502 Cannabis Infused Processing Professional Education SAMPLE

-

Upload

dream-cream -

Category

Documents

-

view

190 -

download

1

description

Transcript of 502 Cannabis Infused Processing Professional Education SAMPLE

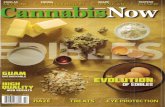

502Cannabis Infused

Processing

Chapter 314-55 WACProfessional Education Series

by James Chaney

Copyright © 2014 by Dream Cream Design

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any form or by any means, including photocopying, recording, or other electronic or mechanical methods, without the pri-or written permission of the publisher, except in the case of brief quotations embodied in critical reviews and certain other noncommercial uses permitted by copyright law. For permission requests, write to the publisher, addressed “Attention: Useage Request,” at the contact below:

Ordering Information:Quantity sales. Special discounts are available on quantity purchases by corporations, associations, and others. For details, contact the publisher at the address above.

Printed in the United States of America

Table of ContentsAbout the Author - Page 3 Introduction - Page 4Processor Specific WSLCB Requirements - Page 5

Drying, Curing & TrimmingAutomatic Trimming - Page 12Manual Trimming - Page 14Sample Manual Trimming Line - Page 16Drying - Page 17Curing - Page 18

Measuring and PackagingScales & Measurements - Page 19Weighing and Measuring Devices Addendum Form - Page 20Scale Choices - Page 21Codes & Rule Violation Penalties - Page 22Packaging - Page 23Commercial Packaging Solutions - Page 24Labeling - Page 27

FDA & WSLCB Label RequirementsFDA Labeling Requirements - Page 28Dietary Supplement Requirements - Page 29WSLCB Labeling Requirements & Tracking - Page 30

Extraction Area Systems Concentrates Processing - Page 32Solventless Hash - Page 33Packaging C02, BHO & Solventless Hash - Page 35

WSDA & Food ProcessingLiquor Control Board Interim Policy - 36WSDA Food Processing - Page 37Food Regulation Common Requirements - Page 38

Shelf Stable Edibles - Page 39

Cannabis AlchemyCannabis Infusion - Page 40Temperature and Time - Page 41Parameters - Page 42

Processor Seminar Workshop - Page 43

3

About Author Jim Chaney

Coming from IT and Marketing backgrounds, Jim has been working in the medical cannabis industry for the past 4 years with considerable results in the edible and design sectors. He is the founder of processing and logis-tics company Dream Cream whose product line includes popular cannabis infused coffees known as Caffe Sativa.The company specializes in processing based on solventless hash extraction and vegetable fat infusions. Jim also serves the cannabis market as a consultant providing branding, packaging, FDA compliant labeling and logistic services to a wide portfolio of established medical and 502 businesses.

Jim has been working with the Coalition for Cannabis Standards & Ethics for the past three years helping to manage marketing and push the envelope in developing rigorous standards for cannabis processors. In 2011 Jim authored the groups official standards for medical processors which were presented to many city and state offi-cials throughout 2012. He currently serves on the Coalition’s board as Secretary.

Contact: [email protected]

4

IntroductionThank you for purchasing Volume 2 of this handbook or attending one of our seminars. We hope to make it a learning experience for you and appreciate your support for professional standards in the cannabis industry. My intention with this document has been to craft a information packed yet slim book you can keep handy in your facility or office.

The first section is a word for word copy of current Washington State Liquor Control Board marijuana regula-tions that specifically affect processors. Along with the regulatory code I have expounded at length in an attempt to read between the lines and glean some practical information about the emerging 502 markets.

We will target the specifics of establishing a food processing facility with Liquor Control Board requirements. We will discuss the various types of processing capacities and the details of many processing tasks.

Then we will move into labeling guidelines as well as the FDA. We’re going to look at some sample packaging and the best ways to pick and purchase packaging solutions for your business.

This book is going to discuss the basics of WSDA compliance. It will cover the differences between food prod-ucts and dietary supplements as well as the requirements for both product categories.

There are over three pages devoted to hash, if you have any specific questions about hash or solventless wax feel free to email me at [email protected] and I will do my best to respond promptly.

We’ll be covering methods and extraction parameters. We’ll also discuss so called cannabis science, the tempera-tures when cannabinoids convert into other compounds and the times and methods to control these changes.

This book includes a workshop portion in the final portion. This is intended as a series of light brainstorming that I hope might help you think about your business from a different perspective.

