New Grade Name screen

To edit the grade, highlight the grade name and tap “Edit” (Figure 5.11). A screen (Figure5.13.), with element list and with lowest and highest allowed concentrations, is shown. To adda new element, tap “New Element”. To remove a highlighted element, tap “Remove Element”.To edit lowest and / or highest allowed concentrations, tap the current value and a screen(Figure 5.14.) is shown where new values can be entered.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

35/76

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

36/76

36

Figure 5.16. Screen settings.

5.2.7. Energy Calibration

In this screen the user can perform an energy calibration measurement. This is done bymeasuring the DUPLEX 2205 sample supplied with the instrument. To do the energycalibration measurement, place the sample in front of the analyzer and press the trigger. After the measurement is finished, release the trigger. If you do not wish to perform thismeasurement you may exit this screen by tapping “Skip Measurement”.

Figure 5.17. Energy calibration

Note: The instrument needs about a 2 minutes warming up period after switching the

instrument power on before it is ready for making measurements.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

37/76

37

5.3. Empirical assay method Settings

Figure 5.18. Settings menu of empirical assay method

5.3.1. Set Measurement Time

The measurement time can be changed by selecting “Set Measurement Time:” on theSettings menu. This brings you to the screen where you are prompted to set the time usingthe keyboard (Figure 5.2). Tapping “Del” deletes the last character entry and tapping “Clear”empties the edit field.

If the measurement time is set to 0 (zero), the measurement time elapses until the trigger isreleased. The result is updated in the screen at approximately two (2) second intervals(Figure 5.19). The final result is calculated after releasing the trigger.

Figure 5.19. Updating screen during measurement

5.3.2. Output Settings

See Section 5.2.2.

5.3.3. Test Measurement

See Section 5.2.3.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

38/76

38

5.3.4. Method Type Parameters

This screen allows the changing of various parameters related to the selected measurementmethod.

Figure 5.20. Method type parameters of empir ical assay method

5.3.4.1. Standard Deviation

See Section 5.2.4.1.

5.3.4.2. Distance Scaling

If distance scaling is enabled, the analysis is automatically corrected for irregular shape of thesample and for distance changes between the sample and the analyzer.

The distance scaling works by identifying the sample and scaling the measured spectrum to a

similar spectrum in the memory. If the sample is not identified, a warning is shown (Figure5.21).

Figure 5.21. Distance scaling failed

In this case, there is no matching reference in the spectrum library of the method. However,the user can add typical samples to the identification library for distance scaling. The sampleto be used for scaling must be even and cover the whole measurement window of theinstrument. Adding samples to a method is described in the Section 6.4.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

39/76

39

5.3.4.3. Edit Grades

On the result screen, the X-MET is able to show the grade name(s), or trade name(s) of themeasured sample. The instrument does this by comparing the assays of the measuredsample with those in a grade table. A grade table is a list of grade names with associatedupper and lower assay limits for the analytes.

Grades for empirical assay methods are always associated with predefined assay methods.Thus the X-MET automatically uses a correct table to look for grades.

To create or edit grade files in the X-MET use the built-in grade editor. To access the gradeeditor, select “Edit Grades” from the Method Type Parameters screen (Figure 5.20.) and ascreen, as shown in Figure 5.11, is displayed.

All the existing grade names for the selected matrix element will be listed. There may not beany grade names if a grade table for the selected matrix element has not been yet created.

To add a new grade, tap “Add”. The user is prompted to give a name to the grade (Figure5.12). The name can have a maximum of 15 characters.

Tapping “Remove” deletes the highlighted grade. The deletion is confirmed before the actualoperation.

To edit the grade, highlight the grade name and tap “Edit” (Figure 5.11). A screen (Figure5.13) with element list and with lowest and highest allowed concentrations is shown. To add anew element, tap “New Element”. To remove a highlighted element, tap “Remove Element”.To edit lowest and / or highest allowed concentrations, tap the current value and a screen(Figure 5.14.) is shown where new values can be entered.

5.3.4.4. Display spectral ID

To display the method and reference used in the distance scaling, change Display spectral IDto “YES”.

Figure 5.22. Displaying method and reference used for distance scaling

5.3.5. User Setup, See Section 5.2.5.

5.3.6. Screen Settings, See Section 5.2.6.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

40/76

40

5.3.7. Method Parameters

Figure 5.23. Method parameters menu of an empirical assay method

The Method parameters menu offers three functions for the maintenance of calibratedempirical assay methods. These features help to insure accurate method analysis over timewhile minimising the need for frequent recalibration. This chapter describes the features andtheir use.

5.3.7.1. Single Point Recalibration

Single point recalibration is a method to correct the results for a selected material type only. Itis useful when the user has to make an accurate analysis within narrow concentration ranges.Be careful when using this feature, because the correction is only valid for samplesclose in concentrations to the specific (reference) sample.

To perform a single point recalibration, go to “Single point recalibration”. A screen similar tothat shown in Figure 5.24 will be displayed. Highlight the analyte you want to correct andpress “Set concentration”. Enter the concentration. Then place the reference sample againstthe measurement window of the instrument and pull the trigger to start the measurement.

If the single point calibration is no longer needed, you can reset the single point recalibrationby pressing “Reset”.

Figure 5.24. Single Point Recalibration

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

41/76

41

5.3.7.2. Check Sample Measurement

The function of the check sample is to provide a reference point during calibration that can beused later for updating calibration equations. This applies to empirical assay methods only.During calibration, a sample is measured and stored as a check sample. This sample isrepresentative of the standards used in the calibration. When the sample is measured, theassay values and standard deviations are stored along with the calibrated method. This sets areference point for the performance of the calibration equation.

At any time, the same sample can be measured using the Check sample option. This displaysthe screen shown in Figure 5.25.

Figure 5.25. Measurement of check sample.

Place the check sample against the measurement window and pull the trigger to start themeasurement. After the measurement is completed the analysis results are displayed (Figure

5.25.). The first column shows the analyte. Original assay values from the analysis duringcalibration are shown in the second column. The third column is the assay value from thepresent analysis. Column four shows the difference between the two values.

Figure 5.26. Results of check sample analysis.

If the difference is less than three standard deviations, it is assumed that there is no statisticaldifference between the measurements. Thus no update is recommended. In this instance, the“Cancel” button should be pressed.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

42/76

42

If the difference between the two measurements of an analyte is more than three standarddeviations, the deviating analyte is marked with yellow colour. In this instance, using thecheck sample results to update the calibration curve is recommended. To update thecalibration simply press the “Save” button. The intercept of the calibration equation will beadjusted so the new analysis will correspond with the original.

If the difference between the two values is more than ten standard deviations, the followingwarning is displayed “Check to see if sample is correct”. Press the “Cancel” button and checkthe following before updating the calibration:

1) Check that the sample currently being analysed is the sample used for the original checksample measurement.

2) Make sure that the sample is stable over time and has not changed in composition sincethe original analysis.

3) Insure that the sample has been properly placed against the measurement window.

If all these conditions have been met, then re-measure the sample and update the calibrationif necessary.

5.3.7.3. Analyte Correction

Correction of the calibration equation (of an empirical assay method) with the check samplecreates a coefficient that is applied to the calibration´s curve intercept value. The “Analytecorrection” option shows the correction coefficient and allows for it to be manually changed.Figure 5.27 shows the correction coefficients. To enter a manual correction coefficient,highlight the element to be changed then press the “Change Offset” button. A dialogue boxopens and the new value can be entered. When the “Ok” button is pressed, the new value will

be used to update the calibration equation.

Figure 5.27. Analyte Correction

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

43/76

43

5.4. Identification method Settings

Figure 5.28.

5.4.1. Set Measurement Time

The measurement time can be changed by activating “Set Measurement Time” on theSettings menu. This brings you to the screen where you are prompted to set the time usingthe keyboard (Figure 5.2). Tapping “Del” deletes the last character entry and tapping “Clear”empties the edit field.

If the measurement time is set to 0 (zero), the measurement time elapses until the trigger isreleased. The result is updated in the screen at approximately 2 second intervals (see Figure5.19.) The final result is calculated after releasing the trigger.

5.4.2. Output Settings

See Section 5.2.2.

5.4.3. Test Measurement

See Section 5.2.3.

5.4.4. Method Type Parameters

This screen allows the changing of various parameters related to the selected measurementmethod.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

44/76

44

Figure 5.29. Method type parameters of an identification method

5.4.4.1. Difference Display

A test value called Difference shows the closeness of the measured sample to the referencein the memory. The closer the value is to zero the more exact the measured sample and thestored reference signatures are to each other. The threshold values between good, possibleand no match can be set during the calibration of the instrument.