I would like to thank the CCSE membership for their help and support in facilitating the orginal Professional Ed-ucation Series and giving me a platform to share my processing knowledge with the broader community. Special thanks to Lara Kaminsky for all her expertise and patience. Kudos to BioTrackTHC executive Matthew Newton for the tracking compliance assistance. Cheers to Amy Gibson and WCPSolutions for serving the cannabis in-dustry’s needs and educating me on commercial packaging equipment. Warm thanks to Nick Kelly for recording multimedia and a hearty hug to Chuck Olivier of Dimebag Scale Company for teaching me about measurements.

May this document serve you and your future well.

Thank You,

James Chaney

Processor Specific State LawThe liquor control has released the following important regulations in regards to cannabis processing:

WAC 314-55-077 What is a marijuana processor license and what are

the requirements and fees related to a marijuana processor license?(1) A marijuana processor license allows the licensee to process,

package, and label usable marijuana and marijuana-infused products forsale at wholesale to marijuana retailers.

(2) A marijuana processor is allowed to blend tested useable mar-ijuana from multiple lots into a single package for sale to a marijua-na retail licensee providing the label requirements for each lot usedin the blend are met and the percentage by weight of each lot is also

included on the label.• • •

(7) Marijuana processor licensees are allowed to have a maximumof six months of their average useable marijuana and six months aver-

age of their total production on their licensed premises at any time.

Application to Processors: This section ensures that cannabis processors have a fair amount of freedom to process and source cannabis infused goods. It also means that there will be a robust need for third party dis-tribution services under the 502 market. Only cannabis processors may sell to retailers and “production only” companies are forced to work with other companies if they do not acquire their own processing facility and license.

WAC 314-55-083 What are the security requirements for a marijuana licensee?

(f) All marijuana or marijuana-infused products that are intendedto be removed or transported from marijuana producer to marijuana processor and/or marijuana processor to marijuana retailer shall be staged

in an area known as the “quarantine” location for a minimum oftwenty-four hours. Transport manifest with product information andweights must be affixed to the product. At no time during the quaran-

tine period can the product be handled or moved under any circumstan-ces and is subject to auditing by the liquor control board or designees.

• • •(h) There is a twenty-four hour mandatory waiting period after

the notification described in this subsection to allow for inspectionbefore useable marijuana, or marijuana-infused products are transpor-

ted from a processor to a retailer.

Application to Processors: All processors will have to accommodate these requirements with a secure area set aside for quarantine purposes. The most effective processors will easily integrate these quarantine periods into drying & curing protocol. For instance, a day can be removed from cure schedules to accommodate the obligatory twenty four quarantine period while packaged cannabis waits for transport to retailers.

5

WAC 314-55-104 Marijuana processor license extraction requirements.

(1) Processors are limited to certain methods, equipment, sol-vents, gases and mediums when creating marijuana extracts.

(2) Processors may use the hydrocarbons N-butane, isobutane, pro-pane, or heptane or other solvents or gases exhibiting low to minimalpotential human health-related toxicity approved by the board. Thesesolvents must be of at least ninety-nine percent purity and a process-

or must use them in a professional grade closed loop extraction systemdesigned to recover the solvents, work in a spark free environmentwith proper ventilation, and follow all applicable local fire, safetyand building codes in processing and the storage of the solvents.(3) Processors may use a professional grade closed loop CO 2 gas

extraction system where every vessel is rated to a minimum of ninehundred pounds per square inch and follow all applicable local fire,safety and building codes in processing and the storage of the sol-

vents. The CO 2 must be of at least ninety-nine percent purity.(4) Processors may use heat, screens, presses, steam distilla-

tion, ice water, and other methods without employing solvents or gasesto create kief, hashish, bubble hash, or infused dairy butter, or oils

or fats derived from natural sources, and other extracts.(5) Processors may use food grade glycerin, ethanol, and propy-

lene glycol solvents to create extracts.(6) Processors creating marijuana extracts must develop standard

operating procedures, good manufacturing practices, and a trainingplan prior to producing extracts for the marketplace. Any person using

solvents or gases in a closed looped system to create marijuana ex-tracts must be fully trained on how to use the system, have direct ac-

cess to applicable material safety data sheets and handle and storethe solvents and gases safely.

(7) Parts per million for one gram of finished extract cannot ex-ceed 500 parts per million or residual solvent or gas when quality as-

surance tested per RCW 69.50.348.