To display the measurement’s difference value, change “Difference Display” to YES.

5.4.4.2. Confirm Possible Match / Confirm No Match

A user may be prompted to confirm a ‘Possible Match’ or ‘No Match’ by selecting ‘Yes’ for thecorresponding option. A pop-up message box is displayed (see example Figure 5.30).

Figure 5.30. Confirmation box of No Match

5.4.4.3. Display Screening Path

Change the “Display Screening Path” to YES, to display the intermediate results of thescreening chain, not only the final result.

5.4.5. User Setup

See Section 5.2.5.

5.4.6. Screen Settings

See Section 5.2.6.

5.4.7. Method Parameters

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

45/76

45

Figure 5.31. Identif ication method parameters

The thresholds options define the limits for Good, Possible or No Match. If the differencebetween the measured sample and the reference sample, that best matches the measured

sample, is below the fine threshold value, it is considered to be a good match. If the differenceis between the fine and coarse threshold values, it is a possible match. If the difference isgreater than the coarse threshold value, there is no match. To change the threshold value,select the button and enter a new value.

If ‘No Match’ is reported for a measurement, the result may be recalculated using a differentmethod. Select “Recalculation Method” and select the method you wish to use for recalculation, from the list.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

46/76

46

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

47/76

47

Instrument calibration

6.1. General

In order to give accurate results the X-MET needs to be carefully calibrated for all the sampletypes to be measured. Although the instrument is often delivered fully calibrated, completesoftware tools for user calibration are available.

6.2. Calibrating with X-MET 3000 Calibration Software

The empirical assay methods and the identification method are created with X-MET 3000Calibration Software, which runs on an external PC. For further information about thissoftware refer to the X-MET 3000 Calibration Manual.

6.3. MSG and FP calibration

Both MSG (Metal Standard Generation) and FP calibration software can be accessed fromthe “Calibration” button on the Main Menu (Figure 4.3). These calibrations are usuallyprovided when the instrument is delivered and in general the user does not need to createthese. For further information about this software refer to X-MET 3000 Calibration Manual.

6.4. Adding a reference to an Identification method

A user can perform the most commonly used operations for the identifications, directly in thePDA program.

The user can add a new reference for an Identification method simply by making a samplemeasurement, and instructing the X-MET to store the measured spectrum.

6.4.1. Adding a reference sample to a predetermined identification method

The user can add samples to any identification method calibrated into the X-MET byproceeding as follows:

Select the method by tapping “Select Method” in the Main Menu (Figure 4.3). Choose theidentification method according to the sample type you are about to add. For example if youhave a Stainless steel sample, then highlight the SS ID method and tap “Select Method”.

Choose Settings in the Main Menu and then Method Parameters. Select “ReferenceMaintenance” at the bottom of the screen (Figure 5.31). This will bring a new menu onto thescreen (Figure 6.1), with a list of all the references stored in the selected method. A date nextto the sample name indicates that the reference is measured and has a spectrum in theidentification library.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

48/76

48

Figure 6.1. Adding a reference into memory

Tap the “Add Sample” button and type in the desired sample name for the sample to beadded (Figure 6.2) Tap the “OK” button. Make sure that the new sample name is highlighted

on the sample list. Place the sample on the analyzer and pull the trigger to start themeasurement. Keep the analyzer on the sample during the entire measurement time. After the measurement is complete the sample name and its spectrum are stored in the memory.

Figure 6.2. Defining standard name

Note: When storing references you should use a measurement time long enough tocollect a well-defined spectrum (60 – 120 seconds).

The sample is now added to the selected X-MET identification library.

6.4.2. Setting screening conditions for a reference

Screening means instruction to the X-MET to use another method to re-calculate the result, if the reference in question has been identified. The reason for this may be that more accurateidentification or concentration analysis is needed.

Note: Screening happens only if the result from the identification is Good match.

To define the screening method for a reference, press the “Set Screening Method” in the“Reference Maintenance” menu (Figure 6.1.). This will bring a menu on the screen, whichshows all the calibrations in the X-MET memory. Scroll to move the cursor to the method youwish to use. Tap the “Select” button to select the method.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

49/76

49

6.4.3. Adding a sample to the identification library when sample type is not known

If the exact type of a sample is not known, it is not possible to allocate it to a predeterminedidentification method. However, the user may allow the X-MET to deduce the general sampletype and target method.

First select the general identification calibration from the “Select Method” menu. Then make ameasurement as usual. The X-MET will now first try to identify the sample type and will switchdirectly into the most likely calibration method. Select this as the target method on the “SelectMethod” screen, and add the reference into the target method as described in Section 6.4.1.

Sa fet y Info rma tion

You MUST: Read and understand this entire safety section. Contact the appropriate regulatory authority to determine what is needed (see

Customer Responsibilities 7.1.1)

Have received training in the safe operation of the X-Met (see Customer Responsibilities 7.1.1).

Complete a risk assessment for the safe operation of the X-Met (Refer to 7.4 for doserates).

Maintain a list of authorized users. Check correct functioning of analyzer once a month. See Customer Responsibilities

7.1.1 and Customer Maintenance 7.6).

7.1. Radiation Safety

The X-Met3000TX series must only be used by persons who have beentrained to operate the probe safely.Do not point the instrument at any person when it is in operation.Users must not try to gain access to the radiation enclosure.Servicing must only be carried out by engineers trained by Oxford Instruments.

7.1.1. Customer Responsibilities

Contact the appropriate regulatory authority to determine if registration or licensingrequirements apply: For example, in the United Kingdom, equipment of this type isdefined as a radiation generator, and its use is governed by the ‘Ionising RadiationRegulations 1999’ (IRR99); the ‘Health and Safety at Work etc. Act 1974’ (HSAW);the ‘Management of Health and Safety at work Regulations 1999’ and the ‘Provisionand Use of Work Equipment Regulations 1998’. Users must notify the Health andSafety Executive (HSE) of their intention to work with ionising radiation. (Notificationis only done once, or when an employer makes a material change to their work thatwould affect the particulars of the original notification. If the employer has alreadynotified the HSE, further notification following the purchase of a 3000TX is notrequired).

Help and advice is available from the HSE infoline on telephone number 0845 3450055. The HSE require 28 days notice. There is a requirement to appoint a Radiation

Protection Advisor (RPA). The RPA will help specify work procedures to be followedincluding training requirements for the correct use of the equipment.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

50/76

50

Test the device for correct operation of the ON/OFF mechanism every six months and keep arecord of the test results. If the instrument fails the test, contact an OIA representativeimmediately for instructions and return the instrument for repair.Maintain a record of the instrument use and any service to shielding and/or containmentmechanisms for two years or until the ownership of the instrument is transferred or theinstrument is decommissioned.

Report to appropriate authority any possible damage to shielding and any loss or theft of theinstrument.Transfer or loan the instrument only to persons specifically authorized to receive it, and reportany transfer to the appropriate regulatory authority, normally 15 to 30 days following thepurchase, if required.Report the transfer of the instrument to an appropriate OIA representative.Comply with all instructions and labels provided with the instrument and do not remove labels.Removal of labels will void the warranty.Do not abandon the instrument.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

51/76

51

7.2. Description and use of the safety interlocks

The X-MET3000TX has been designed with a failsafe safety circuit to prevent inadvertentexposure of the operator to the X-ray beam. The safety system for the instrument consists of

three failsafe lights, a key lock, a trigger to activate X-rays, and an infrared sensor. Thefunction of each safety feature is described below:

Primary power safety keylock –

Yellow, High voltage on, failsafe warning light –

Operator trigger interlock – When the trigger is pulled, X-rays are generated if the followingconditions are met:

Infrared beam safety sensor –

A key lock is employed to control power to all components. The key lock must beturned on before any actions can beinitiated.NOTE: Remove the key from the

analyzer when not in operation toprevent unauthorised use.

When the key lock is turned on, the

yellow light will be activated toindicate there is voltage to the power supply. If the bulb has failed or hasbeen removed, the safety circuit willnot permit application voltage.

The infrared beam safetysensor, located at thenose of the instrument, willnot permit X-rays to begenerated unless a solidobject covers the infraredbeam.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

52/76

52

Dual red X-ray on failsafe warning light –

Do not point the instrument at any person when the probe isactivated. Note that the form of the primary beam is a narrow cone that points obliquely tothe left, not directly forwards. The radiation intensity is high in the primary beam and thereforeno part of the body should be exposed to that radiation. While measuring, make sure that theinstrument is in contact with the sample and that the whole measurement window and infraredsensor are covered by the sample. In cases where the sample doesn’t cover the wholemeasurement window use the safety shield for small samples. Thin samples may allow higher exposure; see 7.2.1.