Practical Application to Processors: The rules will allow processors to produce virtually any popular canna-bis extract in existence. There are minimum standards based on which solvent or method you choose. BHO and C02 processors have the most rigorous regulations. If you plan to extract these concentrates you should plan to invest at least $50,000 - $250,000 in equipment that will meet LCB solvent processing requirements. The rules ensure that all concentrates are somewhat pure with a solvent PPM threshold of 500. The best medical cannabis processors typically do not release products above 25-50 PPM of hydrocarbon.

Processors are responsible for ensuring extraction ventilation systems are compliant with fire and safety codes.

The regulations for solventless hash and fat extractions are the least restrictive out of all the various meth-ods. This makes hash and fat processing methods very attractive to startup processors.

6

Practical applications for processors: The most glaring section is 9 which prohibits adding anything to can-nabis flowers at retail. This means that the Liquor Control Board is attempting to create a flower market that consists of pure cannabis flowers. While this might prevent some legitimate and safe advances in flavoring and preserving cannabis, these regulations are important and a show of good faith from the Liquor Control Board. This regulation prevents various producers from adding synthetic cannabinoids, bath salts or other psychoactive chemicals to flowers in the hopes of a competitive edge. There are no additive prohibitions for concentrates or cannabis infused goods of this nature.

The rules state that consumers will legally never be able to access your product directly, meaning your busi-ness will mainly be interacting with customers through the front display panel of your packaging. Not hav-ing direct access to pick up your product means consumers will be looking for catching front panels from more than a few feet away. This makes designing the right kind of appealing front labels very important for your business and product lines.

Subsection (2) states that a marijuana processor is to package and label useable marijuana and marijuana infused products for sale at wholesale to marijuana retailers. Subsection (3) does not allow marijuana re-tailers to package and label at all, only to sell useable marijuana and marijuana infused products. All prod-uct must be packaged and labeled by the processor prior to being sold to the retailer.

All processors will have considerable labeling requirements. The first area of requirements are the 14 warn-ings concerning health hazards. These warnings are largely fictitious but absolutely required by Initiative 502. However, the important part of this section is “must include accompanying material that contains...”. It is easy to interpret these warnings being provided as a small card or brochure that is ubiquitously available at all retail establishments and is included with every marijuana purchase. It is unlikely the WSLCB means for processors to include over 14 health warnings on every package of cannabis.

Processors will have to include two warnings on every label for every package of marijuana: Warnings that state: “This product has intoxicating effects and may be habit forming”; Statement that “This product may be unlawful outside of Washington state”.

The requirements for packaged marijuana are much less strict than the requirements for infused products. Marijuana does not have to be packaged in child resistant packaging so theoretically we will likely see some low-end recreational marijuana sold to the customer in labeled zip-lock bags or other simple solutions.

Processors of concentrates beverages, infused products and goods must provide child resistant packaging for every retail item in the form of unperforated heat seals, blister packages and other suitable barriers.Processors will also have to include one warning for all cannabis infused edibles or beverages: “Caution: When eaten or swallowed, the intoxicating effects of this drug may be delayed by two or more hours.”

Other than the small amount of health warnings, packaging infused goods is the same as packaging any other retail good in the state of Washington. In addition to WSLCB requirements, processors will have to maintain packaging compliance with FDA and NIST standards.

NIST - Regulates weights, measures in regards to packaging as well as child resistant packaging.

FDA - Regulates food, dietary supplements, drugs and the packaging and labeling of goods.

10

WAC 314-55-089 What are the tax and reporting requirements for

marijuana licensees?(3) Marijuana processor licensees: On a monthly basis, marijuana

processors must maintain records and report purchases from licensedmarijuana producers, production of marijuana-infused products, sales

by product type to marijuana retailers, and lost and/or destroyedproduct in a manner prescribed by the board.

A marijuana processor licensee must pay to the board a marijuanaexcise tax of twenty-five percent of the selling price on each whole-sale sale of usable marijuana and marijuana-infused product to a li-

censed marijuana retailer.

Practical Application for Processors: All processors will have to pay excise tax when they wholesale goods. In addition all processors must have a robust tracking system that satisfies the WSLCB’s requirements.

WAC 314-55-099 Standardized scales.

(1) Marijuana producer andprocessor licensees must have at least one scale on the licensed

premises for the traceability and inventory of products.(2) The scales and other measuring devices are subject to chapter

19.94 RCW, and must meet the requirements of the most current versionof chapters 16-662 and 16-664 WAC.

(3) Licensees must register scales on a business license application with business license services through the department of revenue as required under chapter 19.94 RCW.

Practical Application for Processors: Your business will have to own at least one compliant commercial scale for packaging and inventory. In addition you will be required to register it with the state and ensure it is

sealed and serviced by a compliant professional.

WAC 314-55-015 General information about marijuana licenses.

(10) A marijuana processor or retailer licensed by the boardshall conduct the processing, storage, and sale of marijuana-infusedproducts using sanitary practices and ensure facilities are construc-

ted, kept, and maintained in a clean and sanitary condition in accord-ance with rules and as prescribed by the Washington state department

of agriculture under chapters 16-165 and 16-167 WAC.

Practical Application for Processors: Processors will be responsible for complying with the rules of the WSDA. Simply put, if a business produces food products they will have to be compliant and licensed by the WSDA as a food processing facility. This process is begun by filling out a WSDA processor packet with your facilities information. The facility codes vary based on product types with meat and dairy requiring the most stringent safety features.

11

For boutique and premium quality cannabis providers, an expertly trimmed bud cannot be beat by an automatic trimmer. Hand trimming reveals the true shape of the bud and allows for attractive leaves to remain a part of the flower.

Compared to an automatic trimmer a pair of Fiskars is much cheaper at around $10-$20 but the cost disadvan-tages of manual operations lie in paying hourly employees to trim cannabis. You should expect to pay trimmers at least $15 hourly to do a good job trimming cannabis.

The total cost of trimming a pound varies greatly based on the skill and dedication of your staff. Cost also varies due to strain differences and desired level of trimming (more or less leaves trimmed). Hand trimming can add as little as $50 and as much as $250 to a pound of cannabis.

Allowing your staff to play music and audio books while trimming should be considered a minimum so you will need a decent stereo. However, TVS and laptops playing movies and media should not be allowed in the trim-ming room. Anything taking a trimmers eyes off the bud will result in neglected flowers. You should also consid-er quotas and bonuses to encourage efficiency.

Manual Trimming

Productivity loss in the trim room can be avoided by keeping laptops, videos and food strictly to break areas.

A decent stereo with an iPod dock will allow employees to avoid tedium while keeping their eyes on the cannabis.

The Fiskars’ Softouch micro-tip pruning snip is probably the most popular trimming scissor in the cannabis industry. This is by no accident as the grip is very comfortable, the tip is adequate for getting into nooks and the spring reduces worker stress. This model is available on Amazon for around $10.

14

Codes By educating yourself and your employees in basic Washington State law, your business can easily maintain com-pliance in the areas of packaging and measuring. Marijuana retailers should have accurate scales on premise but NTEP certified and sealed scales are not necessary for retail operations as retailers are not permitted to package cannabis for retail sale.

WAC 314-55-099 Standardized Scales.

(1) Marijuana producer and processor licensees must have at least one scale on the licensed premises for the traceability and inventory of products.(2) The scales and other measuring devices are subject to chapter 19.94 RCW, and must meet the requirements of the most current version of chapters 16-662 and 16-664 WAC.(3) Licensees must register scales on a business license application with business license services through the department of revenue as required under chapter 19.94 RCW.

Some helpful codes to acquaint your business with:

RCW 19.94- Establishes State Weights & Measurements ProgramWAC 16-662- NIST Handbooks are WA LawWAC 16-664- NTEP required

Rule Violations and Penalties

WAC 314-55-515 Failure to maintain standardized scale requirements:

Processors - WAC 314-55-525 - Group 2 Violation1st Offense-5 day suspension or $500 monetary option2nd Offense-10 day suspension or $2,500 monetary option3rd Offense-30 day suspension Cancellation of license4th Offense-Cancellation of license

Producers - WAC 314-55-535 - Group 4 Violation1st Offense- $2500 fine2nd Offense- $5,000 monetary fine and destruction of 25% of harvestable plants3rd Offense- $15,000 monetary fine and destruction of 50% of harvestable plants4th Offense-Cancellation of license`

22

Dietary Supplements

‘Th ese medical cannabis labels show how dietary supplement compliant features can be easily integrated into infused product labeling

Quoted Directly From Th e FDA Dietary Supplement Labeling Guide: How are dietary supplements defi ned?Dietary supplements are defi ned, in part, as products (other than tobacco) intended to supplement the diet that bear or contain one or more of the following dietary ingredients: A vitamin; A mineral; An herb or other botanical; An amino acid; A dietary substance for use by man to supplement the diet by increasing the total dietary intake; or A concentrate, metabolite, constituent, extract, or a combination of any ingredient mentioned above.Further, dietary supplements are products intended for ingestion, are not represented for use as a conventional food or as a sole item of a meal or the diet, and are labeled as dietary supplements. Th e complete statutory defi nition is found in section 201(ff ) of Federal Food, Drug, and Cosmetic Act