7.2.1. Precautions to take when analysing Small samples

Small samples that do not cover the measurement window entirely are quite obviouslypotentially risky to measure because part of the primary radiation may go through the sampleun-attenuated. To eliminate the risk the protective safety shield for small samples is providedto cover the sample entirely.

When the trigger is pulled andthe infrared sensor is engaged,the red lights will be activatedindicating the generation of X-rays. If one or both of the redLED’s are burned out, X-rays willnot be generated.

Protective safetyshield for small

samplemeasurement.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

53/76

53

7.2.2. Precautions to take when analyzing thin samples

A less obvious risk to radiation exposure is caused by the measurement of thin samples. Partof the radiation coming from the X-ray tube is so high energy that it penetrates thin samples,especially if they are of low atomic number material. The following table gives the relativeintensities after the radiation has gone through aluminum / iron sheets of various thicknesses.(The tube is run at 40 kV, 2µA).

luminium sheet Relative int ensity Iron sheet Relative int ensity

0 mm 100 0.0 mm 100

1 mm 55 0.1 mm 31

2 mm 36 0.2 mm 15

3 mm 26 0.3 mm 8

4 mm 19 0.4 mm 5

5 mm 15 0.5 mm 3

10 mm 5 1.0 mm 0,4

NOTE: If the sample is unable to stop the primary radiation the dose rate may be high behindthe sample. An aluminum sample must be quite thick before it absorbs most of the radiationwhereas iron provides much better shielding. In practice the difference is important andmeans that it is wise to measure aluminum samples at arms length.

7.3. Radiation Protection DOs and DONTs

DO DONT

Read and understand the safety information

(Section 7)

Override the safety features

Follow any instructions given Point the analyzer at any person or animal

Store the key away from the analyzer whennot in operation to prevent unauthorized use.

Leave the key with the analyzer when not inuse

Store the analyzer in a safe location when notin use.

Leave the analyzer unattended if not safelystored away.

Keep control over who is authorized to usethe device.

Allow people into the beam path and trainusers in managing this risk.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

54/76

54

7.4. Radiation Dose Rates

7.4.1. The intensity of the primary beam

The following table reveals the intensity of the primary beam when the infrared sensor isintentionally bypassed and no sample is placed in front of the probe. It gives the time that

hands may be kept in the beam at different distances from the probe window withoutexceeding the limit given by the law. The limit for a radiation worker is 500 mSv per year andif we assume that the person works for a 50 weeks a year the weekly dose is 10 mSv /a. Thedistance is calculated from the window, but the tube is actually about 3 cm from the window.Reduce exposure by maintaining the maximum possible distance from the radiation source tothe operator or member of the public. Exposure rate is reduced as the distance from thesource is increased. The greater the distance, the less amount of radiation received. Doublingthe distance from a point source reduces the dose rate (intensity) to 1/4 of the original.Tripling the distance reduces the dose rate to 1/9 of its original value.

Dist a nce cm) Tme per year Tme per w eek

100 1300 h 26 h

50 344 h 6 h 53 min

25 96 h 1 h 55 min

10 20 h 25 min

5 7 h 9 min

0 1 h 1 min

Although occasional ”accidental” bypassing remains within permissible levels carelesshandling of the instrument may cause overdoses. Looking at the distances the doses in thiscase are most likely obtained by the user himself.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

55/76

55

Primary beam direction if the safety logic circuit is bypassed

7.4.2. Scattered Radiation dose rates

Measurements taken at 10cm from analyzer with analyzer pressed against a sample.Operating current 3.1µA. (1µSv = 100µrem).

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

56/76

56

Position µSv/hr Position µSv/hr

1 0.07 8 0.07

2 0.07 9 0.06

3 0.04 10 0.05

4 0.05 11 0.05

5 0.05 12 0.06

6 0.06 13 0.05

7 0.07

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

57/76

57

7.5. What to do In case of emergencies

The X-ray emission from the instrument could be harmful to a person if they operate theanalyzer without the appropriate training. If the instrument is lost or stolen, notify the localand/or state regulatory agency as soon as possible.