What label statements are required on the containers and packages of dietary supplements?Five statements are required: 1) the statement of identity (name of the dietary supplement), 2) the net quantity of contents statement (amount of the dietary supplement), 3) the nutrition labeling, 4) the ingredient list, and 5) the name and place of business of the manufacturer, packer, or distributor.21 CFR 101.3(a), 21 CFR 101.105(a), 21 CFR 101.36, 21 CFR 101.4(a)(1), and 21 CFR 101.5

Where do I place the required label statements?You must place all required label statements either on the front label panel (the principal display panel) or on the information panel (usually the label panel immediately to the right of the principal display panel, as seen by the consumer when facing the product), unless otherwise specifi ed by regula-tion (i.e., exemptions).21 CFR 101.2(b) and (d), 21 CFR 101.9(j)(13) and (j)(17), 21 CFR 101.36(g), (i)(2) and (i)(5)

What label statements must I place on the principal display panel?You must place the statement of identity and the net quantity of contents statement on the principal display panel. Where packages bear alternate principal display panels, you must place this information on each alternate principal display panel.21 CFR 101.1, 21 CFR 101.3(a) and 21 CFR 101.105(a)

How do I locate the principal display panel?Th e principal display panel of the label is the portion of the package that is most likely to be seen by the consumer at the time of display for retail purchase. Many containers are designed with two or more diff erent surfaces that are suitable for use as the principal display panel. Th ese are alternate principal display panels.21 CFR 101.1

What label statements must I place on the information panel?You must place the “Supplement Facts” panel, the ingredient list, and the name and place of business of the manufacturer, packer, or distributor on the information panel if such information does not appear on the principal display panel, except that if space is insuffi cient, you may use the special provisions on the “Supplement Facts” panel in 21 CFR 101.36(i)(2)(iii) and (i)(5). See questions 46 and 56 in Chapter IV for more details.21 CFR 101.2(b) and (d), 101.36(i)(2)(iii) and (i)(5), 101.5, 101.9(j)(13)(i)(A) and (j)(17)

29

Pai n • i ndigestion • Relaxation

indiCa CaPsUles

THE C.P.C.The CPC

teRPene enhanCed

12 grams net wt

40 COUNT - 25MG EACH in Olive Oil with five added essential oils for enhanced terpene potency

Dire

ctio

ns: T

ake

one

caps

ule

on a

n em

pty

stom

ach

and

wai

t 60-

90 m

inut

es.

Repe

at a

s ne

cess

ary.

For B

est R

esul

ts: C

onsu

me

with

sm

all a

mou

nt o

f go

od fa

t suc

h as

pea

nut b

utte

r, ol

ive

or fi

sh o

il, e

tc.

RC

W 69.51a m

edical use ON

LY. THECPC.ORG

Ingr

edie

nts:

Oliv

e Oi

l, Es

sent

ial C

anna

bis

Oil,

Natu

ral O

ils (L

em-

on, L

aven

der,

Rose

mar

y, L

emon

gras

s, B

lack

Pep

per)

, Gel

atin

Amount/Serving %

DV

Amount/Serving

Total Fat .3mg

Sat. Fat 0mg

Trans Fat 0mg

Cholesterol 0mg

Sodium 0m

g

Δ Delta 9 ‐ THC 13mg

Cannabidiol (CBD) 3mg

Cannabinol (CBN) .10mg

Cannabichromene .03m

g Δ Delta 8 - THC .25m

g

0%0%0%0%0%

Supplement

FactsServ. Size 1 Capsule (.3g)Calories 4Calories from

Fat 4Terpene Percentages are based on total terpene content

A-Pinene 30% • B-Pinene 19%

• Limonene 29%

• Linalool 5%

Concentrates Processing

For solvent based concentrates, there is a whole world of technologies, vendors and materials for you to pick when choosing facility equipment and gas providers. Solvent extraction methods deserve their own seminar and we will not be able to address this topic in depth. This seminar is not going to attempt to address all of these products or methods. It’s assumed at this stage of the market that if you wish to make BHO or CO2 oil, you already have extensive experience or are prepared to hire/contract an expert manufacturer currently serving the medical cannabis market.