The first action to take in the event of an accident with instrument is toturn off the device and remove the battery pack.

7.5.1. Minor damage

If any hardware item appears to be damaged, even if the system remains operable, contactyour nearest OIA representative immediately. Use of a damaged analyzer may lead to

unnecessary radiation exposure and/or inaccurate measurements.

7.5.2. Major damage

If the analyzer is severely damaged, contact an OIA representative immediately and theappropriate regulatory agency in your state or country. Care must be taken to ensure thatpersonnel near the device are not exposed to unshielded X-rays that may be generated.Removal of battery pack will stop all X-ray production.

7.5.3. Loss or theft

Notify the appropriate regulatory agency in the country or state in which the device is beingutilized. In addition, contact your nearest OIA representative immediately in case of a stolen

device.

Take the following precautions to minimize the chance of loss or theft:

Never leave the analyzer unattended when in use.When not in use, always keep the device in its shipping container and store it in a lockedvehicle or in a secured area.Keep the key separate from the analyzer.Maintain records to keep track of all instruments, and the operators assigned to use them andwhere they were used.

7.6. Customer Maintenance

Establish a routine for checking the correct functioning of the infrared beam safety sensor,located at the nose of the analyzer: Measure a sample in the normal way but pull away fromthe sample during the measurement. The measurement will immediately cease as the safetybeam is uncovered. Do this once a month to check that x-ray emission does indeed ceaseunless a solid object covers the infrared beam.

Similar rules apply in other countries. Users should contact their local Oxford Instrumentsrepresentative for specific advice.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

58/76

58

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

59/76

59

Appen d ix 1: Toub lesho o t ing

8.1. If measurement will not start

A1. If the X-MET program is started before the instrument power is turned on the programcannot communicate with the instrument.

⇒

1. Exit the X-MET program and turn off the instrument power.

2. Take the PDA out of the instrument and press the reset button at the back of the PDA.

3. Remount the PDA onto the instrument.

4. Make sure the instrument power is switched “ON” before starting the X-MET program.

A2. If the infrared sensor is not covered the measurement will not start.

⇒ Make sure that the infrared sensor is covered completely.

A3. The sample surface may be too darkly coloured to reflect light to activate the infraredsensor.

⇒ Insert a piece of white paper between the sample and the infrared sensor.

A4. The battery is discharged and yellow light is not on or yellow light is blinking.

⇒ Is the yellow light on? If it isn’t or it is blinking change the battery or connect theinstrument to the AC adaptor.

Note! Yellow light wil l become dim when battery is low.

A5. There is no communication between the PDA and the instrument.

⇒ PDA not seated properly. Exit the analysis program, remove the PDA and re-seat it on theconnector assuring that it is firmly seated. Restart the program and try again.

8.2. If the X-MET program ”locks up”

If other programs are running the X-MET program may ”lock up”. Closing other programs frees system memory for other tasks.

1. Go to the ”Start” menu and tap ”Settings”.

2. Tap the ”System” tab.

3. Tap the ”Memory” icon and tap ”Running Programs” and then tap “Stop All”.

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

60/76

60

-

8/17/2019 5102037E_120_User ManualTX,TXS,TXR.pdf

61/76

61

Appe nd ix 2: X-MET3000TXS – Soil mea surem ent s

9.1. Description of the X-MET3000TXS

The X-MET3000TXS is a portable, elemental analyzer with an integrated PDA (PersonalDigital Assistant) computer. It is based on energy dispersive X-ray fluorescence technology. Ituses an X-ray tube as the source of excitation and a Peltier cooled Si-PIN detector.

The X-MET3000TXS provides a method for the chemical analysis of soil. Besides heavyelements measurements in soil X-MET3000TXS can also be used for mining applicationswhere applicable.

Field portable x-ray fluorescence is an exemplary field method offering rapid, cost-effectivescreening of heavy metals in soil. Measurements can be done either in the field (directmeasurements from the soil or bagged soil measurements) or in the laboratory (preparedsamples in the sample cups). Even in instances where laboratory analysis is required, fieldXRF can be used to rapidly pre-screen samples to obtain the optimum efficiency from the

laboratory sampling effort. Since XRF analysis does not destroy the sample, any samplecollected and measured in the field can be retained for verification by a laboratory.