Concentrates processing does not fall under the full jurisdiction of WSDA food processing regulations so does not face a lot of difficulties in finding a suitable location. A concentrates processor will benefit from spaces that function like laboratories. Solventless hash is the most flexible of concentrates for processors as it will never explode. If your extraction method utilizes flammable solvents you are required by the LCB and good sense to utilize extensive interior ventilation. A small sealed room or chamber with high air pressure and powerful ceiling mounted external vented fan is a good choice for an extraction environment.

Natural ventilation using solvents is a cost effective option to avoid expensive ventilation installation during startup phases. Rolling up a warehouse door is an option and so are multiple windows and fans. Make sure to utilize screens to keep insects out of your processing facility. Outdoor extraction is possible using a screened in gazebo as work area and making sure to comply with LCBs requirement to obscure processing activities from public view.

The extraction area is the most important part of your concentrates operation. It should be kept clean and pris-tine with all work surfaces cleaned and cleared after use. Just like the trim room, isopropyl alcohol is a must for reclaiming spilled or stuck cannabis. If you don’t wish to reclaim spilled concentrates, you can use much cheaper denatured grain alcohol for cleaning up sticky messes (never consume cannabis mixed with denatured alcohol).Work surfaces should be restaurant or industrial quality stainless steel tables and work benches. Plastic surfaces should never be utilized in an environment with high temperatures or hot concentrates. If plastic is utilized it should be non porous and non textured.

All containers for concentrates should be glass. It is essential to have a variety of beakers, lidded jars and assorted containers to hold concentrates. Heated lab scales with magnet powered mixing functions should be used rather than hand stirring if possible. Manipulating concentrates is best done with high quality steel kitchen or labora-tory tools. Paint scrapers are very effective at manipulating large quantities of concentrates. Silicon pads, plastic cling wrap, parchment paper and plastic gloves should always be available to separate and cover materials from dirt, heat, air, water and skin oils. When making concentrates it is important to pay attention so it is recommend to provide comfortable tall stools in extraction areas rather than padded office chairs.

32

Cannabis Infusion

Infusion platformsThere are many ways to combine cannabis with food products. The chief methods this document will cover are concentrate infusion, animal fat infusion and vegetable fat infusion. Your business will have to choose the best infusion platforms based on the needs and principles of your company and consumer base. All of the methods work rather well as cannabinoids bond just fine with a wide variety of fats, chemicals, compounds and solvents.

Concentrate infusionConcentrate infusion is the mixture of hash, BHO, oil or other cannabis concentrate into a food product using low heat and automatic or manual mixing. Adding directly to food usually works best when the recipe include suitable amounts of fats or sugars. By testing the concentrate before mixing, a processor can precisely alter the amount of concentrate added per batch to result in the desired dosage of cannabinoids. Concentrate infusion ba-sically skips a long infusion process and multiple tests as the concentrate has already been processed and tested in large batches and will bond to the edible platform in a fraction of the time as plant matter into fat.

Animal Fat InfusionAnimal Fat Infusion is the mixture of raw or already processed cannabis with animal fats such as butter, milk, cream, ghee, lard, grease or other animal derived fatty oils. If your product has cooked meat as an ingredient this is a great platform to use animal grease. Animal fats bond great with cannabinoids and a variety of terpenes though the terpene retention is not as good as vegetable fats. Butter is the most popular infusion platform in the current medical cannabis industry due to its low price point and tolerance for abuse. When using animal fats like butter it is best to add a reasonable amount of water and use salted butter as it will buffer temperatures and avoid burning and vaporization. Due to the volatile nature of animal fat extraction you should expect to practice fat infusion in large batches and test each finished batch of fat to accurately label your cannabis infused goods.

Vegetable Fats and Sugar InfusionVegetable Fat Infusion is the mixture of raw or already processed cannabis with vegetable fats and sugar such as canola oil, safflower oil, coconut oil, peanut butter, cane sugar, corn syrup, almond milk, honey and any vegetable derived food ingredient that bonds with cannabinoids. Vegetable platforms are versatile with olive oil and coco-nut oil being the most popular platforms currently in the medical marijuana market. Processing cannabis into vegetable derived oil is similar to animal fat extractions such as butter with added water being useful to buffer temperatures. Proper temperatures and vigilant mixing are key to quickly extracting cannabinoids locked deep in plant matter. Vegetable milks are among the most efficient platforms too as is the process of creating your own infused cannabis/vegetable/nut milk by processing cannabis with water and heat combined with a suitable vege-table, grain or nut such as almonds, soy, rice, coconut, etc.

40